We make buggy drawings ourselves

Before you start assembling, you need to make a sketch, or even better, a full-fledged drawing, it depends on your level of preparation. The most important thing is to understand in what conditions you will operate buggy, By public roads or solely by off-road?

The chassis geometry and suspension type primarily depend on the operating conditions. After this, you can start making a sketch or searching on the Internet.

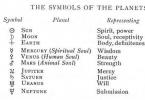

1. Overall width 2. Overall length 3. Overall height 4. Front wheel track 5. Wheelbase 6. Rear wheel track 7. Departure angle 8. Approach angle 9. Width according to mirrors 10, 11. Radius of obstacles to be overcome

The ground clearance is usually set at 250 - 300 mm, which allows you to overcome significant unevenness at speed. Depending on the frame proportions and layout, the wheelbase is approximately 2500 - 2900 mm. The track is usually 1.4 m - 1.5 m. The dimensions of the undercarriage are borrowed from the donor or the following dimensions are used: These dimensions are taken from the showroom AZLK-2141 . This buggy

it is built for amateur riding, not sports driving, which is why the emphasis is on comfort and safety, not power. The height of 1.2 m allows the use of ordinary car seats. If possible, it is better to purchase anatomical “sports” seats. It is also recommended to replace conventional seat belts with 4-point ones, because In this case, ordinary belts are not enough to ensure complete safety.

Buggy layout

So, let's look at the features of the following donors: - M-2141

VAZ-2108 and its modifications (VAZ-2110 is no different for us in terms of units)

VAZ-2101 and its modifications

Each donor has its own characteristics, its own layout. Usually, the interior layout is chosen, and then the units are placed taking it into account. Some inventors, on the contrary, begin the layout with units. The algorithm still turns out to be the same, no matter from which side we approach the engine shield. Drawings bugs, algorithm of work 1. You need to start with a large number of printed buggy photos

2. To make drawings we will need: a protractor, two triangles, a ruler. It is better to draw from printed drawings with lead pencils or a gel pen, because... a regular ballpoint pen quickly becomes clogged with powder applied to a sheet of paper if the printer is laser.

3. Find complete technical information buggy characteristics, so that you can attach any size to your drawing using these parameters.

4. Set a point, the origin of the coordinate system. If you start the layout from the passenger compartment, then it is advisable to take the front mount of the driver's seat slide as the starting point. Some use the front wheel axis or the position of the engine compartment as the origin.

5. Considering buggy parameters with which we copy the proportions, we determine the main parameters of our model.

VAZ 2101 is used as a donor

For those who leave the base from donor, it is recommended to move the engine inside the base for better weight distribution. The middle of the unit in this case is located above the front axle. To avoid costly alterations, it is recommended to use a cardan shaft from Niva 2121 or, given that the original shaft is two-link, remove one link and carry out balancing. Accordingly, the unit needs to move the passenger and driver. The degree depends on the driveshafts. At the rear they usually use a gearbox from a foreign car, preferably cast iron.

Looking at the engine compartment, we pay attention to the fact that the gearbox is located between the pilot and the passenger, this allows us to move the seats a little apart. Outer diameter of wheels VAZ 2101 is 580 mm. To improve the appearance, many people install Volga wheels with a diameter of 640 mm. The difference of 60 mm is not very big, but it has a positive effect on the appearance. Once we have received the length of the driveshaft and specified the layout, we can begin drawing the frame. Let's start with the ground clearance and drawing the lower pipes. We display the position of the wheels. We take the axis of the front wheel as the reference point. We place seats, units and a mannequin above the pipes of the first row. Taking into account the prototype, we determine the position of the frame guide pipes. You need to draw in layers - if on a drawing board, then using drawing film, if on a computer, then using engineering graphics programs. On a computer it is very convenient to highlight layers in different colors, this allows you to visually see the overall picture. Below are some of the steps involved in designing a buggy:

Buggy from VAZ-2108

The most common model buggy from VAZ 2108, this is sandrail. A very light, maneuverable and simple machine in design. Compared to the previous layout, the frame will be more elegant. To fully imagine the shape of the future buggy, we measure the entire interior of the donor with a tape measure, recording all the data, where and how the seats, controls, radio, and armrests are located. We take the 1st bolt securing the driver's seat slide as the starting point. donor We choose a ground clearance slightly higher than that of the donor, since the buggy is intended to be used not only on public roads, but also off-road. We start by drawing the pipes of the first row. Taking into account the position of the engine compartment dimensions (front plane of the radiator) from the wheel axis, we transfer the corresponding dimensions to the drawing. Next we place the mannequin and seats. To save money, wheels can be taken from , also the steering rack, seat and some of the electrics are taken from the donor. Further steps buggy design

repeat the previous layout:

