Greetings to the owners of heavy domestic motorcycles Ural or Dnepr, who are not satisfied with the standard factory engine power of these bikes - this article is for you. Here we will consider how to raise the power of the strangled engines of these motorcycles on our own, but I want to warn you right away that without the familiar turner, borer, milling machine operator and thermist, it will be unrealistic to carry out our plans. Therefore, in advance, choose some kind of factory in your city or a well-equipped workshop and make an acquaintance there, since the completion of some details in a regular garage is not feasible.

In general, the domestic boxer engines of these motorcycles have a good potential for forcing, since in these motors the piston stroke has a shorter distance than the piston diameter itself (the piston stroke is 68 mm, and its diameter is 78 mm). That is, these motors can be quite resourceful (not like the Japanese, but still), but at the factory they are clearly strangled, and the quality of the engine parts, in comparison with the Japanese or European motor industry, to put it mildly, is none.

And now, in general, parts of such basement "firms" have appeared on sale that factory Soviet parts seem to be the height of perfection. So before you start tuning your engine, as I will describe in this article, first make a major overhaul (replace worn gears, shafts, etc.), but only from Soviet parts, which the local population still has plenty of in Russia and the CIS ( especially somewhere in the outback). And find Soviet pistons from 6 volt Dnieper MT-9 (or K-650), with a spherical bottom - they will come in handy for raising the compression ratio of your engine. So let's get started.

Engine head.

The head of any engine is very important, because through it the engine cylinders are filled with a combustible mixture and the exhaust gases are removed. And the more efficiently the cylinders are filled, and the more efficiently the exhaust gases are discharged, the more power of any engine.

The first thing we'll start with is fine-tuning the factory head of your opposite. First dry the head valves and remove the valves. If you have a Ural motorcycle head, then it is more strangled than the Dnieper head, since the diameter of its valves is only 35 mm in the exhaust and 38 mm in the intake. Waste the native Ural saddles and in their place press in the normal Dnieper valve saddles with a diameter of 38 and 40 mm. What fit should be when the seats are pressed in correctly (the saddles should be made of durable malleable and heat-resistant cast iron), any mechanic in a car repair shop knows, so go there. In the same place, the Ural valve saddles will be bored (removed) for you, and the enlarged Dnieper saddles will be pressed correctly.

You will now need Dnieper valves, but when buying, check the evenness of their rods (there is enough leftist), the straightness rate of which is up to 0.03 mm (you can check by rolling the valve stem over a piece of glass, and a probe thicker than 0.03 mm should not be inserted between the glass and the valve stem , and ideally even thinner). You cannot check what the valves should be made of, but it is still useful to know - an alloyed alloy of 40X9 grade inlet valve and EP303 heat-resistant steel at the exhaust valve. Soviet parts are made from these alloys.

Having bought the valve, measure their diameter with a micrometer and select new guide bushings made of cermet or bronze for them, but so that the gap between the valve stem and the bushing is no more than 0.04 mm. (by the way, when buying, immediately measure both bushings and valves). The inner diameter of the sleeve is measured with a small indicator. How to press in bushings, you can read on the example of automobiles, because the principle of pressing is the same, only the device needs to be made specifically for your head (device, and how to use it

I want to assure many opposites that 90% of all NEW heads for boxer engines are now sold overstated as much as 0.5 millimeters !!! gap between the guide sleeve and the valve stem. I will repeat once again - NEW heads, so having bought a new head, immediately dry out the valves and change the bushings, or valves with thicker rods (to get a clearance of 0.04 mm). By the way, I advise you to press in the Zhiguli factory bushings, since a special groove is made on them, on which a very useful valve oil seal is put on (see photo).

Also check all three necessary chamfers on the valve discs: at the inlet of the seat there should be a chamfer of 60 °, which will ensure the maximum filling of the cylinder at the inlet; there should be a 30 ° chamfer at the outlet of the saddle, which will give the outlet minimal resistance; and a 45 ° chamfer that will make excellent contact with the valve disc for excellent sealing performance.

The next operation will be to replace the standard springs with springs from a foreign car, for example, from Avdotya (Audi 100). This must be done, since the speed of your engine will increase after tuning, and the standard springs will not cope with the inertia of the valves and their pushers at higher speeds. And the Audi springs are stiffer and this stiffness, as well as their progressive characteristic, will not allow the valves to hang at high crankshaft speeds.

Springs from Audi, spring plate and valve refinement for Audi crackers.

1 - springs from Audi, 2 - valve crackers from Audi and grooves on the valve for them.

To implement this venture, you will need to slightly shorten the valve stems (up to 90 mm), and cut three grooves at the ends of the stems for the Audi spring locks (see photo). And the trimmed ends of the valve stems (at the point of contact with the rocker arms) will need to be hardened or cemented (which thermal you find at the factory, then do it).

When assembling, do not forget to check that the rocker arm presses exactly into the center of the valve end, because on most factory heads this centering is violated. Achieve with the help of thin adjusting washers, put on the axis of the rocker arm, so that the tip of the rocker arm presses exactly in the center of the end of the valve, this is important.

Before assembly, it is advisable to bore the inlet and outlet channels of both heads a little (about 1.2 - 2 mm) with a roller cutter, and then polish their walls to a mirror shine - this will improve the filling, the motor will breathe better and this will increase the power. Do not forget to thoroughly wash the entire head from processing products.

Well, one more head improvement. It is necessary to make and screw the fittings under the longer threads of modern ones, because all normal (for example) spark plugs have a long thread. And it's time to introduce, which are designed for as much as 200 thousand kilometers, and in our boxer engines. It is better, of course, to make two fittings, as I did on my Dnieper, in order to install two candles for each cylinder in the future. You can see it here in, and there you will also see how the easiest way is to install a homemade electronic ignition on a boxer domestic engine.

