Instructions for the operation of automatic control equipment KTSM-01, KTSM-01D, KTSM-02 on the Oktyabrskaya railway.

(approved by order No. 426 / N of 08/05/2011.).

2.1. This instruction establishes the basic provisions for the placement, operation of the KTSM-01, KTSM-01D, KTSM-02 devices, taking into account the specific working conditions on the Oktyabrskaya railway.

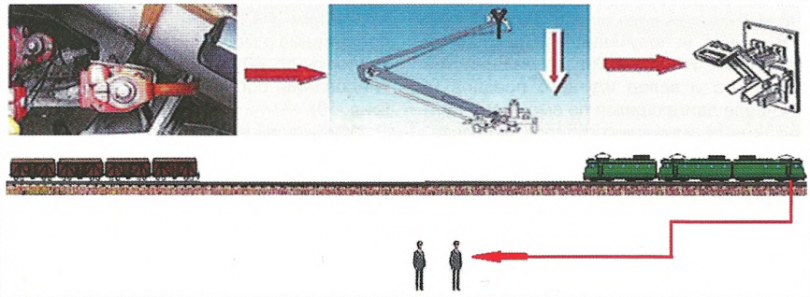

2.2. Control means KTSM-01, KTSM-01D, KTSM-02 are designed for automatic non-contact detection of overheated axle boxes of faulty cars, locomotives.

2.3. The means of control of the CTCM are additional funds, ensuring the safety of train traffic, installed on the approaches to stations and artificial structures.

2.8. In order to exclude accidental activation of the sensors of the UKSPS devices, which supplement the means of control, all employees of the railway transport who inspect the rolling stock before leaving for the flight are required to inspect the conformity of the lower gauge of the rolling stock, avoiding the presence of foreign objects, wire, ice, snow and other objects, going out or threatening to go beyond the lower clearance.

2.11. The principle of operation of the KTSM equipment is based on the perception by sensitive elements of outdoor equipment of infrared radiation pulses from the walls of axle boxes and bogie frame elements of a moving train, followed by the conversion of these pulses into electrical signals, comparing the signals according to a given algorithm and issuing information about the presence and location of overheated axle boxes in the train. Signal light indicators on the road are not used

General order actions of employees when triggered

CTSM Instruments

5.1. When the indications of the KTSM equipment with the “Alarm0” level, the train does not stop. At the station where the train has a stop provided for by the schedule, the wagons for which there were indications are examined by the employee wagon economy. Locomotives, SSPS and wagons of the motor-carriage train are inspected by the locomotive brigade.

5.2. When the KTSM equipment reads with the “Alarm1” level (except for the heating of the pulley), the train stops at the nearest station to inspect the heated rolling unit. When the indications of the KTSM equipment with the “Alarm1” level for heating the passenger car pulley, the train should

5.2.1. In case of indications of KTSM with the “Alarm1” level, the driver reduces the speed to 20 km/h with the minimum braking stage and arrives at the station to inspect the moving unit. If between the ordinate on which the CTSM equipment is installed and the station

there are especially large and critical artificial structures or the distance from the KTSM equipment to the station's entrance traffic light is more than 10 km for freight trains and more than 5 km for other trains, the train stops at the stage or at the place established by the local operating instructions for the station control device. The list of sections where, when the KTSM equipment is indicated with the “Alarm1” level, a stop is required on the stage, is established by order of the head of the regional department of the October Directorate of Infrastructure. The order of train stops on these sections is established in the local instructions for the operation of the station control device. If the train stopped on the haul by the “Alarm1” signal has not detected a malfunction or has been eliminated, then the train can move on with set speed, re-inspection at the station is not required.

5.2.2. After the train stops, the heated wagon is inspected by a wagon farm worker, and at stations where there are no wagon farm workers, locomotive brigade(on a passenger train, except for suburban trains, consisting of passenger cars on locomotive traction, the cars are inspected by the head of the passenger train). If a heated wagon was inspected at an intermediate station by a locomotive crew (head of a passenger train), then upon arrival at the station where the train has a scheduled stop, this wagon must be inspected by an employee of the wagon economy.

5.3. When the indications of the KTSM equipment with the “Alarm2” level, an immediate stop of the train by service braking is required. At the same time, the departure of trains to the neighboring track of the haul of trains of the opposite direction (as well as the passing direction on three-track sections of the track) is stopped, until the situation is clarified according to the report of the train driver, who was stopped by the operation of the KTSM equipment:

5.3.1. After the train stops on the stage, the moving unit with indications of "Alarm2" is inspected by the locomotive crew (the car in the passenger train is inspected by the head of the train). The employee who inspected the mobile unit makes a decision on the procedure

further movement of the train or troubleshooting on the haul (station) or the need to call a wagon worker to fix the problem;

5.3.2. After inspection on the stretch, the following order of further train movement is established:

5.3.2.1. If the indications of the KTSM equipment with the “Alarm2” level were on a wagon in a freight train and after inspecting the train on the haul, the malfunction was not detected, or it was detected and eliminated in another wagon, then, in agreement with the DSC, the freight train follows at a set speed

5.3.2.2. If the readings of the KTSM equipment with the “Alarm2” level were on a wagon in a freight train and after inspecting the train on the haul, a malfunction was detected and eliminated exactly in the car on which the KTSM equipment worked, and also if the readings of the KTSM equipment with the “Alarm2” level were at a locomotive, SSRS or a wagon in a passenger or multiple unit train and after the inspection of the train on the haul, the malfunction was not detected or when the malfunction was promptly eliminated, a second stop at the station for inspection is not required. By agreement with the DSC, the train must continue further at the same speed to the first turnout of the station set, at the first turnout no more than 20 km / h and then, after passing the moving unit, fixed by the equipment of the KTSM, the turnout, the speed set. The station duty officer (train dispatcher) organizes (if possible) an additional inspection of the train “on the move” by the PTO workers. In case of repeated indications for the same rolling unit, after inspection on the haul, the train is taken to the station for a thorough inspection;

5.3.3. If the "Alarm2" signal was caused by the heating of the axle box freight wagon, in which the equipment of one of the previous stations recorded heating with the signal level “Alarm1” or “Alarm2” at the same axle box, the DSP (DNTs) must ensure the uncoupling of the car from the train (due to the mandatory uncoupling of the freight car from the train of need in such cases there is no inspector from another station in the call). The decision on the possibility of further movement of a passenger car as part of a train with the indication "Alarm2" and in the presence of the indication "Alarm1" or "Alarm2" by one of the previous control devices is made by the head of the passenger train.