After this, we indicate on the diagram the location of the instrument panel and controls. The track of the rear and front wheels should be the same, so we safely use the track of the front wheels from our donor. The distance between the wings can be taken as the width of the engine compartment. The cabin height can be taken either as from the donor or increased slightly, because VAZ 2108 is not very convenient for tall drivers. The space also allows you to move the driver's seat back a little. We measure out space for the battery, gas tank and audio speakers. Next, you need to determine the angles of rotation of the wheels so that there is no contact with the wings and frame.

Now that the main elements are thought out, you can start drawing the frame pipes. The middle row of pipes is located at a level that is comfortable to hold your hand while providing maximum protection.

To produce these drawings, engineering experience should be minimal, since such work does not require any calculations; the process is more creative than engineering. The result should be the following drawing. If you are unable to bring the drawing to this form, do not despair and try to redraw it again, this is a matter of practice.

The racing model must have a reinforced pipe frame. A reliable frame is required to protect the driver in the event of a collision or rollover at difficult distances. This car is made as a single-seater. A tourist buggy fits into a body and has two seats.

What tool do we need?

Before you start assembling at home, you need to prepare everything you need. You will need a set of tools for your work:

Welding(for initial setting of frame elements and final welding of pipes). Remember! When welding, metal tension occurs. Therefore, make sure that the frame does not move.

Bulgarian(the pipes will need to be cut and the edges aligned for welding work).

Pipe bender(they vary in price and in the amount of work they can perform: manual, manual hydraulic, electro-hydraulic, electric). The pipes will have to be bent in different places, according to the drawing.

Attention!When buying a pipe bender, ask what diameter and thickness of pipes it can work with, what the maximum bending angle is and the accuracy of the bending angle.

Drill.

Bars and cuttings of boards(for lifting or fixing various elements during construction).

Milling machine.

Metal crown.

Frame material:

Pipes(approximately 50 m of pipe, diameter 40 mm, wall thickness 3 mm). Pipes can be suture or seamless.

What do we take as a basis?

You can assemble a buggy yourself, using the supporting frame of a motorcycle, Oka, Zaporozhets, Niva or VAZ as a basis. You need a body, frame, wheels, fuel tank, engine, brake system, shock absorber, exhaust pipe, air filter, steering wheel (can be taken from a racing kart), seat (preferably equipped with a headrest). This is not a complete list of everything you need.

A homemade buggy model will not have a hood, trunk, or doors. Your windshield will be replaced by a fine metal mesh.

Attention! The engine and fuel tank are separated from the driver's seat by a partition made of fire-resistant material. A fire extinguisher is attached to the right side of the driver (one pipe is directed towards the engine, the second towards the driver). Fire protection must be activated from both sides (from two levers).

Buggy from a motorcycle

If we take an old IZH or Ural motorcycle as a basis, the assembly can result in a compact buggy weighing 300 kg, which can travel off-road at a speed of 80 km/h. To assemble a buggy, you will need a motorcycle engine (although this is a somewhat noisy option) and parts from a small car.

Oka is a good donor for a buggy

Oka is a very profitable donor for a buggy. The Oka engine is liquid cooled and therefore protected from overheating, the hubs are light in weight, and the steering rack has a sufficient margin of safety. The brake system and shock absorbers from Oka are suitable for your buggy.

Attention!When disassembling the car into parts for the buggy, do not forget to keep the certificate of deregistration.

The Oka seat is suitable only for extreme sports enthusiasts (it is too hard). It is best to look for a disassembled seat with good lateral support. At the same time, we must not forget about the headrest - it protects your cervical vertebrae during off-road driving. Buggy based on the Oka is characterized by high cross-country ability.

The Oka seat is suitable only for extreme sports enthusiasts (it is too hard). It is best to look for a disassembled seat with good lateral support. At the same time, we must not forget about the headrest - it protects your cervical vertebrae during off-road driving. Buggy based on the Oka is characterized by high cross-country ability.