Who wants to go even further, in the endless path of tuning, then it is possible to install hydraulic valve lifters from a foreign car on (near the Dnieper the oil pressure is higher than that of the Urals, since the oil pump is more efficient). This will allow you to forget about frequent valve clearances adjustments. To implement this venture, you first need to pick up the hydraulic lifters themselves during disassembly (we twist their diameter as fashionably closer to the diameter of the standard pushers in order to remove less aluminum when boring standard holes in the crankcase), and the valve springs from the same machine.

Having measured the exact diameter of the expansion joints, it is necessary, based on this diameter, to bore the holes (in which the standard valve pushers move) in the Dnieper crankcase, so that the hydraulic lifters move in the bore holes with a clearance of 0.04 mm.

And in order for them to work (compensating for valve clearances), they need to be supplied with oil under pressure from the lubrication system of the Dnieper engine. It is easiest to bring oil to the hydraulic lifters from the standard oil pressure sensor (we connect the fitting shown in the blue photo on the left to the sensor, only it will need to be welded to the steel tube, and the clamp is not needed) and then along the steel pipes, and from the tubes to the crankcase are screwed T-shaped fittings, through which oil is already supplied directly to the hydraulic lifters in the crankcase (see photo below).

But the main thing in this alteration is to install the valve springs from the same machine as the hydraulic lifters. Since the expansion joints are heavier than the standard Dnieper pushers and the regular Dnieper springs do not have enough elastic force to cope with the inertia of heavier expansion joints (at speeds above 4 thousand), and there will be interruptions in the engine operation.

The last thing that is tedious to do here is to drill a hole in the bottom of the compensator (in all four), into which the standard duralumin rod will abut, which pushes the valve (more precisely, the steel tip of the rod).

Camshaft.

The engine, with a modified head, "breathes" even deeper and more efficiently at high revs, if the valve opening stroke is slightly increased (by 1.5 - 2 mm). And for this you need to weld metal onto the camshaft cams, increasing the profile of the cams. By the way, on the Dneprov MT-1036 model, a camshaft with a higher cam profile (than that of other models) was already installed at the factory, so it makes sense to look for this shaft. If there is a possibility (a normal plant or a workshop with good specialists), then you can order to make a new camshaft, but with a 2 mm larger cam profile, from steel 20X, followed by carburizing.

Welding should be done better with an apparatus, by slightly depositing metal on the top of the cam, and at the same time the entire camshaft should be immersed in a bath of cold water (as it heats up, add cold water). This is necessary, otherwise the shaft will lead when heated. Having welded some metal onto all 4 tops of the cam, we process them and constantly check the profile with a template made in advance from cardboard.

The profile of all four cams should be exactly the same both in height and in the shape of the "egg", and after you achieve this, the cams should be polished to a mirror finish. After polishing, it is advisable to harden the cams to a hardness of HRC 43-48 (it is better to contact a familiar thermist). By the way, you can increase the resource of the camshaft by modifying it a little, but here's how to do it, we read.

After the camshaft was refined, no matter how hard we tried, it could still be driven, and not only from welding, but most likely from hardening. This is necessary and important to check if you put the shaft in two prisms, and bring a dial-type nose to it in different places (where there are no cams). We check the shaft by scrolling it in the prisms and following the indicator arrow. And if there is a curvature, then you can fix the matter if you drip a drop of metal in the middle of the shaft with electric welding (where there is no cam) and you will immediately see that the shaft will bend slightly in the opposite direction.

So you can completely remove the curvature, constantly checking the shaft with an indicator, after each drop of welding (at the end we grind down the drop). Just practice first on some unnecessary roller or metal rod.

I want to warn you that it is pointless to carry out painstaking revision of the camshaft if you do not replace all the bearings, especially the crankshaft bearings with high-quality Japanese ones. Also, the piston and crankshaft must be new. And most importantly, what I want to say: with an increase in the profile of the cams, the motor power will increase only at high speeds, and on the contrary, at medium and low speeds, it will decrease.

Why this happens, you cannot explain in a nutshell, and I strongly advise you to read about this in more detail, after reading which you will understand that the modification of the camshaft, as described above, is not justified in most cases. After that, you will have to constantly twist the engine and work twice as often with the gearshift foot, which is not solid for a chopper - its motor must pull from the bottom. If you are building a motorcycle in the style of a cafe racer or streetfighter, then it makes sense to bother, but again, let me remind you that your engine must be brought to the ideal (start, as I said, by replacing bearings with branded ones, replacing carburetor jets with 40% increased, replacements outlet for forward flow, etc.).

Piston group.

When finalizing pistons, we will take into account two main circumstances. The first is to increase the compression ratio, and the second is to make sure that the pistons do not meet at the top with the valves, but at the bottom with the crankshaft cheeks. And as I said at the beginning, in order to raise the compression ratio, the Urals will need pistons from MT-9 with a convex bottom, which is 6 mm higher than the Ural one, and therefore it will provide an increase in the compression ratio.

1 - excess aluminum has been removed from the piston skirt, 2 - a copper tube that pours oil onto the bottom inside the piston, 3 - 12 x 12 mm sample.

But the catch is that it is impossible to rotate the Ural crankshaft with pistons from MT-9, since the crankshaft cheeks will rest against the lower edge of the piston skirt. To eliminate this, the Dnieper pistons need to be sharpened so that only 3 mm of aluminum remains on the side of the piston skirt (where the number 1 is in the photo) to the lower oil scraper ring. (see photo).

Pistons and crankshaft after such revision will cease to interfere with each other. But when the piston goes to the bottom dead center, check that there is a gap of at least 1 mm between the worn-out part of the piston skirt and the crankshaft cheek (so that as the pistons wear and shift, the parts do not meet during operation, and plus the thermal gap).

