Since the appearance of the first cars, designers have been faced with the question of searching the best way damping body vibrations that occur when overcoming irregularities. The best solution, which is still used today, has become integration into the composition car suspension special devices - shock absorbers. On this moment Hydraulic telescopic shock absorbers have become widespread. Damping of vibrations of the body and wheels occurs in them due to fluid friction that occurs when fluid passes through narrow holes in the piston - valves. Thus, the mechanical vibration energy is converted into thermal energy. The characteristics of shock absorbers depend on the following: important indicators, such as stability, controllability and smoothness of the car. Modern shock absorbers, based on general principle works differ in types and design features.

Friction shock absorbers

The first cars with leaf spring suspension had an unpleasant property: when overcoming bumps, their body swayed strongly. Initially, this problem was partially solved by itself, since the effect of interleaf friction was observed in multi-leaf springs, which helped dampen body vibrations. But this was not enough.

Therefore, the next step was to add a separate damping element to the suspension. One of the first such devices were dry friction shock absorbers with friction discs, developed at the beginning of the last century.

In the 1950s, telescopic piston oil shock absorbers began to be used, the operation of which was based on the principle of fluid friction. Their design, borrowed from the design of aircraft landing gear, is still used in car suspension today.

Shock absorber functions

Front and rear shock absorbers are damping elements of a car's suspension. Working in tandem with elastic elements suspensions (springs or torsion bars), shock absorbers perform the following main functions:

- vibration damping of the car body and wheels

- maintaining wheel contact with the supporting surface

- ensuring smooth running of the car

Automotive shock absorber design

Hydraulic shock absorber design

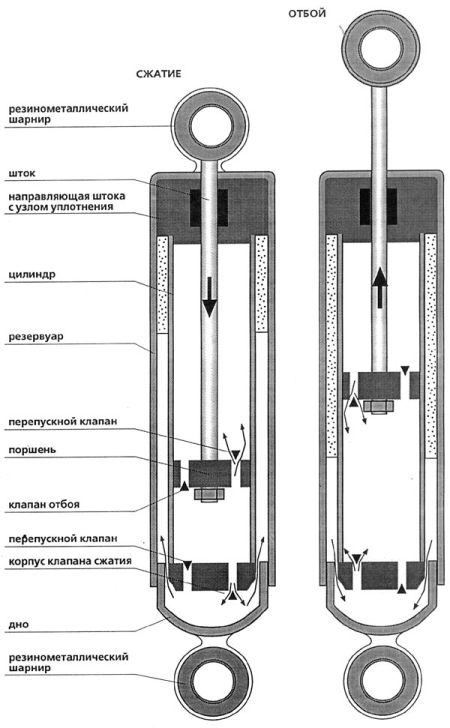

Hydraulic shock absorber design Shock absorbers come in two types: single-tube or double-tube. Its design also depends on the type of shock absorber. Despite this, the basic elements of both types remain common. The shock absorber consists of a cylinder filled with special liquid(oil) through which the piston moves. The piston itself is connected to a round rod, which, in turn, is attached to the car body with its upper part. The piston has small diameter holes (valves) through which liquid passes. In order to increase resistance to fluid flow, they are made spring-loaded. A more detailed description of the design of shock absorbers is given below.

The shock absorber is connected to the suspension arm or axle beam. The shock absorber is mounted through an elastic connection - silent block.

Shock absorber operating principle

Oil shock absorbers operate on the principle of converting fluid friction energy into thermal energy. The moving piston rod forces oil to flow through small valves, thereby creating resistance to its movement. Maximum stroke The rod with the piston is limited by the shock absorber bump stop. The front shock absorbers take up quite a large load, so they are made more reinforced than the rear ones.

Shock absorber classification

Twin tube shock absorber

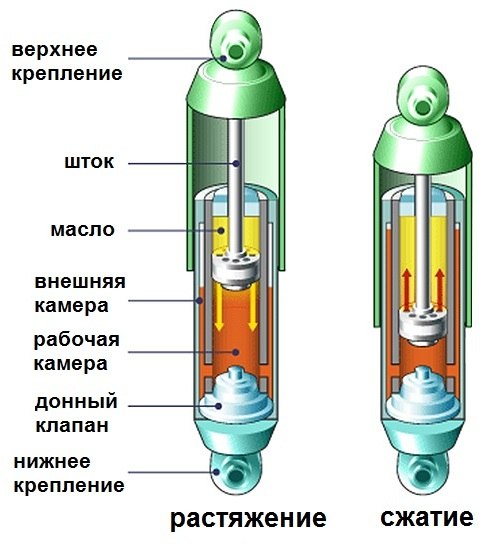

Twin-pipe shock absorber diagram

Twin-pipe shock absorber diagram A twin-tube shock absorber consists of coaxial cylinders, one of which is placed inside the other. The rod with the piston moves in the internal cavity - the working chamber. It communicates with the external one, partially filled with air or nitrogen through the bottom valve. The chamber filled with gas is designed to compensate for the volume of liquid when the rod is immersed.

