Recently at the Paris Motor Show, the Infiniti brand (read: Renault-Nissan alliance) introduced an engine with variable degree compression. The proprietary Variable Compression-Turbocharged (VC-T) technology allows you to vary this very degree, literally sucking all the juice out of the engine.

In an “ideal universe” the rule is simple - the higher the compression ratio of the fuel-air mixture, the better. The mixture expands as much as possible, the pistons move as if wound up, therefore, the power and efficiency of the engine are maximum. In other words, the fuel is burned extremely efficiently.

Everything would be great if it weren’t for the very nature of the fuel. During the course of bullying, his patience sometimes reaches its limit: the smoother the mixture burns, the better, but under high loads (high compression ratio, high speed) the mixture begins to explode rather than burn. This phenomenon is called detonation, and this thing is quite destructive. The walls of the combustion chamber and the piston itself experience severe shock loads and gradually, but quite quickly, collapse. In addition, the efficiency of the motor decreases - normal operating pressure falls on the piston.

Thus, the most profitable option is when the engine in any mode operates on the verge of detonation, preventing this phenomenon. Infiniti engineers have drawn up a graph on which they have identified for themselves the effective operating modes of the engine depending on the load, speed and compression ratio of the fuel-air mixture. (In fact, the efficiency of fuel combustion can be increased in other ways, for example, by increasing the number of valves per cylinder, adjusting their operating schedule, even choosing the place above the piston where the fuel injection is directed. Of course, we remember this.) The first two parameters, Clearly, they depend both on external factors and on careful selection of the transmission. And the third - the compression ratio - it was also decided to change in the range from 8:1 to 14:1.

Technically, this looks like an introduction to the design of the crank mechanism additional element- rocker arms between the connecting rod and the crankshaft. The rocker arm is controlled by an electric motor - the lever can be moved so that the piston stroke range varies within 5 mm. This is enough to significantly change the compression ratio.

There are no advantages without disadvantages. At first glance, they are obvious: an increase in the complexity of the design, some weight gain... However, it’s a shame to complain about these disadvantages - the engine turned out to be very balanced, thanks to which the balancing shafts were removed from the design. It is also likely that the engine is particularly sensitive to the brand and quality of fuel. It seems that this problem - at least to a large extent - can be solved using software methods.

For more than a decade, the core business of this Chinese brand has been television and music services, but now it is rapidly entering the market of smartphones and other consumer electronics. According to preliminary data, mobile devices LeEco sells well in China and other countries. Perhaps the company's debut in the automotive business will be just as successful? Last week, the South China Morning Post reported that LeEco was planning to build a factory to produce electric vehicles. Expected capacity is 400 thousand cars per year.

According to preliminary data, LeEco is going to invest about $1.8 billion in a new production site, which will be located in Zhejiang province. Subsequently, the plant should become part of the Eco Experience Park technology park. So far it is said that the construction of the factory will be completed in 2018.

Previously, LeEco was looking for partners in Chinese market, who could provide their own production capacity. For example, the company was in negotiations with BAIC and GAC. But there were no sufficiently profitable offers, so the management decided to build their own plant. According to preliminary data, it will not only assemble electric cars, but also produce the most important components, including electric motors and traction batteries. To date, LeEco owns 833 patents in the field of electric vehicles.

Perhaps in the future, LeEco will produce electric cars in the United States: construction of a plant by Faraday Future, which is a strategic partner of LeEco, is currently underway in Nevada.

Also last week it became known about some plans Ford. Americans are already engaged in hybrid and electric cars: Ford sells the C-Max Hybrid, C-Max Energi, Focus Electric, Fusion Hybrid and Fusion Energi. However, in the future the manufacturer intends to highlight special series innovative models. It will probably be called ModelE.