The procedure for locomotive and train crews upon operation of the KTSM equipment

9.1. Order d actions in case of "Alarm0" signal.

The train driver, upon receiving a message about the indications of heating of the axle boxes and other parts of the rolling stock with the signal level "Alarm0", is obliged to:

9.1.1. Repeat the DSC (DSP) message about the heating readings in the composition with the “Alarm0” level and ensure that the train continues to run (without stopping at the station or on the stretch) at the set speed;

9.1.2. Transfer data via train radio communication to the head of the passenger train to establish control over the car shown by the equipment;

9.1.3. Upon receipt of information about the operation of the KTSM equipment with indications for a locomotive or SSRS at the nearest train stop of 10 minutes or more, inspect the moving unit, depending on the indications of the equipment. In case of indications for a wagon of a multi-unit train, the inspection should be carried out at the final destination of the train.

9.2. Order d actions in the event of an "Alarm1" signal.

The train driver, upon receiving a message about the indications of heating of the axle boxes and other parts of the rolling stock with the level of the “Alarm1” signal, is obliged to:

9.2.1. Upon receipt of information about the operation of the KTSM equipment with the “Alarm1” level for heating the pulley, transmit data via train radio communication to the head of the passenger train to establish control over the car shown by the equipment. The train stop is not required;

9.2.2. If there are indications of axle box heating or wheel set inhibition, repeat the message of the DNC (DSP, voice informant) about the indications of the KTSM equipment with the “Alarm1” level, if necessary, clarify the reason for the indication (axle box heating or wheel set inhibition). Reduce the speed to 20 km/h with the minimum braking step. Proceed to the station or stop on the stage in accordance with the instructions of the DSC (DSP). The way the train stops at the station according to local conditions is specified by the local instruction;

9.2.3. Ensure the train stops at the station with the exclusion of the passage of the exit signal;

9.2.4. In the absence of a wagon inspector at the station, ensure that the faulty units of rolling stock in the train shown by the control equipment are inspected (for passenger trains - jointly with the head of the train or with the employee acting as the head of the train) and decide on the possibility and procedure for the further movement of the wagon (locomotive). Inspection of the wagon should be carried out depending on the reason for the operation of the KTSM equipment, i.e. if the KTSM has worked to heat the axle box, then it is necessary to inspect the axle box of the specified car, if it is due to the inhibition of wheel sets - to inspect the condition brake equipment wagon. If a malfunction is detected, the driver (head of the passenger train) eliminates the malfunction, if possible. If a malfunction is not detected, it is necessary to examine two adjacent mobile units on both sides of the mobile unit with indications. If there are no faults in the inspected five moving units and if there is information about a failure in the axle count, all cars from the indicated side of the train are inspected. If after that the malfunction is not detected, then in agreement with

9.2.4.1. If there is an assistant driver, the inspection of the rolling unit* in as part of a cargo, passenger-and-freight, suburban (including consisting of passenger cars on a locomotive traction), utility trains are carried out by an assistant driver or the train driver personally. Inspection of a wagon as part of a passenger train is carried out by an assistant driver (driver) together with the head of the train, in the absence of the head of the train - with the conductor of the last wagon or with the senior conductor of the mail and baggage train. If a malfunction is detected, the driver (the head of the passenger train or an employee performing his duties) eliminates the malfunction, if possible.

9.2.4.2. In the absence of an assistant, the driver, after stopping the train, can leave the locomotive (MVPS) only after bringing it to a non-working state, fixing it in the prescribed manner from spontaneous leaving, and locking the driver's cab. Next, the driver inspects the rolling unit as part of a freight, cargo-passenger, suburban (including consisting of passenger cars on a locomotive traction), utility train in the manner specified in clause 8.2.5.1. except for passenger trains for which the following procedure is established:

9.2.4.2.1. The train driver transmits information about the operation of the KTSM equipment received from the DSP (DNC) to the head of the passenger train via radio communication or the conductor of the head car.

9.2.4.2.2. The head of the passenger train, having received information from the driver, organizes an inspection of the axle boxes or brake equipment of the cars fixed by the KTSM equipment, as well as an inspection of the head cars adjacent to the locomotive in case of indications for the locomotive,

if no faults were found during inspection of the locomotive.

9.2.4.2.3. The driver inspects the locomotive with indications for the locomotive, as well as with indications for the car, if the locomotive is one of two adjacent moving units from the car fixed by the KTSM equipment and no malfunctions were detected during the inspection of the car by the train crew.

9.2.4.2.4. If a malfunction of the car is detected, the head of the train and the train electrician eliminate it (the malfunction of the locomotive is eliminated by the train driver), which is reported to the driver, who, in turn, reports on the results of the inspection of the measures taken by the head of the train, indicating his name, reports the DSP (DNTs) and reports on the possibility further

train tracks.

9.2.4.2.5. If a malfunction is detected that cannot be eliminated by the train crew, the head of the train informs the driver about this, indicating possible cause, which, in turn, reports to the DSP (DNTs).

9.2.5. Report to the DSP (DNTS) on the results of the inspection of the train, on the measures taken, on the possibility of further following the car (locomotive) as part of the train or on the need to call the inspector of the cars from the nearest station to eliminate the malfunctions of the cars that the driver cannot fix on his own or to conclude on the condition heated axle box;

9.2.6. Ensure uncoupling of the car in case of emergency heating of the axle box or unacceptable defects in the rolling surface of the wheelset with the participation of a station employee who has the right to manufacture shunting if a decision is made by the wagon inspector (or personal

decisions, provided that it is impossible to promptly deliver the inspector to the station) on uncoupling;

9.2.7. Ensure that after the opening of the exit traffic light of the station, the movement of the train from the station at a set speed. Upon arrival at the station of the scheduled stop and inspection of the train, inform the car inspectors about the results of the car inspection and the actions taken to eliminate the malfunction. If any components or parts were removed from the car during troubleshooting, then transfer them to the inspectors, from the passenger car - to the head of the passenger train. After the trip, the train driver writes a report addressed to the head of the depot, indicating the train number, stop track number, stop time, start and end of the inspection, departure time, inspection results, inventory number of the inspected car, locomotive, repair information. The head of the passenger train, during further movement, draws up an act of the established form, with the exception of an increase in the delay time for drawing up an inspection report.

9.3. Order d actions in the event of an "Alarm2" signal.

The train driver, upon receiving a message about the indications of the KTSM equipment with the level of the “Alarm2” signal, is obliged:

9.3.1. Upon receipt of a message from the DNC (chipboard, voice informant) about the readings of the KTSM equipment, with the “Alarm 2” level, repeat the message and ensure the immediate stop of the train by service braking, turn on two red buffer lights (lanterns) on the locomotive.

