Abbreviated testing of autolikes is made in order to verify air passability by brake highway From locomotive to tail car.

Abbreviated testing performed:

Ø After the trades of the train locomotive to the composition, if the total testing of the auto motors was pre-performed from compressor installation or other locomotive;

Ø after shift locomotive brigadeswhen the locomotive from the train is not uncovered;

Ø After all sorts of sleeves in the composition or between the composition and locomotive (except for the receipt of a pushing locomotive included in the brake line), the sleeves compound due to the trailer of the rolling stock, as well as after overlapping the end crane in the composition;

Ø in passenger trains after the train parking for more than 20 minutes, with a pressure drop in ...

The main tanks are lower 5.5 kgf / cm 2, when changing the control cab or after the transmission of the operating driver of the second locomotive on the distance after stopping the train;

Ø in cargo trains, if, when parking the train, there was a triggering of autolikes, the density of the brake line has changed by more than 20% of the form specified in the certificate Wu-45., After the train parking is more than 30 minutes.

When performing abbreviated testing of the brakes along the wavelers signal, the driver performs the discharge of the brake line by the inhibition stage, as with full testing, and installs the machine crane knob in IV. position. The inspector checks the triggering of the brakes of two tail wagons Upon stock brake cylinder and pressing brake shoes To wheels. By signal viewer "Let go of the brake"the driver releases the brakes of the machine crane knob in the first position. In passenger trains, the handle of the driver's crane is kept in this position until the pressure is obtained in the equalization tank 5.0 - 5.2 kgf / cm 2, and in cargo and cargo-passenger trains to pressure in the equalization tank on 0.5 kgf / cm 2 above the charger. After that, the handle of the driver's crane is transferred to the train position. The inspector of the wagons checks the vacation of the brakes of two tailings on the care of the stock of the brake cylinder and the waste of the brake pads from the wheels. In the event of a trap in the tail of the train group of cars, the inspector checks the operation of the brakes in each attached car.

At the stations where the posts of the wagons are not provided for, workers trained to carry out the testing of auto-motors (the list of posts are attracted to the abbreviated testing (the list of posts is established by the head of the road).

After performing abbreviated testing of the brakes, the wagon inspector is obliged to make a mark in the form Wu-45. about its execution, and the driver lies in the certificate of density data brake network.

If the abbreviation of brakes in the train is made after full testing From the compressor installation, then the inspections of the wagons are required before testing to check the density of the trains brake network during the second and fourth positions of the driver's crane knob, the integrity of the brake line, measure the charging pressure in the tail of the tail truck, and at length freight train More than 100 axes determine the greatest time to leave the auto motors of two tail wagons. At the end of the testing, the machine is given a form certificate Wu-45.like with full testing.

The abbreviated testing of electropneumatic brakes is performed in the points of shifts of locomotives and locomotive brigades on the action of the brakes of two tail wagons and when the car trays with checking the brakes in each attached car. In passenger trains, the abbreviation of electropneumatic brakes is first performed, and then autolike. Abbreviated testing EPT It is made by a procedure similar to their full testing from the locomotive. Brake leave is made short-term, 1 to 2 seconds by moving the handle of the driver's crane in the first position, followed by moving its train position. The triggering of the brakes and their vacation is controlled on the lamps of the alarm in the locomotive cabin, as well as pressing and deploying brake pads from the wheels of two tail wagons.

Without performing abbreviated testing of brakes or with inactive brakes in two tailings, send the train to the distance is prohibited.

The duty officer at the station (chipboard) informs the operator of PTO about the locomotive approach for the train filed to carry out the full testing of autolike.The PTO operator (chipboard in the absence of the PTO operator) gives an indication of the radio interviewes of the cars to arrive at the appropriate path (park, station) and proceed to the full testing of the autolike of the presented train:

- Inspeat wagons on ... The path enters the locomotive, proceed to the complete testing of the brakes.

- - On ... The path comes the locomotive to start the full testing of the brakes. Inspecchikwagons "Surname".

The inspector of the headgroup wagons tells the driver about passenger cars, locomotives and wagons of a motor-reshagous rolling stock in the cargo train, on the loading of cars in the composition (loaded, empty), and also gives the command to the locomotive machine to perform a clutch with the composition and reports the radio operator to the PTC operator:

- - On ... Locomotive trampling is made to the composition.