“Zaporozhets” for buggy, ready-made version

If we take the Zaporozhets as a basis, then this will be a ready-made rear-engine model. The engine needs to be mounted backwards (this will improve its cooling and evenly distribute the weight along the axles). The differential will have to be reversed (switching the right and left sides). Rework the gear shift drive (since the gearbox rod rotates towards the rear bumper from the driver - and this complicates the rocker system).

Make a buggy from a VAZ

If you are afraid of problems with electronics, then it is better to use a carburetor VAZ as a basis. The engine, like all buggies, is mounted behind the driver. The rear wheels are driven by front axle shafts and VAZ hubs. The axle shafts are attached to a cut-off bridge from a VAZ 2106.

The axles on the rear axle are fixed without the ability to turn. And the front ones are like on a car. The differential is blocked (for uniform transmission to the axles). If you take the front struts with springs from the 41st Moskvich, the rigidity of the rear suspension will increase. The upper part of the buggy frame will need to be welded from seamless water pipes (section 30 - 50 mm).

Buggy based on Niva

If you are going to use a buggy as transport for fishing or in the forest, then you can take the Niva as a basis. On the basis of the Niva, you can build an all-wheel drive buggy. Both front suspensions from Niva are used as suspension (the entire front suspension assembly weighs 130 kg). UAZ tires are installed on overcooked Niva wheels. To increase travel, you can lengthen the suspension arms as much as possible (the track can increase to 1550 mm).

If you are going to use a buggy as transport for fishing or in the forest, then you can take the Niva as a basis. On the basis of the Niva, you can build an all-wheel drive buggy. Both front suspensions from Niva are used as suspension (the entire front suspension assembly weighs 130 kg). UAZ tires are installed on overcooked Niva wheels. To increase travel, you can lengthen the suspension arms as much as possible (the track can increase to 1550 mm).

Choosing a suspension

Independent suspension is a great option for a buggy. The levers are suitable for longitudinal and transverse (you can take the front suspension from Japanese cars). This is a triangular lever: one side of it is attached across the car through one silent block, and the second serves as a jib that takes on the load. On sports buggies it is recommended to install a suspension with one trailing arm. This option is the simplest and easiest. With such a suspension, body roll will be minimized, and the weight of the car will be evenly distributed.

Good to know! If you plan to drive a buggy on public roads, you will have to install headlights, a bumper, and direction indicators (everything is the same as on a regular car, so as not to violate traffic rules).

In an independent candle-type suspension, the elastic element is a spring that moves along vertical guides at the ends of the bridge beam. If the driving wheels of the buggy have independent suspension, then the universal joint is used to transmit torque from the main gear to the wheels. The most commonly used cardan is with two joints. On simpler designs, one universal joint is installed in the axle shafts.

Front

The front suspension of the buggy is best done in the form of the letter “A” on long wishbones. It is this design that gives large wheel travel and allows you to change the angle of the spring with the shock absorber (thus adjusting the stiffness of the suspension).

The front suspension of the buggy is best done in the form of the letter “A” on long wishbones. It is this design that gives large wheel travel and allows you to change the angle of the spring with the shock absorber (thus adjusting the stiffness of the suspension).

When assembling the pendulum arm, pay attention to the material and quality of the welds, because this part will be subject to very heavy loads. Calculate the levers for the maximum width of the base of the letter “A” (this will extend the life of the silent blocks). The width of the lever should not interfere with the rotation of the wheel. The disadvantage of the design is that the travel of the lower ball joint pin in its socket is limited (up or down, it will not be in the place where we would like).

Rear

For the rear suspension of the buggy, we select a trailing arm, which keeps the wheel from moving (the wheel sits rigidly on the cardan). However, there is one flaw: the wheel camber changes for the worse.

To achieve stability in motion, variable values of the wheel inclination angle are needed. Levers will allow movement in two planes. If there is such a suspension on the rear axle, then the front suspension can be anything. If in such a suspension the swing axis of the lever passes through the center of the axle shaft cardan, then there is no need to install a second cardan at the wheel hub.

To achieve stability in motion, variable values of the wheel inclination angle are needed. Levers will allow movement in two planes. If there is such a suspension on the rear axle, then the front suspension can be anything. If in such a suspension the swing axis of the lever passes through the center of the axle shaft cardan, then there is no need to install a second cardan at the wheel hub.

