A simple, obvious, but brilliant idea came to mind. After all, given that a stepper motor is not only a motor that provides mechanical operation of completely different devices (from printers, scanners and other office equipment, to various units used in more serious devices). A stepper motor can also serve as an excellent generator of electricity!

And its main plus in everything is that it does not require high speeds at all, it may well work properly even at low loads. That is, even with the minimum action of the force directed to it, the stepper motor produces energy perfectly. Most importantly, this energy is quite enough for various needs, such as lighting the road for a cyclist using a lamp connected to a stepper motor.

Unfortunately, with a conventional alternator, a standard bike will still need initial revs before the flashlight can emit enough beams of light to clearly illuminate the path. But when using a stepper motor, this drawback is removed by itself, that is, the lighting will be supplied as soon as the wheel starts to rotate.

But the truth is that this miracle of design will still have a number of shortcomings. For example, the most obvious of them is a large magnetic sticking. But in fact, it is not so scary for a cyclist.

That getting started we will need to find some details:

1) Actually the stepper motor itself.

2) a couple of large capacitors.

3) LED lights

4) voltage stabilizer 5-6 volts.

Finding a stepper motor is quite easy due to the fact that it is very common in all office appliances. The only thing to understand is that the larger the stepper motor, the better for us, respectively.

Here several models of stepper motors and various options for their attachment to an iron horse will be described and presented.

To begin with, let's take the largest engine that the author managed to get. He dismantled it from an ordinary office plotter for printing (in fact, this is a printer, only several times larger).

Externally, the engine is quite large.

But before proceeding to the study of the stabilization circuit as well as the power circuit, you should pay attention to the method of attaching this unit to the bike.

If you look at the picture, you will understand that the generator is located closer to the axis of the wheel and the rotation is transmitted from an additional circle.

And yet, since everyone has their own bike model and someone does not want to damage the frame with self-tapping screws, you will need to develop the mount yourself as well as the circle of rotation, there are really a lot of options.

If you have no idea how to screw a large stepper motor to the structure, there is a smaller option:

You just have to choose the generator option that fits the size of your vehicle.

Well, when you figured out the stepper motors, you can proceed to the flashlights and power circuits.

Lights must be LED. the rectification circuit will look like this: a block of rectifier diodes, several high-capacity capacitors and, of course, a voltage regulator. In principle, this is a standard power scheme.

A stepper motor has four output wires as standard, which correspond to two coils. it is for this reason that there are also two rectifier blocks in the image. This homemade electricity generator may well produce up to 50 volts of voltage at high speeds, so it is better to take the appropriate capacitors (voltage above 50). Well, a stabilizer for a voltage of 5-6 volts.

And so what is the essence of homemade, and why was it needed?

It's all about its advantage, even just starting off - your path will already be brightly lit by a lantern powered by our stepper motor - it's also a generator.

I would also like to note that during the movement the lamp will not blink or go out - the lighting will be smooth and even.

Cycling past summer cottages, I saw a working wind generator. Large blades rotated slowly but surely, the weather vane oriented the device in the direction of the wind.

I wanted to implement a similar design, albeit not capable of generating enough power to provide “serious” consumers, but still working and, for example, charging batteries or powering LEDs.

One of the most effective options for a small homemade wind turbine is to use stepper motor(SHD) (English) stepping (stepper, step) motor) - in such a motor, the rotation of the shaft consists of small steps. The windings of a stepper motor are combined into phases. When current is applied to one of the phases, the shaft moves one step.

These engines are low-speed and a generator with such an engine can be connected without a gearbox to a wind turbine, Stirling engine or other low-speed power source. When using a conventional (collector) DC motor as a generator, a 10-15 times higher speed would be required to achieve the same results.

A feature of the stepper is a fairly high starting torque (even without an electrical load connected to the generator), reaching 40 grams of force per centimeter.

The efficiency of the generator with stepper motor reaches 40%.

To check the performance of a stepper motor, you can connect, for example, a red LED. By rotating the motor shaft, you can observe the glow of the LED. The polarity of the LED connection does not matter, as the motor generates alternating current.

Five-inch floppy disk drives, as well as old printers and scanners, are a storehouse of such powerful enough engines.

For example, I have a SD from an old 5.25″ drive that was still working as part of ZX Spectrum– compatible computer “Byte”.