- - Carefully, on ... The path to the composition is made of a locomotive.

After the locomotive trail to the composition and transition of the driver in working cabin. The driver's assistant driver should be a long three-time opening of the crane through the end sleeve to blow the brake line of locomotive from the composition of the composition, following the safety equipment, connect the sleeves of the brake line between the locomotive and the first car, open the end valve at the locomotive, and then at the car.

Responsibility for the proper clutch of the autospar, the connection of the sleeves, the opening of the end cranes between the locomotive and the first car is assigned to the locomotive driver.

When servicing a locomotive with one machinist, blowing the brake line, connecting the sleeves and the opening of the terminal cranes performs the inspector of the wagons.

After full charge The brake line of the train The driver of the locomotive reports the PTC operator (chipboard) on the readiness for the complete testing of autotractors.

The inspections of the wagons report to the PTO operator (chipboard) on the readiness to carry out the full testing of autotractors (inspection of wagons of all groups, starting with the head):

- - The train number ... on ... the paths proceed to the complete testing of the brakes. Lookwear cars"Surname".

- ...... Inspecodes of the wagons "Surname" (all groups).

Testing.

- - Start a complete testing of brakes on ... Paths, time .... Lookwear cars"Surname".

The PTC operator (chipboard), making sure the correctness of the indication, the time began to start testing the brakes on the work schedule and confirms the message:

- - Do sure. Time ... Operator (chipboard) "Surname".

- - At ... I blow the way. In the "tail" "Surname".

When the locomotive auto motors is triggered, determined by the lighting of the lamp "TM" of the alarm N 418, the driver is obliged to stretch the rac of the speedingman (if the locomotive is not equipped with a club, efficiency).

After at least 2 minutes, the driver supplies one short signal and produces a stroke of the pressure with a decrease in pressure in the equalization tank by 0.5-0.6 kgf / cm2 (translates the handle of the driver's crane from II position in v position), followed by transferring the driver's crane knob In IV position.

The inspector of the radio group of radio communications reports the inspection of the wagons of the tail group:

- - "On ... We produce the braking stage". In the "head" "Surname".

The inspector of the wagons of the tail group, making sure to exit the stock of brake cylinders and pressing the brake pads to the surface of the wheel riding, by radio over the viewer of the headgroup transmits the indication by the locomotive driver "release the brake":

- - Tailing brakes worked. Release brakes. In the "tail" "Surname".

Having indicated from the inspection of the wagons of the head group "Release the brakes", the locomotive driver stretches the speed-resistant tape (if the locomotive is not equipped with a club, efficiency), two short signals gives a vacation of autootors:

When translating a crane handle in I, the Location of the headgroup wagon gives the command to the inspector of the tail of the tail group on the measurement of the time of vacation of two tailings:

- - On ... Ways Measure the time of vacation of tail wagons. In the "head" "Surname".

The inspector of the tail of the tail group confirms:

- - Clear, on ... the way I measure the time of vacation. In the "tail" "Surname".

- - The time of vacation of tail cars ... seconds. In the "tail" "Surname".

The PTO operator fixes the vacation time of two tailings in the executed schedule. With a train length of less than 100 axes, the driver independently makes a vacation in the same order, while the time of vacation of 2-cane is not measured.

After complete charging of the brake train to the installed pressure, the driver and the inspector of the headgroup wagons must check the brake network density. To do this, after disconnecting the compressors by the regulator upon reaching the limit pressure locomotive (on steam locomotics by closing the steam valve of the pump) and the subsequent decrease in this pressure by 0.4 - 0.5 kgf / cm2 to measure the time for its further decrease of 0.5 kgf. cm2 When train the handle of the driver's crane.

On freight locomotives equipped with a brake line density control device (UKHPTM), check the density test according to this device.

For trains with locomotive in the head, the smallest permissible time to reduce the pressure when checking the density of the brake line, depending on the length of the composition and the volume of the main tanks of locomotives, is indicated in Appendix B.

