A hybrid engine (or hybrid) is a power plant that uses several types of fuel (two or more sources) and the synergistic effect of their combined use. It can be gasoline and electricity, gasoline and gas, diesel and electricity, hydrogen, gasoline and electricity, and many other combinations. Fortunately, modern technology allows you to do this.

History of hybrid engines.

Considering a hybrid engine as some kind of cutting-edge invention is a slight delusion. Yes, modern hybrids are a high-tech engineering project, but if you look closely, the hybrid engine dates back to the 19th-20th centuries. So, in 1897, the French company Parisienne des Voitures Electriques began to produce cars with hybrid engines.

A little later, in 1900, the famous American corporation General Electric began to master the production of hybrids. Interestingly, hybrid trucks were manufactured in Chicago until 1940, although, in general, this was a non-serial production.

Hybrid technology did not take root at that time for several reasons. First, fuel and energy prices in those years were so low that they discouraged any economic viability of producing hybrids. Secondly, the power of a conventional gasoline engine was definitely much greater then.

The energy crisis of recent years, associated with the rapid rise in energy prices, as well as the tightening of environmental regulations, have spurred manufacturers to develop and produce new generation efficient hybrid engines. A modern hybrid is, as a rule, a system of two main power plants: gasoline (or diesel) and electric. In addition to them, several more providing nodes are involved in the chain. For example, they can be: an electric generator, a battery (accumulates charge), an inverter (converts direct current to alternating current) and an electronic variator. All this is controlled and controlled by a modern powerful computer, which increases the efficiency of energy use by dozens of times compared to traditional manual or analog control. The fuel part of the system can work simultaneously with the electric part, but separate cycles are also provided. It is important that during the operation of the fuel system, the electric one does not stand idle, but accumulates (accumulates) energy.

The device, the principle of operation of a hybrid engine. To date, there are several types of hybrids:

- Sequential (series hybrid). In this scheme, the internal combustion engine drives a generator, the electricity from which powers the electric motor. The latter, in turn, rotates the wheels of the car. This approach allows the use of a low power gasoline engine, provided that it will constantly operate at maximum efficiency. Cars with this arrangement tend to be small and have a large battery (such as the Chevrolet Volt);

- Parallel (parallel hybrid). In this case, the wheels of the car are driven by both a gasoline engine and an electric one. Depending on driving conditions, the electric motor can generate additional power. This pattern is very common. The batteries in this case are compact and are charged directly while the vehicle is moving. The main disadvantage here is that the electric motor cannot simultaneously rotate the wheels and charge the battery. A similar scheme is implemented on Civic Hybrid and Volkswagen Touareg Hybrid cars;

- Series-parallel (mixed). From the name it is easy to assume that the third type combines the two previous ones. At the moment, this is the most efficient hybrid scheme. Combined traction (petrol engine plus electric motor) can be used to turn the wheels. In addition, an electric motor can simultaneously generate electricity (act as a generator) and generate thrust (as a motor). The disadvantage of the scheme is its very high cost.

An example of a mixed circuit is the Hybrid Synergy Drive from Lexus (Toyota). There is a 3.3-liter gasoline engine, 2 electric motors and a battery. For communication between these three structural elements, a power distribution device with a compact planetary gear is used, which reduces energy losses due to friction. To control the energy flows, there is a control unit and a semiconductor switching device. The inverter in the HSD unit converts the DC battery current into AC power for the motor.

An electric motor is used to move the car at low speeds and to start. This allows you to save gasoline and move off smoothly. When switching to normal driving mode, the gasoline engine is turned on, which works in parallel with the electric motors. Excess energy is given to the battery. During acceleration, the internal combustion engine is actively working. In braking mode, the so-called regenerative braking system is used, when the electric motors operate in generator mode, recharging the battery. Those. in the main modes of operation, a gasoline engine is used, and in intermediate (transitional) electric ones.

Advantages and disadvantages of a hybrid engine. Of course, despite the high level of technology, the hybrid installation has both undeniable advantages and some disadvantages that leading engineers continue to work on. Let's start with the advantages:

- efficient fuel consumption and saving up to 35%;

- low level of toxicity of exhaust gases;

- low noise;

- excellent handling and smoother acceleration of the car;

- full control of the installation using the on-board computer and electronic systems;

- hybrid vehicle battery components are easy to dispose of and recycle;

- regenerative braking system helps conserve energy;

- long battery life in a hybrid vehicle.