You should also cut out a window 3 (see photo) in the skirts of both pistons, 12 mm wide and 12 mm high. This is necessary so that the piston does not cling to the oil supply pipe to the bottom of the piston during operation (but more on that later). On the cylinder, you will also need to cut the same 12 by 12 mm window (see photo below).

After all seams and adjustments, ensure that both pistons have exactly the same weight in grams. Next, assemble the piston and install the heads, then, bringing the pistons to TDC, fill in engine oil through the spark plug hole to check (in turn) the compression ratio. To do this, you need to divide the larger amount of fluid that will fit in the cylinder at BDC by a smaller amount of fluid that will fit in the combustion chamber at TDC. You should get about 9.0 - 9.2. (standard motors have a compression ratio of 6.5 - 7).

When turning the crankshaft of a Ural engine with Dnieper pistons by hand, make sure that the piston does not meet the valves (this will immediately prevent you from turning the crankshaft by hand). And you should also make sure that there is a gap of at least 1 mm between the fully open valve and the piston. This can be checked by sticking plasticine or window putty, a couple of millimeters thick, on the bottom of the piston.

The valves will leave a distinct imprint in the clay. If the piston touches an open valve (or two), then a cut should be made on the piston. Such samples are made on more modern Dnieper pistons (and on a piston from a foreign car too).

By the way, you can raise the compression ratio on a Dnepr motorcycle without changing the standard piston, if you grind off the mating plane of the engine head, but how much to grind it off? It depends on the degree of compression you want to get, as well as on the thickness of the piston bottom. After all, after you grind off (butt) the head, for example, by 2 mm, for the same 2 mm you should choose a recess for the valve with a cutter, otherwise the piston and valves will touch each other and will not allow the crankshaft to rotate (do not forget about the 1 mm gap between piston bottom and open valves).

Cooling and lubrication system.

After the alterations described above, the antediluvian air cooling system (if you can call it that) should be improved. This is especially true of Ural motorcycles, the ancient cast-iron cylinders of which barely cope with the fact that the engine does not overheat, even with a standard compression ratio of 6.5. And what can we say, if we raised the compression to 9, then without modifications, overheating is ensured.

By the way, the factory engineers of KMZ long ago took into account that cast-iron cylinders are a stone age, and after the notorious lower-valve cacique (K-750), they began to install aluminum cylinders with a cast-iron sleeve, which are much more efficiently cooled, on all overhead valve motors of subsequent Dnepr models.

It is a pity that Irbit engineers riveted cast iron (cast iron cylinders) constantly overheating in the heat until the end of the 90s, until the more perfect Ural Voyage appeared, and then the Wolf, on which they finally repeated the cylinders like those of the Dnieper, making them aluminum , and fastening them with through pins (probably a few years later, enlightenment came to the minds of the engineers of the Urals).

So, what am I doing? And besides that, ideally, you need to install on more ancient Ural motorcycles, cylinders from the Wolf. But before that, they should be shortened by as much as 10 mm (and remake their fastening with through pins, as on the Dnieper), since the Wolf has a piston stroke 10 mm longer than that of the ordinary Urals. But, of course, it is better not to spoil the Volkov cylinders, but also to install a crankshaft from the Wolf, and then the engine volume will also grow to 750 cubic meters, but this is a topic for a separate article. In general, to be honest, for me the Dnipro motorcycle is much more pleasant and easier to tune than the Ural, no offense to the owners of the Urals, of course.

1 - a copper tube is screwed into the pump body, 2 - the tube outlet is sealed with a sealant.

Okay, enough philosophy; no matter what cylinders are on your opposite, you still need to do the following: first, you need to bring additional coolness to the bottoms of the pistons - the zone of the highest temperatures. To do this, to the standard Ural oil pump, through an adapter and an elongated roller, we connect another Ural oil pump, or better a more efficient Dnieper oil pump (see photo).

And connect a separate oil line to it, which is connected further through the oil cooler (in series), then bifurcates and pumps oil exactly to the bottoms of the pistons from the inside. Check that both oil supply pipes are directed exactly to the piston bottoms from the inside (bring the piston to the BDC and bend the tube, directing it to the piston bottom from the inside, but so that it does not touch the piston skirt).

An oil cooler can be found on dismantling motorcycles of foreign cars, since many Japanese road bikes are air-oil-cooled, and what our opposer is worse. The radiator can even be fitted from a Zaporozhets - even it has air = oil cooling. And in the crankcase itself, the oil volume should be increased to 3 liters, using a higher aluminum oil pan (see photo below), they are already on sale now. The additional volume of oil will have a good effect on the temperature regime of the engine, along with the radiator.

Oversized aluminum oil pan.

Power and ignition.

It remains to install electronic ignition on your opposed, as described in the article about its installation (link above in the text), as well as normal from a Japanese motorcycle, which will add power. Do not forget to just switch to a higher-octane gasoline, since your compression ratio is no longer seven, but nine! Engine revs will rise to 7,500, and new opportunities will open up for the boxer engine and the motorcycle in general. And since the revolutions have increased, then some standard bearings may not be able to cope with the revolutions. Therefore, as they wear out, I advise you to replace them with branded ones, and how to choose a bearing and recognize its markings, I advise you to read.

And of course, it does not hurt to install third and fourth gear tuning gears in the gearbox in order to reduce their gear ratios (from 1.7 to 1.55 - third gear, and from 1.3 to 1.09 - fourth gear). And also install the tenth pair of gears in the rear axle gearbox (we read how to do this correctly in). This will allow you to move at speeds over a hundred without twisting the engine.

If you do tuning the engine of a motorcycle Ural or Dnepr as described in this article, the capabilities of your bike will be much higher than the serial factory bikes, and you will get great pleasure from a sharper start and an increased top speed, and after all, the motorcycle was created for pleasure; success to all!