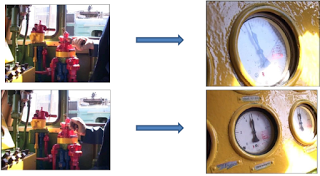

The inspector of the wagons of the tail group is obliged to produce a charging pressure in the tailing truck highway with a pressure gauge. To do this, the inspector sets the pressure gauge on the connecting sleeve head and opens the terminal crane, reporting the results of the VET operator (chipboard) and the inspection of the headgroup wagons:

- - The train number ... on ... Path Pressure in the tail ... kgf / cm2, tail wagon№ .... In the "tail" "Surname".

The inspector of the headgroup wagons confirms the transmitted information:

- - The train number ... on ... Path pressure in the tail ... kgf / cm2, tail car number .... In the "head" "Surname".

The PTO operator (chipboard) confirms the information transmitted by the inspector of the wagons of the tail group:

- - tail car number ..., pressure in the tail ... kgf / cm2. Operator (chipboard) "Surname".

At the end of the above operations and after complete charging of the brake line to the prescribed pressure, the locomotive driver reports the inspection of the headgroup wagons on the readiness to test the actions of the auto motors in the train.

The inspector of the headgroup wagons reports readiness to check the actions of the autotractoros of the inspector of the tail of the tail group:

- - The train number ... on ... the path is ready for braking. In the "head" "Surname".

- - on ... the way "brake". In the "tail" "Surname".

The inspector of the headgroup wagons reports the inspection of the tail group on the start of braking:

- - The train number ... on ... the paths slowed down. In the "head" "Surname".

The inspector of the tail of the tail group will measure the yield of the brake cylinder of the tail of the tail braking and transmits the information to the inspection of the headgroup wagons:

- - on ... Path out the outlet of the brake cylinder of the tail car ... mm. In the "tail" "Surname".

The inspector of the headgroup wagons confirms the transmitted information:

- - on ... Path out the outlet of the brake cylinder of the tail car ... mm. In the "head" "Surname".

After 2 minutes (120 seconds) for freight trains, which all air distributors are included on the plain (mountain) mode or 10 minutes (600 s) - with air distributors included on the mountain mode before the tightened descents, inspections of the wagons pass along the composition ( On the right side) and check the condition and effect of the brakes from each car and are convinced of their normal work on braking on the output of the brake cylinder rods and pressing the pads to the surface of riding the wheels with the application of chalk marking on defective devices brake equipment.

|

Scheme of passing passes |

- - Train number ... on ... The paths of the brake worked. Release brakes. The inspector of the wagons "Surname".

Inspeckers of the wagons at the meeting put inscriptions on the oncoming car "TGV" - the inspector from the head of the composition and "TX" - the inspector from the tail of the composition.

In case more than two examiners are browseed for the full testing of autolikes, more than two viewers information about the oncoming car for introduction to the certificate are attracted: "Help on providing trains to brakes and a working action" transmits each inspector on radio interviewing the headgroup wagons.

PTO operator (chipboard), having received a message from the inspection of wagons about readiness for checking the leave of autotractors, gives an indication of a locomotive driver for auto-motors:

- - Machine train number ... on ... brake paths worked. Release brakes. Operator (chipboard)"Surname".

The locomotive driver after receiving the command from the inspector of the headgroup wagons or the PTO operator (chipboard) "release the brake" gives two short signals and releases the brakes:

After the start of the leave of the autolikes, the tracks of the wagons must check the brake vacation from each trades of the brake cylinder stock cargo and the windbag washed from the surface of the wheel riding with the application of chalk marks on the faulty brake equipment devices.

If the air distributors who have not worked for vacation, it is not allowed to perform their leave manually before finding out the reasons for editors. All the identified brake equipment malfunctions on cars must be eliminated, and the effects of the brakes in these wagons are checked again.

The inspections of the wagons after checking on the leave of autotractors report, starting with the head operator (chipboard):

- - Train brakes number ... on ... The way was released. The inspector of the wagons "Surname".

- ...... .. Inspeckers of the wagons "Surname" (all groups).

The inspector of the wagons of the tail group after checking on the vacation of autotractors reports the inspection of the headgroup and the operator (chipboard):

- - Brakes of the tail of the train number ... on ... The way was released. The inspector of the wagons "Surname".