9.3.2. Immediately inform by train radio about the place where the train stopped and preliminary data on the state of the train and the adjacent track and on the measures taken to find out the cause of the operation of the KTSM equipment:

drivers of trains of passing and opposite directions with the requirement to increase vigilance;

duty stations, limiting the haul;

head of a passenger train or senior conductor commuter train on locomotive traction (in the absence of radio communication, the head of the train is informed by the assistant driver through the conductor of the head car or personally);

9.3.3. Give a general alarm signal (sound and light transparent-white spotlight) when an oncoming train approaches in the line-of-sight zone, if no response is received from it by radio;

9.3.4. The message is repeated by the driver until a response is received from the drivers of trains on the haul and those on duty at adjacent stations;

9.3.5. If necessary, clarify with the station duty officer (train dispatcher) the reason for the operation of the KTSM equipment (heating of the passenger car pulley, heating of the axle box or violation of the lower clearance);

9.3.6. The driver of an oncoming (or passing direction on multi-track sections of the track) train that left the station before receiving a message about the operation of the KTSM equipment with the “Alarm2” level and the closing of the DNC of the haul track is obliged to reduce the speed to 20 km / h and follow the composition of the standing train with special vigilance and readiness to stop immediately if an obstacle to movement is encountered. After the train has passed the section of the track to the tail of the stopped train, the driver is allowed to proceed further at a set speed, provided that there are no traces of dragging the car parts. If there are traces of dragging parts of the rolling stock, then the driver continues to move to the place of their appearance with a speed limit of up to 20 km / h, with special vigilance and readiness to stop. The driver informs the station duty officer (train dispatcher) about the results of the inspection of the track section and the rolling stock standing on the adjacent track;

9.3.7. Ensure the inspection of the faulty units * of the rolling stock shown by the control equipment in the train (for passenger trains - together with the head of the train or with the employee acting as the head of the train) and decide on the possibility and procedure for the further movement of the car (locomotive). Inspection of the wagon should be carried out depending on the reason for the operation of the KTSM equipment, i.e. if the KTSM worked to heat the axle box, then it is necessary to inspect the axle box of the specified car, if it is for dragging, it is necessary to inspect the condition of the lower gauge of the car from both sides.

The procedure for the indications of the KTSM “Alarm2 dragging” equipment is determined by the requirements of the Instruction “On the installation, operation and maintenance of devices for detecting the dragging of parts and derailment of rolling stock in trains (UKSPS) on the Oktyabrskaya Railway” approved by order of the head of the road No. 425 / N dated 05.08.2011 (Section 6 Action of the station workers, train and locomotive crews, the operator of the AS SS, DNTs when the UKSPS installed on the KTSM is triggered).

When the indications of the KTSM “Alarm 2” equipment for heating the axle box or heating the pulley of a passenger car, the following procedure is established:

9.3.7.1. If there is an assistant driver, the inspection of a rolling unit* consisting of a freight, cargo-passenger, suburban (including consisting of locomotive-hauled passenger cars), utility trains is carried out by an assistant driver or the train driver personally. Inspection of a wagon as part of a passenger train is carried out by an assistant driver (driver) together with the head of the train, in the absence of the head of the train - with the conductor of the last wagon or with the senior conductor of the mail and baggage train. If a malfunction is detected, the driver (the head of the passenger train or an employee performing his duties) eliminates the malfunction, if possible. If a malfunction is not detected, it is necessary to examine two adjacent mobile units on both sides of the mobile unit with indications.

9.3.7.2. In the absence of an assistant, the driver, after stopping the train, can leave the locomotive (MVPS) only after bringing it to a non-working state, fixing it in the prescribed manner from spontaneous leaving, and locking the driver's cab. Next, the driver inspects the rolling unit (or the entire train) as part of the freight,

freight-passenger, suburban (including consisting of passenger cars on locomotive traction), utility train in the manner specified in clause 8.3.7.1. except for passenger trains for which the following procedure is established:

9.3.7.2.1. The train driver transmits information about the operation of the KTSM equipment received from the DSP (DNC) to the head of the passenger train via radio communication or the conductor of the head car.

9.3.7.2.2. The head of the passenger train, having received information from the driver, organizes an inspection of the axle boxes or pulleys of the cars fixed by the KTSM equipment, as well as an inspection of the head cars adjacent to the locomotive with indications for the locomotive, if no malfunctions were detected during the inspection of the locomotive.

9.3.7.2.3. The driver inspects the locomotive with indications for the locomotive, as well as with indications for the car, if the locomotive is one of two adjacent moving units from the car fixed by the KTSM equipment and no malfunctions were detected during the inspection of the car by the train crew.

9.3.7.2.4. If a malfunction of the car is detected, the head of the train and the train electrician eliminate it (the malfunction of the locomotive is eliminated by the train driver), which is reported to the driver, who, in turn, reports the results of the inspection of the measures taken by the head of the train, indicating his last name, reports to the DSP (DNTs) and informs about opportunities for further

train tracks.

9.3.7.2.5. If a malfunction is detected that cannot be eliminated by the train crew, the head of the train informs the driver about this, indicating the possible cause, who, in turn, reports to the DSP (DNTs).

9.3.7.2.6. If a malfunction is not detected, it is necessary to examine two adjacent mobile units on both sides of the mobile unit with indications.

Note to clause 9.2.4. and 9.3.7.: Counting rolling stock units when searching for a wagon with indications of KTSM, taking into account the locomotive, while taking into account that each section of the locomotive, and each car, regardless of the number of axles, is determined by the KTSM equipment for one rolling unit. For example, if information is received from the DSP (DNTs) about the operation of the KTSM equipment on the 7th unit, then with a two-section locomotive it will be the 5th car from the head.