Among the disadvantages of hybrids, it is worth mentioning the following:

- the high cost of cars with a hybrid power plant;

- high cost of spare parts and repairs. It is unlikely that it will be possible to repair it on your own, and so far such cars can only be provided with a full-fledged service in very large cities. In addition, there may be hitches with the supply of the necessary spare parts;

- the electrical system does not tolerate significant temperature changes.

A popular misconception about hybrid engines is the loss of power and efficiency of the propulsion system. This is not so, the power of the hybrid is in order. In addition, no special fuel is required for refueling.

The world's leading automakers have already appreciated the benefits of hybrid engines. Every year the number of hybrid cars is growing, gaining more and more popularity among drivers. The markets are expanding. The hybrid engine is a real masterpiece of engineering, an ultra-modern economical and environmentally friendly device, which holds the near future of the global automotive industry. In view of the rise in the cost of hydrocarbon fuel, we can safely predict that in 5-10 years hybrid power plants will be widely distributed throughout the world.

More and more, in recent years, people are thinking about the environment. The auto industry is no exception. Every year, environmental standards are rising, and with this, vehicle engines are being modernized and improved. A hybrid engine is one of the solutions to improve the environmental friendliness of a car.

What is a hybrid engine

What is a hybrid engine and its device? The very word "hybrid" is translated from Latin as "cross". In fact, this is a mixture of the classic version of the power unit and the electric motor. So, the drive of the driving wheels is carried out by rotation using a conventional internal combustion engine or an electric motor.

Each of the power units performs a specific function in motion. So, when the vehicle is in city traffic jams, the movement is carried out with the help of an electric motor, but on the highway, a gasoline power plant comes into operation.

Advantages of a hybrid

Perhaps the biggest plus in using a hybrid powertrain is its economy. As a rule, such an engine consumes 25-30% less fuel than standard gasoline engines.

The second positive point is the high environmental standard. As fuel consumption decreases, less exhaust emissions enter the ecosystem.

The third plus is that the batteries for the electric motor are charged from a gasoline engine and if they sit down, you can always switch to gasoline. This also includes the same specifications. In terms of power characteristics, the “hybrid” is in no way inferior to a conventional motor.

The "hybrid" engine feels best in the urban cycle of use, where there are frequent stops. In this case, basically, the electric motor itself works. In many countries, "hybrid" cars are driven by city police.

Cons of using a "hybrid"

The first disadvantage worth noting is the expensive repair of hybrid motors. The manufacturers of the "hybrid" explain this by the fact that the power unit is structurally complex, both in maintenance and in restoration.

The batteries of a hybrid engine are quite sensitive to changes and temperature drops, which is why when they fall below -15 degrees Celsius, they are quickly discharged, and operation is carried out mainly on gasoline.

The high cost of the vehicle itself with a hybrid engine. Not every car enthusiast can afford a car that costs $20,000. Despite this, a number of countries have introduced preferential taxes on customs clearance, registration and use of hybrid engines to encourage buyers to buy these cars. This has not yet been done on the territory of the CIS countries.

Modern indicators

Toyota is the leader in the number of hybrids and has been actively producing these cars since 1997, and in modifications of both conventional cars of the Prius series, crossovers of the Lexus RX400h series, and luxury cars - Lexus LS 600h.

In 2006, over half a million Prius models alone were sold worldwide. Toyota HSD hybrid drive technology has been licensed by Ford (Escape Hybrid), Nissan (Altima Hybrid).

Mass production of hybrid vehicles is constrained by the shortage of nickel-metal hydride batteries.

In 2006, 90,410 hybrid vehicles were sold in Japan, up 47.6% from 2005.

In 2007, sales of hybrid vehicles in the US increased by 38% compared to 2006. Hybrid vehicles in the US account for 2.15% of the new passenger car market. In total, about 350,000 hybrid vehicles were sold in the United States in 2007 (excluding GM sales).

A total of 1,002,000 hybrid vehicles were sold in the US from 1999 to the end of 2007.