Which owner of a domestic motorcycle did not think about tuning the engine of the Ural motorcycle? This burning question worries many fans of domestic Ural motorcycles! The fact is that the standard Ural engine has many manufacturing inaccuracies and is technically imperfect. Depending on the model and year of production, the power of the Ural motorcycle varies from 32 to 36 horsepower, which is now considered a low indicator for an engine capacity of 650 cubic centimeters. In this article, we will look at how to increase the power of a standard outdated engine. I want to note right away that a lot of turning work will be required, find a workshop in advance that will agree to help you in this matter.

The Ural boxer engine has great potential for tuning, thanks to a piston diameter of 78mm and a stroke of 68mm. With this configuration, the engine could be revving, unfortunately the workmanship of the parts, and the purpose of the motorcycle does not allow this. In the article we will consider a solution to this problem, due to which it is possible to achieve impressive results of the operation of such an engine, namely:

- Tuning engine heads

- Camshaft tuning

- Cylinders and pistons

- Carburettors and ignition

Tuning engine heads

Through the channels of the engine heads, the cylinders are filled with a fuel mixture, and the exhaust gases are released. The more efficiently the cylinders are filled and the easier the exhaust gases are emitted, the greater the engine power. For tuning the Ural engine heads, you will need to remove the valves. The diameter of the native valves of the Urals is only 38mm inlet and 35mm in outlet, which affects the suffocation of the engine. Together with the valves, you need to press out the old valve seats and guides. The seats for the saddles should be bored to the size of the Dnieper saddles. New enlarged saddles will allow the installation of valves with a larger diameter 40mm inlet and 38mm outlet from the Dnieper. The best alternative to the Dnieper valves will be valves from Audi. The quality of car parts is an order of magnitude higher, and also thanks to fixing with breadcrumbs of a new type, it is possible to significantly increase the resource of the heads. Valve guides are recommended to use bronze from VAZ 2101-2107.

Internal serrations will improve valve stem lubrication. Valve movement is most efficient with minimal friction losses and much longer service life. Bronze perfectly removes heat from the valve, which will have a positive effect on the stability of the valve clearances.

It is important to know: when choosing valves, do not run into a fake. The exhaust valves made of heat-resistant steel must not be magnetically magnetised. Bronze guides do not magnetise either.

Note that the clearance between the guide and the valve stem is 0.04 to 0.06 mm. The valve should move freely in the bushing, without dangling in it. By the way, we want to note that the car rails have a seat for the valve stem seal. It is highly discouraged to install it, as lubrication occurs by splashing oil, and not under pressure as in cars. After installing the new valve guides, pay attention to the trimming of the valve seats. It is necessary to trim the saddle along three chamfers: 60.30 and 45 degrees, of which 45 degrees is a working one, which is in contact with the valve disc, ensuring a snug fit. You will also have to replace the standard valve springs with automobile springs from the VAZ 2108. They are somewhat stiffer than their own, and are able to ensure accurate operation of the valves at high speeds. But keep in mind that with such springs, the camshaft is subject to accelerated wear - tuning a motorcycle engine requires sacrifice. The final tuning procedure for the heads is boring the inlet and outlet channels with a roller cutter a couple of millimeters larger in diameter. At the same time, it will be possible to get rid of the sagging of the casting and provide better engine breathing. The outlet duct should be polished up to the mirror, and the inlet duct should be left matt slightly rough to prevent condensation of fuel on the walls. After tuning the heads, do not forget to blow out all channels and hard-to-reach places with compressed air, and grind new valves. Lapping must be done by hand using a two-component lapping paste. Never use a drill. A hose is put on the opposite end of the valve stem, thus turning the valve with your palms to obtain a matte band on the valve seat and plate with a thickness of 1.2-1.6 mm. Check the tightness of the valve by pouring kerasin into the channels for 1-2 minutes.

Camshaft tuning

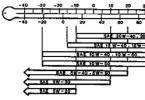

This modification requires a very deliberate approach, as a rule, a new form of cams is created empirically and may not meet your expectations. A wide-phase camshaft will help to fully realize the capabilities of the tuned cylinder heads. For moderate tuning, you can simply put it from the Ural model M 67-36. The photo below shows a wide-phase shaft on the left, a normal one on the right.

If you want to get the maximum out of the engine, then it is possible to increase the profile of the cams of the standard shaft. This can be done by welding the metal with argon welding. By increasing the width and height of the cams by a couple of millimeters, it is possible to achieve a shift in torque to the high rpm region and increase power also by increasing the rpm from the valve timing. Consider the fact that such an engine will lose traction at low revs and may even stall at idle. For this modification, we recommend finding a workshop or factory where the correct processing of the cam profile with subsequent carburizing is possible. Then, it is important to make sure that the geometry of the shaft is even, there is a high probability that the shaft could be driven from a sharp temperature drop, the curvature is checked with a dial indicator by an experienced turner.

Cylinders and pistons

One of the most important parts of an engine is the pistons. They take on an enormous load from the expanding gases and the temperature. Standard low-quality pistons do not withstand loads well, often have different weights, and piston rings cannot provide high compression due to an outdated design, this significantly affects power, as well as the massiveness and number of rings heavily weight the piston, which prevents the motor from spinning. It is recommended to install forged pistons with imported rings. A good solution would be to install forged pistons from the Ural Wolf motorcycle, they have a convex surface that will allow you to raise the compression ratio and significantly increase the engine power.