Advantages:

- simple design and high price manufacturing

- short length

- low internal pressure (even if a small amount of oil leaks through the oil seal, performance characteristics are maintained)

- soft damping of suspension shocks

- better resistance to mechanical damage

Flaws:

- oil foaming after long work and, as a consequence, a decrease in damping efficiency

- insufficient cooling

- installation, storage and transportation of the shock absorber is carried out in only one position - with the rod up

Both front and rear shock absorbers can have a twin-tube design. But still, in most cases on modern cars, twin-tube shock absorbers are installed on rear axle.

Monotube shock absorber

Mono-tube shock absorber diagram

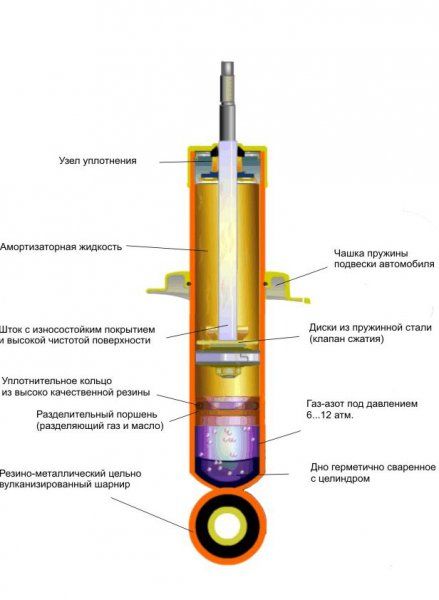

Mono-tube shock absorber diagram Monotube shock absorbers are gas-filled. Their design provides only one cylinder, in the lower part of which there is a chamber filled with gas under a pressure of 2...3 MPa. This chamber is separated from the liquid by a special floating piston and is designed to compensate for the volume of liquid when the shock absorber is compressed. Due to the fact that the gas constantly pressurizes the liquid in the working chamber, during high-frequency operation of the shock absorber, the effect of oil foaming (emulsification) is prevented, and it also becomes possible to install it in any position.

Advantages:

- better damping and stability

- improved cooling compared to a two-pipe system

- possibility of installing the shock absorber in any position

Flaws

- long shock absorber length

- low resistance to mechanical stress

- high manufacturing costs due to the use of higher quality seals and housing materials

Monotube gas-filled shock absorbers are able to withstand severe loads without loss of performance properties. They are mainly used as front shock absorbers.

Adjustable shock absorbers with variable area valve

Adaptive (or adjustable) shock absorbers involve the ability to change damping properties (damping coefficient). Shock absorbers are equipped solenoid valve, the cross section of which changes under the influence of an electrical signal. Reducing the cross-section makes it more difficult for fluid to pass through the valve, increasing the stiffness of the shock absorber. Increasing the valve cross-section, on the contrary, makes it softer.

