Is it possible to build a car that would accommodate six people, consume less gasoline than a scooter, and emit a minimum into the atmosphere? harmful substances, and on short trips - and completely zero? Maybe yes. And so that at the same time it would also cost like the most ordinary passenger car? Be surprised.

In the history of the "car in the air", which has been developing and improving for many years, and also "pushed" to serial production, the French inventor Guy Negre opened new chapter: American company Zero Pollution Motors announced the imminent introduction of these unusual cars to the US market. Moreover, the Americans intend to produce in their homeland one of the most capacious and striking models of the Frenchman.

Let us briefly recall. General Principle The "air" car is simple: compressed air is supplied to the cylinders of an engine, which in many ways resembles an internal combustion engine, from cylinders that replace the gas tank for such a device. This air pushes the pistons, rotating the crankshaft.

Negre and his engine on compressed air(photo from the site zeropollutionmotors.us).

Zero Pollution Motors is going to implement in the United States exactly the developments of Negre's company - Motor Development International (MDI), whose official headquarters are now located in Luxembourg, and the key division (where they create experimental miracle cars) in France, in Nice.

It must be said that the American-French project is not the only example of a return to the long-standing idea of compressed air machines. There is, for example, an Australian project. In Australia, however, this type of "fuel" is used by an open micro-truck and a trolley for transporting goods in workshops.

But after all, MDI does not limit its development to cars. The company recently built two mini-tractors (wheeled and tracked) with the same "air" motors. Their advantages as in-plant transport are the absence of exhaust emissions (in comparison with devices based on internal combustion engines) and instant recharging (in comparison with electric cars and electric forklifts).

Mini tractors from MDI are prototypes for the factory transport of the future. They are capable of towing trailers weighing several tons and operate from a single charge of onboard compressed air cylinders for 2-4 hours. The "filling" itself (from large stationary cylinders, pre-inflated by a compressor) takes 30 seconds, at most - a minute (MDI photos).

Among the newcomers to the field of "auto in the air" it is necessary to mention the often flashing in the press company Air Car Factories, founded by Miguel Celades Rex in Barcelona. Technical details not on the site, but it is actually about a variation of Negre's development.

The fact is that Miguel worked with Guy at MDI (as a representative of the company in Spain) for 8 years, and recently decided to go on an independent "voyage".

It is not known exactly how it was. But Negre, in an MDI press release dated February 3, 2008, writes in plain text about a quarrel and a break in all relations with Selades. And also that the statements of the Spaniard about the development of his company technologies from MDI are fraudulent.

These are the battles that flare up around the development, all the delights of which people have not even had time to properly taste.

By the way, why is a French engineer still fighting with such persistence for the spread of compressed air machines? After all, progress in batteries promises the emergence of more or less practical electric vehicles, and there are still hydrogen cars?

The reason is simple: compressed air cars are much cheaper than their purely electric or hydrogen rivals with approximately equal technical parameters (size, speed, power reserve). In addition, unlike chemical batteries of electricity (whether sulfuric acid or lithium), air cylinders can be charged a huge number of times. They are almost no demolition.

Examples of "air" vehicles of the past: the tram that entered the Nantes line in 1879 and experimental car compressed air, presented in Los Angeles in 1932 (photos from theaircar.com).

It is interesting that Jules Verne wrote about the spread of compressed air cars in the future in 1860.

His prediction does not look so surprising considering that around the same time, compressed air machines (city trams, trucks and intra-plant transport) received some limited distribution in Europe. Only due to the capabilities of the technology of that time, the power reserve on one charge of these devices was extremely small, so that they were quickly forgotten.

Negre is one of the first modern engineers to put the question of "air" machines back on the agenda. And the compatriot of the great science fiction writer now seems to have brought his invention to the assembly line.

The only thing that probably darkens his joy a little is that the car manufacturers are not going to embody the development of France, but India and the United States.

These vehicles do not have fuel tanks, batteries, or solar panels... These cars do not need hydrogen, diesel fuel, or gasoline. Reliability? Yes, there is almost nothing to break. But who believes in a perfect solution today?

Australia's first compressed air vehicle to enter the real world commercial exploitation, recently took up his duties in Melbourne.

The device was built by the Australian company Engineair engineer Angelo Di Pietro (Angelo Di Pietro).

The main problem that the inventor pondered over was to reduce the mass of the engine while maintaining high power and completeness of use of compressed air energy.