Output

As the current trend shows, more and more motorists are beginning to prefer hybrid powertrains. They are more economical, silent and environmentally friendly. The disadvantage of using it is expensive repairs, and the sensitivity of batteries to temperature changes.

How it works, consider the example of Touareg, with a hybrid powertrain.

What does the term "hybrid technology" mean?

The term "hybrid" originates from the Latin word hybrida, and means something crossed, or mixed. In engineering, a hybrid is a system in which two different technologies are combined with each other. In connection with drive concepts, the term hybrid drive technology is used to refer to two areas: bivalent (or dual-fuel) powertrain hybrid powertrain

In the case of hybrid drive technology, it is a combination of two different power units, the operation of which is based on different operating principles. Currently, hybrid drive technology means a combination of an internal combustion engine and an electric motor-generator (electric machine). This electric machine can be used as a generator to generate electrical energy, a traction motor to drive a car, and a starter to start an internal combustion engine. Depending on the execution of the main structure, three types of hybrid power unit are distinguished: the so-called. "microhybrid" power unit, the so-called. "medium hybrid" power unit, the so-called. "full hybrid" powertrain.

"Micro-hybrid" powertrain

In this drive concept, the electrical component (starter/alternator) is exclusively used to implement the start-stop function. Part of the kinetic energy can be used again as electrical energy (recuperation). Drive only from electric traction is not provided. The parameters of the 12 volt fiberglass battery are adapted to frequent engine starts.

"Medium hybrid" drive

The electric drive supports the operation of the internal combustion engine. The movement of the car only on electric traction is impossible. With a "mid-hybrid" drive, most of the kinetic energy during braking is regenerated and stored as electrical energy in a high-voltage battery. The high voltage battery as well as the electrical components are designed for higher electrical voltage and thus higher power. Thanks to the support of the electric motor-generator, the mode of operation of the heat engine can be shifted to the region of maximum efficiency. This is referred to as load point displacement.

"Full hybrid" powertrain

A powerful electric motor-generator is combined with an internal combustion engine. Only electric drive is possible. The electric motor generator, if conditions permit, supports the operation of the internal combustion engine. Movement at low speed is carried out only on electric traction. The Startstop function for the internal combustion engine has been implemented. Recovery is used to charge the high voltage battery. Thanks to the decoupling clutch between the internal combustion engine and the electric motor-generator, it is possible to ensure the separation of both systems. The internal combustion engine is connected to work only when necessary.

Fundamentals of hybrid technology

Full hybrid powertrain systems are divided into three subgroups: parallel hybrid powertrain, split powertrain (with split power flows), and series hybrid powertrain.

Parallel hybrid powertrain

Parallel execution of the hybrid power unit is simple. It is used when it is necessary to "hybridize" an existing vehicle. The internal combustion engine, electric motor generator and gearbox are located on the same axis. Typically, a parallel hybrid powertrain system uses a single electric motor/generator. The sum of the unit power of the internal combustion engine and the power of the electric motor-generator corresponds to the total power. This concept provides a high degree of borrowing components and parts of the old car. In all-wheel drive vehicles with a parallel hybrid powertrain, all four wheels are driven by a Torsen differential and a transfer case.

Separate hybrid drive

The split hybrid drive system has an electric motor generator in addition to the internal combustion engine. Both engines are located under the hood. The torque of the internal combustion engine, as well as from the electric motor-generator, is fed through the planetary gear to the vehicle gearbox. In contrast to a parallel hybrid drive, it is not possible to extract the sum of the individual powers for wheel drive in this way. The generated power is partly spent on driving the car, partly, in the form of electrical energy, accumulates in a high-voltage battery.

Series hybrid powertrain

The car is equipped with an internal combustion engine, a generator and an electric motor-generator. However, unlike both of the previously described concepts, the internal combustion engine does not have the ability to independently drive the car through a shaft, or through a gearbox. Power from the internal combustion engine is not transferred to the wheels. The main drive of the car is carried out by an electric motor generator. If the capacity of the high-voltage battery is too low, the internal combustion engine starts. The internal combustion engine charges the high-voltage battery through the generator. The electric motor generator can again be powered by the high voltage battery.