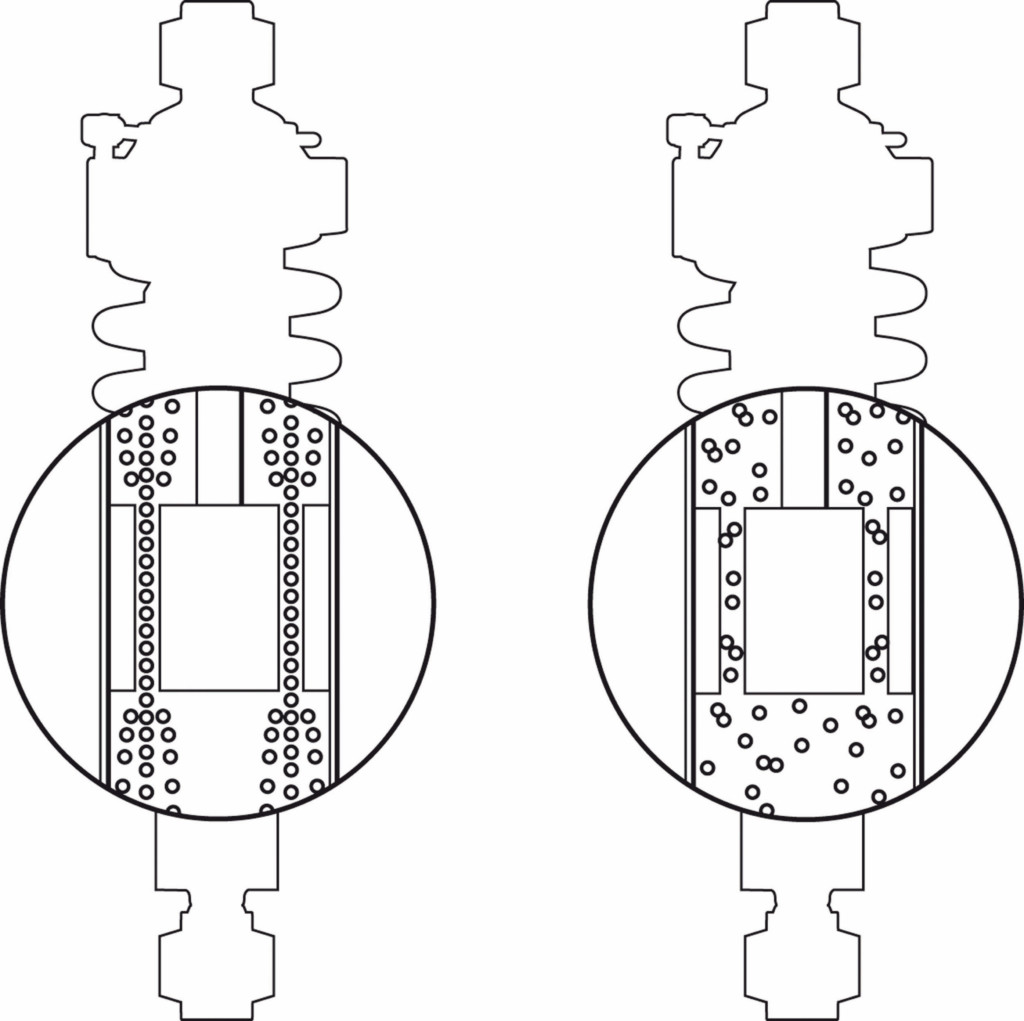

Adaptive shock absorbers with magnetorheological fluid

Scheme of action of magnetorheological fluid

Scheme of action of magnetorheological fluid Adjustable shock absorbers of this type are filled with liquid containing metal particles. This oil changes its structure under the influence of a magnetic field, which is created using coils built into the shock absorber piston. Thanks to magnetorheological fluid, magnetic shock absorbers change their stiffness characteristics in a fraction of a second. The advantage of adaptive shock absorbers is the ability to change the characteristics of the suspension in accordance with current driving conditions: a stiffer suspension will improve the handling and stability of the car, while a softer one will increase ride comfort. Main disadvantage adaptive shock absorber: high cost of its production.

Sports shock absorbers

Sports shock absorbers are designed to operate under extreme loads. They are distinguished by increased rigidity and stability, providing better vehicle handling.

Main faults and service life of shock absorbers

Oil leakage through shock absorber seal

Oil leakage through shock absorber seal The most common malfunction of a shock absorber is a violation of the sealing seal of the rod. This occurs if the shock absorber boot is damaged, and, as a result, dirt gets on the surface of the rod. Damage to the rod seal leads to gas leakage and shock absorber fluid, due to which the shock absorber itself loses its damping properties.

Under normal operating conditions, the service life of shock absorbers can be 3-5 years or more. Front shock absorbers undergo a heavy load, however, on a new car their service life is approximately 100-125 thousand kilometers. Rear shock absorbers usually exceed these indicators.

No matter how expensive and modern car convenience and comfort of movement primarily depend on the performance of the suspension on it. This is especially acute in domestic roads. It's no secret that the most important part of the suspension responsible for comfort is the shock absorber. Therefore, choosing the right ones is the key comfortable trip on your car. Let's look at the structure and functions that shock absorbers perform, as well as what types of them exist today.

General shock absorber device

Structurally, the shock absorber consists of several main components, regardless of type and design. The main element of any shock absorber passenger car serves as a working cylinder assembled in a housing with lugs for connection. It houses hydraulic fluid(a mixture of liquid and gas or only gas). This cylinder also contains a piston, which is attached to a rod. The piston has special compression and rebound bypass valves and o-rings. They allow, when the liquid in the cylinder is compressed due to the movement of the piston, it is pumped into the free cavity of the cylinder.

As a rule, the shock absorber is attached using a rod, and to the suspension with a cylinder. For this purpose, there are special fasteners at their ends - supports. To protect the internal cavity of the cylinder and the rod itself, a protective casing or boot is installed on top of the shock absorbers. And in order to prevent the liquid from splashing out of the cylinder, a special cuff with a guide sleeve is installed in its upper part. These elements are included in both the simplest hydraulic shock absorber and more complex designs. In addition to these, the shock absorber design may differ in a number of additional parts.

