The transition from the rear to the front drive demanded from automakers to develop new technical solutions that would allow to effectively transmit rotation on the wheels even at the maximum corner of turn. The traditional cardan shaft, applied on rear-wheel drive cars, could not cope with this task, due to the limited angle of rotation of the hinge and high losses. Taking the scope of the cardan hinge as a basis, car manufacturers improved it, thanks to which the loss decreased and the angle of rotation increased. So the hinge of equal angular velocities appeared (Solus), which is often called a grenade.

How the glus is arranged

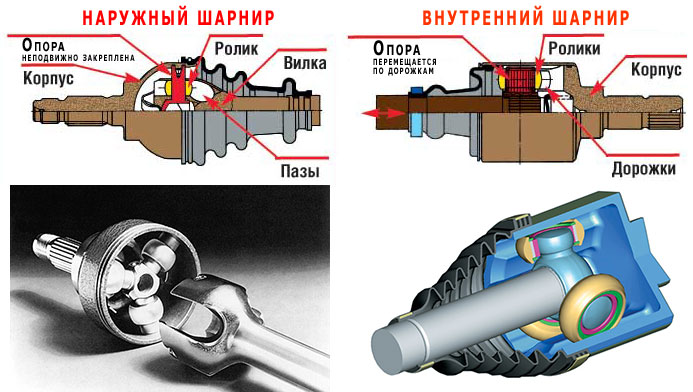

Most of the passenger cars use a "flipper" type hinge (sometimes it is called "six-walker"), consisting of an inner and outer clip with grooves, separator and six balls. This design works well even on high revs and the most turned movies. Another type that was distributed in some Japanese models is called "Tripod". The three-beam star is fixed in the hull of the tripode, on which spherical rollers are installed. Rotation to the hinge enters the plug inserted into the housing with spherical channels for rollers. The lack of a tripode is a small angle of changing the axis of rotation of the hinge, however, the possibility of axial movement allows them to be used as an internal silver.

Drive Vala device

Solmin itself can not transmit rotation from the gearbox to the wheels, so the drive shaft is necessary. The base of the drive shaft is a steel tube that connects the internal and external shrus. The internal Slus is constantly working at an angle of rotation of 10 - 30 degrees. The same angle of rotation and the outer Sls with a straightforward movement forward. When the wheels rotate, the angle of operation of the outer screen increases up to 60 degrees. When the car moves along the uneven surface, the distance from the outer to the inner Slus is constantly changing. Therefore, the shaft, on which the two hinges of the type "DzPPP" are installed inside the hinges in such a way that when the distance changes, it moves inside, or vice versa, extends outward. Therefore, the use of the shaft on which the outer-type outer hinge is installed and the inner type "tripoda" allows you to firmly fix the pipe, increasing the total strength and reliability of the shaft. However, the manufacture of such a shaft is more expensive than with the two "disc" hinges ", so it does not apply it on budget vehicles.

Video - Principle of operation of the drive front shaft with a screen

Malfunction and diagnostics Sls

- Damage to the anther.

- Drying or lubrication contamination.

- Wear balls or rollers.

During driving from under wheels, small stones fly out that can break the boot shrus. When this happens, dust and dirt begins in the lubricant. As a result, the lubricant turns into an abrasive substance that destroys the balls, rollers and other internal parts of the hinge, leading to its breakdown.

Due to the hub in the lubricant, when driving at high speed, driving parts of the hinge are heated to hundreds of degrees. This temperature changes the properties of the lubricant, leading to its drying. The operation of a hinge with a dried lubricant leads to strong wear of the parts and after 3 - 5 thousand kilometers there comes critical damage, after which the hinge cannot be repaired and it is necessary to change it.

Diagnostics Sls can be divided into two stages. The first is performed every 3 - 5 thousand kilometers. If you have to drive off off-road or dirt roads, then each 1000 kilometers. For such diagnostics, it is necessary to drive a hole or flight, or raise the car on the lift. If there is no such possibility, the diagnosis can be carried out with the help of 2 jacks. How to raise a car with jacks and the necessary security measures are described in the article.

Having lifted the car in front or rear, carefully inspect the anthers of the exterior and internal pomegranate. Machine the wheels to explore the boot from all sides. If cracks, spoins or breaks are detected, it is necessary to remove the drive shaft to change the anthers and check the lubrication status and the details of the hinge.

The second stage of diagnostics is carried out if suspected damage or click on the movement with a fully turned into any side of the steering wheel. The drive shaft is removed from the car to check the status of the Sls details. About how to do this, read in the article (drive shaft). This procedure is the same as on Russian cars of the VAZ family and in most foreign cars.

Removing the shaft, turn the hinge in different directions, then try to fold with an angle of 30 - 40 degrees and rotate it, holding one hand for the pipe, the other for the slave shaft outdoor or the leading shaft of the internal shrus. Competitive hinge rotates easily, without clicks and hotels. Keep the drive shaft with one hand, and the other is lightly try to check the slave or leading tree Sls. Even a small backlash indicates the need to replace the hinge. Remove the boot with the Sls and inspect the lubricant. If it has pieces of sand or dirt, the lubricant must be changed. If the externally lubricant looks clean, with two fingers, take a little lubricant next to the ball or roller. Distribute grease between your fingers. Clean lubrication is easy to unlock, making your fingers smooth, so you will easily feel even a little contamination.

Repair shrus

Repair Sls consists of two operations - and replacement of lubrication.

To replace the boot, you must remove one of the hinges from the wired shaft. If the hinges of both types are installed on the drive shaft, it is easier to remove the inner (tripoid). Remove the locking ring and remove the pipe with a three-beam star planned. Remove the lock ring holding the star and use the hammer and the bronze slope to run it from the tip of the pipe. Similarly, disassemble the hinge of the type "Dress". Sometimes the top of the hinge is removed hard, in this case turn it into any side to the maximum angle and pull the balls one by one. Then remove the locking ring from the inner cutting and knock it down from the tip of the pipe. Build in reverse order.

To replace the lubricant, remove the locking ring that holds the internal details of the hinge, then disassemble it. During the replacement of lubricants, carefully inspect the grooves and balls (rollers). If scratches are detected on them, then the hinge is preferably replaced. After all, even with a new lubricant, its mileage is unlikely to exceed 10 thousand kilometers. If you find cracks or chips on the separator, the hinge must be replaced, even a new lubricant will not be able to make it properly work. Detailed installation of the drive shaft on the car is described in the article.