Materials and units used in the construction of the all-terrain vehicle:

1) The body and most parts from the VAZ 2109

2) metal profile

3) muffler from cherry amulet

4) Hubs from Niva

5) brake discs from Niva

6) wheel bearings

7) Two external grenades from the field

8) anthers from VAZ 2109

9) sheet of iron 5 mm thick

10) reinforced balls

11) wheels from the field

12) org sheet. glass

13) transfer case from the Niva

14) factory levers from Niva

Let's take a closer look at the stages of building an all-terrain vehicle.

Initially, the author received an ordinary nine, with which he began to experiment.

To begin with, the standard VAZ 2109 was turned into a convertible:

And the author drove it for the whole summer in exactly this form, but since the car was quite shabby, it could not withstand such use and the rear beam was torn off along with part of the spar.

A metal profile and welding were also used to make a safety cage to replace the sawn-off parts.

Then, due to insufficient experience in welding, the author encountered a problem when welding a standard muffler from a VAZ 2109, in the end the author abandoned this idea and installed the middle part of the muffler from a Cherry Amulet.

Which only took half an hour:

Then the author began work on the bridges, installing a transfer case from the Niva, modifying the gearbox, as well as minor repairs to the VAZ 2109 engine.

All this is attached to a reinforced frame, which stands on an independent suspension, on four steering knuckles of the field. The levers were taken from the factory and underwent minor processing.

After assembling and installing the main structural elements, the all-terrain vehicle was tested on forest roads, where the all-terrain vehicle showed excellent handling, maneuverability and speed characteristics.

After driving on a wet road after rain, the author came to the conclusion that the car needs to install rear mudguards. For these purposes, plastic fender liners from the same VAZ 2109 were used:

In this form, the all-terrain vehicle was tested for one season, after which the author made the following conclusions:

Handling on roads after rain left much to be desired, the reason for this was the fact that the front part of the all-terrain vehicle dug in very quickly. It is also necessary to make a normal gas tank instead of the used canister, since the fuel does not last long and, moreover, there is no tightness, which is why the canister leaked on uneven surfaces.

Also, for installation on the all-terrain vehicle, the hubs from the Niva were machined to the size of the nine bearings. Disc brakes and boots were installed, and brake adapters were made from a five-millimeter sheet of iron. The author also began installing reinforced ball joints on the all-terrain vehicle.

Wheels from the Niva were also installed on the all-terrain vehicle:

Since the standard windshield was broken in a minor accident, a new one was made from org sheet. glass, which was secured with sealant and screws. The fenders and bumper were also removed from the car.

Here are photos of the all-terrain vehicle after all the major modifications:

As you may have noticed, due to the not entirely identical mounting design, the wheels from the field had to be installed with the reverse side. Although at first the author thought about installing stands, it turned out to be too long, and it also affected the budget of the car.

It is also planned to install four-point seat belts for safety.

Despite the fact that the hubs were weakened after turning, they can cope quite well with the loads, both lateral and the weight that falls on two bearings.

"Light bogies", that is, worn-out and converted cars stripped of almost all parts of the body, have long been popular in many countries. The first ones for off-road and sand dune racing appeared in the 50s of the 20th century in America.

How does a buggy differ from other cars?

What all cars have in common is the presence of 4 wheels, a frame, a body, an engine, a gas tank, brakes, a driver's seat and a steering wheel. There may, of course, be other common parts. How is a homemade buggy different from its automotive counterparts?

- It is traditionally made with your own hands without a body with trim, doors, hood and trunk. The body of this homemade product is a pipe frame welded to the supporting frame.

- Instead of a windshield, the driver is protected by a metal mesh with small cells, secured to the front arch with tape clamps.

- Do-it-yourself mini-buggies are made in the form of a compact lightweight car. Its weight is usually about 300 kg.

- Most often, parts and assemblies from different brands of cars are used for assembly: the engine is from VAZ, the shock absorber is from Zaporozhets, the brake system parts are from GAZ, VAZ or Moskvich. From the ChZ cross-country motorcycle you can use an exhaust pipe, an air filter and a carburetor.

- A fire-resistant partition is installed between the engine and the driver's seat.

- The frame for the buggy with your own hands (from a VAZ) is welded from strong steel pipes.

- The steering wheel can be used from a racing kart.

As is clear from the above incomplete list, a buggy is a special model, assembled, like a kit, on a homemade reinforced frame from adapted components of different automobile models. Craftsmen make many parts for this machine themselves.