9.3.8. If, as a result of inspection of the mobile unit, fixed by the KTSM equipment and two adjacent units in each direction from the fixed one, no malfunctions were detected and information was received from the DSP (DNC) about malfunctions of the KTSM equipment during the train passage outdoor devices, the entire train is inspected from the indicated side;

9.3.9. If the indications of the KTSM equipment with the “Alarm 2” level were on a wagon in a freight train, and after examining the train on the haul, a malfunction was not detected in this wagon or was detected in another wagon, then, in agreement with the DSC, the freight train follows at a set speed up to

9.3.10. If the indications of the KTSM equipment with the "Alarm 2" level were on a wagon in a freight train and after inspecting the train on the haul, a malfunction was detected and eliminated exactly in the car on which the KTSM equipment worked, and also if the readings of the KTSM equipment with the level

"Alarm2" was on a locomotive, SSRS or wagon in a passenger or multiple unit train, and after inspecting the train on the haul, the malfunction was not detected or, when the malfunction was promptly eliminated, a second stop at the station for inspection is not required. The train can follow further, while the speed to the first turnout of the station is set, along the first turnout not more than 20 km/h and then set. The station duty officer (if possible) organizes an additional inspection of the train "on the move" by the PTO workers;

9.3.11. If the indications of the KTSM equipment are with the “Alarm1” or “Alarm2” level, this car must be uncoupled from the train at the nearest station. It is not required to call a wagon inspector to conclude on the condition of the axle box. In case of repeated indications for the same moving unit of a locomotive, SSRS or wagon in a passenger or multiple unit train and

during inspection on the haul, no malfunction was detected, the train is accepted to the station for re-examination in accordance with clause 9.3.9. this manual. Before the train arrives at the station, the head of the passenger train provides control over the readings of the axle box heating control system (SKNB) of the cars by the train crew. Each time a passenger train stops

instrument readings that caused the delay of the train, the head of the train draws up an act of the established form;

9.3.12. Report to the DSP (DNC) on the results of the inspection, on the measures taken, on the possibility and procedure for the further movement of the car, locomotive as part of the train, or on the need to call the inspector of the cars to the train from the nearest station to eliminate malfunctions that the driver cannot eliminate on his own or to conclude on state of the heated axle box. Based on the results of the inspection of the passenger train by the driver and the head of the train, the head of the passenger train makes a decision on the possibility of further movement. In case of disagreement, the final decision is made by the head of the passenger train;

9.3.13. When making a decision on the withdrawal from the haul of a train with a heated axle box for re-check at the station, if there are signs of its malfunction, the speed of the train should not exceed 20 km / h, from the first switch when the train enters the station - also no more than 20 km / h. Movement must be carried out without sharp jerks and braking, the train is taken to

station to the main track, if it is busy - to one of the side tracks with the minimum possible deviation along the turnouts;

If, after stopping the train on "Alarm2", as a result of examining the axle box of the car, the destruction of the axle box is determined, which excludes the rotation of the wheel pair (skewed rollers, dismantling the end fastening, destruction of the separator, etc.), the driver and the inspector of the cars must ensure that the train is taken out of the haul under the conditions exclusion of rotation of the wheelset, movement to the station at a speed of not more than 5 km / h with a box without a viewing cover under the supervision of a wagon inspector and exclusion of train traffic on an adjacent track;

9.3.14. After stopping at the station, inform the wagon inspector about the results of the inspection on the haul. If the wagon inspector makes a decision (or a personal decision, provided that the wagon inspector is unable to promptly deliver the wagon inspector to the station for inspecting the wagons) to uncouple the wagon (locomotive), ensure the uncoupling with the participation of the station employee who has the right to perform shunting operations;

9.3.15. After repair or uncoupling of a faulty unit of rolling stock, ensure the further movement of the train at the set speed. Upon arrival at the station of the scheduled stop and inspection of the train, inform the car inspectors about the results of the car inspection and the actions taken to eliminate the malfunction. If any components or parts were removed from the car during troubleshooting, then hand them over to the inspectors.

After the trip, the train driver writes a report addressed to the head of the depot indicating the train number, stop track number, kilometer and picket of the stopping place (the way and stopping place are determined by the local operating instructions for the KTSM), stop time, start and end of the inspection, departure time, inspection results , the inventory number of the inspected car, locomotive, information about the repair. The head of the passenger train draws up an act in the prescribed form.

Diesel locomotives are equipped not only with fuel, oils, water and coolant, but also with sand. The idea to increase the traction force of a locomotive by sprinkling sand on the rails arose a very long time ago - as soon as the steam locomotive industry began to develop.

A sandbox is installed on a rolling stock (locomotive, tram, etc.) - large capacity designed to supply sand under the wheels.

The main goal is to improve the adhesion of the wheels to the rails to increase the tangential traction force and avoid slipping.

![]()

What kind of sand is suitable?

The sandbox is installed between the steamer and the chimney. Quartz sand with a particle size of 0.2-0.5 mm is used.

It should be a homogeneous material with the lowest content of harmful impurities and clay particles.

On the main railways use sand of increased and normal quality, for industrial railway transport - normal.

The working mass in it should be at least 90%, grains with a size of 0.1 mm - no more than 10%. Humidity should not be more than 0.5%, the heating temperature during drying should not exceed +350 °C.

In order to achieve such indicators, the sand is dried in ovens before feeding. Moisture is the total content of mechanically added water and hygroscopic moisture relative to the weight of the sand.

How the system works

The design of sand systems is usually the same. These are sand bunkers (four per section of the diesel locomotive), each with a capacity of 200 kg, nozzles, sandboxes, air distributors, pipelines with tips and rubber sleeves, electro-pneumatic valves.

The latter are connected to the contacts of the reverser, which, depending on the direction of movement, change position.

Sand is fed into the nozzles using compressed air. From there, a jet of sand is directed to the contact zone of the wheels with the rails.

Sand is fed into the nozzles using compressed air. From there, a jet of sand is directed to the contact zone of the wheels with the rails.

In modern locomotives, sandboxes are installed in specially designated body pockets.

Previously, they were at the top of the boiler. Diesel locomotive refueling with sand does not occur at the same time as refueling lubricants and fuel.

When to Use and When Not to Use

Sand supply is used if the train needs to move on a steep slope, when starting from a stop, on curved tracks, during precipitation that provokes slipping of the wheels, sometimes when braking.

The traffic light will take this as information that the path is clear, although in fact there will be a train on this section.

Sand supply is carried out only under the first and fourth wheel pair along the locomotive. They are the ones who start boxing first when adverse conditions. To save this consumable it is very important to direct its supply to the point of contact of the wheel with the rails.

Sometimes it is enough to apply sand only under the first pair of wheels.

The main elements of the bridge are its load-bearing structures. These include supports, spans, etc. Bridge building is not complete without a rig...

The ratio "quality of sand / price" will be the most optimal if a decent amount is paid for pure material, and for sand with many...

The technology of sand extraction depends on its origin - river, sea or quarry (mountain). Sometimes dune is also distinguished into a separate group ...

High quality This natural material allows it to be used in various fields. In construction, it is not as popular as quarry ...

Sand belongs to fine-clastic sedimentary rocks. In addition, this name is used in relation to an artificial material, to ...

Depending on the size of sand grains, mining methods, and the degree of contamination, sand is divided into several types. Each of them has a wide scope ...

In preparation concrete mix 4 components are involved - cement, sand, crushed stone (gravel), water. In some cases, additives are added in the form of...