Separate sequential hybrid powertrain

The split series hybrid powertrain is a mixed form of the two hybrid drives described above. The car is equipped with one internal combustion engine and two electric motors-generators. The internal combustion engine and the first electric motor generator are located under the hood. The second electric motor generator is located on the rear axle. This concept is used for all-wheel drive vehicles. The internal combustion engine and the first electric motor generator can drive the vehicle's gearbox through a planetary gear. And in this case, the rule applies, according to which single drive powers cannot be taken for wheel drive in the form of total power. A second electric motor generator on the rear axle is activated when needed. In connection with this design of the drive, the high-voltage battery is located between both axles of the vehicle.

Other terms and definitions Other terms and definitions often used in connection with hybrid drive technology will be briefly explained here.

Recovery. In the general case, this term in technology means a way to return energy. During recuperation, the available energy of one type is converted into another, used in the subsequent form of energy. The potential chemical energy of the fuel is converted in the transmission into kinetic energy. If the car is braked by a conventional brake, then the excess kinetic energy is converted into heat energy through the friction of the brakes. The resulting heat is dissipated in the surrounding space, and therefore it is impossible to use it in the future.

If, on the contrary, as with hybrid drive technology, in addition to the classic brakes, the generator is used as an engine brake, then part of the kinetic energy is converted into electrical energy and thus becomes available for subsequent use. The energy balance of the car is improved. This kind of regenerative braking is called regenerative braking.

As soon as the vehicle speed is reduced by decelerating by depressing the brake pedal in over idle mode, or the vehicle is coasting or the vehicle is moving downhill c The hybrid drive system includes an electric motor-generator and uses it as a generator.

In this case, it charges the high-voltage battery. So in forced idle mode

running, it becomes possible to "refuel" cars with an electric hybrid drive with electricity.

When the car is coasting, the electric motor-generator, operating in generator mode,

converts from motion energy into electrical energy only such an amount of energy that

required for the operation of the 12 volt on-board network.

Electric motor-generator (electric machine)

The term electric motor-generator, or electric machine, is used instead of the terms generator, electric motor, and starter. In principle, any electric motor can also be used as a generator. If the motor shaft is driven by an external drive, then the motor, like a generator, generates electrical energy. If electrical energy is supplied to the electric machine, then it works like an electric motor. Thus, the electric motor generator of electric hybrid vehicles replaces the conventional combustion engine starter as well as the conventional generator (lighting generator).

Electric booster (E-boost)

Similar to the kickdown function of internal combustion engines, which makes maximum engine power available, the hybrid drive features an electric E-Boost function. When using the function, the motor-generator and combustion engine deliver their maximum individual powers, which add up to a higher total power. The sum of the individual powers of both types of engines corresponds to the total power of the transmission.

Due to power losses in the electric motor-generator, its power in the generator mode is lower than in the traction motor mode. The power of the electric motor-generator in the engine mode is 34 kW. The power of the electric motor-generator in generator mode is 31 kW. In the Touareg with hybrid drive, the internal combustion engine has an output of 245 kW and the electric motor-generator has an output of 31 kW. In traction motor mode, the electric motor-generator produces 34 kW of power. Together, the internal combustion engine and the electric motor-generator in the traction motor mode develop a total power of 279 kW.