What cannot be installed on homemade cars

Any car must meet safety requirements and certain standards accepted in the state. According to existing KIT requirements, it is prohibited to use the following for assembling buggies:

- tires from tractors and agricultural machines;

- protectors with mechanical damage and restored pattern;

- all anti-slip devices: chains, spikes or bracelets on tires.

What you need to have on your buggy for safety

You can, of course, get into a Jeep and drive through the steppes and ravines. There are also competitions for crossover owners. You can, without bothering, drive quietly in an old, worn-out Zhiguli car, expecting every minute that some part is about to “fly.” Adrenaline and extreme excitement will be provided by these actions!

Those who love extreme driving in a homemade car in an asphalt-free area, who are passionate about the idea of doing it themselves, are fans of buggies. How to make this machine with your own hands? What will be superfluous, and what is necessary to have “on board”?

- It is mandatory to have seat belts with four anchorages at different points.

- A 3-kilogram fire extinguisher is installed on the right side of the driver's seat. One of the pipes is directed towards the driver, the other towards the engine. You can start the fire protection system using two levers. One of them is installed externally on the main safety bar, the other is accessible to the driver.

- The engine and gas tank, installed in the rear of the frame, must be separated from the driver's seat by a partition made of fire-resistant material.

- The trunk on a sports buggy is a completely unnecessary detail.

- The driver at racing events must wear a helmet.

- KiTT requirements recommend installing side and brake lights and a sound signal (turned on by button) on a homemade buggy with your own hands.

- The driver's seat should be equipped with a headrest.

- Eyelets with a diameter of about 4 cm must be welded on the rear and front sides of the frame to ensure towing.

- The steering wheel and dashboard should be installed at a distance convenient for controlling the buggy.

Just ride or race?

There are two types and possibilities for making buggies with your own hands: drawings of sports and touring cars. The characteristics of sports mini-crossovers are not very different from the driving characteristics of tourist homemade vehicles. Sneakers are placed on a reinforced tubular frame. over rough terrain must also have stability, maneuverability and easy controllability. A tourist car is made with a passenger seat, for racing - a single-seat buggy. A car that is not intended for racing is “dressed” in a body.

What competitions do racing cars take part in?

- Sports championships and championships in Russia for racing cars of the Buggy type provide the opportunity for teenagers and adults to participate in competitions.

- In a car designed for racing on difficult natural landscapes, you can successfully participate in various competitions in hill climbs and descents, winter and summer slalom, and figure driving.

What to choose: buy a ready-made car or build it yourself

Some car factories have long established the production of sports buggies with a simplified body model and tourist or pleasure buggies. How to make this machine with your own hands? This is possible, but it is easier and faster to buy a ready-made vehicle. However, many racers make a car for themselves, taking into account their special requirements for the model. For a racing car, a strong frame is not just a base for mounting the overall structure. The buggy frame is a reliable frame to protect the driver during rollovers and collisions.

Main characteristics of the buggy

Buggy racing has long been transformed into a motor sport called “autocross”. The machines are easy to operate, light in weight, resistant to rollovers, have powerful motors, increased maneuverability and the ability to quickly gain speed. The values of characteristics and abilities given below will be useful to you if you are planning to make a buggy with your own hands. How to make the best car for yourself? Just select the parts and you will get a car with the following parameters:

- 33 hp engine With.;

- maximum speed is about 80 km per hour;

- weight - about 300 kg;

- turning radius - 2.5 m;

- independent front axle suspension;

- independent rear axle suspension;

- with all-wheel drive;

- shock absorbers combined with elastic elements;

- length - 2.5 m;

- height - 1.3 m;

- width - 1.4 m.

How to make a strong buggy frame

The frame construction uses seamless steel pipes. You need to take products with an outer diameter of 25-30 mm. The wall thickness of the prepared pipe is 2 mm. To obtain a smooth bend (without folds or creases), the tubes cut into the required lengths are tightly packed with sand. Using a blowtorch or gas torch, heat the areas of the intended bends of the future frame. Using clamps and rigid stocks, the desired shapes of the parts are obtained. All parts are checked against the template, adjusted and adjusted to the required dimensions.

We weld the prepared fragments of the buggy frame. How to make a strong frame for a car with your own hands? The preparatory step will allow you to see and eliminate shortcomings and unexpected errors. Then all correctly and tightly installed frame elements are finally secured. It is necessary to ensure complete and high-quality welding of all seams along the entire perimeter of the structure.