There are no cylinders or pistons, and there is no triangular rotor like a Wankel engine or a turbine wheel with blades.

Instead, a ring rotates in the motor housing. From the inside, it rests on two rollers eccentrically mounted on a shaft.

Cutaway engine of Australian Italian Di Pietro (photo from gizmo.com.au).

6 separate variable volumes in this expansion machine cut off movable semicircular petals installed in the cuts of the body.

There is also a system for distributing air to the chambers. That’s almost all.

By the way, the Di Pietro engine produces maximum torque immediately - even in a stationary state and spins up to quite decent rpm, so that a special transmission with variable gear ratio he doesn't need to.

So you can arrange the drive of a passenger car according to the Di Pietro system. Two rotary air motors, one per wheel. And no transmission (illustration from gizmo.com.au).

Well, simplicity of design, small size and low weight are another plus for the whole idea.

What's the bottom line? Here, for example, a pneumocar from Engineair, which is being tested in a warehouse of one of the grocery stores in the Australian capital.

The carrying capacity of this cart is 500 kilograms. The volume of air cylinders is 105 liters. Mileage at one gas station is 16 kilometers. In this case, refueling takes a few minutes. While charging a similar electric vehicle from the mains would take hours.

The strange connection between the piston and the crankshaft in the French air motor allows the piston to stop at dead center while maintaining a uniform rotation of the output shaft of the engine (illustration from the site mdi.lu).

It is logical to imagine how a similar attitude more power can be mounted on a small passenger car intended for movement mainly within the city.

Here it is necessary to mention the important advantage of pneumatic vehicles over electric vehicles, which are also tipped to be a promising means of transportation in a city that cares about clean air.

Batteries, even simple lead-acid ones, are more expensive than cylinders and are contaminants environment after the resource has been used up. Batteries are heavy, and so are electric motors. Which increases the energy consumption of the machine.

True, when the air is compressed in the compressors of the "pneumatic filling" station, it heats up, and this heat uselessly heats the atmosphere. This is a minus in terms of total costs and energy consumption (the same fossil fuel) for refueling such cars.

But still, in many situations (for metropolitan centers), it is better to come to terms with this and get in return a car with zero emissions at a reasonable price.

Pneumatic CityCAT's Taxi and MiniCAT's from Motor Development International (photo from mdi.lu).

Therefore, Di Pietro has reason to believe that he will be the one who will be able to launch airborne vehicles into a "large orbit."

Let us remind you that the idea of using compressed air as an energy carrier for vehicle- very old.

One of these patents was issued in the UK in 1799. And, as A.V. Moravsky reports in his book "The History of the Automobile", at the end of the 19th century, with the creation of reliable cylinders designed for high pressure, such machines became somewhat widespread in Europe and the United States - as intra-plant technological transport and even as urban trucks.

However, the energy consumption of compressed air, even if the pressure was brought to 300 atmospheres, was low. Gasoline looked more profitable, and hardly anyone thought about air pollution then.

It took more than a hundred-odd years for a new generation of inventors to bring air cars back onto the road.

In this new "air" wave, the Australian engineer was not the first. Let's say we already talked about the Frenchman Guy Negre.

His company - Motor Development International, engaged in the development and promotion of the original Negre air engine and cars based on it - is still full of bright hopes, but nothing has been heard about serial production, although a lot of prototypes have been made.

The design of its engine (and, in fact, it is piston motor), we note, is constantly undergoing changes. In particular, it should be noted an interesting mechanism of communication between the piston and the crankshaft, which allows the piston to stop at a dead point for a while and then to break down with acceleration - with uniform rotation of the output shaft.

Power unit machines CAT's (illustration from the site mdi.lu).

This "hesitation" is needed in order to have time to supply more air into the cylinder and then make full use of its expansion.

By the way, another sane idea was proposed by the French.

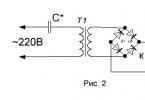

Negre cars can refuel not only directly from the compressor station, but also from the outlet - like electric cars.

In this case, the generator installed on the air motor turns into an electric motor, and the air motor itself turns into a compressor.

Designed by French by Motor Development International (MDI) AIRPod is powered by compressed air. Although it has been produced since 2009, for a long time it caused only a condescending smile from everyone (with the exception of environmental fans). Indeed, initially it could only be operated in warm climates: the air-propeller engine developed in the early 1990s did not start when low temperatures... And although a compressed air heating system has already been developed, expanding the geography of AIRPod application, it can be purchased only in Hawaii (USA).