Today, many people do to buy sand in St. Petersburg. What can be interesting in the sand? Yes, in principle, there is nothing interesting in the sand. It's just some magic...

The use of sand in pure form much more widespread than sand mixtures. However, the latter are also used and have a number of advantages...

Sand is an indispensable element of the equipment of locomotives - along with fuel, water and lubricants. It is used to increase the traction force of a diesel locomotive. This method began to be used at the dawn of steam locomotive construction. Since then, a more effective and cheaper way to improve traction has not been found, and now sandboxes are installed on all locomotives, as well as on ordinary city trams. Sandboxes are containers large sizes, which supply sand under the wheels of the composition, thereby improving the level of adhesion of rails and wheels and preventing slippage.

To improve friction, the purest material with a homogeneous structure is required. In this regard, in railway transport quartz sand is often used, the size of the fractions of which is from 0.2 to 0.5 millimeters. The content of sand grains of 0.1 mm is allowed, but should not exceed 10 percent. Before use, the material is subjected to additional drying in ovens at a temperature not exceeding 350 degrees Celsius. As a result, it reaches a moisture level of up to 0.5 percent. Sand of normal quality is intended for use on industrial railways. Sand of high and normal quality is used on the main tracks.

The principle of operation of sand systems in railway transport is generally universal. The system consists of large bunkers with a capacity of 200 kg of sand. There are four such containers per section of the locomotive. In modern locomotives for bunkers, separate compartments of the body are provided. In older locomotives, the tanks were located above the boiler.

The components of the system are sandboxes, nozzles, pipelines, air distributors and electro-pneumatic valves. Sand is fed into the nozzles under pressure using compressed air. The feed is adjusted in such a way as to direct the sand to the working surface of the rail.

The locomotive is refueled with sand in the depot - simultaneously with refueling and lubrication.

![]()

There are several situations where it becomes necessary to supply sand to the rails for additional grip on the wheels of the locomotive. These are starting and braking, the movement of the train up a steep slope, the movement along rounded tracks, as well as the deterioration weather conditions- when rain or snow causes the rail to slip.

Sand is fed under the first and fourth wheel sets along the locomotive, since it is from them that slippage begins. In some cases, sand is supplied only under the first wheelset. To save material, it is sprinkled directly on the contact point of the wheel with the rail surface.

At the same time, it is not recommended to use sand when braking is performed by a single locomotive - there is a possibility that a layer of sand will be between the rails and wheels. In this case, the railway traffic light will automatically perceive the absence of contact between the wheels and the rails as a signal of a free path and will give a green light.

In Sverdlovsk training center professional qualifications, a graphic summary was developed to study the regulations for the interaction of locomotive crews with the employees of Russian Railways involved, whose activities are directly related to the movement of trains, in the event of emergency and non-standard situations on the infrastructure of Russian Railways. This regulation was approved by order of Russian Railways dated December 30, 2010 No. 2817r.

The graphic abstract provides a much deeper level of structuring the educational material, as it divides it into small portions, presents it in a standard and eye-friendly visual-spatial form, improves the perception and consolidation of complex educational material, and significantly increases the speed of reading. We bring to the attention of readers some sections of this abstract in a journal version.

Violation of the integrity of the brake line

Separation of the brake hoses or other violation of the integrity of the brake line as part of the train. When detecting the separation of the brake hoses, the locomotive crew is obliged:- inspect the sleeves and connections, if necessary - replace (removing from tail car or locomotive), making sure that the number of the tail car corresponds to the number indicated in the certificate of form VU-45;

- carry out a reduced test of the brakes (Fig. 1).

If a violation of the integrity of the brake line of the train is detected due to a malfunction of the brake equipment of the cars and the impossibility of eliminating it, the locomotive crew is obliged to request employees of the wagon economy to eliminate the malfunction, be sure to indicate how many axles the car has, or, in agreement with the DSC, order an auxiliary locomotive from the tail of the train to remove the tail haul parts. If the end valve is closed to the faulty car, it is necessary to secure the tail section of the train from the faulty car in accordance with the fixing norm.

Actions of the locomotive crew in the event of rolling stock derailment

Departure of the rolling stock. When a rolling stock derailment is detected, the assistant driver is obliged to immediately secure the tail section of the train in accordance with the fixing standards, fence the derailment site in accordance with the fencing standards and report to the train driver (Fig. 2).

The train driver, having received information about the derailment of the rolling stock, is obliged to turn on the red lights of the buffer lights, ensure established order train guardrail.

After a personal inspection of the gathering place, it is required to report to the DSC (DSP) the following information:

- whether there are human casualties; the presence of a clearance on the adjacent path;

- the exact coordinates of the descent point, the nature of the terrain, the availability of entrances to the railway track;

- the number of derailed rolling stock units (is there a derailment of the locomotive);

- data on the state of the contact network and supports of the contact network.

"Kick-in-the-Road" Fault

When detecting a side, vertical “push” along the way, the train driver is obliged to apply service braking and carefully monitor the condition of the rolling stock until it stops completely. If, when traveling with a train, a track malfunction is detected that directly poses a threat to traffic safety (rail break, track erosion, collapse, snow drift, path overshoot, etc.), apply emergency braking, taking all possible measures to stop the train to a dangerous place.Immediately report via train radio communication to the drivers of the following or oncoming train, chipboard, limiting the stage, or DNC in the form: “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, on __ kmpicet I found a “jolt” (lateral, vertical, knock, etc.) at a speed of __ km / h.

I have no information about the presence of a gauge on the adjacent track (or there is a gauge on the adjacent track). Repeat information until confirmation is received.

After stopping the passenger train, together with the head of the train, inspect it. Inspection of other trains is carried out by the train driver.

If, during the inspection of the train, no malfunctions of the locomotive, wagons and the track under the train were detected, after the report of the chipboard on the results of the inspection, movement is allowed at a speed of not more than 20 km / h. After passing through a dangerous place, the entire train should proceed at a set speed.

Chipboard, having received a message from the driver about the presence of a "push" on the way, is obliged to stop the departure of passing trains to the haul along the specified path, inform the drivers of trains sent from the station earlier, and the road foreman (foreman of the track) about the "push" on the way.

The drivers of the following trains, having received information about the “shock”, are obliged to stop the train near specified place obstacles, make sure that it is possible to proceed further and follow this place with the whole train at a speed that ensures the safety of train traffic, but not more than 20 km/h (Fig. 3).

Report all malfunctions identified at the obstacle site by radio communication to the drivers following trains and chipboards, and if a malfunction is detected that threatens traffic safety, stop the train and resume movement only after this malfunction has been eliminated by the track workers.