Start-stop function

|

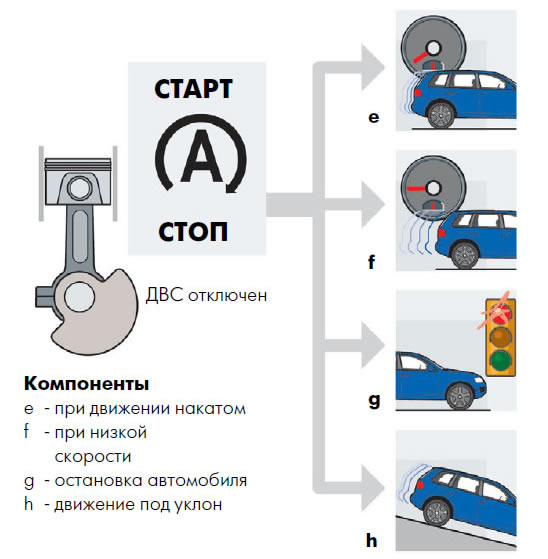

The hybrid drive technology makes it possible to implement the Start-Stop function in this vehicle design. In the case of a conventional vehicle with a start-stop system, the vehicle must come to a stop in order to switch off the internal combustion engine (example: Passat BlueMotion). However, an all-hybrid vehicle can also run on electric power. This feature allows the StartStop system to shut off the internal combustion engine when the vehicle is moving or coasting. The internal combustion engine is switched on depending on the need. This can occur when accelerating quickly, when driving at high speed, with a high load, or when the high voltage battery is very low. When the high-voltage battery is highly discharged, the hybrid drive system can use the internal combustion engine in combination with the motor generator operating as a generator to charge the high-voltage battery. In other cases, a full hybrid vehicle may run on electric power. The internal combustion engine is in stop mode. This is also true in the case of slow traffic, stopping at a traffic light, when driving in overrun mode downhill, or when the vehicle is coasting. When an internal combustion engine is not running, it does not consume fuel or emit harmful substances into the atmosphere. The start-stop function integrated into the hybrid drive system increases the vehicle's efficiency and environmental friendliness. While the combustion engine is in stop mode, the air conditioner can continue to operate. The air conditioner compressor is an element of the high-voltage system. |

|

Arguments in favor of hybrid technology

Why do we combine an electric motor-generator with an internal combustion engine? To take off the torque, the rotational speed of the internal combustion engine must not be lower than the idling speed. When stopped, the engine cannot deliver torque. With an increase in the rotational speed of an internal combustion engine, its torque increases. The electric motor generator with the first revolutions produces the maximum torque. It does not have an idle speed. As the speed increases, its torque decreases. Thanks to the operation of the electric motor-generator, the most difficult operating mode is excluded from the internal combustion engine: in the range below idle speed. Thanks to the support of the electric motor-generator, the internal combustion engine can be operated in more efficient modes. This displacement of the load point increases the efficiency of the power unit.

Why use a full hybrid powertrain (drive)?

The full hybrid unit, unlike other hybrid drive options, combines the function of the integrated Start-Stop system, the E-Boost system, the recuperation function and the ability to drive only on the electric motor (electric traction mode).

Electric motor-generator

The electric motor-generator is located between the internal combustion engine and the automatic transmission. It is a three-phase synchronous motor. The power electronics module converts the 288 V DC voltage into a three-phase AC voltage. Three-phase voltage creates a three-phase electromagnetic field in the electric motor-generator.

high voltage battery

Access to the high-voltage battery is provided through the luggage compartment floor covering. It is designed as a module and includes various components of the Touareg high-voltage system. The high voltage battery module has a mass of 85 kg and can only be replaced as an assembly.

The high voltage battery cannot be compared with a conventional 12 V battery. In normal operation, the high voltage battery is used in a free range of charge level from 20% to 85%. A conventional 12 volt battery is unable to carry such loads for a long time. Therefore, a high-voltage battery should be considered as an operational energy storage device for an electric drive. Like a capacitor, it can store and release electrical energy again. In principle, recuperation, energy regeneration, can be considered as the possibility of refueling a car with energy while driving. The use of a high-voltage battery in a hybrid vehicle is distinguished by the alternation of charging (recovery) and discharging (electrically driven driving) cycles of the high-voltage battery.

Example: If we compare the energy of a high-voltage battery with the energy generated by burning fuel, then the amount of energy that the battery can produce will correspond to approximately 200 ml of fuel. This example demonstrates that on the path to electric vehicles, batteries need to be significantly upgraded in terms of their ability to store energy.

Lexus RX400h hybrid powertrain

The hybrid power plant combines the work of a modern internal combustion engine and an electric motor. The whole complex is controlled by an electronic system, including fuel consumption (depending on the chosen driving method).

The movement is started by an electric motor, which also works at low speeds. As the speed increases, the energy is sent from the batteries to the power management unit, which distributes it to the electric motors. Electric motors allow hybrids to start very smoothly. The whole principle of the hybrid power plant demonstrates Lexus Rx400h hybrid car.