Types of shock absorbers and their design

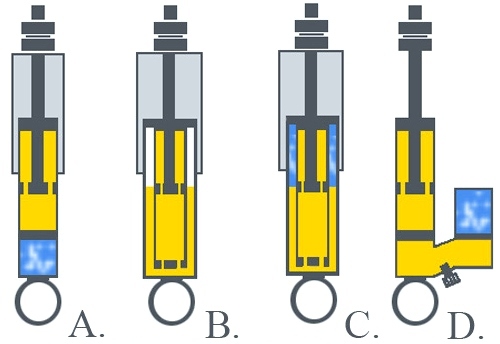

As already mentioned above, depending on the design, the design of shock absorbers can vary greatly. Let's look at the main classes of shock absorbers and their structural differences. First of all, shock absorbers are distinguished by architecture into single- and double-tube.

Twin-tube shock absorbers

Let's start with them, since until recently this design of shock absorbers prevailed on the market. This shock absorber, in addition to the cylinder (flask), piston and rod, has another cylinder in which the flask with liquid and piston is hidden. During operation, the piston compresses the liquid, and it flows through the valve below into the outer cylinder. There, additional air compression is created due to the incoming liquid. This is when the shock absorber is compressed, and during rebound operation (when the piston rises in the flask), due to the opening of the valves on the piston itself, liquid from the outer cylinder again enters the flask.

This shock absorber design, despite its simplicity, has a number of significant shortcomings. First, flow working fluid occurs from one container to another through different air valves at the top of the shock absorber. This causes the so-called aeration phenomenon, when the liquid is partially mixed with air, which significantly reduces its properties. In addition, due to the use of a double casing, such shock absorbers are cooled worse, which again negatively affects their performance and efficiency. Such shock absorbers cannot be installed with the rod down, as this will lead to their incorrect operation.

Monotube shock absorbers

In monotube shock absorbers there is no external cylinder, and the entire process of fluid flow occurs thanks to built-in valves directly on the piston (the so-called De Carbon system). If, in addition to liquid, there is gas in the shock absorber, then it is also located in the upper part of the shock absorber body, separated from the liquid by an additional free-floating piston. Considering the fact that this type of shock absorber does not have lower compression valves, the piston is a complex structure with built-in compression and rebound valves. Sometimes, along with the valves, special grooves and holes are machined. Such shock absorbers due to better cooling more effective . In addition, due to the use of only one cylinder, with the same dimensions, a monopipe shock absorber has a larger volume compared to a double-pipe shock absorber, and this is also a significant plus. And due to the fact that the gas is separated from the oil by a piston, such shock absorbers can be installed with the rod either up or down. This allows you to significantly reduce the unsprung mass of the car.

But there are also a number of disadvantages. The first and most important is the vulnerability of such shock absorbers to mechanical damage. It only takes one dent on the body to make it necessary to replace the shock absorber. Also due to high speed heat transfer, monotube shock absorbers are subject to the influence of external temperature on their characteristics. At high temperature The gas pressure increases due to heating and therefore the suspension works harder; at negative temperatures the opposite is true. However, to eliminate such negative phenomena, manufacturers often move an additional gas and hydraulic chamber outside the shock absorber cylinder. This allows not only to eliminate the strong susceptibility of operation depending on temperature, but also to increase the volume of gas and oil in the shock absorber without changing its size. And also noticeably increase the stroke of the rod.

But that's not all. Some manufacturers, for specific settings of shock absorbers, use special compression valves in the channels through which oil moves from additional chambers to the shock absorber cylinder, similar in design to valves in twin-pipe shock absorbers. This allows you to significantly increase the efficiency of shock absorbers, and also makes available a wide range of settings for such shock absorbers. The number of settings (operating modes) can vary from one to 10. In this case, not only rigidity changes, but also many other parameters: rod stroke length, piston speed, etc.

Hydraulic shock absorbers

In addition to design architectural features, shock absorbers can also differ in filling - the type of working fluid. Until recently, the most common were hydraulic shock absorbers, where . However, recently many leading manufacturers are switching to the production of gas-hydraulic shock absorbers. In addition to liquid, they also contain gas pumped under high pressure (from 4 to 20 atm). Less common are shock absorbers where only gas is pumped inside. The gas pressure inside such shock absorbers can reach 60 atm.

Construction of gas-hydraulic shock absorbers

Considering the widespread and widespread use of this type of shock absorbers, it is worth considering their main design features. The design of such shock absorbers is almost identical to conventional hydraulic ones. Except that gas-hydraulic ones have special gaskets and cuffs that are capable of holding gas inside the shock absorber at high pressure. Often, instead of air, inert gases are used in such shock absorbers, the most common being nitrogen. You should know that the larger the diameter of the shock absorber, the less pressure the gas is in it and, accordingly, vice versa. In addition, depending on whether it is a front or rear shock absorber, the pressure may also differ.