Such a drive contains two windings, from the ends and the middle of which conclusions are drawn - in total, six wires:

first winding coil 1) - blue (English) blue) and yellow (eng. yellow);

second winding coil 2) - red (eng. red) and white (eng. white);

brown (English) brown) wires - conclusions from the midpoints of each winding (eng. center taps).

disassembled stepper motor

The rotor of the engine is visible on the left, on which “striped” magnetic poles are visible - north and south. To the right is the stator winding, consisting of eight coils.

The resistance of half the winding is

I used this motor in my original wind turbine design.

My less powerful stepper motor T1319635 firms Epoch Electronics Corp. from the scanner HP Scanjet 2400 It has five outputs (unipolar motor):

first winding coil 1) - orange (English) orange) and black (eng. black);

second winding coil 2) - brown (eng. brown) and yellow (eng. yellow);

red (English) red) wire - leads connected together from the midpoint of each winding (eng. center taps).

The resistance of half of the winding is 58 ohms, which is indicated on the motor housing.

In an improved version of the wind generator, I used a stepper motor Robotron SPA 42/100-558, produced in the GDR and designed for a voltage of 12 V:

There are two options for the location of the axis of the impeller (turbine) of the wind generator - horizontal and vertical.

advantage horizontal(most popular) location axis, located in the direction of the wind, is a more efficient use of wind energy, the disadvantage is the complexity of the design.

I chose vertical arrangement axes - VAWT (vertical axis wind turbine), which greatly simplifies the design and does not require orientation to the wind . This option is more suitable for roof mounting, it is much more effective in conditions of rapid and frequent changes in wind direction.

I used a type of wind turbine called a Savonius wind turbine. Savonius wind turbine). It was invented in 1922 Sigurd Johannes Savonius) from Finland.

Sigurd Johannes Savonius

The operation of the Savonius wind turbine is based on the fact that the resistance (Eng. drag) to the oncoming air flow - the wind of the concave surface of the cylinder (blade) is greater than the convex one.

Aerodynamic drag coefficients ( English drag coefficients) $C_D$

concave half of the cylinder (1) - 2.30

convex half of the cylinder (2) - 1.20

flat square plate - 1.17

concave hollow hemisphere (3) - 1.42

convex hollow hemisphere (4) - 0.38

The indicated values are given for Reynolds numbers (eng. Reynolds numbers) in the range $10^4 – 10^6$. The Reynolds number characterizes the behavior of a body in a medium.

Body resistance force to air flow $ =<<1 \over 2>S\rho

Such a wind turbine rotates in the same direction, regardless of the direction of the wind:

A similar principle of operation is used in a cup anemometer (eng. cup anemometer)– instrument for measuring wind speed:

Such an anemometer was invented in 1846 by the Irish astronomer John Thomas Romney Robinson ( John Thomas Romney Robinson):

Robinson believed that the cups in his four-cup anemometer moved at a speed equal to one third of the wind speed. In reality, this value ranges from two to a little more than three.

Currently, three-cup anemometers, developed by Canadian meteorologist John Patterson, are used to measure wind speed ( John Patterson) in 1926:

DC brushed motor generators with a vertical microturbine are sold at eBay for about $5:

Such a turbine contains four blades located along two perpendicular axes, with an impeller diameter of 100 mm, a blade height of 60 mm, a chord length of 30 mm, and a segment height of 11 mm. The impeller is mounted on the shaft of the DC commutator micromotor with the marking JQ24-125p70. The rated supply voltage of such a motor is 3. 12 V.

The energy generated by such a generator is enough to light up a “white” LED.

Savonius wind turbine rotation speed cannot exceed wind speed , but this design is characterized high torque (English) torque).

The efficiency of a wind turbine can be estimated by comparing the power generated by the wind generator with the power contained in the wind blowing around the turbine:

$P =<1\over 2>\rho S

Initially, the impeller of my generator used four blades in the form of segments (halves) of cylinders cut from plastic pipes:

segment length - 14 cm;

segment height - 2 cm;

segment chord length - 4 cm;

I installed the assembled structure on a fairly high (6 m 70 cm) wooden mast from a bar, attached with self-tapping screws to a metal frame:

The disadvantage of the generator was the rather high wind speed required to spin the blades. To increase the surface area, I used blades cut from plastic bottles:

segment length - 18 cm;

segment height - 5 cm;

segment chord length - 7 cm;

the distance from the beginning of the segment to the center of the axis of rotation is 3 cm.