The engine is mounted on a subframe attached to the main frame with rubber bushings (to dampen vibration).

How to assemble a buggy with your own hands? Creating a mini-buggy begins with a plan and analysis of the detailed installation of machine components. This process ends with a test start of the engine. Everything is working? You can go! Bon Voyage!

Before you build anything, you need to make drawings. Well, at least a sketch of what should be built. No matter what level of training everyone has, there is not much to do - you need to determine the operating conditions, select the units and layout of the buggy. Only after this should you start drawing the main arcs of the frame.

Terms of Use.

We formulate operating conditions: public roads (dirt roads also include them) in the central part of Russia (any other region), meadows, forests, ravines - operating conditions are determined based on environmental conditions, the geometry of the chassis depends on this - unlike sports buggies, drive over rough terrain rather than on a prepared road.

Geometric parameters of the buggy.

1. Wheelbase

2. Front wheel track

3. Rear wheel track

4. Overall width

5. Overall height

6. Overall length

7. Approach angle

8. Departure angle

9, 10. Radius of obstacles to be overcome

11. Width according to mirrors

Ground clearance can be set to 200…250 mm. This will allow you to move on light off-road conditions, or at a fairly high speed over rough terrain. The wheelbase for a two-seater buggy is approximately 2400...2800 mm, it depends on the layout and proportions of the frame from which the proportions are taken. The track is assumed to be approximately 1400...1500 mm. When using extended drive shafts, the track can be increased to obtain greater stability. We take the dimensions of the crew part from the donor or use these dimensions:

These are the dimensions of the AZLK-2141 interior, it is larger than the masterpieces of the Volga Automobile Plant, but smaller than the Volga. The car is not built for sports, but for amateur rides, which is why comfort should be maximum. With a cabin height of 1200 mm, you can use regular seats, both driver and passenger. If your budget allows, you can purchase “sports” anatomical seats. Since the required level of safety cannot be achieved with conventional seat belts, it is necessary to purchase 4-point belts.

Buggy layout.

So, we have the following donors at our disposal:

- VAZ-2101 and its modifications

- VAZ-2108 and its modifications (VAZ-2110 is no different for us in terms of units)

- M-2141

All these donors dictate a different layout of the buggy, but cover all the layouts we need. Many people are starting to make assemblies from units. I do it a little differently - I choose the interior layout, and then I start placing the units. In principle, this does not matter, the algorithm is still the same - it makes no difference to us from which side we approach the motor shield. If you reverse the steps, nothing will change.

The algorithm for working on the drawings is as follows:

1. First you need to have a bunch of printed pictures with similar buggies on hand. This will allow you to clearly see all the cars from different angles; you need to constantly look at these cars in a new way - this will allow the eye to become less “blurred”. You can’t look at these cars all the time and try to draw something. You need to give yourself rest, you need to let your brain deal with other problems and let the idea of a buggy sit in your subconscious. This will allow the brain to better think through the concept of a buggy. If after some time you pick up the drafts, the solution will come on its own.

2. You need to have a ruler, a protractor, and two squares on hand (this will allow you to draw parallel lines - those who have studied graphics or draw know). Based on the printout, it is better to draw with gel pens or slate pencils. A regular pen quickly becomes clogged with powder applied to a sheet of paper during printing (if the printer is laser).

3. It is necessary to find on the Internet and write out the full technical specifications of the buggy, so that according to these parameters you can link any size to your drawing.

4. It is necessary to set the starting point, the origin of the coordinate system. Since I start the layout from the interior, I took the front fastening of the driver's seat slide as the zero point. It’s so convenient for me, someone can take as a starting point the position of the engine compartment, the axis of the front wheel, or in general any other point from which it is easier to calculate everything.

5. Based on the parameters of the buggy from which the proportions are torn off, the parameters of our buggy are specified. We must take into account that when we deviate from the used units, components and parts, some parameters change. Let’s say that the buggy from which we are ripping off the proportions has 15″ rear wheels with an outer diameter of 670 mm (205/70R15). Our donor has 580 mm wheels (classic, VAZ-2108, 13″ or 14″ – different profile heights, outer diameter according to GOST 580 +/- 1%). We will change the appearance of the car, ground clearance, and suspension settings. In addition to these parameters, others may change - you need to look in each case at what changes and how.