The American company filed a patent for the Model E name back in 2013. It has been producing Ford E-Series vans for many years, but it is unlikely that the new name has anything to do with them. At the same time, the head Tesla Motors Elon Musk lamented in 2014 that he would not be able to release car Model E: “We were going to call the new product Model E, but then Ford legally prohibited us from doing this, saying that he himself was going to use that name. I thought it was crazy: Ford is trying to kill SEX ( Tesla would have three models - Model S, Model E and Model X. - approx. ed.)! So we had to come up with a different name. New model will be called Model 3."

A whole series of electric and hybrid Ford models will exist under the Model E brand. The manufacturer has not yet shared exact information about them, but it is already known that at least some of them will be offered in several versions at once: a hybrid, a hybrid with external charging, and an electric car. A similar approach is used in the new Hyundai IONIQ model.

Construction is already underway on a new plant for the Ford Model E series. This will be the company's first completely new production site in the territory North America over the past 20 years. The total investment in the factory should be $1.6 billion, which is a huge amount even by the standards of the American automotive industry. It is noteworthy that the plant will be located in Mexico, and not in the USA.

Construction of the new factory should be completed in 2018, and the first production hybrids and electric cars will roll off the assembly line in 2019. Last year, Ford announced plans to invest about $4.5 billion in electric vehicles through 2020. With this money it is planned to develop and launch 13 new models. They are supposed to compete Tesla cars, Chevrolet Bolt and Nissan Leaf. At the same time, fully electric versions should have a range of around 320 kilometers. Most likely, the majority of innovative models will be hatchbacks and compact crossovers.

Meanwhile, Norway plans to completely ban sales of gasoline and diesel cars from 2025. We discussed a similar initiative several months ago. Then the Norwegian newspaper Dagens Næringsliv reported that four key parties in Norway agreed to introduce a ban on the sale of new fuel-burning cars from 2025. However, now a representative of the country's Ministry of Transport has officially denied this information.

In general, such an initiative looks quite logical. Firstly, this northern European country has long had high duties on models with internal combustion engines. Thanks to this, in 2015, sales of electric cars and hybrids increased by 71%. Secondly, the country does not have its own production of cars, which must be supported by any means. To be fair, we note that Norway is Europe's leader in oil production, so promoting electric vehicles may run counter to the country's interests.

The Ministry of Transport confirmed information that the Norwegian National Transport Development Plan provides for certain steps aimed at reducing the amount of harmful substances released into the atmosphere, but it does not include proposals for a complete ban on all types of engines internal combustion from 2025. Wherein official representative department mentioned that “the government wants to encourage more environmentally friendly pure species transport, but use carrots instead of sticks.” He told autonews.com about this.

It is curious that last week many Russian media outlets rushed to announce that Norway plans to completely ban the sale of new passenger cars with internal combustion engines from 2025. Thus, they shared outdated unofficial information or misinterpreted a new message from the Ministry of Transport of a European country.

⇡ Automotive technology

The internal combustion engine was originally the most complex component of a car. More than a hundred years have passed since the appearance of the first cars, but nothing has changed in this regard (if you do not take into account electric cars). At the same time, leading manufacturers are neck and neck in terms of technical progress. Today, every self-respecting company has turbo engines with direct fuel injection and a variable valve timing system on both the intake and exhaust (if we are talking about gasoline engines). More high-tech solutions are less common, but still occur. For example, the Audi SQ7 TDI crossover recently received the world's first engine with electric turbocharging, and BMW introduced diesel engine with four turbochargers. Among the most exotic serial solutions, the FreeValve system developed by Koenigsegg stands out: the motors of the Swedish company are completely devoid of camshafts. It is easy to notice that engineers from European companies mostly like to experiment. However, now there is interesting news from Japan: engineers Infiniti introduced the first engine with a variable compression ratio.

Many people often confuse the concepts of compression ratio and compression, and this is often done by people whose occupation is related to cars and their maintenance or repair. Therefore, to begin with, we will briefly explain what the compression ratio is and how it differs from compression.