Design features of shock absorber struts

By the way, some shock absorbers can be installed separately from the springs, as, for example, on the classic VAZ. And some are installed together with a spring. This design is called a shock absorber strut. It consists of a shock absorber inside and a spring outside connected to each other by a special fastener. And in this form the rack is installed on the car. , the spring on the shock absorber strut can play either an additional or a major role. In addition, very often the design of the shock absorber strut provides special nut with which you can easily change the height of the stand and therefore change the ground clearance of the car.

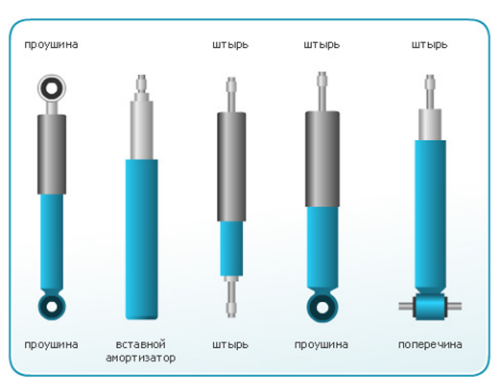

Differences in the design of shock absorbers according to the mounting option

Depending on the car model, shock absorbers in the suspension can be mounted according to different options. The most common mounting options are lug-lug, lug-pin, pin-pin. In addition to these fastening variations, there are also the following fastening schemes: pin-cross member, plug-in shock absorber.

The role of shock absorbers in a car suspension

The shock absorber is designed primarily to dampen vertical vibrations of the car body when driving on an uneven road surface. But this wording for an ordinary motorist means absolutely nothing. After all, the fact that the shock absorber dampens vibrations is good, but why then were they made in so many types and designs if the goal is one. To do this, you should clearly understand in what cases vertical vibrations of the body may occur. This is not only about moving through holes and potholes, but also about maneuvering, especially at high speed. For example, during dynamic acceleration, a large load and the mass of the body shifts to the rear axle, thereby unloading the front wheels, which significantly reduces them. In case of emergency braking the situation is completely opposite. When cornering at high speeds, the weight of the car also shifts to the outside of the turn, which also causes unstable traction of the car's wheels on the road. And in order to minimize this kind of load on different wheels and use shock absorbers of the most various types and designs.

Video - car shock absorbers

Conclusion!

Therefore, when choosing shock absorbers for your car, first of all, you should not be guided by advertising or the manufacturer’s brand. First of all, you need to decide what characteristics your car should have. Be hard and sharp for sporty and dynamic driving, or vice versa soft and rolly for calm and smooth driving. Therefore, choosing a shock absorber is a search for a balance between comfort and driving precision.

The author of the project, a member of the advisory council at the Moscow City Duma, Vladimir Chibirev, spoke about this. According to him, it is proposed to extend the experience of the Eastern Administrative District throughout the capital, where almost all free public toilets have a similar parking lot, reports m24.ru. It is assumed that parking places will appear not only next to city toilets, but also next to commercial modules...

The State Duma approved a bill on deprivation of rights for three traffic violations

403 deputies voted for the adoption of the bill submitted to the State Duma by the government, 40 were against it, and two more abstained, Interfax reports. The document involves entering into Code of Administrative Offenses articles 12.38, according to which drivers who violated traffic rules and received punishment for this three or more times will be deprived of their rights for a period of 1 to 1.5 ...

The Germans made a luxurious office on wheels

Appearance the car has not changed very much: 18-inch wheel disks, bi-xenon headlights and new bumper with LED “whiskers” daylight. Nothing is said about pumping the engine, which, apparently, simply did not happen. But the Germans reported that for a smooth ride they equipped the car with air suspension. But as for the interior, cardinal things happened here...

Data Center: Moscow will stop after the holiday season

As Alexander Polyakov, deputy head of the capital's data center, said, travel time in Moscow will increase by 36% on average due to the end of the vacation period in early September, Interfax reports. Polyakov also noted that the main difficulties will be observed in the period from 7:00 to 9:00 and from 16:00 to 20:00. During the evening rush hour the greatest traffic difficulties will be...

Popular Russian SUV celebrates birthdayLet us recall that Chevrolet Niva- this is the second generation VAZ Niva. At the beginning of the 2000s, AvtoVAZ managed to master small-scale production of a new generation of SUV, but due to insufficient funding, it was not possible to launch full-scale production of the VAZ-2123. In 2002, the compromise was the creation joint venture GM-AvtoVAZ, which received the license for the model, ...