The road foreman (in his absence, the foreman of the track) leaves for the stage on the first train leaving the station and takes everything necessary measures troubleshooting.

If the cause of the shock was a broken rail, erosion of the track, collapse, ejection of the track and other malfunctions that threaten the safety of train traffic, then further train movement in a dangerous place is allowed only after inspection this place track worker (position not lower than foreman) and with the obligatory entry by him in the form DU-61 about the possibility to proceed dangerous place indicating the speed of movement.

When a train stops at a broken rail, along which, according to the conclusion of the foreman of the track (an entry in the warning form for the DU-61 train), it is possible to skip the train, only one first train is allowed to pass through it. On a broken rail within a bridge or tunnel, the passage of trains in all cases is prohibited.

In the event of an obstacle (washout of the track, landslide, snow drift, collapsed cargo, etc.) on the adjacent track, the driver must give a general alarm signal (one long and three short ones) and organize its fencing.

The train driver, who detected a track malfunction, in the event of a radio communication malfunction, is obliged to take all possible measures to transmit the relevant information to the DSP (DNC). In exceptional cases, it is allowed to use cellular communication.

Checking the integrity of the brake line

Insufficient braking effect (auto brake failure). In case of detection of unsatisfactory operation of autobrakes along the route, insufficient braking effect (after the first stage of braking, the initial effect was not obtained in a passenger train or MVPS for 10 s, in an empty freight train up to 400 axles long and in a passenger-and-freight train - for 20 s, in other freight trains - within 30 s), the driver is obliged to apply emergency braking and take all possible measures to stop the train.Emergency braking is also applied when, when checking the operation of autobrakes, it was revealed that the required braking effect was not obtained at a distance established by local instructions for reducing the speed by 10 km / h in a freight, freight-passenger, passenger train, MVPS, as well as a single locomotive.

In the absence of a braking effect after applying emergency braking, the driver must take all measures to stop the train:

- transfer the crane double thrust in the emergency braking position;

- actuate the stop valve, emergency discharge valve buttons, emergency braking valves;

- turn off the EPC and turn it on without pressing the RB button;

- turn off the EPC in the absence of pressure in brake cylinders or impulse line on a locomotive equipped with a KOH device;

- press and hold the RB button on a locomotive equipped with ALSN or KPD;

- turn off the power switch K / 1UB-U with the EPC turned on;

- turn off the ALSN circuit breakers or the "Locomotive signaling" button when the EPK is on.

In a passenger train, it is necessary to transmit by radio communication a demand to the head of the train about the need to activate the stop cranes and hand brakes of the train, and if it is impossible to communicate via radio communication, give a “three long” signal (requirement for train crew employees to activate hand brakes composition).

If the attempt to stop the train is unsuccessful, it is necessary to give a general alarm signal and, via train radio communication, additionally inform the DSP (DNC) in front of the station located in front of the station about what happened in the form: “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, I follow the __ stage, __ km, the brakes failed. Take action." Repeat this message after 12 - 15 s until a response is received from the DSP (DNTs).

After the train stops, the driver must:

- fix the auxiliary brake valve in the extreme braking position and install it on the latch;

- report in the prescribed manner to the DSP (DNTs) of the nearest station, as well as to the drivers of following and oncoming trains about the reason for the stop in the form: “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, stopped at __ km, __ picket, __ track, stage __, due to unsatisfactory operation of auto brakes, there is a clearance on the adjacent track, be careful! Repeat information until you get a response.

Taking into account the track profile and ensuring traffic safety, the driver and DNC jointly determine the station at which the control check will be carried out and the order of the train to this station on the basis of a registered order transmitted to the driver via train radio communication. Control check brakes are carried out jointly by employees of the locomotive, wagon or passenger facilities.

When the train moves to the station, the driver must:

- with a green traffic light, drive at a speed of no more than 40 km / h;

- at a yellow traffic light, drive at a speed of no more than 20 km / h;

- when following a traffic light with a prohibitory indication, stop the train at a distance of 400 - 500 m before the traffic light, followed by its pulling up at a speed of no more than 5 km/h (Fig. 5).

In the event that the identified cause of the failure of the automatic brakes cannot be eliminated, the locomotive crew is obliged to:

- to secure the train from leaving with brake shoes;

- if necessary, apply the hand brakes; further order the withdrawal of the train from the haul to be determined jointly with the DNC.

The movement of the train towards the lost control

Movement towards a train that has lost control of the brakes or a rolling stock that has left the station. After receiving a message from the DSP (DNTS) about the oncoming train that has lost control of the brakes (rolling stock that has left the station), the driver is obliged to immediately stop the train emergency braking. At the same time, it is necessary to confirm the received message and specify the time of departure of the train towards. Depending on the train situation, by radio, inform the DSP (DNTs) limiting the haul, and the drivers of oncoming and passing trains on the haul, about the stopping place.When following a passenger train after a stop, it is necessary to give a command to activate the hand brakes and to evacuate passengers, unhook the locomotive from the braked train and drive away from it as far as possible. Depending on the situation, inform the train dispatcher or the station attendant about the measures taken by radio communication.

After stopping the locomotive, it is required to brake the auxiliary brake until reaching maximum pressure air in the brake cylinders and, depending on the type of locomotive, lower the pantographs, turn off the diesel engine, turn off the circuit breaker battery. Observing personal safety measures, immediately leave the locomotive and move to a safe distance (Fig. 6).

Depending on the situation, after the train stops or the locomotive is uncoupled from the train, the assistant driver, observing personal safety measures, must:

- put the brake shoes on the rails at the greatest possible distance to detain the oncoming train;

- after laying the shoes, immediately move to a safe distance.

Means of automatic control of the technical condition of the substation

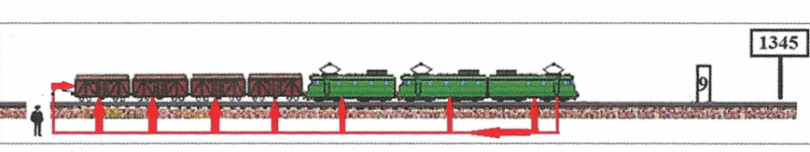

Indications of automatic controls technical condition rolling stock on the train. Upon receipt of a message from the DSP (DNTS) about the indication of means of automatic control of the technical condition of the rolling stock on the move of the train (KTSM) of the emergency heating level (Alarm-1), guided by the message of the voice informant “Attention! The driver of the odd (even) train to the station (station name) KTSM. Anxiety one. Warning” the driver is obliged to take measures to reduce the speed to 20 km/h, while strengthening control over the condition of the train and stop it at the nearest station (Fig. 7).After the train stops, the driver is obliged to check with the DSP (DNC) the previously received information:

- the presence of faulty wagons in the train and their number;

- type of malfunction - heating of the axle box, inhibition of wheel sets, violation of the lower dimension (drawing);

- serial number registered mobile unit;

- the side in the direction of travel and the serial number of the axle of the registered unit;

- heating temperature;

- the presence of failures of control means in the account of wagons.