Compression ratio (CR) is the ratio of the volume of the cylinder above the piston in the lower position (bottom dead center) to the volume of space above the piston in its upper position (top dead center). Thus, we are talking about a dimensionless parameter that depends only on geometric data. Roughly speaking, this is the ratio of the volume of the cylinder to the volume of the combustion chamber. For each car this is a strictly fixed value that does not change over time. Today it can only be influenced by installing other pistons or cylinder heads. In this case, compression is called maximum pressure in the cylinder, which is measured with the ignition off. In other words, this is an indicator of the degree of tightness of the combustion chamber.

So, Infiniti engineers managed to create a Variable Compression-Turbocharged (VC-T) engine, which is capable of changing the compression ratio. Of course, no matter how hard you want, it is impossible to change pistons and other structural elements on the go, so the Japanese company used a fundamentally different approach, thanks to which the internal combustion engine is able to vary the compression ratio from 8:1 to 14:1.

The majority of modern engines have a compression ratio of about 10:1. One exception is gasoline engines Mazda Skyactiv-G, in which this parameter is increased to 14:1. In theory, the higher the SG, the more high efficiency can be achieved at this motor. However, this medal also has back side: under heavy load, high coolant can provoke detonation - an uncontrolled explosion of the fuel-air mixture. This process can lead to significant damage to internal combustion engine parts.

Manufacturers have long dreamed of creating an engine that would have a high compression ratio at low speeds and loads and a low compression ratio at high speeds. This would improve engine efficiency, which has a positive effect on power, fuel consumption and harmful emissions, but at the same time avoids the risk of detonation. For the reasons stated above, such an idea cannot be realized in an internal combustion engine with a traditional layout. Therefore, Infiniti engineers had to significantly complicate the design.

The schematic diagram of the VC-T describes the general operating principle of the innovative mechanism. IN in this case the connecting rod is not attached directly to crankshaft, as in conventional internal combustion engines, but to a special rocker arm (Multi-link). On its other side comes an additional lever, which is connected to the wave transmission module (Harmonic Drive) through the Control Shaft and the Actuator Arm. Depending on the position of the last element, the position of the rocker arm will change, which, in turn, sets top position piston

VC-T will be able to change the compression ratio on the fly. The required parameters will depend on the load, speed and probably even the quality of the fuel: the computer will take into account all this data in order to set the optimal position of all elements. At the moment, the developers have not published all the parameters of the new engine: it is only known that it will be a two-liter four-cylinder engine. From the very name Variable Compression-Turbocharged it is obvious that it will be equipped with a turbocharger. Most likely, it was for this reason that engineers decided to create an unusual internal combustion engine: when high blood pressure supercharging significantly increases the risk of detonation. This is where the ability to reduce the compression ratio comes in handy. In other words, such a complex design would not be needed for an atmospheric engine. According to Infiniti, the new engine will replace the 3.5-liter naturally aspirated V6.

The world premiere of the new engine will take place on September 29 at the International Motor Show in Paris. It is expected that the new VC-T engine will be the first to receive crossover Infiniti The next-generation QX50, due in 2017. Probably, a little later the promising unit will become available for Nissan cars. It is possible that over time it will be offered for Mercedes-Benz passenger cars (today the opposite situation is observed: for some Infiniti models a two-liter Mercedes-Benz turbo engine is offered).

Apparently, the VC-T engine can be awarded the “Breakthrough of the Year” award in absentia. Even if this project completely fails, and the costs of its development do not pay off, a more revolutionary change in internal combustion engines will no longer be expected in 2016. It should be noted that Infiniti/Nissan engineers are not at all alone in the pursuit of a variable compression ratio. For example, in 2000 there was a lot of talk about SVC - Saab Variable Compression engine. At the same time, it used a completely different principle: the block head could move up and down, which ensured a change in the volume of the combustion chamber. There was already talk about the imminent appearance of cars with SVC on sale, but the American concern General Motors, after buying out the full stake in Saab in 2000, decided to close the project. But the MCE-5 engine developed by Peugeot is in many ways similar to the VC-T. It was introduced in 2009, but still no one is talking about using MCE-5 on production machines.