Pokemon Go first became cause of the accident

According to Carscoops, a 28-year-old gamer from Auburn, New York, was hunting for rare Pokemon on his smartphone. He used his brother's car as a means of transportation. Distracted by a game event, the inattentive player drove to the side of the road and crashed into a tree at high speed. Fortunately, the man was not seriously injured and suffered only minor bruises. ...

Today we will look at six crossovers: Toyota RAV4, Honda CR-V Mazda CX-5 Mitsubishi Outlander, Suzuki Grand Vitara and Ford Kuga. To two very fresh new products, we decided to add the debuts of 2015, so that the test drive of the 2017 crossovers would be more...

HOW to order a car from Japan, a car from Japan in Samara.

How to order a car from Japan Japanese cars- top sellers all over the world. These machines are valued for their reliability, quality, maneuverability and ease of repair. Today, car owners want to be sure that the car came straight from Japan, and...

Which cars are the safest?

When deciding to purchase a car, many buyers first of all pay attention to the operational and technical properties cars, its design and other attributes. However, not all of them think about the safety of the future car. Of course, this is sad, because often...

HOW to order a car from Germany, how to order a car from Germany.

How to order a car from Germany There are two options for buying a used one German car. The first option involves an independent trip to Germany, selection, purchase and transfer. But this method is not suitable for everyone due to lack of experience, knowledge, time or desire. The solution is to order a car...

Crises and the financial situation are not very conducive to buying a new car, especially in 2017. But everyone has to drive, and buy a car at secondary market Not everyone is ready. There are individual reasons for this - those whose origin does not allow them to travel...

What cars are most often bought in Russia in 2017-2018?

The number of cars on the roads of the Russian Federation is constantly growing - a fact that is confirmed by an annual study of sales of new and used models. So, based on the results of a study that can answer the question of what cars are bought in Russia, for the first two months of 2017...

Car reliability ratingWhat are reliability ratings used for? Let's be honest with each other, almost every car enthusiast often thinks: the most reliable car– mine, and it doesn’t cause me much trouble with various breakdowns. However, this is simply the subjective opinion of each car owner. When purchasing a car, we...

Rating of the best-selling cars 2017-2018 model yearSince the time of the first steam propulsion device, Cagnoton, created in 1769, the automobile industry has made great strides forward. The variety of brands and models nowadays is amazing. Technical equipment and design will satisfy the needs of any buyer. The purchaseability of a particular brand, the most accurate...

- Discussion

- In contact with

A very sensible article, everything is clearly and competently explained, Thank you.

Hello, dear car enthusiasts! We are so accustomed to comfortable movement in a car, without shaking, without sudden rolls, that we don’t even think about how this comfort is achieved. The answer lies on the surface. In the car suspension, one of the leading roles is played. There are only four small mechanisms, but how important they are for a modern dynamic car.

The shock absorber is the device on whose “fragile shoulders” a number of the most important tasks: softening shocks when driving a car, damping (suppression of mechanical vibrations), influence on the braking and acceleration dynamics of the car, and so on.

Have you ever wondered how and why the design of a shock absorber, a seemingly simple pipe, allows it to perform the task of constant contact of the car’s wheels with the road? No? Let's take a look at how a shock absorber is designed for information. Maybe this knowledge will help you with...

Features when choosing shock absorbers

When choosing shock absorbers, your task is to pay less attention to the brand. The operation of a shock absorber involves many nuances that need to be taken into account when purchasing and installing a shock absorber.

- Selecting the type of shock absorber that provides the optimal balance between comfortable overcoming road irregularities and vehicle handling.

- Heat generation (heat removal). The stiffness of the shock absorber is affected by high viscosity working fluid and a reduction in the bypass holes of the piston, which accordingly increases the temperature during operation of the shock absorber.

- Aeration when mixing working fluid and gas located in gas-assisted shock absorbers. Disadvantage - when mixed, foam is formed, which, unlike oil, compresses, thereby reducing the damping efficiency of the shock absorber.

- The position of the shock absorber directly affects damping efficiency. Most best option shock absorber location – vertical with minimal angular deviation.

General classification of shock absorbers for the consumer market:

- By design: single-tube and double-tube shock absorbers.

- By filling with working substance: hydraulic (oil), gas (with hydraulic gas boost). Moreover, there are only gas shock absorbers(gas pressure 4-10 atmospheres), but they use little demand at the consumer.

The main parts of shock absorbers of all types, taking into account design features, are:

- housing with fastening eye.

- shock absorber cylinder,

- shock absorber rod complete with casing and mounting eye,

- piston and compression and return valves and rings

- shock absorber spring,

- sealing elements

The most effective shock absorber is a double-acting shock absorber - a hydraulic double-acting shock absorber.