The problem turned out to be the strength of the blade holders. At first I used perforated aluminum strips from a Soviet children's designer 1 mm thick. After several days of operation, strong gusts of wind led to a break in the slats (1). After this failure, I decided to cut out the blade holders from foil textolite (2) with a thickness of 1.8 mm:

The strength of textolite for bending perpendicular to the plate is 204 MPa and is comparable to the bending strength of aluminum - 275 MPa. But the modulus of elasticity of aluminum $E$ (70000 MPa) is much higher than that of textolite (10000 MPa), i.e. Texolite is much more elastic than aluminium. This, in my opinion, taking into account the greater thickness of the textolite holders, will provide much greater reliability of fastening the wind turbine blades.

The wind generator is mounted on a mast:

Trial operation of a new version of the wind generator showed its reliability even with strong gusts of wind.

The disadvantage of the Savonius turbine is low efficiency – only about 15% of the wind energy is converted into shaft rotational energy (this is much less than can be achieved with wind turbine Darya(English) Darrieus wind turbine)), using lifting force (eng. lift). This type of wind turbine was invented by the French aircraft designer Georges Darier. (Georges Jean Marie Darrieus) - 1931 U.S. Patent #1,835,018 .

The disadvantage of the Darrieus turbine is that it has very poor self-starting (the turbine must already be spinning up to generate torque from the wind).

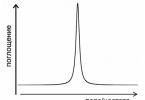

Converting the electricity generated by the stepper motor

The stepper motor leads can be connected to two Schottky bridge rectifiers to reduce the voltage drop across the diodes.

You can use popular Schottky diodes 1N5817 with a maximum reverse voltage of 20 V, 1N5819- 40 V and a maximum direct average rectified current of 1 A. I connected the outputs of the rectifiers in series in order to increase the output voltage.

You can also use two mid-point rectifiers. Such a rectifier requires half as many diodes, but at the same time, the output voltage is also reduced by half.

Then the ripple voltage is smoothed out using a capacitive filter - a 1000 uF capacitor at 25 V. To protect against increased generated voltage, a 25 V zener diode is connected in parallel with the capacitor.

my wind turbine diagram

electronic unit of my wind generator

In windy weather, the open-circuit voltage at the output of the electronic unit of the wind generator reaches 10 V, and the short-circuit current reaches 10 mA.

CONNECTING TO JOULE THIEF

Then the smoothed voltage from the capacitor can be applied to Joule Thief– low voltage DC-DC converter. I assembled such a converter based on germanium pnp- transistor GT308V ( VT) and pulse transformer MIT-4V (coil L1- conclusions 2-3, L2– conclusions 5-6):

Resistor resistance value R is selected experimentally (depending on the type of transistor) - it is advisable to use a 4.7 kΩ variable resistor and gradually reduce its resistance, achieving stable operation of the converter.

my transducer Joule Thief

CHARGE OF IONISTORS (SUPERCAPACITORS)

Ionistor (supercapacitor, eng. supercapacitor) is a hybrid of a capacitor and a chemical current source.

Ionistor - non-polar element, but one of the conclusions can be marked with an “arrow” - to indicate the polarity of the residual voltage after it has been charged at the factory.

For initial research, I used an ionistor 5R5D11F22H with a capacity of 0.22 F for a voltage of 5.5 V (diameter 11.5 mm, height 3.5 mm):

I connected it through a diode to the output Joule Thief through a germanium diode D310.

To limit the maximum charging voltage of the ionistor, you can use a zener diode or a chain of LEDs - I use a chain of two red LEDs:

To prevent the discharge of an already charged ionistor through the limit LEDs HL1 and HL2 I added another diode - VD2.

My homemade wind generator on a stepper motor, My exciting and dangerous experiments

My self-made wind generator on a stepper motor While cycling past summer cottages, I saw a working wind generator. Large blades slowly but surely rotated, weather vane

Stepper motor as a generator?

I had a stepper motor lying around and I decided to try to use it as a generator. The motor was removed from an old dot matrix printer, the inscriptions on it are as follows: EPM-142 EPM-4260 7410. The motor is unipolar, which means that this motor has 2 windings with a tap from the middle, the winding resistance was 2x6 ohm.

For the test, you need another motor to spin the stepper. The design and mounting of engines are shown in the figures below:

We smoothly start the engine so that the rubber band does not fly off. I must say that at high speeds it still flies, so I did not raise the voltage above 6 volts.