We have already mentioned the company a little higher Koenigsegg, since it is involved in the development of revolutionary engines without camshafts. Last week there was further news about advanced technologies Swedish manufacturer. Now they concern the catalytic converter. Let us remind you: this component should reduce the amount of harmful substances in the car exhaust. Today such devices are installed on all new Cars, and heavy-duty sports cars are no exception. Those who chase every extra horsepower, this is not very encouraging: catalytic converters are an obstacle to the free movement of gases from the combustion chamber into the atmosphere. As a result, engine power decreases slightly. Koenigsegg engineers did not want to put up with this state of affairs and invented their own unique system.

Instead of simply installing a catalytic converter after the turbocharger, as in conventional cars, the developers placed a small "pre-catalyst" on the bypass valve(wastegate) turbines. The first time after starting the engine, the flap is activated, which blocks the passage exhaust gases through the turbocharger: they go through the same bypass valve and a small “pre-catalyst”. In this case, a main converter is provided at the turbine outlet. Since it begins to work only after the entire system has already warmed up well (catalytic converters become effective only when they reach operating temperature), it was possible to make it significantly shorter. Thanks to this, losses caused by obstructed air passage have significantly decreased.

According to Koenigsegg engineers, a patented design using two catalysts allows you to add (or rather, not lose) about 300 Horse power. So the owners of the Koenigsegg Agera coupe can say without a twinge of conscience that the neutralizer alone in their car gives more power, than the engine in most modern passenger cars develops.

Now let's move on to another topic that is relevant every week - news from the development sector smart cars. Previously, many famous people from the automotive business, including the head of Tesla Motors, Elon Musk, have repeatedly said that the creation of cars with full-fledged autopilots will not only change the usual way of life for many people, but will also significantly affect automotive industry, as well as related businesses. For example, a significant increase in demand for car sharing services is expected: in developed countries this service is just beginning to gain momentum, but it will only really take off in the era of self-propelled cars. Some manufacturers have already begun to prepare for this. For example, last week representatives FordMotorCompany announced the start of mass deliveries of unmanned vehicles for business in 2021.

"The next decade will be defined autonomous car, and we see that such vehicles have a significant impact on society, just like Ford's introduction of assembly line 100 years ago,” said the chief executive of the automobile company, Mark Fields. — We are making every effort to put autonomous vehicles on the roads. vehicle, which can improve safety and solve social and environmental problems for millions of people, not just those who can afford luxury cars."

Behind the pathetic words there are very specific actions. Ford Company doubled the size of its Silicon Valley lab. Now the total area of the manufacturer's buildings has reached 16 thousand square meters, and the staff has 260 employees. In addition, last week the American automobile giant announced a joint investment with the Chinese information conglomerate Baidu: the pair will invest $150 million in the development of hardware and software for creating autopilots. Part of the funds went to Velodyne, which produces lidars.

According to Velodyne representatives, the investment will be used to accelerate the development and release of a new generation of sensors. They must become more high-performance, but at the same time inexpensive. Additionally, Ford acquired the Israeli startup SAIPS. The company is engaged in developments in the field of algorithmic solutions and technologies for image recognition and machine learning. SAIPS was founded in 2013, however, despite its modest age, its services are already used by HP, Israel Aerospace Industries and Wix.

If the idea of Ford management justifies itself, then by 2021 the company will have a car in its arsenal that can completely do without a person. At the same time, the “blue oval” plans to bet on the corporate sector: first of all, Ford hopes to interest companies specializing in car sharing, as well as brands like Uber and Lyft associated with taxi services.

The future of smart machines was also discussed in TeslaMotors. But it was not representatives of the company who spoke about this, but employees of the publication electrek.co. According to them, work on the Autopilot 2.0 system is now in full swing.

As we know, in September 2014, Tesla for the first time introduced hardware such as front-camera and radar, as well as an ultrasonic sensor that shoots 360 degrees around. A year later, in October 2015, the manufacturer released an update called Autopilot update (software version 7.0), which made it possible to activate an electronic assistant capable of taking control on the highway or parking the car in automatic mode. After this, the company updated several times software, but the hardware remained the same. Of course, every piece of hardware has its limits, so not every problem can be solved with a few new lines of code.