Operator (chipboard), having received a message from inspections of wagons confirms the information:

- - The train number ... on ... The brake paths let go. Operator (chipboard) "Surname".

After the end of the full testing of automatic brakes in the train The inspector of the headgroup wagons must be handing the driver of the leading locomotive Help: "Help on providing trains to brakes and their working action" on the maintenance of trains by brakes and their serviceable action, and after testing with excerpt for 10 minutes. Before the protracted descents, make a mark on the testing of the testing, saying the operator (chipboard) on the completion of the complete testing of the auto motors and the train availability:

- - The train number ... on ... Paths (park station) "...", the full testing of the brakes is completed, a certificate: "Help on providing the trains by the brakes and their working action" the "Last Name" driver was presented, time ... In the "surname" "Surname".

Abbreviation of brakes.

| Name of parameter | Value |

| Theme of article: | Abbreviation of brakes. |

| Rubric (thematic category) | Auto |

The abbreviated testing of autolikes is made in order to verify air passability over the brake line from the locomotive to the tail car.

Abbreviated testing performed:

Ø After the trains of the train locomotive to the composition, if the complete testing of the auto motors was pre-performed from the compressor installation or other locomotive;

Ø After changing the locomotive brigades, when the locomotive from the train is not unloaded;

Ø After all sortsage of sleeves in the composition or between the composition and locomotive (except for the captive of a pushing locomotive included in the brake line), combined the sleeves due to the trailer of the rolling stock, as well as after overlapping the terminal crane in the composition;

Ø in passenger trains after the train parking for more than 20 minutes, when the pressure drops in the main tanks below 5.5 kgf / cm 2, when changing the control cab or after the transmission of the operating driver of the second locomotive on the distance after stopping the train;

Ø in cargo trains, if, when parking a train, there was a triggering of autolikes, the density of the brake line has changed by more than 20% of the form specified in the certificate Wu-45., After the train parking is more than 30 minutes.

When performing abbreviated testing of the brakes along the wavelers signal, the driver performs the discharge of the brake line by the inhibition stage, as with full testing, and installs the machine crane knob in IV. position. The inspector checks the triggering of the brakes of two tailings to the outlet of the brake cylinder rod and pressing the brake pads to the wheels. By signal viewer '''Otpoty brake'''''''''''''''''''''''''the driver releases the brakes of the machine crane knob in the first position. In passenger trains, the handle of the driver's crane is kept in this position until the pressure is obtained in the equalization tank 5.0 - 5.2 kgf / cm 2, and in cargo and cargo-passenger trains to pressure in the equalization tank on 0.5 kgf / cm 2 above the charger. After that, the handle of the driver's crane is transferred to the train position. The inspector of the wagons checks the vacation of the brakes of two tailings on the care of the stock of the brake cylinder and the waste of the brake pads from the wheels. In the event of a trap in the tail of the train group of cars, the inspector checks the operation of the brakes in each attached car.

At the stations where the posts of the wagons are not provided for, workers trained to carry out the testing of auto-motors (the list of posts are attracted to the abbreviated testing (the list of posts is established by the head of the road).

After performing abbreviated testing of the brakes, the wagon inspector is obliged to make a mark in the form Wu-45. About its implementation, and the driver lists the data on the density of the brake network.

If the abbreviated testing of the brakes is carried out in the train after full testing from the compressor installation, then the inspections of the wagons are required before testing to check the density of the train brake network during the second and fourth positions of the machine's crane handle, the integrity of the brake line, measure the charging pressure in the tail trunk road The length of the cargo train is more than 100, to determine the greatest time to leave the auto motors of two tail wagons. At the end of the testing, the machine is given a form certificate Wu-45.like with full testing.

The abbreviated testing of electropneumatic brakes is performed in the points of shifts of locomotives and locomotive brigades on the action of the brakes of two tail wagons and when the car trays with checking the brakes in each attached car. In passenger trains, the abbreviation of electropneumatic brakes is first performed, and then autolike. Abbreviated testing EPT It is made by a procedure similar to their full testing from the locomotive. Brake leave is made short-term, 1 to 2 seconds by moving the handle of the driver's crane in the first position, followed by moving its train position. The triggering of the brakes and their vacation is controlled on the lamps of the alarm in the cabbage of locomotive, as well as pressing and deploying brake pads from the wheels of two tail wagons.