We smoothly start the engine so that the rubber band does not fly off. I must say that at high speeds it still flies, so I did not raise the voltage above 6 volts.

We connect the voltmeter and start testing, first we measure the voltage.

We connect the voltmeter and start testing, first we measure the voltage.

I think nothing needs to be explained and everything is clear from the photo below. The voltage was 16 volts, the speed of the spinning engines is not large, I think if you spin it more strongly, you can squeeze out all 20 volts.

I think nothing needs to be explained and everything is clear from the photo below. The voltage was 16 volts, the speed of the spinning engines is not large, I think if you spin it more strongly, you can squeeze out all 20 volts.

We set the voltage to a little less than 5 volts, so that the stepper motor after the bridge gives out about 12 volts.

Shines! At the same time, the voltage dropped from 12 volts to 8 and the engine began to spin up a little more slowly. The short-circuit current without the LED strip was 0.08A - let me remind you that the spin-up motor did NOT work at full power, and do not forget about the second winding of the stepper motor, you just can’t parallel them, but I didn’t want to assemble the circuit.

Shines! At the same time, the voltage dropped from 12 volts to 8 and the engine began to spin up a little more slowly. The short-circuit current without the LED strip was 0.08A - let me remind you that the spin-up motor did NOT work at full power, and do not forget about the second winding of the stepper motor, you just can’t parallel them, but I didn’t want to assemble the circuit.

I think you can make a good generator out of a stepper motor, attach it to a bicycle, or make a wind generator based on it.

I think you can make a good generator out of a stepper motor, attach it to a bicycle, or make a wind generator based on it.

Stepper motor as a generator? Meander - entertaining electronics

Stepper motor as a generator? I had a stepper motor lying around and I decided to try to use it as a generator. The engine was removed from an old dot matrix printer, the inscriptions

Riding a bicycle past summer cottages, I saw a working wind generator:

Large blades rotated slowly but surely, the weather vane oriented the device in the direction of the wind.

I wanted to implement a similar design, albeit not capable of generating enough power to provide "serious" consumers, but still working and, for example, charging batteries or powering LEDs.

Stepper motors

One of the most effective options for a small homemade wind turbine is to use stepper motor(SHD) (English) stepping (stepper, step) motor) - in such a motor, the rotation of the shaft consists of small steps. The windings of a stepper motor are combined into phases. When current is applied to one of the phases, the shaft moves one step.

These engines are low-speed and a generator with such an engine can be connected without a gearbox to a wind turbine, Stirling engine or other low-speed power source. When using a conventional (collector) DC motor as a generator, a 10-15 times higher speed would be required to achieve the same results.

A feature of the stepper is a fairly high starting torque (even without an electrical load connected to the generator), reaching 40 grams of force per centimeter.

The efficiency of the generator with stepper motor reaches 40%.

To check the performance of a stepper motor, you can connect, for example, a red LED. By rotating the motor shaft, you can observe the glow of the LED. The polarity of the LED connection does not matter, as the motor generates alternating current.

Five-inch floppy disk drives, as well as old printers and scanners, are a storehouse of such powerful enough engines.

Engine 1

For example, I have a SD from an old 5.25″ drive that was still working as part of ZX Spectrum- compatible computer "Byte".

Such a drive contains two windings, from the ends and the middle of which conclusions are drawn - in total, six wires:

first winding coil 1) - blue (English) blue) and yellow (eng. yellow);

second winding coil 2) - red (eng. red) and white (eng. white);

brown (English) brown) wires - conclusions from the midpoints of each winding (eng. center taps).

disassembled stepper motor

On the left, the rotor of the engine is visible, on which "striped" magnetic poles are visible - north and south. To the right is the stator winding, consisting of eight coils.

The resistance of half of the winding is ~ 70 ohms.

I used this motor in my original wind turbine design.

Engine 2

My less powerful stepper motor T1319635 firms Epoch Electronics Corp. from the scanner HP Scanjet 2400 It has five outputs (unipolar motor):

first winding coil 1) - orange (English) orange) and black (eng. black);

second winding coil 2) - brown (eng. brown) and yellow (eng. yellow);

red (English) red) wire - leads connected together from the midpoint of each winding (eng. center taps).

The resistance of half of the winding is 58 ohms, which is indicated on the motor housing.