When the car is moving normally, the energy is distributed between the wheels and the generator, the generator that drives the electric motors. Controls energy, in order to maximize its savings, electronic system. The generator, if necessary, gives off excess battery energy, charging it.

When accelerating the hybrid, the internal combustion engine is running, and in order to improve the dynamics, there is an electric motor. During braking, energy is converted - kinetic into electrical. It is sent by electric motors to the power control unit, which, in turn, returns it to the high-voltage battery. At the same time, the gasoline engine is running in normal mode.

The task of hybrid power plants:

- Achieve good performance and fast acceleration with instantaneous power delivery.

- To save part of the energy during braking, partly converting it into electricity, and partly into heat (unlike conventional cars, where it is 100% converted into heat).

- Provide the hybrid with a modern energy management system.

- Reduce the size and weight of components.

“That is, hybrid powertrains in cars must combine the desire to protect the environment with high driving safety and maximum enjoyment from it.” This is from the chief engineer of the Lexus RX400h, who also said that the company's new hybrid system is great for large and medium-sized cars.

hybrid transmission

Its purpose in a hybrid power plant is to redistribute the flow of power to where it is needed more. But, in addition to ensuring the most economical use of power, it also manages the joint operation of the two engines, responding to the driver's need for more power instantly.

Two sources of energy– the electric and petrol that the RX400h (like any other car) power are the perfect complement to each other. Instantly providing additional power, electric motors do not consume fuel, while maintaining a clean atmosphere. Each of the sources works in the system in an optimal mode, providing fuel efficiency to the car and excellent running qualities.

Energy recovery in a hybrid power plant

Energy that is irretrievably lost under normal conditions, hybrid technologies of the power plant make it possible to partially use, i.e. this is one of the sources of savings. In particular, Lexus hybrid technologies provide high performance thanks to a high-performance main power source, which uses a modern V6 internal combustion engine and a high-torque electric motor to provide additional power. At the same time, no vibrations occur, the noise level, gasoline consumption and the amount of CO2 emitted into the atmosphere are reduced. The driver only feels how instantly the engine responds to commands. Sophisticated and compact at the same time, the hybrid power plant, which includes a high-voltage electric motor, provides smooth acceleration and maximum comfort while driving.

When braking the car, the generator is also used, which is especially effective when traveling around the city. In a hybrid power plant, there is practically no friction due to the fact that there is no gearbox, which allows you to save kinetic energy by converting it into electrical energy.

Inverter in a hybrid power plant

The direct current is converted into alternating current, which feeds the electric motor, thanks to the inverter. The Lexus RX400h uses a high-voltage circuit that increases the voltage, due to which, at the same current value, the electric power increases, the performance and torque of the electric motor drive increase.

VDIM, or Integrated Vehicle Dynamics Management System

Improvement in the quality of control is also provided by a modified suspension, an electronic control system, a modern stability control system and VDIM itself, which was developed with the aim of combining systems that had previously tended to develop separately, even if they were installed in one car: ABS - anti-lock braking system, TRC - anti-slip system, VCS - course stability system, EPS - electric power steering. This improved the characteristics of the hybrid, and safety, as well as made it possible to make the behavior of the car more predictable and soft. VDIM not only combines them all, receiving information from numerous sensors about the current state of the vehicle, but also controls the all-wheel drive system and the hybrid power plant. And the optimization of system operation, thanks to VDIM, has a positive effect on dynamic characteristics. This power plant is much more efficient and less "intrusive" than conventional stability control systems. The dynamic management system, using high-speed transmission, brake and engine control technology, fully controls the hybrid powertrain, braking system and all-wheel drive, controlling both engines simultaneously according to specific driving conditions.

System start

The power supply system turns on, having received confirmation from the electronic key, which means that the driver is inside the car. As soon as the ignition is turned on, the system checks the health of all sensors, the gasoline and electric motor, the battery and the generator. Then the various components of the high-voltage system are turned on - the car is ready for work.

System shutdown

Before the driver who turned off the ignition leaves the passenger compartment, all components of the power unit are turned off - the computer is the last to turn off, making sure that the deactivation of the components is completed.