Road show

In the spring of 2015, the independent company ZPM (Zero Pollution Motor - "Zero Pollution Motor") held a public road-show during the prime time of the American TV channel ABC - a presentation aimed at attracting investors (literally translated into Russian as "road show"). ZPM bought from the French the right to manufacture and sell the new model AIRPod - so far only in Hawaii, chosen as the "launch market".

Presented a project of a plant for the production of environmentally clean cars two shareholders of ZPM - famous American singer Pat Boone (the peak of his career was in the 1950s) and film producer Eitan Tucker ("Shrek", "Seven Years in Tibet", etc.). They offered potential investors (so-called "business angels") 50% of ZPM shares for $ 5 million.

Investors were in no hurry to shell out. At the same time, Robert Herjavets, the owner and founder of the Canadian IT company Herjavec Group, who was considered the most promising of them, said that he was interested in AIRPod sales not in one particular state, but in the entire United States. So, at present, the ZPM management is negotiating with the French to expand the sales territory.

/ 11

Worst Best

The fact that pneumatic vehicles can become a full-fledged replacement for gasoline and diesel vehicles is still in doubt. However, compressed air engines have their unconditional potential. Compressed air vehicles use an electric pump - compressor to compress air to high pressure (300 - 350 bar) and accumulate it in a reservoir. Using it to move pistons like an engine internal combustion, work is being done and the car is running on clean energy.

1. The novelty of technology

Despite the fact that the car with an air engine seems to be an innovative and even futuristic development, the power of air was used in driving cars as early as the late nineteenth and early twentieth century. However, the seventeenth century and the development of Dani Papin for the British Academy of Sciences must be considered the starting point in the history of the development of air engines. So the working principle air engine discovered more than three hundred years ago, and it seems all the more strange that this technology has not found application in the automotive industry for so long.

2. Evolution of air-powered cars

Compressed air engines were originally used in public transport. In 1872, Louis Mekarski created the first pneumatic tramway. Then, in 1898, Howdley and Knight improved the design by extending the engine cycle. Among the founding fathers of the compressed air engine, the name of Charles Porter is also often mentioned.

3. Years of oblivion

Pay attention to long history air engine, it may seem strange that this technology did not get the proper development in the twentieth century. In the thirties, a locomotive with a hybrid engine running on compressed air was designed, but the installation of internal combustion engines became the dominant trend in the automotive industry. Some historians transparently hint at the existence of an "oil lobby": in their opinion, powerful companies interested in the growth of the market for sales of oil refined products made every possible effort to ensure that research and development in the field of creating and improving air engines was never published.

4. Advantages of compressed air motors

In the performance of air engines, it is easy to see many advantages over internal combustion engines. First of all, it is cheapness and obvious safety of air as an energy source. Further, the design of the engine and the car as a whole is simplified: there are no spark plugs, a gas tank and an engine cooling system; the risk of leakage is eliminated charging batteries, as well as pollution of nature by car exhaust. Ultimately, given mass production, the cost of compressed air engines is likely to be lower than the cost of gasoline engines.

However, it will not do without a fly in the ointment: according to the experiments carried out, compressed air engines in operation turned out to be noisier than gasoline engines. But this is not their main drawback: unfortunately, in terms of their performance, they also lag behind internal combustion engines.

5. The future of air-powered vehicles

A new era for compressed air vehicles began in 2008, when former Formula 1 engineer Guy Negre presented his brainchild, the CityCat, an air-powered car that can reach speeds of up to 110 km / h and cover distances without recharging. 200 kilometers It took more than 10 years to turn the starting mode of the pneumatic drive into a working one. Founded with a group of like-minded people, the company became known as Motor Development Internation. Her initial project was not a pneumatic car in the full sense of the word. The first engine of Guy Negre could run not only on compressed air, but also on natural gas, gasoline and diesel. In the MDI motor, the processes of compression, ignition of the combustible mixture, as well as the working stroke itself, take place in two cylinders of different volumes, connected by a spherical chamber.