If we have a donor VAZ-2101 on our hands

If you leave the base from the donor, then the engine must be moved inside the base for better weight distribution. For the donor, the middle of the unit is located above the front axle. To avoid costly alterations, you can use a long driveshaft from the Niva VAZ-2121, or, taking into account the fact that the original shaft is a two-link one, remove one link and balance it. Accordingly, it is necessary to move both the driver and passenger with the unit. How much depends on the cardan shafts. At the rear you can install a final drive gearbox from a foreign car, preferably cast iron. It will improve the weight distribution of the car. I have a gearbox from a BMW 5 series - it weighs 40 kg, real, cast iron. I bought it only because it has the same mounting holes for CV joints from Moskvich. When choosing gearboxes from other foreign cars, you should take into account that sometimes there is a splined fit with the hinges secured with a retaining ring (as on front-wheel drive cars made by VAZ).

Photo of the gearbox

If you look at the engine compartment, you can see that the gearbox is located between the pilot and the passenger, in which case you can move the seats a little further. Or you can leave the same interior layout, but move the units and seats back.

The VAZ-2101 has an outer diameter of wheels of 580 mm. To make the buggy look better, you can install Volga wheels on it with an outer diameter of 640 mm. The excess is small, but with its width it will look a little better. The differential will not be affected, since compared to the donor, the mass of the buggy is guaranteed to be reduced by 40-50%. Once the layout is refined (once the length of the driveshaft is known), you can begin drawing the frame. Let's determine the ground clearance and draw the pipes of the bottom row. Let us indicate the position of the wheels. Let us take the axis of the front wheel as the origin. Above the pipes of the first row we place the units, seats and mannequins. According to the selected prototype, we determine the position of the main frame pipes.

You need to draw in layers - if on a computer, then engineering graphics programs allow you to draw in layers, if on a drawing board, then it is best to use drawing film. If we draw on a computer, then we need to highlight the layers with different colors - this will allow us to visually separate the parts of the buggy. Another advantage of drawing in layers is that if you have several frames you like, you can place several options on different layers and see how it looks from the outside

Some of the design steps for a buggy are shown below:

Final buggy layout:

If we are not satisfied with something in the design of the frame or in the inclination of individual pipes, we can redraw it all as many times as necessary for the final version of the buggy. The following drawing shows various options for the upper arches. It can be seen that the buggy can look different depending on the slopes of the main arcs.

In any case, you have to try and spoil the drafts, otherwise the result will be different from the desired one.

If we have a donor VAZ-2108 on our hands

The easiest way is to take the most common buggy as an idea - sandrail. The machine is extremely light, simple and best suited for the VAZ-2108 unit. Unlike the previous layout, the frame should be more elegant. We begin to copy the buggy and decide on the crew part. To fully imagine the ergonomics of the car, we measure the entire interior of the donor with a tape measure and write down all the data - where and how the controls are located, how the seat is placed and what positions it can occupy with various adjustments, where the radio, armrests, edges of the windows (windshield and side) and etc. We take the first bolt securing the seat slide as the zero reference point and measure all distances from it. The armrest allows you to hold your hand comfortably; the car is not a sports car and most people hold the steering wheel with one hand. That is why we look at where the hand will be comfortable and it will not go numb in uncomfortable positions, we measure this height. After that, we proceed to the layout. We choose a ground clearance a little higher than that of the donor - we will sometimes have to make our way through ditches, uneven roads and light off-road conditions. After this we draw the pipes of the first row. At the donor, we mark the distance from the axis of the front wheel to the skid mounting bolt - the point that is taken as the starting point. You can increase this value, since the driver of the buggy is shifted back and the front part of the buggy is narrowed; the width of the space under the pedals should be approximately 350 mm. We measure the position of the engine compartment dimensions (along the front plane of the radiator) from the wheel axis and transfer it to the drawing. After this we place the seats and mannequin. To reduce the cost, the wheels come from the donor. It also uses part of the electrics, seats, steering rack

All stages of buggy design repeat the previous layout

After this, we show the placement of controls, dashboard and other elements (at least schematically). The track of the front and rear wheels should be the same, so we safely accept the track of the donor's front wheels. The width of the engine compartment can be taken as the distance between the wings in the place where the shock absorber strut mounting cups are located. Interior height - you can take the same as the donor, or increase it a little, since the Lada is a little cramped for tall drivers. You can also move the seats back a little. We make room for the gas tank, battery, speakers, and some other components and assemblies that may be useful. Now let's determine the angles of rotation of the wheels - the inner wheel will turn by about 32 degrees, the outer wheel by about 25. Let's turn the wheels and find out how much space they need so that there is no contact with the frame in extreme positions.