Braking control in a hybrid powertrain

The electronically controlled regenerative braking system, in order to optimize the amount of energy stored, independently decides when it is necessary to use hydraulic brakes, and when to apply regenerative braking, which it (the system) applies as often as possible.

Power management

The power plant monitors the energy consumed throughout the car, determining, based on the current state of the hybrid, which of the two motors should be included in the work. That is, it comes from whether acceleration is required, as well as on the signals supplied by the computer from the battery. If the battery charge is sufficient, and the temperature is not too low, then at the first start the car runs on an electric motor, for which the motor is first started from the generator (the energy needed for the entire car is immediately calculated). Next, the traffic conditions are calculated based on ensuring the maximum efficiency required to generate the necessary energy. After that, the signal is sent to the engine to get the required number of revolutions, which are further controlled by the generator.

A car should not be a luxury, but a daily means of transportation, this truth has long won the hearts of drivers. To realize this dream of Ostap Bender, the owners make great efforts to minimize the cost of their beloved "friend". You can influence something yourself: drive carefully - there will be less, buy high-quality parts - you will have to change less often, refuel with expensive, high-quality gasoline - engine breakdowns are minimized. But the most expensive part of operation is still refueling. Prices do not depend on us. That is why at present the hybrid engine in cars is beginning to gain great popularity.

There are several reasons for this and motorists can be divided into two camps. For the former, the main and most common reason is the price of fuel. We don't live in Venezuela, Saudi Arabia or Kuwait, where petrol is cheaper than water. A four-wheeled “friend” needs to be “fed” regularly. For the latter, the protection of the natural environment and everything connected with it is vital.

Why did the idea of creating such engines come about? Consider the principle of operation, the advantages and disadvantages of cars running on, and. Internal combustion engines are more powerful, but at the same time, developers cannot completely eliminate carbon dioxide emissions into the environment. This factor is the reduction of world oil reserves and, as a result, a regular and systematic rise in the price of such an energy source.

Electricity has its undeniable advantages, first of all, it is environmentally friendly and cheaper. But at the same time, electric vehicles cannot currently become very popular, since, figuratively speaking, “infrastructure” is needed: car charging stations, specialized service stations focused on the repair and maintenance of this type of engine. But the most important factor is power, which is significantly inferior to internal combustion engines. And as a result, the speed wants the best (there are simply not enough “horses” under the hood).

These factors have forced manufacturers to consider alternatives and develop hybrid vehicles that will combine the advantages and nullify the disadvantages of these two types of vehicles.

Features of hybrid cars

The developers approached this issue comprehensively. In this case, several tasks were solved: reduced to a minimum, which positively affects the ecological situation not only in cities, but also on the Earth as a whole; due to the combination of two types of energy, operating costs are reduced; The shortcomings of the electric motor (low power) are compensated by the advantages of the gasoline upwards. In fact, such cars in high-speed mode do not differ from gasoline ones. Unlike the above described vehicles with a hybrid engine, they have two power sources, consist of two power units and several elements:

- fuel tank. Gasoline, unlike, has a high energy density. To understand, let's give an example - the energy of 1 liter of gasoline is equated to a battery weighing about 450 kg;

- Petrol engine. They are usually smaller and upgraded with the latest technology, which significantly reduces the overall weight of the car and increases power;

- An electric motor - not only more powerful, but also designed to work in conjunction with gasoline. It can also work as a generator to charge the battery;

- Batteries, the main function of which is to accumulate energy for the electric motor, which, in turn, can feed them mutually;

- Generator - working on the principle of an electric motor, but to generate electricity.

- Transmissions - the functions are almost the same as in conventional cars. But at the same time, depending on the type of hybrid, they can be different. The transmission of the Toyota brand is characterized by a branching of power flows. In this case, the motor operates in the most comfortable range of loads and revolutions. And this, in turn, contributes to significant fuel savings.

Principle of operation

The very word hybrid means crossing. In our case, two different technologies and two energy sources are combined to accomplish one task - moving forward. The operation of a hybrid engine is that the internal combustion engine rotates and provides energy to the electric motor, which, in turn, rotates the transmission, which helps its "partner" to work optimally, creating additional force. As a result, sharp fluctuations and loads are eliminated, and productivity is significantly increased.