Engine 3

In an improved version of the wind generator, I used a stepper motor Robotron SPA 42/100-558, produced in the GDR and designed for a voltage of 12 V:

wind turbine

There are two options for the location of the axis of the impeller (turbine) of the wind generator - horizontal and vertical.

advantage horizontal(most popular) location axis, located in the direction of the wind, is a more efficient use of wind energy, the disadvantage is the complexity of the design.

I chose vertical arrangement axes - VAWT (vertical axis wind turbine), which greatly simplifies the design and does not require orientation to the wind . This option is more suitable for roof mounting, it is much more effective in conditions of rapid and frequent changes in wind direction.

I used a type of wind turbine called a Savonius wind turbine. Savonius wind turbine). It was invented in 1922 Sigurd Johannes Savonius) from Finland.

Sigurd Johannes Savonius

The operation of the Savonius wind turbine is based on the fact that the resistance (Eng. drag) to the oncoming air flow - the wind of the concave surface of the cylinder (blade) is greater than the convex one.

Aerodynamic drag coefficients ( English drag coefficients) $C_D$

two-dimensional bodies:

concave half cylinder (1) - 2.30

convex half of the cylinder (2) - 1.20

flat square plate - 1.17

3D bodies:

concave hollow hemisphere (3) - 1.42

convex hollow hemisphere (4) - 0.38

sphere - 0.5

The indicated values are given for Reynolds numbers (eng. Reynolds numbers) in the range $10^4 - 10^6$. The Reynolds number characterizes the behavior of a body in a medium.

Body resistance to air flow $(F_D) = ((1 \over 2) (C_D) S \rho (v^2) ) $, where $\rho$ is air density, $v$ is air flow velocity, $S $ - sectional area of the body.

Such a wind turbine rotates in the same direction, regardless of the direction of the wind:

A similar principle of operation is used in a cup anemometer (eng. cup anemometer)- instrument for measuring wind speed:

Such an anemometer was invented in 1846 by the Irish astronomer John Thomas Romney Robinson ( John Thomas Romney Robinson):

Robinson believed that the cups in his four-cup anemometer moved at a speed equal to one third of the wind speed. In reality, this value ranges from two to a little more than three.

Currently, three-cup anemometers, developed by Canadian meteorologist John Patterson, are used to measure wind speed ( John Patterson) in 1926:

DC brushed motor generators with a vertical microturbine are sold at eBay for about $5:

Such a turbine contains four blades located along two perpendicular axes, with an impeller diameter of 100 mm, a blade height of 60 mm, a chord length of 30 mm, and a segment height of 11 mm. The impeller is mounted on the shaft of the DC commutator micromotor with the marking JQ24-125H670. The rated supply voltage of such a motor is 3 ... 12 V.

The energy generated by such a generator is enough to light up the "white" LED.

Savonius wind turbine rotation speed cannot exceed wind speed , but this design is characterized high torque (English) torque).

The efficiency of a wind turbine can be estimated by comparing the power generated by the wind generator with the power contained in the wind blowing around the turbine:

$P = (1\over 2) \rho S (v^3)$ , where $\rho$ is the air density (about 1.225 kg/m 3 at sea level), $S$ is the swept area of the turbine (eng. swept area), $v$ - wind speed.

My wind turbine

Option 1

Initially, the impeller of my generator used four blades in the form of segments (halves) of cylinders cut from plastic pipes:

Segment sizes -

segment length - 14 cm;

segment height - 2 cm;

segment chord length - 4 cm;

I installed the assembled structure on a fairly high (6 m 70 cm) wooden mast from a bar, attached with self-tapping screws to a metal frame:

Option 2

The disadvantage of the generator was the rather high wind speed required to spin the blades. To increase the surface area, I used blades cut from plastic bottles:

Segment sizes -

segment length - 18 cm;

segment height - 5 cm;

segment chord length - 7 cm;

the distance from the beginning of the segment to the center of the axis of rotation is 3 cm.

Option 3

The problem turned out to be the strength of the blade holders. At first I used perforated aluminum strips from a Soviet children's designer 1 mm thick. After several days of operation, strong gusts of wind led to a break in the slats (1). After this failure, I decided to cut out the blade holders from foil textolite (2) with a thickness of 1.8 mm:

The bending strength of the textolite perpendicular to the plate is 204 MPa and is comparable to the bending strength of aluminum - 275 MPa. But the modulus of elasticity of aluminum $E$ (70000 MPa) is much higher than that of textolite (10000 MPa), i.e. Texolite is much more elastic than aluminium. This, in my opinion, taking into account the greater thickness of the textolite holders, will provide much greater reliability of fastening the wind turbine blades.