After all the elements are more or less thought out on the frame, we proceed to drawing the frame pipes. The middle row pipes are located at the height at which it is comfortable to rest your hand, while the protection will be as complete as possible from side collisions.

Printouts of frames from different angles should be in front of your eyes. This will allow you to carefully consider your frame, while you can safely copy all the angles and inclinations of the elements of the frame you like. It won't work the first time, but don't despair. To do this, you will need a ruler, a protractor, pens and a little time. Engineering experience may be minimal, since there is no need to calculate anything - the work is creative everywhere. This is what it should look like.

If we have donor AZLK-2141 on our hands.

The easiest places to find as a starting point are drawings of the MPI buggy frame and drawings of the B-2908 buggy frame. The second drawings are more crude (or more precisely, less complete), so we carefully read this article and note what may be useful.

Here are the drawings of the MPI buggy from the Modelist-Konstruktor magazine

This is how the buggy looks in metal (photo from the archive of the author of the article, V. Shcheglov)

We transfer these drawings to the computer and start working. What's the first thing we do? We decide on the unit. There are almost no Cossacks left, so you need to choose something that is more interesting for the money and at the same time fresher. What's left? Moskvich-2141 - all rusty, but the units are in order. Consequently, we begin to experiment with the frame and install a unit from a Muscovite into it, especially considering the fact that there are three units to choose from - VAZ-2106-70 (and, in principle, any unit from a classic or from a front-wheel drive model, but with modifications, will do), UZAM331 (can be of different volumes) or a more preferable unit - Renault F3R. I chose it, especially since the donor was very inexpensive in terms of money - namely the complete power unit, electrics, spare parts for the chassis and much more. Based on the dimensions of the units, we can say the following - the length of the engine, taking into account water cooling, is the same as that of the MeMZ engine, the box has the same length, but narrower in cross section than that of the Moskvich. The distance from the gearbox flange to the differential axis is the same.

So, let's start working on the layout. Having the original drawing with all the proportions in hand, we will try to adapt it to the look that suits us.

This is what happened when replacing round pipes with profile ones. Special thanks for this drawing Sfairat

When adapting drawings to your units, the result may not be exactly what you expect. There is no need to be afraid of this; in the absence of experience, nothing will ever work out right away.

mpi_design

I've been looking at sites dedicated to cross-country cars for quite a long time. Some of the ideas are posted here. That is why I decided to make drawings of a frame that would look more modern and with a different unit. I took this Czech buggy as a prototype, especially taking into account the fact that there are wheel sizes, drawings of 1:1 units, there is a drawing of a dummy - everything should turn out almost the same.

So, the dummy, wheels, and main arcs have been drawn, now all that remains is to install the power unit and refine the layout. By going to the website http://www.raf.su, you need to clarify the technical requirements in order to know in which places of the frame which pipes are used. We install the unit. Let's see what happened. It very rarely succeeds the first time - as a rule, many nuances arise that I have not encountered before. That is why the layout has to be redone several times.

How to make a suspension yourself is described here, and this particular buggy is shown. To read this article you will need Adobe Reader.

Many steps are not shown, however, this is a clear example of what you can achieve yourself if you put in a little effort and don’t beg for drawings on the forum. The end result would be this:

Detail of drawings. The drawings do not have to be detailed - if you get confused, you can make the entire package of documents, right down to the technological maps. But we are garage DIYers, not mass-produced designers. The main thing where you need to put the dimensions is the main arcs, which determine the geometry of the safety cage, suspension mounting points, and levers. In fact, more than half of the car is brewed on site.

Here are the drawings of the buggy from the classics: (clicking on the picture will open a larger picture in a new window)

Behind the wheel of this buggy is N.A. Leskov.

Article views - 205,373 viewsWarning:

All links and pictures posted above are provided for informational purposes only and are not located on our server. Only those pictures whose authors are the Portal Administration can be located on our server website And IZIKASTOM.INFO. All other files are located on third-party servers, to which the site website has absolutely nothing to do with it. The site is a technical information portal on which users post links to these files, which are publicly available. If you do not agree with the site rules, please leave the site. To comment or discuss articles, use