Without performing abbreviated testing of brakes or with inactive brakes in two tailings, send the train to the distance is prohibited.

Abbreviation of brakes. - Concept and species. Classification and features of the category "Abbreviation of brakes." 2014, 2015.

To check the serviceable state of the brakes of rolling stock, there are two types of their testing: full and abbreviated. The first is performed at the formation and turnover stations before sending the train, after the change of locomotive, before the protracted descents and in a number of other cases.

The first phase of the process of complete testing of the brakes is to check the density of the brake network. In passenger trains, overlap the combined crane or crane double traction and after 20 ° C measure the drop in the pressure in TM, which should not exceed 0.02 MPa per 1 min or 0.05 MPa for 2.5 minutes.

In cargo trains, unlike passenger, due to the disconnection of check valves BP with a decrease in pressure in TM, it is faster than dark softness in it compared to dark softness, and the brakes are triggered. Therefore, in them, the density check is carried out indirectly, based on the analysis of the pressure reduction rate at gr.

After the compressor is turned off the pressure regulator and the subsequent pressure reduction in G by a value of 0.05 MPa (for stabilizing thermodynamic processes), the time of its further fall is measured by 0.05 MPa when the KM handle position is tested and compared with the table. The latter, depending on the length of the composition and the type of locomotive, should be less than the resulting. Otherwise, it is necessary to increase the TM density of the car, reducing leakage from it. In addition, in all cargo trains, they are obliged to measure train pressure in the tail trunk highway, using a pressure gauge installed on the connecting sleeve head, and make sure that the pressure is not lower than the instruction set (the average pressure difference between the head and tail parts of the train should not exceed 0 07-0.08 MPa).

The second phase of full testing is to check through the drying of the brakes on the output of the TC rod and pressing the pads to the surface of the wheel riding, but not earlier than 2 minutes after the braking produced. The vacation brakes of each car is checked for the care of the shopping center of the shopping center and the deployment of the pads from the wheels.

In passenger trains, according to the regulations, after checking the density, the operation of the EPT and the sensitivity of the automatic brakes of the discharge stage of the TM at 0.05-0.06 MPa, after which all brakes should come into action and spontaneously not to let go to the moment of their vacation. All faults identified in the process of complete testing of brake equipment on cars must be eliminated and it is checked on these cars.

After completing full testing, the inspector is obliged to hand the driver in the form of Wu-45 on the secrecy of the train brake means. It specifies data on the required and actual calculation of the pads, quantity manual brakes In the axes to hold trains on the spot and the presence of manual brake axes in them, quantities (in%) in the train of composite pads, data on the density of the trains brake network, the value of the train pressure in the TM tail of the cargo train, as well as the value of the exit rod of the TC last car .

Abbreviated testing of the brakes according to their action on the last two cars in trains are produced in the following cases: After the train locomotive travelers to the composition, the brakes of which are tested with full testing; After changing locomotive brigades without checking locomotive; After any separation of sleeves in the train, after the parking lot more than 20 minutes of passenger trains and more than 30 minutes of freight, as well as in a number of other cases provided for by the instructions. The density of the brake network is not determined. The mark of conducted abbreviated testing is made in the certificate of Wu-45 available from the driver.

9.3.1. The abbreviated testing of the brakes with checking the state of the brake line on the action of the brake of two tailings in the trains is produced:

after the traded locomotive tray to the composition, if a complete testing of autotractors from the compressor installation (station network) or locomotive was performed at the station. After changing the locomotive brigades, when the locomotive from the train is not uncovered;

after all the separation of the sleeves in the train or between the composition and locomotive (except for the receipt of a pushing locomotive included in the brake line), the sleeves connections due to the trailer of the rolling stock, as well as after the overlapping of the end crane in the train:

in passenger trains: after parking for more than 20 minutes, when the pressure drops in the main tanks below the TM charging pressure, when changing the control cabin or after transmitting the control of the second locomotive driver on the distance after stopping the train due to the impossibility of further control of the train movement from the main cabin;

in cargo trains, if there was spontaneous triggering of the brakes or a change in the density of more than 20% of the indicated reference on the brakes of F. Wu-45; In cargo trains after parking more than 30 minutes.