Now the company is thinking about introducing the Autopilot 2.0 system. It will introduce large-scale changes to the configuration of sensors. It is expected that the new equipment will allow reaching the third degree of control automation, which implies that the car will no longer require constant control by the driver, as in the current version of Tesla Autopilot, but under certain conditions the computer will still turn to a person for help. At the same time, the developers admit that in the future, software updates will be able to bring the system to the coveted fourth stage of automation, at which cars can easily drive on any roads (only the fifth level will remain ahead, when controls such as the steering wheel and pedals will disappear from the interior altogether).

Unnamed sources closely familiar with the Autopilot program told electrek.co journalists about some of the details of the new system. It is expected that the next generation will retain the same front-facing radar, but will receive two more of the same in addition. Most likely they will be installed at the edges front bumper. In addition to this, the complex will be replenished with a triple front camera. According to unofficial data, the new housing for it began to be installed on production Model S electric cars last week.

Apparently, even in Autopilot 2.0, Elon Musk’s company is going to do without lidars. And although one such prototype based on the Model S was spotted near the Tesla Motors headquarters, it could be an experiment that has nothing to do with the development of the next generation autopilot system.

Perhaps the new triple front camera will be based on the Front-facing Trifocal Constellation system from Mobileye. It will use a main sensor with a viewing angle of 50 degrees, as well as two additional ones with a field of view of 25 and 150 degrees. The latter will allow better recognition of pedestrians and cyclists.

Autopilot 2.0 will require a powerful platform as its data center. Perhaps it will be an NVIDIA Drive PX 2 module. It was first unveiled at CES 2016 in January, but deliveries are not expected to begin until the fall.

Most likely, the Autopilot 2.0 system will be introduced in the near future. Anonymous sources inside the company say that updated wiring harnesses are already being delivered to the Model S assembly line, which include connectors for the triple camera and other new equipment. This indicates that the manufacturer is preparing with all its might to begin deliveries of a new version of the auxiliary system. In addition, given the recent fatal case with involving Tesla Autopilot - Elon Musk will try to speed up the development of the next major update as much as possible in order to tell everyone about getting rid of the errors of previous versions.

We have already written about the technology of the new Infiniti engine in our review articles. A unique model of a gasoline engine that can change the compression ratio “on the fly” can be as powerful as a regular gasoline power unit and economical as if you were driving a diesel engine.

Today Jason Fenske will explain the essence of the engine and how it achieves highest power and efficiency.

Variable compression technology, or if you want turbocharged engine with a variable compression ratio, can almost instantly change the piston pressure by fuel-air mixture in ratio from 8:1 before 14:1 , while offering highly efficient compression under light loads (in the city, for example, or on the highway) and low compression required for the turbine during hard acceleration, with maximum throttle opening.

Jason, together with Infiniti, explained the principle of operation of the technology, not forgetting to note the nuances and previously unknown details of the operation of the amazing innovative engine. Exclusive material can be viewed in the video that we will publish below; do not forget to turn on the translation of subtitles if necessary. But first, we will select the technical “grain” of the engine building of the future and note those nuances that were previously unknown.

The central technology of the unique motor was the system of a special rotary mechanism, which, thanks to a complex piston rod, has a central rotary multi-lever system that is capable of changing its angle of operation, which leads to a change in the effective length of the piston rod, which in turn changes the length of the piston stroke in the cylinder, which ultimately changes the compression ratio.

The drive technology in detail is as follows:

1. The electric motor turns the actuator lever 1.30 minute video

2. The lever turns the drive shaft using a similar principle to drive conventional camshafts, using a cam system.

3. Third, lower arm changes the angle of the multi-link drive connected to the upper arm. The latter is connected to the piston (1.48 minute video)

4. The entire system, at certain settings, allows the piston to change the height of the top dead center, reducing or increasing the compression ratio.