The power plant was tested on a Citroen AX hatchback. On the low speeds(up to 60 km / h), when the power consumption did not exceed 7 kW, the car could only move on the energy of compressed air, but at a speed above the specified mark, the power plant automatically switched to gasoline. In this case, the engine power increased to 70 Horse power... On-highway fuel consumption was only 3 liters per 100 km - a result that any hybrid car will envy.

However, the MDI team did not stop at the achieved result, continuing to work on improving the compressed air engine, namely, on creating a full-fledged air car, without replenishing gas or liquid fuel. The first was the Taxi Zero Pollution prototype. This car "for some reason" did not arouse interest in developed countries, which at that time were heavily dependent on the oil industry. But Mexico became interested in this development, and in 1997 signed an agreement on the gradual replacement of the taxi fleet in Mexico City (one of the most polluted megacities in the world) for "air" transport.

The next project was the same Airpod with a semicircular fiberglass body and 80-kilogram compressed air cylinders, a full supply of which was enough for 150-200 kilometers. However, the OneCat project, a more modern interpretation of the Mexican taxi Zero Pollution, became a full-fledged serial air car. Lightweight and safe carbon cylinders at 300 bar can hold up to 300 liters of compressed air.

The principle of operation of the MDI engine is as follows: air is sucked into a small cylinder, where it is compressed by a piston under a pressure of 18-20 bar and heats up; the heated air goes into a spherical chamber, where it mixes with cold air from the cylinders, which instantly expands and heats up, increasing the pressure on the piston of the large cylinder, which transfers the force to the crankshaft.

One of the most significant problems of our time is the problem of environmental pollution. Every day, mankind emits a huge amount of carbon dioxide into the atmosphere. Every car powered by an internal combustion engine harms our planet and does ecological situation even worse. Unfortunately, this is not all. The energy problem is no less acute, because oil reserves are not endless, gasoline prices are still growing, and there is no reason to decrease them. In search of alternative sources of fuel, many projects have been invented, but all of them are either too expensive or ineffective. Although one of them looks very promising. Judging by it, it is possible that ... air will become the new fuel of the future!

Sounds fantastic, doesn't it? Is it possible for a car to drive on air? Of course it is possible. But this air is not in the form in which we breathe it now - to move the car, you need compressed air. Compressed and under high pressure, the air moves the engine pistons and the car moves! After it has worked in the engine, the air returns to the atmosphere absolutely clean. There is enough tank for 200 kilometers, and the speed is also quite impressive - up to 110 kilometers per hour! (Surprisingly, car engines compressed air have a very long history. For the first time this technology was applied back in the eighties of the nineteenth century, when Louis Mekarski patented his invention, called the "pneumatic tram".) This car is not only completely environmentally friendly, it will also significantly save money for its owner! One full refueling compressed air will cost one and a half euros, and in a matter of minutes the car will be ready for travel again. One and a half euros are practically equal at the price of two liters of gasoline. Calculate how much your car will travel on two liters - for sure the figure will be much less than 200 kilometers. After all, after small and simple calculations, the daily filling of the car with compressed air will cost at least 10 times less! The inventor of this interesting concept the tireless Frenchman Guy Negre, a former Formula 1 engineer, has been working on his project for over ten years. The original scheme of the engine, similar to a conventional internal combustion engine, made it possible to drive a car using compressed air stored in cylinders. The