When monitoring the state of the axlebox assembly, the driver is obliged to check visually and by touch the degree of heating of the axleboxes, wheel rims, inspect the rolling surface of the wheels in order to identify sliders, welds, discoloration due to inhibition of the wheel pairs (in the event of a malfunction of the auto-braking equipment of cars). Particular attention should be paid to the displacement (shift) of the axle box body, the misalignment of the axle box, its turn in the axle box opening of the sidewall; in winter time- on melting snow on the body of the axle box (unlike other axle boxes).

If there are no signs of axle box heating, as well as braked wheel sets of the inspected car, the driver is obliged to inspect two adjacent cars in each direction from the registered one. If there is information about failures of control devices in the account of wagons for this train, it is necessary to inspect all wagons on the specified side of the train. If no malfunctions are detected, the driver is obliged to notify the DSP (DNTs) and follow at a set speed to the nearest station where there is an employee of the wagon economy.

If during inspection of a registered wagon, heating of the axle box is revealed in comparison with adjacent axle boxes of the wagons or clear signs its destruction (sliding, destruction of the bearing separator, jamming of the wheelset, heating of the axle to a color change), the driver reports this to the chipboard (DNC). A conclusion on the possibility of further movement of a faulty car as part of a train is issued after inspecting the axle box assembly by a wagon worker, and in his absence, by a locomotive driver.

In case of detection of blockage of wheel sets, the locomotive crew is obliged to identify its cause (in passenger trains, together with the head of the train or the person replacing him) and, if possible, eliminate the malfunction (in passenger trains, assist the head of the train or the person replacing him). In the absence of defects, rejection parameters on the tread surface of wheel sets, proceed further at a set speed to the station where there is a maintenance of wagons.

When receiving a message from the DSP (DNC) about the indications of the KTSM with a critical heating level (Alarm-2), guided by the message of the voice informant “Attention! The driver of the odd (even) train to the station (station name) KTSM. Alarm two. Stop”, the driver is obliged to take measures to stop the train on the haul by service braking, following the tail part of the floor control devices (Fig. 8). Then inform the drivers of trains that are on the haul, chipboard stations that limit the haul, or DNC in the form “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, stopped at __ km, __ picket, __ track, __ haul due to the activation of the “Alarm-2” KTSM, there is a clearance on the adjacent track, be careful!” Repeat periodically until confirmation is received.

Upon receipt of information about the dragging, it is necessary to stop the train with a service brake and inspect the train in the manner indicated earlier. If obvious external signs of the destruction of the axle box are found, the driver must report this to the DSP (DNC), which calls a wagon management employee to the train to determine the possibility of further movement of the registered wagon.

If, as a result of the inspection of the train on the haul, it is established that the condition of the axle box allows it to proceed to the nearest station or no malfunction has been detected, the locomotive crew can continue moving to the station at a speed of no more than 20 km/h, which must be reported to the CPD of the nearest station (DNC) and call to this station workers of the wagon economy for inspection and giving an opinion on the possibility further movement trains. When moving, the locomotive crew is obliged to monitor the condition of the train in curved sections of the track from the locomotive cab.

Inspects the train at the station and makes a decision on its further movement by an employee of the wagon economy, and in his absence - by the train driver. In the case when the train was stopped with information about dragging, and the driver, when inspecting the registered car, did not reveal the reason, he is obliged to inspect the condition of the entire train from both sides.

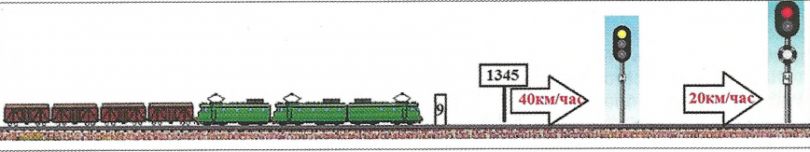

In the absence of a malfunction, the speed of the train is no more than 40 km/h to the entrance traffic light of the station and 20 km/h from the entrance traffic light to a stop on the receiving path (Fig. 9). Inspection of the train is carried out by an employee of the carriage economy, and in his absence - by the train driver with a report from the DSP (DNC) on the results of the inspection and the possibility of further movement.

When a train stops at a station according to the indications of the CTSM or according to the timetable, the locomotive crew (in the absence of a wagon inspector) is obliged to inspect the wagons with a pre-emergency heating level (Alarm-0) of the axle box or wheel set inhibition (if it has such information).

In order to exclude unreasonable stops according to the indications of the KTSM control devices, the driver is prohibited from applying service braking at the locations of floor devices, there is no need. In the event of a stop of a passenger train on a stretch, according to the indications of the CTSM, the driver is obliged to inform the head of the train about this. The driver, together with the head of the train (or an employee of the train crew replacing him), is obliged to inspect the faulty cars. Depending on the condition of the units and parts, the head of the train decides on the procedure for the further movement of the train, about which the train driver is obliged to report to the DSP (DNTs). Based on the results of the inspection, the head of the train, together with the driver, draws up an inspection report.

Operation of derailment control devices

If in front of the station (artificial structure) where the rolling stock derailment control device (UKSPS) is installed, while the train was running, the input (gateway) traffic light switched from allowing to prohibitive indication, the warning traffic light to a more prohibitive indication, the barrier traffic light came on, and also received a warning about the operation of the UKSPS from a voice informant or a message from the DSP (DNTs) via train radio communication, the driver is obliged to take measures to stop the train and turn on the red lights of the lights at the buffer beam. Inform the train drivers of the oncoming and passing directions, the chipboard limiting the stage, or the DNC in the form: “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, stopped at __ km, __ picket, __ track, haul __ due to the operation of the UKSPS, I have no information about the presence of a gauge on the adjacent track, be careful!In case of failure to receive confirmation of the perception of information from the drivers of the oncoming and following trains (including those moving along the adjacent track of a double-track or multi-track haul), the driver is obliged to inform the DSP (DNTs) about this, which take measures to inform the drivers of these trains about the need to take measures to stop . Give a general alarm signal (sound and light transparent-white spotlight) when an oncoming train approaches in the line-of-sight zone in the absence of a response from it via radio communication, send an assistant driver to inspect the train.