For example, if the engine goes from the “maximum power” mode to the “fuel saving and increasing efficiency” mode, the wave gearbox will rotate to the left. Shown in the right photo (2.10 minutes of video). The rotation will be transmitted to the drive shaft, which will pull the lower arm down slightly, which will raise the multi-link drive, which in turn will move the piston closer to the cylinder head, reducing volume and thereby increasing compression.

Additionally, there is a transition from the traditional Otto internal combustion engine operating cycle to the Atkinson cycle, which differs in the ratio of cycle cycle times, which is achieved by changing the closing time of the intake valves.

By the way, according to Fenske, the transition from one mode of engine operation to another takes no more than 1.2 seconds!

Moreover, the new technology is able to vary the compression ratio over the entire range from 8:1 to 14:1, permanently adapting to driving style, load and other factors affecting engine performance.

But even explaining how such complex technology works is not the end of the story. Another important characteristic of the new engine is the reduction of piston pressure on the cylinder walls, which will avoid ovalization of the latter, since in conjunction with the piston drive system, a system is used to reduce the friction of the piston on the cylinder walls, which acts by reducing the angle of attack of the connecting rod during the piston stroke.

The video noted that the inline four-cylinder engine, due to its design, was somewhat unbalanced, so engineers were forced to add a balance shaft, which complicates the engine design, but leaves it a chance for a long life without the killer vibrations that arise from the operation of a complex connecting rod.

VC-T engine. Image: Nissan

Japanese automaker Nissan Motor has introduced a new type of gasoline internal combustion engine, which in some respects is superior to advanced modern diesel engines.

The new Variable Compression-Turbo (VC-T) engine is capable of change the compression ratio gaseous combustible mixture, that is, to change the stroke pitch of the pistons in the cylinders of the internal combustion engine. This parameter is usually fixed. Apparently, the VC-T will be the world's first internal combustion engine with a variable compression ratio.

Compression ratio is the ratio of the volume of the piston space above the cylinder of an internal combustion engine with the piston position at bottom dead center (total cylinder volume) to the volume of the cylinder space above the piston with the piston position at top dead center, that is, to the volume of the combustion chamber.

Increasing the compression ratio generally increases its power and increases Engine efficiency, that is, it helps reduce fuel consumption.

In regular gasoline engines, the compression ratio is typically between 8:1 and 10:1, but in sports cars and race cars it can be as high as 12:1 or more. As the compression ratio increases, the engine requires fuel with a higher octane number.

VC-T engine. Image: Nissan

The illustration shows the difference in piston pitch at different compression ratios: 14:1 (left) and 8:1 (right). In particular, the mechanism for changing the compression ratio from 14:1 to 8:1 is demonstrated. It happens this way.

- If it is necessary to change the compression ratio, the module is activated Harmonic Drive and moves the actuator lever.

- The actuator lever turns the drive shaft ( Control Shaft on the diagram).

- When the drive shaft turns, it changes the angle of inclination multi-link suspension (Multi-link on the diagram)

- The multi-link suspension determines the height to which each piston can rise in its cylinder. Thus, the compression ratio changes. The bottom dead center of the piston appears to remain the same.

Changing the compression ratio in an internal combustion engine can in some ways be compared to changing the angle of attack in controllable pitch propellers, a concept that has been used in propellers and propellers for many decades. The variable propeller pitch makes it possible to maintain the propulsion efficiency close to optimal, regardless of the speed of the carrier in the flow.

The technology of changing the compression ratio of the internal combustion engine makes it possible to maintain engine power while complying with strict standards for engine efficiency. This is probably the most real way comply with these standards. “Everyone is now working on variable compression ratio and other technologies to significantly improve the efficiency of gasoline engines,” says James Chao, managing director for Asia Pacific and consultant for IHS, “at least for the last twenty years or so.” . It is worth mentioning that in 2000, Saab showed a prototype of such a Saab Variable Compression (SVC) engine for the Saab 9-5, for which it received a number of awards at technical exhibitions. Then the Swedish company was bought by General Motors and stopped working on the prototype.

