Another 20 years ago, the drive on the rear wheels for conventional road vehicles was recognized as world grandi as the most reasonable and reasonable decision. In the early construction of freight and passenger cars for a long time, a chain transmission, easier and economical for low speeds and modest loads. But with a sharp increase in the weight of the car, the speed of its movement and power of the engine of the chain showed a low transmission efficiency and were replaced with the "Cardan - rear axle reducer". The modern gearbox easily carries 300-400 thousand km, subject to the use of high-quality transmission oil and proper transmission adjustment.

Rear axle reducer performs three main tasks:

For your information! The overwhelming majority of the rear axle reducers of modern rear-wheel drive cars have almost identical construction of the design of the mechanism.

The appearance of the gearbox can scare its intricateness, but the system is based on two simple mechanisms related to each other - the main transmission and the satellite differential system.

In the hyperships in the back bridge, the differential lock system can be additionally installed, which allows you to turn off the buxying wheel.

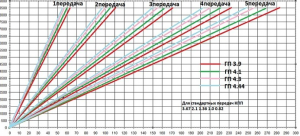

The parameters of the rear axle gear are as important for the dynamics of the car, as well as correctly selected PPC numbers. For various modifications of one brand of the car, this is well noticeable on Soviet vases, the manufacturer used a different gear ratio of the rear axle reducer. Value ranged from 3.9 to 4.22. The higher the transmission rate of the gearbox, the more dietar than the car accelerated at the beginning of the movement, with small values \u200b\u200bof the gear ratio, the machine perfectly accelerated in high-speed mode and had a mediocre dynamics at the start.

To estimate the characteristics of the machine, it is important to understand the question - how to find out the transfer value of the rear axle gearbox. For this, enough:

- post on the jack any of the wheels of the rear axle of the machine;

- make notge white paint on the cardan shaft;

- install on the CAT neutral gear;

- turn the wheel of ten complete revolutions, at the same time counting the number of revolutions of the cardan shaft.

The number of curl revolutions, divided by 10, will give the desired transmission of the rear axle gearbox.

The technical characteristics of the Gazelle rear axle reducer are indicative. The passenger gas 2705 or the on-board gas 3302 was established a reducer of the rear axle of classical layout - the main transmission of hypoid engagement with a gear ratio of 5,125 and a conical gear differential. For auto with the formula of wheels 4x4, a gearbox was used with a gear ratio of 4.3, and for fans of high-speed options - from passenger gas 33105 with a transmission of 3.5.

![]()

Features of the gearbox design

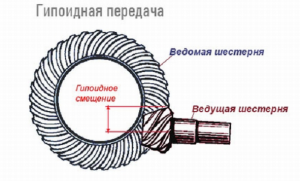

In the design of the node, the magnitude of the gear ratio determines the parameters of the main transmission, called the rear-axis reversing gearbox. This is a regular gear, consisting of a smaller smaller gear and larger gear. The unusual view of the gear and gear is explained simply - this is the most effective way of engagement using a spiral teeth of hypoid engagement. Without going deep into the theory, it can be added that the use of conventional gears would increase the overall dimensions of the gearbox at least twice. In the hypoid gear, several teeth are adhesive simultaneously, which reduces the contact load on them.

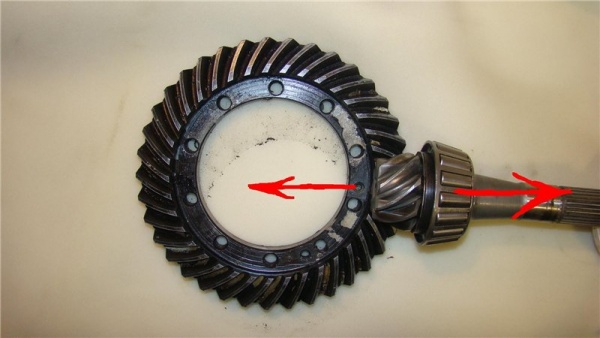

The pair of gear-wheel is carried out by the plant with the selection of individual gearing parameters, so it is not recommended to change them in an arbitrary order.

According to the scheme, it can be seen that the axis of rotation of the drive shaft from the gear is shifted below the main axis of rotation by the value of the so-called hypoid displacement, due to which its bearings are in a semi-loaded state, are intensively lubricated and cooled.

Remove and adjust the gearbox

The main problem with which motorists faces, if necessary, repair or restoring the reducerbility of the gearbox, is the correct selection of gear ratio and adjustment of the gearing gap. Therefore, it is necessary to dismantle the gearbox, check the degree of wear of the main transfer and regulate.