idea was borrowed by Nagrom precisely from the design of racing cars, in which a turbine powered by compressed air from a special cylinder is used for acceleration. Guy Nagre began with the original concept of a hybrid car, which would be powered by air at low revs and would run a conventional internal combustion engine at high revs. This car was developed in the mid-90s, but the inventor decided to go even further. Over 10 years of hard work have resulted in several models that run exclusively on compressed air. At the heart of “ air car mobile“Guy Negra is a motor that is very similar in design to a standard internal combustion engine. The engine has two working and two auxiliary cylinders. Warm air is drawn directly from the atmosphere and is additionally heated. Then it enters the chamber, where it is mixed with compressed air cooled to -100 degrees Celsius. The air quickly heats up, sharply increases in volume and pushes the piston of the master cylinder, which sets in motion crankshaft... The first prototypes of a purely air car, created by the French from Guy Negra Motor Development International (MDI), were demonstrated in the early 2000s, and now, finally, it has come to a large-scale implementation of this remarkable development. Tata Motors, the largest automobile manufacturer in India, has agreed with MDI to start licensed production of a small, three-seater compressed air eco-vehicle. The MiniC.A.T model is equipped with a 90cc carbon fiber cylinder. m. of compressed air. With one air refueling, the car can travel from 200 to 300 km, with a maximum speed of 110 km / h. With the help of the compressors installed at the gas station, it will be possible to refuel it in 2-3 minutes, while paying some 1.5 euros. Possible and Alternative option refueling with a built-in compressor connected to a regular network alternating current... It will take 3-4 hours to completely fill the “tank”. Despite the fact that electricity is produced mainly by burning fossil raw materials, the air eco-car turns out to be much more efficient than cars with internal combustion engine. In terms of efficiency, it surpasses ordinary cars 2 times, and electric cars - 1.5 times. In addition, it is distinguished by the complete absence of harmful emissions, as well as extreme simplicity in maintenance: due to the absence of a combustion chamber, the oil in the engine can be changed no more often than every 50 thousand kilometers. Eco-car MiniC.A.T will be produced in four modifications. They include a three-seater passenger car, a five-seater taxi, a minivan and a light cargo pickup... The cars will sell for around £ 5,500 (roughly $ 11,000), which is quite affordable. by Tata- the annual production of at least 3 thousand "air cars". They are planning to sell them in Europe and India, but if the project gains popularity, perhaps all over the world. The initiative of the Indians was supported by the American company Zero Pollution Motors, which announced the imminent withdrawal to American market cars powered by compressed air and built using Guy Negre technology. Zero Pollution Motors plans to produce CityCAT cars with an engine option (6-cylinder, 75-horsepower Dual-Energy), which allows it to operate in two modes: simply on compressed air, or with the consumption of a small amount of fuel to increase the air temperature in the cylinders and, accordingly, power. In this mode, the car consumes about 2.2 liters of gasoline per 100 kilometers outside the city. CityCAT is a six-seater car with a spacious trunk. The body consists of fiberglass panels attached to an aluminum frame. The car will be able to travel 60 kilometers in the city with one supply of air, and out of the city with low gas consumption - 1360 kilometers. The speed of the car when working only on compressed air is 56 km / h, when using gasoline - 155 km / h. The estimated cost of the car is 17.8 thousand dollars. The first batch is due to enter the market in 2010. Hopefully, this is not the last step in the development of environmentally friendly modes of transportation. However, the reviews about the "air car" in the media gradually turned from enthusiastic into skeptical. About them - below.