The wind generator is mounted on a mast:

Trial operation of a new version of the wind generator showed its reliability even with strong gusts of wind.

The disadvantage of the Savonius turbine is low efficiency

- only about 15% of the wind energy is converted into shaft rotational energy (this is much less than can be achieved with wind turbine Darya(English) Darrieus wind turbine)), using lifting force (eng. lift). This type of wind turbine was invented by the French aircraft designer Georges Darier. (Georges Jean Marie Darrieus) - 1931 U.S. Patent #1,835,018 .

Georges Darier

The disadvantage of the Darrieus turbine is that it has very poor self-starting (the turbine must already be spinning up to generate torque from the wind).

Converting the electricity generated by the stepper motor

The stepper motor leads can be connected to two Schottky bridge rectifiers to reduce the voltage drop across the diodes.

You can use popular Schottky diodes 1N5817 with a maximum reverse voltage of 20 V, 1N5819- 40 V and a maximum direct average rectified current of 1 A. I connected the outputs of the rectifiers in series in order to increase the output voltage.

You can also use two mid-point rectifiers. Such a rectifier requires half as many diodes, but at the same time, the output voltage is also reduced by half.

Then the ripple voltage is smoothed out using a capacitive filter - a 1000 uF capacitor at 25 V. To protect against increased generated voltage, a 25 V zener diode is connected in parallel with the capacitor.

my wind turbine diagram

electronic unit of my wind generator

Wind turbine application

The voltage generated by the wind generator depends on the magnitude and constancy of the wind speed.

With the wind swaying the thin branches of trees, the voltage reaches 2 ... 3 V.

With the wind swaying the thick branches of trees, the voltage reaches 4 ... 5 V (with strong gusts - up to 7 V).

CONNECTING TO JOULE THIEF

The smoothed voltage from the wind generator capacitor can be fed to - low-voltage DC-DC converter

Resistor resistance value R is selected experimentally (depending on the type of transistor) - it is advisable to use a 4.7 kΩ variable resistor and gradually reduce its resistance, achieving stable operation of the converter.

I assembled such a converter based on germanium pnp- transistor GT308V ( VT) and pulse transformer MIT-4V (coil L1- conclusions 2-3, L2- conclusions 5-6):

CHARGE OF IONISTORS (SUPERCAPACITORS)

Ionistor (supercapacitor, eng. supercapacitor) is a hybrid of a capacitor and a chemical current source.

Ionistor - non-polar element, but one of the terminals may be marked with an "arrow" - to indicate the polarity of the residual voltage after it has been charged at the factory.

For initial research, I used an ionistor with a capacity of 0.22 F for a voltage of 5.5 V (diameter 11.5 mm, height 3.5 mm):

I connected it through a diode to the output through a germanium diode D310.

To limit the maximum charging voltage of the ionistor, you can use a zener diode or a chain of LEDs - I use a chain of two red LEDs:

To prevent the discharge of an already charged ionistor through the limit LEDs HL1 and HL2 I added another diode - VD2.

To be continued

I already wrote at the beginning of summer about a homemade windmill - an anemometer.

His goal was to organize the collection of wind statistics and the adoption of a decision on the construction of a large, serious windmill based on it. Unfortunately, there was neither a programmer willing to write a program for processing data from an anemometer, nor a specialist in microcontrollers to create an appropriate device. Therefore, alas, I had to observe the wind visually, since the weather vane was always in sight. And unfortunately, these observations are extremely depressing ...

The fact is that the wind in the middle zone of the European part of Russia has extreme turbulence in its surface layers. Literally within 3-5 minutes, the windmill repeatedly stops (or slows down a lot) and spins up so that the blades are not visible. At the same time, the direction of the wind changes in the sector up to 90-120 degrees. It is extremely rare that there are days when a relatively strong and even wind blows. For the whole summer in my area there were only 4 such days. There were several calm days. And in the rest - the wind was very turbulent, both in speed and in direction.

Under such conditions, it is completely pointless to make a “global” wind power generator (for 1-2 kW or more). Not only will it never pay for itself, but it will generally work poorly. Since a powerful generator will require large blades, and they will have great inertia and, therefore, “pass” gusts of strong wind. Those. simply will not have time to unwind. Sometimes such gusts, carrying the main power of the "average" wind flow, last only 15-30 seconds.