The most frequently recommended way to check the state of the rear axle gear is noise when switching to increased and then reduced transmission. In the absence of distinguishable knocks or noise in the rear axle, braking the engine from a speed of 60-70 km / h to a complete slowdown.

Under the action of the inertia of the movement and the gear of the differential, linked with the semi-axles, are spinned to large revolutions differential and the drive wheel in the shank. The presence of a hum or noise indicates unfortunate gaps in gear gear. The sound published by the "problem" bearings will appear with an increase in the speed of movement regardless of the transmission load.

At the end of the shank of the rear axle gearbox is a flange connection with a cardan shaft. The dismantling of the gear is usually starting with the removal of the fastening bolts.

Tip! Before removing the cardan, be sure to put the mark on the flanges, it will help to choose the correct position of the cardan shaft on the shank.

Before removing the gearbox, preparatory operations are performed:

- clearance is measured under the rear axle crankcase;

- the bridge of the car rises by the jack, the rear wheels are removed, after which it falls on the supports at the level corresponding to the magnitude of the clearance measured in paragraph 1;

- remove the cardan shaft. Having unscrewed the lower tube and the level control plug, the oil from the rear axle crankcase;

- the mounting of the semi-axes on the hubs of the rear wheels is taken, the semi-axes are extracted from the "stockings" of the left and right side of the rear axle cooked with the central crankcase in a single design;

- having unscrewed the bolts around the perimeter of the fastening of the gear body to the Carter of the bridge, neatly, trying not to damage the gasket, remove the heavy mechanism.

Attention! In some cases, for centering the position of the gear housing relative to the crankcase, instead of centering pins use a pair of fastening bolts, the holes of which are made with increased accuracy.

In the presence of traces of deep wear, chip or painting of metal particles, it is necessary to replace the problem details. Additional attention should be paid to the presence of tight pins of satellite shafts. With frequent braking, the engine is precisely the pins are destroyed first, which leads to the displacement of the shafts and the destruction of the satellites of the differential.

Adjusting the rear axle gearbox

Strong low noise or hum in the rear axle gearbox is the first and main reason for which the decision is made to dismantle, adjust or repair. Few people pay attention to the shank or ventilation hole of the lubricant drops through the gland.

To check the reasons and solving the issue - how to eliminate the hum in the rear axle gearbox, it is necessary to check the presence and lubrication level, unscrewing the oil level control plug on the bridge crankcase. Do not rush to top up the oil into the rear axle gearbox - if there is no complete confidence in quality, drain it, rinse the cherosin crankcase and fill a good transmission oil with anti-shine additives. Operational norms provide for oil replacement every 30 thousand km.

By the way! The hum occurs when heating the rear axle reducer to high temperatures, which often happens when driving in a heat with large overload. Superheated oil loses viscosity and ability to remove heat. If the gearbox threw "on the cold" - there is no lubricant in the crankcase or the gear displacement occurred.

Which oil is better pouring into the rear axle gearbox? Use GL5 transmission oil, 90W viscosity for warm weather and small cold weather, and 80w - for strong frosts. But, in any case, you should adhere to the recommendations of the Specification of the operational liquids of the car shown in the repair and operation manual.

If the oil replacement in the rear axle gearbox did not remove the hum, it is removed and exposed to adjust. The economy and resource of the rear axle gearbox is determined by the mutual location of the leading and driven gear gear. Confirmation of the correctness of the contact of the leading gear and gear tooth is the form and location of the contact spot.

In a properly adjusted mechanism, the contact location is located in the center and is evenly distributed almost all over the surface of the gear tooth. To visually determine the quality of the engagement:

- on the gear wheel apply an easy-to-wave emulsion paint, usually white or red,

- collect the main gear in the gearbox housing;

- wash the wheel and evaluate the spot of contact.

If the spot is shifted to the outer part of the gear wheel for direct stroke and to the inside for the reverse, under the head of the drive gear, an additional metal gasket is installed, thereby bringing it to the slave gear. The gaskets are cleaned or replaced with thinner, if the contact zone in direct transmission is shifted to the center, and the rear to the outer part of the gear. As a rule, the manufacturer's plants are used 17 sizes with an interval of 0.05 mm, a total thickness of 2.5 to 3.4 mm.

In the rear axle gearbox, the bearing is a conical, single-row, fixed in the locking nut and filled with a consistency lubricant, designed to work until the first overhaul.

The main problems of the rear axle gearbox

Significantly reduced resource and reliability of the reducer operation, if:

- the frequency and timing of the replacement of transmission oil is disturbed, which can lead to increased wear of the working surface of the teeth;