In 2000, numerous media outlets, including the Air Force, predicted that mass production of cars using air instead of fuel would begin in early 2002.

The reason for such a bold statement was the presentation of a car called e.Volution at Auto Africa Expo2000, which took place in Johannesburg.

The amazed public was informed that e.Volution can travel about 200 kilometers without refueling, while developing speeds of up to 130 km / h. Or for 10 hours at an average speed of 80 km / h. It was stated that the cost of such a trip would cost the owner of e.Volution 30 cents. At the same time, the machine weighs only 700 kg, and the engine weighs 35 kg. The revolutionary new product was presented by the French company MDI (Motor Development International), which immediately announced its intention to start serial production of cars equipped with a compressed air engine. The inventor of the engine is the French engine engineer Guy Negre, known as the developer of the starting devices for Formula 1 cars and aircraft engines... The Negro said that he managed to create an engine that runs exclusively on compressed air without any admixtures of traditional fuel. The Frenchman called his brainchild Zero Pollution, which means zero emission of harmful substances into the atmosphere. The motto of Zero Pollution was "Simple, economical and clean", that is, the emphasis was on its safety and environmental friendliness. The principle of the engine, according to the inventor, is as follows: “Air is sucked into a small cylinder and compressed by a piston to a pressure of 20 bar. In this case, the air heats up to 400 degrees. Then hot air is pushed into the spherical chamber. Although nothing burns in the combustion chamber, cold compressed air is supplied from the cylinders under pressure, it immediately heats up, expands, the pressure rises sharply, the piston of the large cylinder returns and transfers the working force to the crankshaft. You can even say that the "air" engine works the same as a conventional internal combustion engine, but there is no combustion here. " It was stated that the car's emissions are no more dangerous than the carbon dioxide emitted by human breathing, the engine can be lubricated with vegetable oil, and the electrical system consists of only two wires. It takes about 3 minutes to refuel such an air vehicle. Representatives of Zero Pollution said that to refuel the "air car" it is enough to fill the air tanks located under the bottom of the car, which takes about four hours. However, in the future it was planned to build "air filling" stations capable of filling 300-liter cylinders in just 3 minutes. It was assumed that sales of "air vehicles" will begin in South Africa at a price of about $ 10 thousand. They also talked about the construction of five factories in Mexico and Spain and three in Australia. More than a dozen countries have allegedly already received a license to manufacture the car, and the South African company seems to have received an order for the production of 3,000 cars, instead of the planned experimental batch of 500 units. But after loud statements and general jubilation, something happened. Suddenly, everything calmed down and the "air car" was almost forgotten. The silence seems all the more ominous since the official site of Zero Pollution "stalled" some time ago. The reason is ridiculous: the page supposedly cannot cope with a huge stream of requests. However, the creators of the site vaguely promise to "improve" it someday. The advent of air vehicles on the roads was to pose a serious challenge to traditional transport. It is believed that green development was sabotaged car giants: Foreseeing the impending collapse, when the gasoline engines they produce will not be needed by anyone, they allegedly decided to "strangle the upstart". This version is partly confirmed by Deutsche Welle: “Car refineries and oil concerns unanimously consider the car with an air engine to be 'unfinished'. However, this can be attributed to their bias. However, many independent experts are rather skeptical, especially since a number of large automotive concerns - for example, Volkswagen, - already in the 70s and 80s, conducted research in this direction, but then curtailed them due to complete futility. " Environmentalists share much the same opinion: “It will take a very long time to convince car manufacturers to start production of "air" engines. Car companies have already spent a huge amount of money experimenting with electric cars which turned out to be inconvenient and expensive. They don't need new ideas anymore. " Zero Pollution - Zero emission engines. In addition, they are lightweight and compact. But Deutsche Welle draws attention to the fact that in various publications "a description of the engine and circuit diagram his works are full of inaccuracies and errors, and, in addition, the versions in different languages not only differ considerably, but sometimes directly contradict each other. Almost every edition has its own, different from others, technical specifications... The range of numbers is so great that one involuntarily wonders: do they really refer to the same car? Another strange pattern is that with each next publication, the parameters of the car improve: either the power will grow, then the price will fall, then the mass will decrease, then the capacity of the cylinders will increase. So, doubts here are quite appropriate and justified. However, the wait was not long. Probably, already in the coming year, we will know for sure what this MDI-developed compressed air engine is - a revolution in the automotive industry or, in all senses of the word, a “blown” sensation ”. Meanwhile, it is quite possible that in 2002 the intrigue with the "air car" will not be resolved. As a result of lengthy searches for information on the Web, one more or less "live" site was discovered, which promises mass production revolutionary cars in 2003. By the way, in the process of searching, a lot of interesting things on the "air" theme were found. It is curious that at the international toy fair held in February 2001 in Nuremberg, the Canadian company Spin Master offered buyers a model of an aircraft equipped with a compressed air engine. The mini-tank can be inflated with any pump, and the propellers take the original toy into the heavens. In addition, there is a commercial offer on the Internet, apparently addressed to the Moscow government. In this document, one metropolitan company invites officials “to familiarize themselves with the proposal of the automobile company MDI (France) on the production in Moscow of absolutely environmentally