As for the cylinders, it is preferable to replace them with aluminum ones with a cast iron sleeve. The thermal conductivity of aluminum is much higher, and efficient heat dissipation is ensured. Re-cylindering is a significant improvement on cylinders. The standard inner diameter of the cylinder liner is 78 mm, and if the volume of the standard engine of 650 cubic meters does not suit you, by replacing the native cylinder liners with Moskvich 412 liners with an inner diameter of 82 mm, it will be possible to significantly increase the volume and, accordingly, power. Accordingly, select the pistons for the new diameter.

To combat overheating, a cooling system will be useful in the form of installing an oil cooler and by forcibly spraying oil on the bottoms of the pistons. An additional oil pump is needed to connect the oil cooler, as one standard is very weak. To run the oil through the radiator, it is advisable to install an oil pump from the Dnepr motorcycle. Drive the second pump through an adapter from the standard Ural pump. In order for the additional pump to fit in the crankcase, an enlarged sump is needed, which will also have a positive effect on cooling. By slightly increasing the amount of oil in the system, it will be possible to distribute the heat load, and the new aluminum sump removes heat even better.

By connecting to the new oil pump an oil line from a copper or steel capillary tube, which must first pass into the radiator, then the cooled oil from it must get to the inside of the pistons. To do this, the line from the radiator goes back into the crankcase, bifurcates in such a way that the oil supply is directed to the piston crown from the inside. An oil cooler can be purchased at the dismantling of Japanese motorcycles, as well as an automatic transmission radiator of the size you need from any car is perfect.

Carburettors and ignition

Ural motorcycle engine tuning affects all engine systems, including ignition and carburetors. It is recommended to read the information: how is it going right. The standard ignition is so outdated that it is not even suitable for everyday driving, let alone a larger one. It is desirable to install a microprocessor ignition with the possibility of an automatic advance angle. this article will help you. Ideally, there will be an installation of such an ignition with a programmable controller with the ability to adjust the firmware. In such ignition systems, there is another useful feature - a cut-off in terms of revolutions. It will allow you not to twist a heavily boosted engine. Well, for maximum spark force in conjunction with a new ignition, you can use a coil from an Oka or Gazelle. Branded high-voltage wires with silicone insulation and internal resistance are required, for example, from Tesla from Vaz 2108. They will provide an uninterrupted spark in any weather and exclude the possibility of a spark breakdown to ground. As for the carburetors, then it will be necessary to install Japanese vacuum carburetors with a diffuser diameter from 32 to 36 mm, followed by the selection of jets, synchronization and tuning with a gas analyzer. A dyno tuning is highly desirable, where you can check different settings and ignition timing and get the most out of your motorcycle tuning!

Additional engine modifications

In addition to the above methods, Ural has a few more secrets. On the Ural engine, it is possible to install a crankshaft from K 750, which will increase the cylinder stroke up to 78mm.

Thus, it is possible to significantly increase the working volume of the Ural engine. Finding it is difficult enough, but worth it. Another motorcycle problem is tight throttle response and slow revs. This is due to the too heavy flywheel, the weight of which is designed for driving with a sidecar and for carrying heavy loads.

According to the drawing, it is possible to reduce its weight by a couple of kilograms. By reducing the weight, the inertia of the crankshaft will decrease, and the acceleration dynamics will noticeably increase. To fully realize the power on the road, the gears of the reducer must be replaced with 9 or 10 pairs. In conclusion, we want to note that tuning the engine of the Ural motorcycle justifies itself only for racing purposes, for everyday use such a motor will have a small resource and significant fuel consumption.

A classic motorcycle is a two- or three-wheeled vehicle (sidecar) with a mechanical engine, the distinctive features of which are gearless front wheel control, an upright riding position and the presence of footpegs. A typical representative of this class is the family of heavy motorcycles "Ural", the serial production of which, until recently, was carried out at the Irbit motorcycle plant (Sverdlovsk region). At the same time, the motorcycle engine is a two-cylinder boxer power unit with a cylinder volume of 650 to 750 cc. The engines of the Ural motorcycle have great power, which allows you to confidently overcome the off-road characteristic of the Russian "outback".

In addition, these power units are resistant to harsh climatic conditions - they can be easily started even in 30-degree frost. At one time, this made the Ural motorcycle, equipped with a sidecar, a worthy and relatively inexpensive alternative to a car, for example, in agriculture and / or when transporting small loads.

Currently, heavy Ural motorcycles with a sidecar are popular mainly with collectors who are willing to pay decent money for them. For example, "Ural" of the first years of production with a sidecar in the basic configuration costs about 12 thousand euros.

Specifications

The engine of the Ural motorcycle was constantly modernized during the production process and its last modification (2015) has the technical characteristics of the modern level.| INDEX | MEANING |