There are several options:

Parallel. The gasoline engine is powered by a fuel tank, and the electric motor is powered by batteries. As a result, both engines turn the transmission, which in turn drives the wheels.

Microhybrid. This principle was developed by Toyota. "Hybrid" moves at low speeds and starts solely due to the electric motor. When switching to an increased speed, the internal combustion engine (ICE) is connected. But at the same time, during climbs, driving on difficult sections of the road (sand, mud), increasing other loads, the electric motor is additionally powered from the battery for parallel operation and increased traction. All this is electronically controlled and does not require driver intervention.

Medium hybrid. Such a car with a hybrid engine has its own characteristics - driving on an electric motor is impossible. But at the same time, electric traction significantly increases the efficiency of the heat engine by generating a voltage slightly higher than batteries can provide, which, in turn, increases the power of the main engine.

Full hybrid. In this option, electricity comes first. The movement is only at his expense. The charging of the high-voltage battery is due to recuperation. The existing separate clutch between the two types of engine ensures the separation of these systems. As a result, the internal combustion engine is connected only when necessary.

Separated. It has an engine-generator and gasoline. Through the planetary gear, the torque is transmitted to. Part of the power is used directly to move the car, the rest is stored in a high-voltage battery in the form of clean electrical energy.

Consistent. The operation of the hybrid engine is that the gasoline drives the generator, which charges the batteries, and they, in turn, provide energy to the electric motor, which rotates the transmission and, as a result, the wheels.

Advantages

If you analyze the prices of hybrids, you will notice that they are more expensive than conventional cars. Should I be afraid of "biting" amounts? It is necessary, first of all, to analyze what you get as a result when buying such an option. And only after that decide whether they are ready to invest capital (even if it is a purchase on credit), which will eventually turn into daily savings. And the more gas prices go up, the bigger your net income will be.

But let's start a little differently. A car with a hybrid engine helps to reduce carbon dioxide emissions into the atmosphere, which are reduced tenfold. As a result, life in the city becomes more comfortable and you contribute to the improvement of the planet. In addition, save on fines for exceeding emissions into the atmosphere.

The batteries are recharged from the onboard power plant, as a result, an external source is not needed for constant charging, as in electric motors. In essence, you are purchasing an additional source of energy, which increases the efficiency of the internal combustion engine.

Thanks to the developments of experienced specialists, the mass of a gasoline engine is significantly reduced, as a result, and the total weight of the car. Every car enthusiast knows what this means. Gasoline consumption per 100 km "Oka" can not be compared with. And it depends primarily on the mass. As a result, there are complex savings due to refueling and the use of electricity.

For the manufacture of all parts, including the body, light materials are used. At the same time, they are strong and reliable: made of metals (aluminum alloys, magnesium), as well as carbon fiber. For general information: the Insight 1 liter engine weighs only 56 kg, while the power is quite decent (67 horsepower) and rpm (5,700). The "help" of the electric motor at the start allows you to accelerate from 0 to 100 km / h.

In such cars, there is no need for a gearbox. There is an automatic change in the traction force of the drive wheels, which is provided by the electric motor.

Thanks to the constant development of designers, aerodynamics are increasing. This is what all designers strive for. It is the resistance to the force of air and wind that does not allow "eating up" significant resources of the inner "heart", multiplied by the help of a parallel energy system.

Another savings resource is the installation of special tires that are stiffer than conventional tires. They are inflated at relatively high pressure. This helps to reduce the resistance of the road surface.

Prospects for the development of this area of mechanical engineering are possible only with an integrated approach: the development of lightweight bodies, capacious, but at the same time compact batteries (so that they do not take up much space under the hood); improving easier, faster and more affordable battery charging; improvement of the system of "re-use" of energy.

Having considered all the features of a car with a hybrid engine, we can come to the conclusion: of course, this is not a perpetual motion machine that any motorist and fighters for a clean environment dream of. Rather, this is another step towards the modernization of motors, the struggle to save dwindling natural resources. But they help to significantly save money on every gas station. Therefore, if you are faced with the choice of a new car, think about the fact that buying such a model will eventually give you significant bonuses: in fact, every hundred kilometers of travel will “put aside” additional money into your wallet compared to internal combustion engines.