friendly and economical cars". There was also a proposal by V.A.Konoshchenko, who reports on the car he invented that runs on compressed air, attaching a description of the device. Also caught my eye was the invention of Rais Shaimukhametov - "Sadokhod", which "is driven by compressed air: under the hood there is a small engine and a serial compressor. The air rotates autonomously from each other two blocks (left and right) of eccentric rotors (pistons). The rotors in the block are connected by a caterpillar chain through the running wheels. " As a result, there was a double impression: on the one hand, the story with the French "air car" is not completely clear, and on the other, there is a much clearer feeling that "air" transport has been used for a long time, and especially for some reason in Russia. And, moreover, from the century before last. There is evidence that a 33-meter submarine with a compressed air engine, designed by self-taught I.F.Aleksandrovsky, was launched in the summer of 1865, successfully passed a number of tests, and only after that sank. NEGRA'S MACHINE - BLOOLING SENSATION A dazzling idea - a compressed air car - turned out to be a myth Sergey LESKOV The known oil reserves on Earth will last no more than 50 years. They are trying to replace gasoline, which, among other things, is the main source of air pollution in big cities. And liquefied natural gas, and all kinds of synthesized gases and liquids, and even alcohol. For a long time, hopes were pinned on an electric car, but its technical characteristics are low, and the utilization of the energy source turned out to be a problem for the environment. And here is a new, stunning idea - a compressed air car. French engineer Guy Negro earned fame in automotive world its starters for Formula 1 cars and aircraft engines. There are 70 patents in his design dossier. This suggests that the Negro is not self-taught from among those who annoy everyone with their discoveries car companies the world. A few years ago, the respected Negro founded the MDI (Motor Development International) company, which was engaged in the development of compressed air engines. The first reaction of any expert is nonsense, whim and again nonsense. But back in 1997 in Mexico, the parliamentary commission on transport became interested in this development, specialists visited the plant in Brignola and signed an agreement on the gradual replacement of all 87,000 taxis in Mexico City, the most bitten capital of the world, with cars with clean "exhalation." Two years ago at Auto Africa Expo 2000 there was a presentation of a concept car created by the Negra team called e. Volution. As promised, he used compressed air as fuel. In Johannesburg, on the wave of general interest, the start of the serial production of the wonder car with the Zero Pollution engine was announced in 2002. In South Africa, it was supposed to make 3 thousand e. Volution. The appointed year is in the yard. Where is the "air vehicle"? There are many publications on this topic, but the characteristics are jumping, as if we are not talking about technology, but about an Arab stallion. If you average all the protocols, you get the following portrait: e. The Volution weighs 700 kg, the Zero Pollution motor 35 kg. The car can travel 200 km without refueling. Maximum speed- 130 km / h. At a speed of 80 km / h, it can move for 10 hours. Estimated price - 10 thousand dollars. It takes energy to pump air into cylinders, and power plants are also a source of pollution. The authors of the project calculated the efficiency in the chain "refinery - car" for a gasoline, electric and air engine: 9, 13 and 20%, respectively. That is, the "air vent" is in the lead by a noticeable margin. The refueling itself takes about 4 hours, and the cylinders are hidden under the bottom. The principle of operation of the "air vent" does not differ from the internal combustion engine. No, due to the lack of fuel, only the combustion itself. Besides, there are no ignition systems, fuel injection systems, or a gas tank. The air in the cylinders is under a pressure of 200 atmospheres. The idea of the designers is as follows: part of the exhaust is sucked into a small cylinder and compressed by a piston to a pressure of 20 atmospheres. Air heated to 400 degrees is pushed into the chamber, which is analogous to the combustion chamber. It is supplied with compressed air from cylinders. It heats up - and as a result, the cylinder piston moves, transmitting the working force to the crankshaft. As we approach the announced release date, the inconsistency in publications on this topic is becoming more noticeable. It seems that Guy Negra's team is facing serious technical problems. To clarify the situation, Izvestia-Nauka turned to the most authoritative specialists in our country from the State scientific center"Research Automotive and automotive institute(NAMI) ". We calculated the operating cycle of this engine, - said the head of the gas cylinder equipment department at NAMI, Vladislav Luksho. - This is another attempt to deceive the fundamental laws of nature, to slip past the rules of thermodynamics. You can develop this idea: make the driver pump air with his feet. on compressed air is absurd, because its efficiency is very low. The energy obtained from mechanical compression per kilogram of weight is 20-30 times less than the chemical energy of hydrocarbon fuel. Gasoline has no competitors. Only atomic energy has higher performance. This e. Volution will be able to drive. only for short distances, like toys with pneumatic motors fly.Skeptical attitude to a compressed air engine does not mean at all, NAMI specialists are sure of this, that attempts to find an alternative gasoline engine doomed. Already managed to achieve tolerable characteristics in gas engines on propane-butane, which are only 1.5 times inferior in fuel heat transfer to a gasoline engine. In continuation of the precepts of Chonka's friend Gladyshev, efforts are being made to master the biogas engine, which is obtained from all kinds of waste. Hydrogen has great prospects, and the ways of its use are very diverse - from additives to gasoline to liquefaction or use in the form of compounds with metals (hydrides). According to latest developments US, it is better not to burn hydrogen: it reacts in the fuel element, electricity, which is converted into mechanical energy. Another option is alcohol, which is energetically "stronger" than gas, although "weaker" than gasoline. Alcohol engines are widely used in Brazil. True, in Russia it's not even worth talking about the introduction of this design - it's just stupid.