|---|---|

| engine's type | 4-stroke, OHV, opposed, two-cylinder |

| Engine displacement, cc | 745 |

| Number of cylinders | 2 |

| Number of valves per cylinder | 2 |

| Maximum power (at 5600 rpm), hp with. | 40 |

| Maximum torque (at 4000 rpm), N * m | 52 |

| Cylinder diameter, mm | 78 |

| Piston stroke, mm | 78 |

| Compression ratio | 8.6 |

| Grease type | SAE 15W / 40 |

| Lubrication system | Combined (under pressure + spray) |

| Carburetor | К-37А, К-52, KEIHIN 32 CVK, L22A |

| Number of carburetors | 2 |

| Air filter element | JR 120047 (FM Filter A177) |

| Engine oil volume, l | 2 |

| Fuel supply system | injector |

| Average fuel consumption, l / 100 km | 6.5 |

| Fuel | Unleaded gasoline А-92 |

| Crankcase gas recirculation system | Closed type with internal breather |

Engine description

The engine of the Ural motorcycle is an air-cooled two-cylinder four-stroke power unit. It is equipped with an electronic fuel injection system (injector) developed by the engineering company ElectroJet Inc. The main power element of the motor housing is the crankcase. Structurally, it consists of:➤ the actual crankcase; ➤ junction box covers; ➤ front and rear bearing housings; ➤ pallet; ➤ front cover. The crankcase is cast from a high-strength aluminum alloy. Pistons and a junction box cover are also made from it. The cylinders, which are installed in the crankcase, are cast from special cast iron, which has increased strength. Their inner surfaces are honed before installation, bringing the surface cleanliness to almost a "mirror state". The materials from which the pistons and cylinders are made during operation form a good antifriction pair that is not subject to severe wear. In addition to the parts of the cylinder-piston group, a crank mechanism, a gas distribution mechanism, etc. are installed inside the crankcase and on its outer walls. In this case: ➤ the camshaft is installed in the upper part of the crankcase on bearing supports, and the pushers are located on its two sides; ➤ the cover of the junction box is attached to the front wall; ➤ the oil filler neck with a plug equipped with a dipstick is located on the left wall; ➤ the crankshaft is mounted on main bearings installed in the walls; ➤ the bottom of the crankcase is closed with a special steel pan, which is used as a reservoir with engine oil. The assembled engine is mounted on the motorcycle frame and attached to it with two studs.

Maintenance

Like any vehicle, motorcycle engines need regular maintenance. The procedures related to routine maintenance are recommended to be carried out after 2 thousand kilometers. The list of works that must be carried out during the maintenance of K-750 motors includes: Checking and, if necessary, adjusting the valve clearances of the gas distribution mechanism. Change engine oil and oil filter. Monitoring the condition of the spark plugs. A certain number of motorcycles with engines equipped with carburetors K-37A, K-52, etc. are still in operation. If the motorcycle engine has one of these carburetors, then during maintenance it must also be checked and, if necessary, adjusted.Malfunctions

One of the features of the power units of Ural motorcycles is the relatively frequent occurrence of minor malfunctions, which must be eliminated rather quickly. Delaying the repair can lead, and as a rule, leads to more serious breakdowns and a significant increase in the cost of work to eliminate them. The main malfunctions and the reasons for their occurrence are summarized in the table.| FAILURE | REASON OF APPEARANCE |

|---|---|

| The motor does not start. | 1. Clogged fuel supply system. |

| 2. Failed spark plugs (carbon deposits, etc.). | |

| 3. Insufficient compression in the cylinders (valve clearances, rings, etc.). | |

| The power unit is intermittent. | 1. Uneven fuel supply. |

| 2. Water in the engine or fuel. | |

| 3. Plugged injector nozzles or nozzles. | |

| 4. Defective spark plugs. | |

| 5. The integrity of the wiring is broken. | |

| 6. Excessively enriched fuel-air mixture. | |

| Extraneous knocking in the engine. | 1. Exposed early ignition. |

| 2. Overheating of the motor. | |

| 3. Problems with pistons and rings (loose fit, etc.). |

Tuning

The boxer two-cylinder engine of the Ural motorcycle has great potential for technical tuning. However, this process is recommended to be carried out only on a new or well-repaired engine. In addition, its completion must be trusted only by highly qualified specialists who have experience in carrying out such work. This is due to the fact that the process of increasing power affects almost all engine components. So, it is necessary to subject the following to completion: cylinder heads; camshaft; pistons and cylinders; fuel supply system; ignition system; crankshaft and flywheel. Having completed the entire volume of work, it is possible to achieve a significant increase in engine power, however, it should be noted that this significantly increases fuel consumption and decreases motor resource. Therefore, such tuning is recommended only if the motorcycle is intended for participation in sports competitions. It is impractical to use it for another purpose. At one time, the brainchild of the Irbit plant was in great demand. An excellent assistant in agriculture and serving as an excellent alternative to the car, the Ural was able to move on any road surface. At the moment, the plant has stopped producing motorcycles. This happened due to a banal economic downturn. In recent decades, the assembly of the Ural motorcycle engine has become an analogue of the German BMW-R71, as well as the stubborn rival of the Dnieper. The engine of the Ural motorcycle, the technical characteristics of which may well compete with the new generation motorcycles, is subject to severe wear and tear. Therefore, owners often have to independently sort out all the parts and replace them. The Soviet bike is considered a heavy motorcycle designed for rural work and transportation of goods. At the same time, it has relatively small, but sufficient indicators. The engine of the Ural motorcycle on the Solo model produces 40 horsepower. And when forcing, you can achieve 55 hp. The maximum speed of the bike is 110 km / h. For such power, this is a rather modest figure, because the weight of the motorcycle greatly affects the speed. However, the acceleration is fast and the dynamics of the bike are very pleasant for the rider. The engine capacity of the Ural motorcycle is 745 cm3, which makes it one of the largest in Russian production.

2018 motorcycle changes

Ural motorcycle models of 2018 have undergone tremendous changes, the power unit has undergone a particularly strong modernization.

URAL motorcycle engine disassembly video

Ural-4320 is a dual-purpose off-road truck with a 6 × 6 wheel arrangement, manufactured at the Ural Automobile Plant in Miass (Russia), including for use in the armed forces in the family of unified army vehicles "Susha" until 1998. Thanks to good unification, most truck parts have been borrowed from previous models.

Ural-4320 has been designed to transport goods, people and trailers on all types of roads. It has significant advantages over similar vehicles: it easily overcomes swampy areas, fords up to 1.5 m, ditches up to 2 m, ditches, rises up to 60 ‰. For 1986, more than a million trucks were produced. Today the Ural is produced with a diesel 230/300 hp engine (Euro-2).

History

Production began in 1977 and is still in production today.

The main difference from the Ural-375D line is the presence of a diesel engine.