The basis of the shock absorber is the internal working cylinder, which contains shock absorber oil (hydraulic fluid).

When compressed, as the shock absorber rod moves in, hydraulic fluid is pumped through a valve on the shock absorber piston. The working cylinder contains a rod with a piston, which has a valve system. At the bottom of the working cylinder there is a compression valve connecting the intra-cylinder cavity with the cavity located between the shock absorber body and the working cylinder.

- Shock absorber rod – the most important detail shock absorber Its outer surface is made of polished chrome. To protect the rod, a shock absorber boot is installed, which prevents foreign particles from entering the rod mirror. If the rod mirror is damaged (delamination of the chrome coating, chips), rapid wear cuffs And, as a consequence, loss of shock absorber tightness.

- To center the rod relative to the body, a shock absorber guide bushing is used. Structurally, the bushing is pressed into the shock absorber body.

The shock absorber strut support is used to attach the shock absorber to the car body. In addition, the shock absorber mount is designed to improve the connection between the shock absorber and the vehicle chassis.

The shock absorber support bearing and the shock absorber bump stop (rubber gasket) are the main parts of the support. You can determine the failure of the shock absorber support yourself: visual inspection, or when the car moves on uneven roads, dull impacts are heard in the body.

A feature of the shock absorber design for passenger cars, is that the rear shock absorber is more powerful compared to the front shock absorber. This is due to the calculation full load trunk (rear part) of the car. If one shock absorber fails, as a rule, both shock absorbers on the same axis are replaced. Shock absorbers are repaired, but modern shock absorbers are basically non-separable. Therefore, you only need knowledge of the shock absorber structure for information.

The shock absorber design fully complies with the functionality of the suspension, ensuring comfortable movement on roads with different surfaces and conditions. The main unit is a cylinder with a piston, bypass valves. The reliability of contact between the wheels and the road depends on the composition of the mixture filling the cylinder. There are hydraulic, hydropneumatic modifications that duplicate the mechanical spring, which is present in some models. “Soft” suspension is necessary for uneven roads, while “hard” suspension better holds the car on the road in the urban cycle.

Twin tube shock absorber

The two-pipe type rack structure is predominant in the market. When compressed, the hydraulic mixture flows from a cylinder of a smaller diameter to a larger one, compressing the air located there. During the rebound, the valve opens and the liquid returns to the inner flask. The main characteristics of the oil/gas used to fill the flask are incompressibility and viscosity.

The disadvantage of the scheme is the excessive saturation of the mixture with air, since it flows from cylinder to cylinder through different valves(the phenomenon of aeration). When the machine moves, mechanical energy (body vibrations on road unevenness) is converted into thermal energy (expansion/compression of the hydraulic mixture). The double case is cooled worse, therefore, this device the shock absorber is not effective enough. Twin-pipe models cannot be installed with the stem in the lower position as this will guarantee incorrect operation.

Monotube rack

The monotube type shock absorber differs from the previous version by valves built into the piston (De Carbon system). When using a hydropneumatic mixture, the gas is separated from the liquid by a floating piston. Cooling of this design is more efficient, however, the design of the valves becomes more complicated. In certain modifications, holes and grooves are used. A car using this shock absorber device holds the road more confidently. With the same dimensions, the single-pipe model has a larger working chamber volume. Gas separation by the piston allows any installation options (rod up/rod down). Wherein unsprung mass the car decreases.

The disadvantages of such a stand are:

- vulnerability - the unit is sensitive to mechanical damage, any dent in the body guarantees the need for replacement

- intensive heat transfer - single-tube struts are dependent on the ambient temperature, the characteristics change in different weather, the suspension becomes softer in cold weather, harder in hot weather

To improve the characteristics of the shock absorber, manufacturers use the displacement of the hydraulic and gas chambers outside the cylinder. Thus, without changing the dimensions, the volume of the working mixture increases, the dependence on the weather disappears, and the stroke of the rod increases. Compression valves installed in the oil passages allow you to change/adjust operating modes (speed, rod stroke length, stiffness).

Hydraulic shock absorber

Despite simple diagram shock absorber, it can change the characteristics due to additional built-in components. Each brand of car has individual characteristics, therefore, the racks must take into account vibration amplitudes, driving modes, and driving style. At closed valves, when the fluid moves through the bypass channel, an absolutely rigid system is obtained. The open valve of the compensation chamber adds “flexibility” to the system. Different intake sections, exhaust valves create an asymmetrical system. Center valves on the piston create a non-linear "soft" strut system.