The driver's assistant must:

- inspect the train from both sides to the tail, turning Special attention for drawing, parts going beyond the gauge of the rolling stock, derailment of wheel sets in the train;

- examine the condition of the UKSPS sensors (provided they are under the train or not further than 300 m from the tail car), paying attention to their number, sensor numbers, traces of destruction or interaction with elements running gear trains.

- find out the state of the rolling stock, the presence of clearance on the adjacent track and immediately transfer this information to the DSP (DNC) limiting this haul;

- in case of derailment of the rolling stock, immediately protect it.

If no malfunction is found in the train, then the chipboard, in agreement with the DSC, accepts the train to the station at a prohibitive indication of the input traffic light in the prescribed manner at a speed of no more than 20 km / h. To the entrance traffic light of the station, the driver must proceed at a speed of no more than 40 km / h. In the event that the UKSPS is triggered in front of an artificial structure, the driver can increase the speed to 40 km / h, only after the structure has been passed by the entire train (Fig. 10).

Arriving at the station, the train is inspected by the worker of the station Maintenance wagons, and in his absence - the locomotive driver. According to the results of the inspection, the order of further following is determined. If a malfunction is not detected, then the train goes to the nearest wagon maintenance point at a set speed.

When the UKSPS is triggered under a train moving along the wrong track according to the signals of an automatic locomotive signaling on a double-track (multi-track) section or when moving on a single-track section, the DSP of the departure station via train radio communication must give a command to the train driver with the following content: “Attention! The driver of train #__ following the __ track in the wrong direction on the stretch __, stop immediately! Your train triggered the UKSPS! DSP station (station name, surname). The command is transmitted until a response from the train driver is received.

In the event of a stop of a passenger train on the haul due to the operation of the UKSPS, the driver, after fulfilling the requirements of these Regulations, is obliged to inform the head of the train about this and, together with him, inspect the cars and the locomotive. Based on the results of the check or troubleshooting, the head of the train with the driver of the locomotive make a decision on the procedure for further movement, about which the driver is obliged to report to the DSP (DNC) via radio communication.

The driver of the locomotive and the head of the train draw up an act about the reasons and time of the stop, which is transferred to the driver at the next station, where the train will have a stop on schedule. The train follows at a set speed to the point of maintenance of passenger cars, where the inspection of the cars and the locomotive is carried out by employees of the wagon and locomotive facilities.

Damage to the gauge bar of the rolling stock

Upon receipt of information about damage to the gauge bar of the rolling stock, the driver is obliged to stop the train using service braking, inform the drivers of trains of oncoming and passing directions, DSP (DNTs) of stations limiting the haul, the text in the form: “Attention, attention, listen to everyone! I am a driver of train No. __, __ surname, stopped at __ km, __ picket, __ way, stage __ due to bottom rail damage, I don’t have information about the presence of a clearance on the neighboring track, be careful! ”,The driver must send an assistant driver to inspect the train. The driver's assistant is obliged to inspect the train from both sides to the tail (Fig. 11), paying special attention to dragging, parts going beyond the gauge of the rolling stock or derailment of wheel sets in the train. The driver must report the results of the inspection and the measures taken, as well as the possibility of further movement of trains on the haul, to the DSP (DNC).

If the locomotive crew of a stopped train detects a derailment or dragging of parts of the rolling stock, then it is necessary:

- find out the state of the rolling stock, the presence of gauge on the adjacent track and immediately transfer this information to the DSP (DNS);

- in case of derailment of the rolling stock, immediately fence it; measures to eliminate the consequences of dragging or derailment of the rolling stock and the restoration of traffic must be coordinated with the DSP (DNC).

When stops of a passenger train due to damage to the gauge bar of the rolling stock, the driver is obliged to inform the head of the train about this and, together with him, inspect the cars and the locomotive. Based on the results of the check or troubleshooting, the locomotive driver, together with the head of the train, decides on the procedure for further movement, about which the driver is obliged to report to the DSP (DNC) via radio communication. An act is drawn up about the reasons and time for the stop by the head of the train and the locomotive driver, which is transferred to the driver at the next station where the train will have a stop on schedule. The train follows at a set speed to the point of maintenance of passenger cars, where the inspection of the cars and the locomotive is carried out by employees of the wagon and locomotive facilities.

Forced train stop

When following the haul, depending on the current situation and the train situation and the inability to bring the train to the station, driver is obliged:- stop the train, if possible, on the site and on the straight section of the track (unless an emergency stop is required);

- actuate the automatic brakes of the train and the auxiliary brake of the locomotive with its obligatory fixation in the extreme braking position;

- immediately announce by radio communication to the drivers of trains of oncoming and passing directions, DSP (DNTs) of stations limiting the haul, about the reasons and place of the stop in the form: “Attention, attention, listen to everyone! I am the driver of train No. __, __ surname, stopped at __ (time) at __ km, __ picket, __ track, haul __ due to a malfunction on the locomotive, there is a clearance on the adjacent track, be careful! Repeat information until a response is received.

In exceptional cases, in the absence of train radio communication with the DSP (DNTs), the driver of the stopped train takes measures to transmit a message about the stop (about requesting an auxiliary locomotive) through the drivers of trains of the opposite (following) direction or using cellular communication, after which the driver must begin to find and troubleshooting.

Duties of an Assistant Driver:

- fix the time of transmission by the driver via radio communication of information about the reasons, place and time of the forced stop of the train, as well as the time and names of the drivers of the following and (or) oncoming trains, DSP (DNC) to confirm the information they received on reverse side warning form form DU-61;

- actuate the hand brakes of the locomotive;

- make sure that the train is braked, and the handle of the auxiliary brake valve is in the extreme braking position with fixation;

- if necessary, negotiate by radio, indicating his name and position;

- control the countdown from the moment of stopping and report to the driver.

If the movement of the train cannot be resumed within 20 minutes from the moment of stopping and it is not possible to keep the train in place on automatic brakes, it is necessary to give a signal to activate the hand brakes included in the composition of the passenger cars by conductors; conductors, work managers - in the economic train. The assistant driver must be instructed to secure freight train brake shoes and hand brakes of wagons. The brake shoes are laid under loaded cars from the side of the descent (the toe of the brake shoe skid laid on the rail must touch the car wheel rim).

After returning, the driver’s assistant must report to the driver about the fixing of the train with brake shoes, indicating their number, as well as the number of cars on which the hand brakes are activated, and then make a note about this in the log form TU-152. Report by radio to the officer on duty at the nearest station limiting the haul and to the train dispatcher about securing the train, indicating the number of brake shoes that secure the rolling stock. The order to close the section for the movement of trains is passed by the DNC to the chipboard, which restricts the section, to the train driver who requested help, and to the driver of the auxiliary locomotive.