Saab Variable Compression (SVC) engine. Photo: Reedhawk

The VC-T engine is promised to be launched on the market in 2017 with Infiniti QX50 cars. The official presentation is scheduled for September 29 at Paris Motor Show. This 2.0-liter four-cylinder engine will have about the same power and torque as the 3.5-liter V6 it replaces, but will deliver 27 percent fuel economy over it.

Nissan engineers also say the VC-T will be cheaper than today's advanced turbocharged diesel engines, and will fully comply with current nitrogen oxide and other exhaust gas emissions regulations in force in the European Union and some other countries.

After Infiniti new engines are planned to equip others Nissan cars and possibly partner company Renault.

VC-T engine. Image: Nissan

It can be assumed that the complicated internal combustion engine design at first it is unlikely to be reliable. It makes sense to wait a few years before buying a car with a VC-T engine, unless you want to participate in testing experimental technology.

More and more authoritative opinions are being heard that the development of internal combustion engines has now reached highest level and it is no longer possible to significantly improve their performance. Designers are left to engage in creeping modernization, polishing the supercharging and injection systems, as well as adding more and more electronics. Japanese engineers do not agree with this. Infiniti has had its say, building an engine with a variable compression ratio. Let's figure out what the advantages of such a motor are and what its future is.

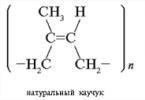

As an introduction, let us recall that the compression ratio is the ratio of the volume above the piston at the bottom “dead” point to the volume when the piston is at the top. For gasoline engines this figure ranges from 8 to 14, for diesel engines - from 18 to 23. The compression ratio is set fixedly by the design. It is calculated depending on octane number the gasoline used and the presence of supercharging.

The ability to dynamically change the compression ratio depending on the load allows you to increase efficiency turbocharged engine, ensuring that each portion air-fuel mixture burned at optimal compression. For light loads, when the mixture is lean, maximum compression is used, and in loaded mode, when a lot of gasoline is injected and detonation is possible, the engine compresses the mixture minimally. This eliminates the need to adjust the ignition timing “backwards”, which remains in the most efficient position for removing power. Theoretically, the system for changing the compression ratio in the internal combustion engine makes it possible to reduce the engine displacement by up to two times while maintaining traction and dynamic characteristics.

Diagram of an engine with a variable combustion chamber volume and connecting rods with a piston lifting system

One of the first to appear was a system with an additional piston in the combustion chamber, which, by moving, changed its volume. But the question immediately arose about placing another group of parts in the head of the block, where camshafts, valves, injectors and spark plugs were already crowded. Moreover, the optimal configuration of the combustion chamber was disrupted, causing the fuel to burn unevenly. Therefore, the system remained within the walls of laboratories. The system with variable height pistons did not go further than the experiment. The split pistons were excessively heavy, and design difficulties immediately arose with controlling the lifting height of the cover.

Crankshaft lifting system on FEV Motorentechnik eccentric couplings (left) and traverse mechanism for changing the piston lift height

Other designers have gone the route of controlling the crankshaft lift height. In this system, the crankshaft bearing journals are placed in eccentric couplings driven through gears by an electric motor. When the eccentrics turn, the crankshaft rises or falls, which, accordingly, changes the height of the pistons to the cylinder head, increases or decreases the volume of the combustion chamber, and thereby changes the compression ratio. This motor was shown in 2000 German company FEV Motorentechnik. The system was integrated into the 1.8 liter turbocharged four-cylinder engine from Volkswagen concern, where the compression ratio varied from 8 to 16. The engine developed a power of 218 hp. and torque 300 Nm. Until 2003, the engine was tested on the Audi A6, but did not go into production.

Wasn't too lucky reverse system, which also changes the lifting height of the pistons, but not by controlling the crankshaft, but by lifting the cylinder block. A working motor of a similar design was demonstrated in 2000 year Saab, and also tested it on the 9-5 model, planning to put it into mass production. Dubbed Saab Variable Compression (SVC), the 1.6-liter five-cylinder turbocharged engine produced 225 horsepower. With. and a torque of 305 Nm, while fuel consumption at medium loads decreased by 30%, and due to the adjustable compression ratio, the engine could easily consume any gasoline - from A-80 to A-98.