Initially, the Ural-4320 was equipped with a KamAZ-740 engine, but as a result of a fire at the KamAZ engine plant in 1993, deliveries of this engine stopped, and the YaMZ-236 and YaMZ-238 engines of the Yaroslavl Motor Plant began to be used. Initially, the modifications with the YaMZ-238 engine differed in their outwardly longer engine compartment, and the cars with the YaMZ-236 engine retained the same engine compartment as the cars with the KAMAZ-740 engine (the difference is that the cars with the YaMZ-236 have an air filter on the right wing). Since the mid-2000s, all cars, regardless of engine model, have been produced with an extended engine compartment.

Since the mid-1990s, a wide bumper with headlights has appeared on the Ural-4320 and Ural-5557, and plastic plugs have appeared in the wings, at the old headlight attachment points. However, exclusively for the needs of the Ministry of Defense, by special order, cars with a narrow bumper and headlights in the wings are still supplied.

Since 2009, a new cab with fiberglass front empennage has been installed on cars of the series.

Modifications

Ural-4320 - **** - **- chassis with a standard ("classic") metal cab, carrying capacity of about 7-9 tons;

Ural-4320-19 ** - **- long wheelbase chassis, carrying capacity of about 12 tons;

Ural-43203 - **** - **- chassis with reinforced front suspension;

Ural-43204 - **** - **- chassis of a pipe-rail tractor, increased carrying capacity;

Ural-44202 - **** - **- a truck tractor for operation with a semitrailer on all types of roads;

Ural-5557/55571 - **** - **- chassis for mounting technological equipment and special installations weighing ~ 12-14 tons with low-profile wide tires with adjustable wheel inflation, which significantly increases the vehicle's cross-country ability;

Ural-43206 - **** - **- chassis with a wheel arrangement 4 × 4;

Cab and empennage options:

Ural-4320 * / 5557 * - **** - 40/41- all-metal, three-seater, two-door cab, also under the index cars with a double four-door cab are produced;

Ural-4320 * / 5557 * - **** - 44- all-metal, three-seater, two-door cabin with a sleeping bag;

Ural-4320 * / 5557 * - **** - 48/58/59- a version with a new, more voluminous, comfortable bonnet-type cab, plastic plumage, a sprung driver's seat;

Technical characteristics of Ural-4320:

| Years of production | 1977 - present |

| Assembly | OJSC "Automobile plant" Ural " |

| Class | off-road truck |

| Design | |

| Body type (s) | airborne |

| Layout | front-engine, all-wheel drive |

| Wheel formula | 6x6 |

| Engines | KamAZ-740, YaMZ-236NE2 or YaMZ-238 |

| Transmission | mechanical 5-speed |

| The transfer case is two-stage. | |

| Gear ratios | 1st gear - 2.05; 2nd gear - 1.30 (since 2002 the gear ratio of 2nd gear is 1.21). |

| The main gear of the driving axles is double, the gear ratio is 7.32. | |

| Mass-dimensional | |

| Length | 7366 mm |

| Width | 2500 mm |

| Height | 2715 (with awning 3005) mm |

| Clearance | 400 mm |

| Wheelbase | 3525 + 1400 mm |

| Back track | 2000 mm |

| Front track | 2000 mm |

| Dynamic | |

| Max. speed | 85 km / h |

| On the market | |

| Predecessor | Ural-375D |

| Similar Models | ZIL-131, KrAZ-255B |

| Other | |

| Fuel consumption | 27 l / 100 km at 40 km / h |

| Volume of the tank | 300 + 60 l |

It has become popular, at the same time expensive, to have a high-quality and powerful motorcycle from well-known world suppliers. But also our bike is a motorcycle Ural not far from foreign motorcycles, if you look at the prices, you will go crazy, the price is the same as that of a car. Therefore, on the domestic market, the new Urals are little bought, although they are supplied for the Armed Forces of the Russian Federation and other power structures, but abroad they enjoy a small, but definite demand. Most of the older motorcycle models available to the population, produced in the last century, the prices at that time were affordable. Speaking about the Ural motorcycle, the first thing that comes to mind is what is its engine IMZ-8.103-10 (IMZ-8.103-30, M-67-36), are there limitations and weak spots after all, it is the qualities and characteristics engine are at the heart of the characteristics motorcycle Ural.

|

Specifications engines of motorcycle modifications Ural |

M62 |

M63 |

M66 |

M67 |

M67-36 |

IMZ-8-103 |

|

Type of engine |

4-stroke, carburetor, 2-cylinder, opposed, air-cooled, combined lubrication system |

|||||

|

Wed gasoline consumption per 100 km, l |

||||||

|

Working volume, cm 3 |

||||||

|

Cylinder diameter, mm |

||||||

|

Piston stroke, mm |

||||||

|

Compression ratio of the combustible mixture |

||||||

|

Max. power, l. with |

||||||

|

Max. power, kWt |

||||||

|

Rotation frequency crankshaft at max. power, rpm. |

||||||

|

Max. torque, Nm |

||||||

|

Carburetor brand (2 pcs.) |

||||||

|

Air cleaner type |

Combined inertial contact-oil filter with two-stage cleaning |

|||||

|

Characteristics of transmissions of modifications of motorcycles Ural |

M62 |

M63 |

M66 |

M67 |

M67-36 |

IMZ-8-103 |

|

Clutch type |

Dry 2-disc, driven discs with linings on both sides |

|||||

|

Cardan transmission type |

With cardan shaft and flexible coupling and needle bearing hinge |

|||||

|

Final drive type |

With 2 helical bevel gears, gear ratio -4.62 |

|||||

|

Transmission type |

4-speed, has gear ratios for I, II, III, IV gears 3.6; 2.28; 1.7; 1.3 respectively |

|||||

|

Refueling volumes of gasoline and oils for Ural motorcycle modifications, liters |

M62 |

M63 |

M66 |

M67 |

M67-36 |

IMZ-8-103 |

|

In the fuel tank, (gasoline A-80) |

||||||

|

In the crankcase |

||||||

|

In the gearbox housing |

||||||

|

In the final drive housing |

||||||

|

In the air cleaner |

||||||

Weaknesses of the engine IMZ-8.103-10 (IMZ-8.103-30, M-67-36) of the Ural motorcycle

- Kick starter (kickstarter);

- Throttle and clutch cables;

- Generator;

- Carburetors;

- Cylinder heads;

- Reverse gear (gearbox).