Gas-hydraulic shock absorber

The design of this car shock absorber has slight differences from the previous version. Gas under high pressure is held inside by cuffs and gaskets. Instead of air, manufacturers use nitrogen or other inert gases. Smaller diameter racks are filled with gas high pressure, and vice versa. In addition, the gas pressure of the car's shock absorber in the front and rear units is also different. On the classic VAZ, the springs are installed separately; on other models, the struts are assembled into one unit with an external spring location and a special fastening. In this case, the spring is not always the main element of the unit, but only duplicates the hydraulics.

The height of the stand is adjustable with a nut, allowing you to change the vehicle's ground clearance. The following mounting of the car shock absorber to the body and suspension is possible:

- eye/eye

- pin/pin

- bottom eye/pin

- bottom crossbar/top pin

- plug-in shock absorber

The first three options are most often used, as they are the most convenient to install.

The role of a shock absorber in a car suspension

The unit is designed to dampen vibrations of the car body (vertical). They occur when driving on uneven roads, dynamically accelerating, or sharp braking. Turning at speed reduces tire traction. The variety of designs and mixture compositions is due to different operating conditions of the vehicle. An increase in the viscosity of the liquid used leads to increased “hardness” and increased heat generation.

Car shock absorber or so-called “amort” - special device in the suspension of a car, the purpose of which is to reduce mechanical vibrations (damping) when driving or completely absorb them.

Photo gallery:

The role and purpose of shock absorbers in a car suspension

Shock absorbers give a soft and smooth ride to the car, and also protect the elements of the chassis from the loads that arise as a result of driving on an uneven road surface. Automotive shock absorbers are used as part of the elastic elements in a car suspension together with springs, torsion bars and leaf springs.

Shock absorber device

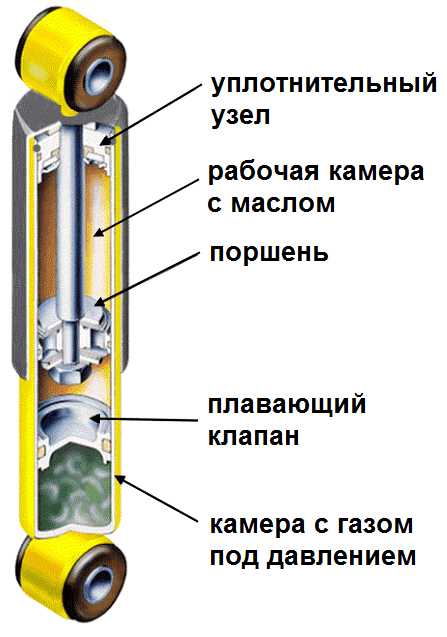

Car shock absorber consists of: seal assembly, car suspension spring cup, rod with wear-resistant coating and high surface finish, compression valve, o-ring made of high-quality rubber, separating piston, rubber-metal all-vulcanized hinge, hermetically welded bottom, shock-absorbing liquid and gas, flask and piston.

Types of shock absorbers

Types of shock absorbers: A. - single-tube gas, B. - double-tube oil, C. - double-tube gas, D - gas with remote chamber

Types and design of shock absorbers

By constructive solution shock absorbers are distinguished:

- With two-pipe working chamber. The principle of operation of this type of shock absorber is that the piston located in the inside of the flask moves when it oscillates, passing shock-absorbing liquid through special channels and squeezes out some of the liquid (oil) through the compression valve;

- Monotube shock absorbers. This type of design consists of a working cylinder and a housing at the same time. In such a shock absorber, liquid and gas are located in the same cylinder with the piston. IN this type There is no compression valve, as in a two-pipe one, so the piston does all the work of controlling the resistance during compression. Monotube shock absorbers hold the car more accurately road surface. Shock absorbers with a separate gas compensation chamber located outside the shock absorber in a separate reservoir are also under the guise of a single-pipe type.

Problems with shock absorbers

Car shock absorber struts have several main reasons why they fail - these are incorrect installation and violation of operating rules. Mostly, inexperienced car owners may forget to tighten the nut, place the removable cups upside down, forget to install boots, damage the shock absorber rod with pliers, etc.

Problems that you most often encounter:

Ways to identify problems with shock absorbers and solve them

There are a lot of reasons why a shock absorber is damaged. So, for example, a rupture of the oil seal can be caused by damage to the chrome coating of the rod or its corrosion. In the practice of car repair, there are several ways to do this.:

shock absorber diagnostics Failure shock absorbers can cause rapid wear of the mechanical components of the car: suspension springs, steering mechanism, differential, rapid wear of tires, rapid failure rubber bushings pendants, wheel bearings

, suspension and CV joints.

Units that are adversely affected by faulty shock absorbers

Importance of shock absorber in car suspension