Saab Variable Compression engine system, in which the compression ratio is varied by deflecting the top of the cylinder block

Saab solved the problem of lifting the cylinder block this way: the block was divided into two parts - the upper one with the head and cylinder liners, and the lower one, where the crankshaft remained. On one side, the upper part was connected to the lower part through a hinge, and on the other, an electric drive mechanism was installed, which, like the lid of a chest, raised the upper part at an angle of up to 4 degrees. The range of compression ratios during lifting and lowering could vary flexibly from 8 to 14. To seal the moving and stationary parts, an elastic rubber casing was used, which turned out to be one of the most weak points structures, together with hinges and lifting mechanism. After the acquisition of Saab by General Motors, the Americans closed the project.

Project MCE-5, which uses a mechanism with working and control pistons connected through a gear rocker arm

At the turn of the century, French engineers from MCE-5 Development S.A. also proposed their design for an engine with a variable compression ratio. The turbocharged 1.5-liter engine they showed, in which the compression ratio could vary from 7 to 18, developed a power of 220 hp. With. and torque 420 Nm. The design here is quite complex. The connecting rod is divided and equipped at the top (in the part mounted on the crankshaft) with a toothed rocker arm. Adjacent to it is another part of the connecting rod from the piston, the end of which has rack. Connected to the other side of the rocker arm is a control piston rack, which is driven through the engine lubrication system by means of special valves, channels and an electric drive. When the control piston moves, it acts on the rocker arm and the lifting height of the working piston changes. The engine was tested experimentally on a Peugeot 407, but the automaker was not interested in this system.

Now Infiniti designers have decided to have their say, presenting an engine with Variable Compression-Turbocharged (VC-T) technology, which allows you to dynamically change the compression ratio from 8 to 14. Japanese engineers used a traverse mechanism: they made a movable joint between the connecting rod and its lower journal, which, in in turn, connected by a system of levers driven by an electric motor. Having received a command from the control unit, the electric motor moves the rod, the system of levers changes position, thereby adjusting the height of the piston lift and, accordingly, changing the compression ratio.

Design of the Variable Compression system for the Infiniti VC-T engine: a - piston, b - connecting rod, c - yoke, d - crankshaft, e - electric motor, f - intermediate shaft, g - thrust.

Thanks to this technology, the Infiniti VC-T two-liter gasoline turbo engine develops a power of 270 hp, being 27% more economical than the company's other two-liter engines with a constant compression ratio. The Japanese plan to put VC-T engines into mass production in 2018, equipping them with the QX50 crossover and then other models.

Note that efficiency is now the main goal of developing engines with variable compression ratios. At modern development technologies of supercharging and injection, it is not difficult for designers to increase the power in the engine big problems. Another question: how much gasoline in a supercharged engine will fly out the pipe? For conventional serial engines, consumption indicators may be unacceptable, which acts as a limiter for increasing power. Japanese designers decided to overcome this barrier. According to Infiniti, their Gas engine VC-T can act as an alternative to modern turbocharged diesel engines, showing the same fuel consumption with better power characteristics and lower exhaust emissions.

What's the result?

Work on engines with variable compression ratios has been going on for decades - designers from Ford, Mercedes-Benz, Nissan, Peugeot and Volkswagen have been working in this area. Thousands of patents have been issued by engineers at research institutes and companies on both sides of the Atlantic. But so far not a single such motor has gone into mass production.

Not everything is smooth for Infiniti either. As the developers of the VC-T motor themselves admit, their brainchild still has common problems: the complexity and cost of the design have increased, and vibration issues have not been resolved. But the Japanese hope to finalize the design and put it into mass production. If this happens, then future buyers will only have to understand: how much they will have to overpay for new technology how reliable such an engine will be and how much it will save on fuel.