More details about the weak points of the motor ...

Kickstarter (kickstarter)

The foot starter of the IMZ-8.103-10 engine is a weak point due to slipping of the dog. The malfunction is eliminated after dismantling the gearbox and disassembling it, moving the pawl to the other side or replacing it. I have an assumption that the metal of the dog is of underestimated hardness. On the other hand, if the dog is made harder, then the gear will fail. You need to choose the middle ground.

Throttle and clutch cables

Clutch control cables and fuel supply cables are weak points due to their short lifespan. To put it simply, they are torn, and before that they are stretched, which makes it necessary to adjust the timing of the fuel mixture supply, as well as the clutch.

The generator "does not run" for a long time.

Gasoline gets into the floats, after which it fills the cylinder with gasoline. In addition, the carburetors are not matched to these engines, half of the fuel is blown to the wind, which is not economical. It would be nice to have one carburetor on the engine instead of two.

Cylinder heads

You can not overtighten the candles on the heads, the threads break off quite easily. It is impossible to overheat the engine, the result will be clearly visible on the heads, the pins are pulled out, the landing plane of the heads leads. If it was not possible to avoid breaking the thread under the spark plug, contact a familiar turner, he will be happy to repair it for a modest fee and install a steel threaded bushing. I can recommend the same for worn valve seats and chamfers. It is much cheaper to repair the heads than to buy new ones; a good turner can do it, just spit.

Reverse gear (transmission)

Reverse gear does not work for a long time due to rapid wear of the reverse gear in the gearbox.

Disadvantages of the IMZ-8.103-10 (IMZ-8.103-30, M-67-36) engine of the Ural motorcycle

- Small resource;

- Difficulty starting or does not start at all;

- In hot weather, it gets very hot in lower gears;

- Interruptions in the work of the cylinders;

- Knocks;

- High fuel consumption;

- There is a sufficient number of cases of inaccuracy in the manufacture of the engine crankcase at the points of attachment of the cylinders;

- Oil leaks at the joints.

More details about the disadvantages ...

Small resource

Unlike engines of analog imported motorcycles, the service life of the IMZ-8.103-10 engine before repair is small from 20 to 45 thousand km, which is explained by the increased wear of parts of the crank and piston group. Increased wear is a consequence of insufficient air cooling, as well as from poor quality parts (material, manufacturing precision).

Difficulty starting or won't start at all

For the most part, starting the IMZ-8.103-10 engine is difficult when the ignition, fuel supply and gaps in the valves of the gas distribution mechanism (between the rods and rocker arms) are not adjusted. The reason may be low compression in the cylinders, the carburetor jets are clogged, water in the carburetors, the candles do not work, the condenser is out of order, the lean fuel mixture coming from the carburetors (a lot of fuel).

In hot weather, it gets very hot in lower gears

Unfortunately, air cooling has a detrimental effect on the engine when operating in hot weather. Therefore, in the heat, when driving in lower gears, overheating must not be allowed, therefore it is necessary to stop more often to cool the engine. If the engine is new, it can easily overheat.

Interruptions in the work of cylinders

To a greater extent, interruptions in the operation of the cylinders are caused by the lack of synchronous operation of the cylinders due to the different amount of the supplied combustible mixture, but by a violation in the adjustment of the valves.

Engine knocking can be caused by: earlier ignition; overheat; wear of pistons, rings, fingers; wear of the main rolling bearings of the crankshaft; valve adjustment is broken.

High fuel consumption

Carburettors are simple and uneconomical, the consumption even according to the instruction manual, like that of the Zhiguli, but in fact it is even higher. In the days of the USSR, they did not think about efficiency, and the drivers poured gasoline into the ground, there was nowhere to put it. Such fuel costs are too high for a motorcycle these days.

There is a sufficient number of cases of inaccuracies in the manufacture of the engine crankcase at the points of attachment of the cylinders

This leads to overheating of the cylinder due to the difference in dimensions until the upper plane of the pistons coincides at the top dead center with the upper edge of the cylinders. In the event that one of the cylinders overheats and nothing is treated, as an option, it is necessary to check whether the piston at its top point reaches the upper plane of the cylinder, if not, then this is the problem. To eliminate overheating, it is necessary to bring the symmetry of the dimensions, for which, gaskets are removed from under one of the cylinders, and a heat-resistant sealant is used in its place when installing the cylinder. Installation of a thin gasket is possible.

Oil leaks at the joints

This disease does not affect the operation of the engine, the leaks are small. But the engine, which is greasy with dust adhered to the oil, has to be washed. Tightening the head covers, oil pan does not help. After replacing the seals after a while, the oil starts to leak again. It also leaks through the valve rod guide bushings.

In conclusion, probably many thought that the IMZ-8.103-10 engine was just a bucket of bolts ... Well, what can we do, we are used to digging in motorcycles since childhood, or rather to repair them. Therefore, many people miss the do-it-yourself engine bulkhead. This is a joke, of course, but there is some truth in every joke. In general, if you properly monitor the engine, carry out maintenance in a timely manner, then of course you can take it. With high consumption, the problem is solved by installing one carburetor from the car. The engine is very simple and very easy to repair. The engine, like the Ural motorcycle itself, is well suited for tuning.