In addition, any rotating object has a significant moment of inertia in the plane of rotation and is, in fact, a gyroscope. I hope the reader remembers a simple school experience in demonstrating the gyroscopic effect with a bicycle wheel. Being untwisted, it is easily held with literally “two fingers” for one of the protruding ends of its axis. And it is extremely difficult to turn it sideways and make it spin in a different plane. Approximately the same thing will happen with the propeller of a windmill when the direction of the wind changes. Both the axis and the propeller blades will experience monstrous lateral alternating loads.

These circumstances actually put an end to the hopes of getting by with one large windmill. He will work, of course. But rarely and stupidly. With weak turbulent winds, it will still give out meager power, and with strong ones, you will not know what to do with the excess. And of course, you should forget about its payback. It will be just an expensive and beautiful toy, the most stupid investment of money and labor that you can imagine.

The promising designs of windmills are small low-power wind generators with almost zero inertia. It is they who are able to take from the wind almost all the energy that it carries. Such that they would have time to quickly spin up and work out the change of tack. And to obtain high power, it will be necessary to install a kind of wind farm of wind generators located on masts of different heights (so as not to shield each other from the wind). This, by the way, will significantly increase the storm resistance, solving problems with powerful heavy masts and guy lines (the masts will hold each other), with the reliability of the “power plant” - after all, all generators cannot break down at once, and scheduled repairs and maintenance will not lead to a complete stop of generating capacities .

Having come to such disappointing conclusions, I decided to convert my anemometer into a working model of a wind turbine. Those. instead of stupid contemplation of the weather vane, begin to receive practical benefits from it. Moreover, the windmill generator is a stepper motor with 200 “steps” per revolution and generates electricity quite quickly even at low speeds. Generator power approximately Watts 7-8

First of all, it was necessary to replace the blades with less inertial ones. The mugs from the fan are still quite heavy. I made new windmill blades from the remnants of duralumin reflux for plastic windows. The propeller diameter is about 50 centimeters, which promises reaching the maximum power for the generator even with a wind of 4 m / s. I cut a triangle out of thick plywood. I glued a bushing into it (with epoxy resin), the inner diameter of which coincided with the diameter of the axis of the stepper motor. Having carefully marked out, he made cuts in the plywood “cockpit” and glued the blades into the slots. Additionally fixed them with small screws. Until the epoxy hardened, I tried to balance the screw as much as possible so that it did not vibrate during rotation. After the epoxy had hardened, I checked the balance again and brought it to perfection by cutting off the thinnest strips of duralumin from the edges of the blades.

Generally speaking, undersized wind turbines have a nice property. There is practically no point in bothering with the most complex calculations of KIEV, blade profiles and their manufacture. The simplest, flat ones will work great too. And the required power can be obtained by simply lengthening them (hence, increasing the sweeping area).

All this greatly reduces the cost of the wind generator, it makes sense to manufacture and use it. In particular, I spent about 3-4 hours on mine (including the weather vane) and without taking into account the polymerization time of the epoxy resin. The costs amounted to "zero", since everything was done "from garbage", i.e. improvised materials.

It would seem, where can such a low-power generator be used? In the long run, I'm going to use it for... water heating. Rather, to compensate for the heat loss of water heated by the sun. The simplest calculation shows the absolute viability of my hopes.

Suppose there is a certain tank - a thermos, 50 liters, where in the evening water heated to 50 degrees is drained from the solar collector. The size of the tank is approximately 40 x 40 x 40 cm. Accordingly, the surface area will be equal to 1 square. meter. The tank is surrounded by thermal insulation with TO thermal conductivity of 0.15 W / m * deg and a thickness of 30 cm. and heat loss will be approximately 0.5 W / deg. Those. in order to maintain a temperature difference of 20-25 degrees between the hot water in the thermos tank and the surrounding air, a generator with a power of only 10-15 W is enough! It will compensate for heat loss and once heated water will never cool down. And if there is a strong breeze, it will also warm up.

Now my generator is spinning without load yet, undergoing “sea trials”. But in the near future I will make him charge the batteries in the lighting of the country toilet and lighting the path to it. And then dragging the network wire there is too lazy and difficult, but changing the batteries in the Chinese lantern is already tired.