When parking freight trains for more than 30 minutes on distillations, as well as on the roads, overtook items and stations, where there are no inspections of cars or workers who trained in the testing of auto-motors (the list of posts is indicated by the head of the road), the autotractoros should be checked in accordance with P. 9.4.1, this instruction.

if, when checking the TM density, the driver will detect its change more than 20% of the specified reference f. Wu-45, perform abbreviation of brakes:

if on the locomotive, which has alarm device number 418, signal lamp "TM" lights up in the parking lot, check the serviceability of the braking step in which the lamp "TM" should go out. Making advantage of the normal operation of the alarm, to carry out the abbreviation of autotractors:

At stations where there are regular inspections of wagons, abbreviation is carried out by these inspections at the application of the driver, and in the absence of examiners - a locomotive brigade or employees, trained to carry out the testing of auto motors.

The abbreviated testing of electropneumatic brakes is performed in locomotive shift points and locomotive brigades on the action of two tail brakes and when car trays with checking the brakes in each attached car:

9.3.2. In passenger trains, abbreviated testing is performed first electropneumatic brakes, and then auto motors. Testing EPT is made by a procedure similar to their full testing from locomotive in accordance with clause 9.2.3. Without checking the EPT voltage in the tail carriage and without turning off the EPT power supply chain table during the period of checking its vacation, and. 9.3.1. This instruction on the action of the brakes of two tailings.

9.3.3. When performing abbreviated testing at the employee signal, which is responsible for testing the brakes, "braking" the driver is obliged to give a whistle one short signal and reduce the pressure in the equalization tank by the value set for full testing.

After checking the triggering of the brakes of two tailings on the braking, the signal "Release the brake" is served. Under this signal, the driver gives the whistle two short signals and releases the brakes with the handle of the driver's crane in I position in passenger trains with an increase in pressure in the equalization tank to 5.0-5.2 kgf / cm 2, and in the cargo and cargo massage train to receiving Pressure in the equalization tank 0.5 kgf / cm 2 above the charging pressure with the transfer of the handle on the train position. If the abbreviated testing of brakes in trains is performed after full testing from the compressor installation (station network), the inspections of the wagons and the driver are required before testing to check the density of the trains braking network and the integrity of TM in accordance with

p.P.9.2.3., 9.2.4. This instruction, and with the length of the freight train more than 200 axes, the inspector of the wagons is obliged to check the charging pressure in the highway of the latter by the order established by claim 9.2.4. After the end of such testing, the driver f. Wu-45, as with full testing.

9.3.4. When tracing to the train, which arrived, the car or group of cars is made abbreviated testing of the brakes with a mandatory check of their action in each trailed car and the density of the brake line of the train, and in the cargo train, in addition, check the integrity of TM trains. With each abbreviated testing of autotractors, the inspector of the wagons, and where this position is not provided, on duty at the station, the main conductor, the compiler of trains or workers who are entrusted to carry out the testing of the brakes, make a mark about the abbreviated testing of autotractors (with a mark on changing the train composition, With the address of the tail car) in the reference f. Wu-45, which has a driver. In the event of a change in the TM density due to the caught knuckles, the new brake network density data enters the driver in the certificate F. Wu-45.

If the abbreviated testing of the passenger train brakes was performed with the involvement of the head (mechanic-brigadier) of the train and conductors of the wagons, the head (mechanic-brigadier) should make a mark on performing abbreviation of the brakes in the reference f. Wu-45, which has a driver.

9.3.5. At the stations where there is no position of the inspection of wagons, the effect of brakes of the tailings in passenger trains check the conductors of cars, in cargo trains - employees who trained to carry out the testing of auto motors (the list of posts establishes the head of the road).

9.3.6. Without performing abbreviation or with inactive brakes in two tail cars, send the train to the distance is prohibited.

In the case of identifying during the testing, the air distributors not worked for vacation is not allowed to produce their leave manually until the reasons for editors. In these cases, it is necessary to check whether there are no overlapped taps on the train, especially in those places where wagons have trahaded or uncovered, re-abbreviated the testing of the brakes. Faulty air distributors replace, and at intermediate stations - turn them off and release air through exhaust valve, Make a mark about this in Help Wu-45.