When operating a car, as a result of the wear of the elements, a large free move of the clutch pedal may occur, the reason for which, as a rule, is to erase the friction linings of the disk or the violation of the adjustments of the leverage of the casing. Alone to eliminate these faults is quite simple. About this further in the article.

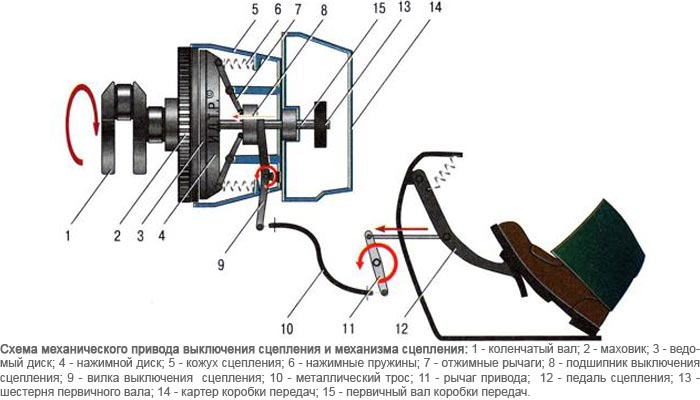

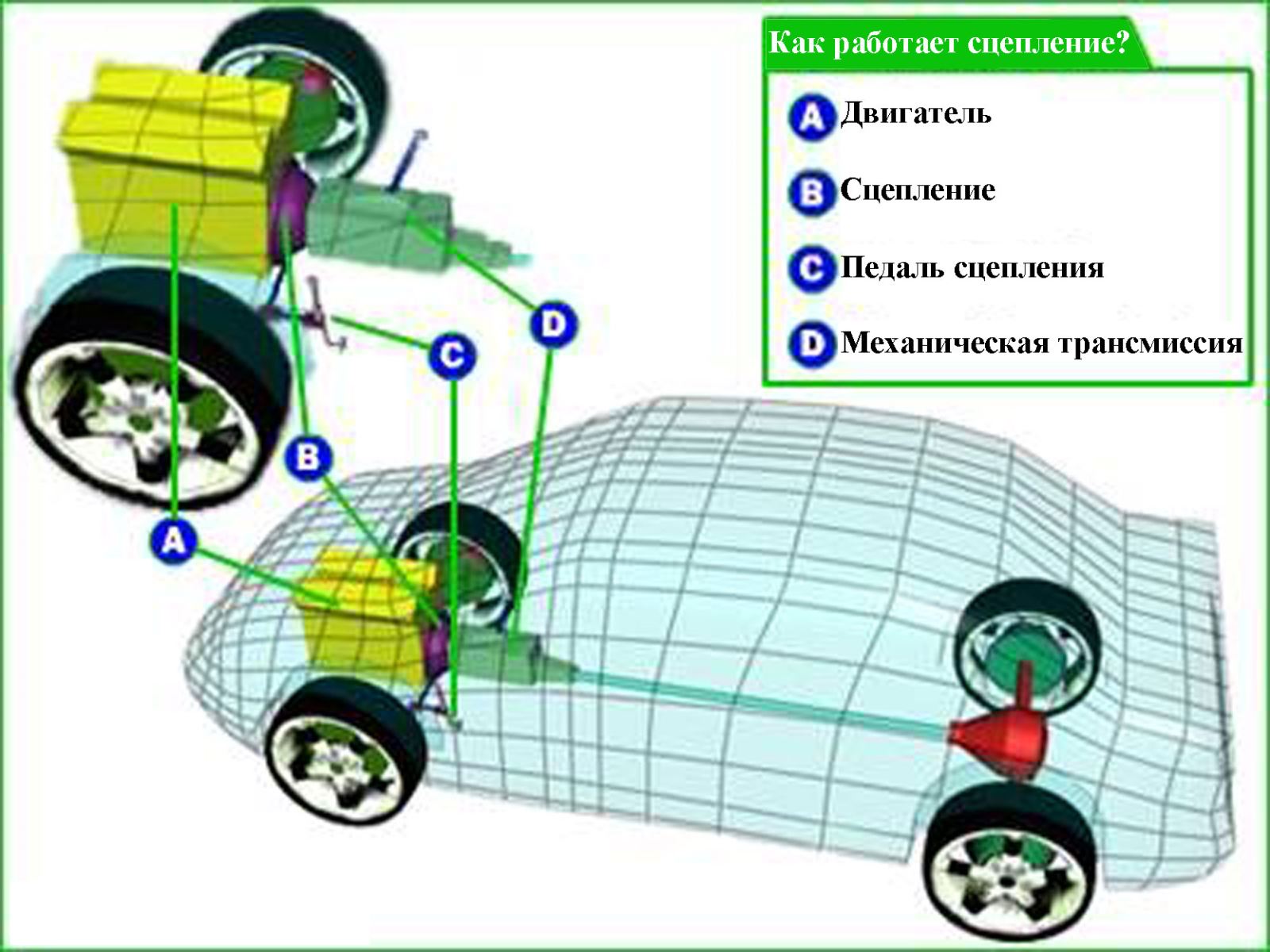

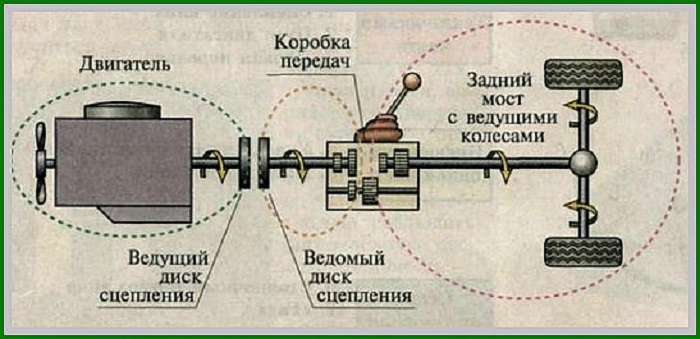

This device is placed in the housing, which is set between the checkpoint and the power unit. In it, the PPC includes a leading shaft, and from the motor side - the flywheel. In addition, the flywheel includes a terminal of the leading shaft to comply with the accuracy between the drive shaft of the PPC and the crankshaft.

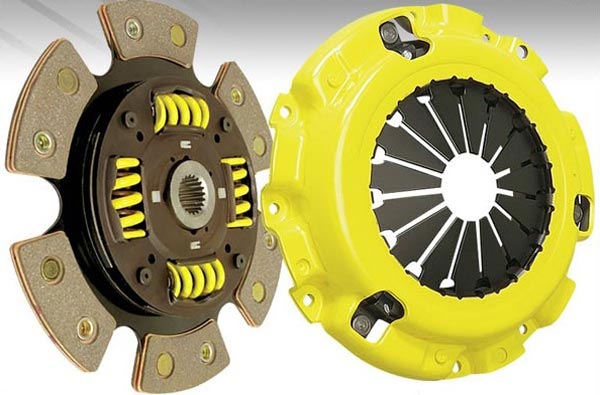

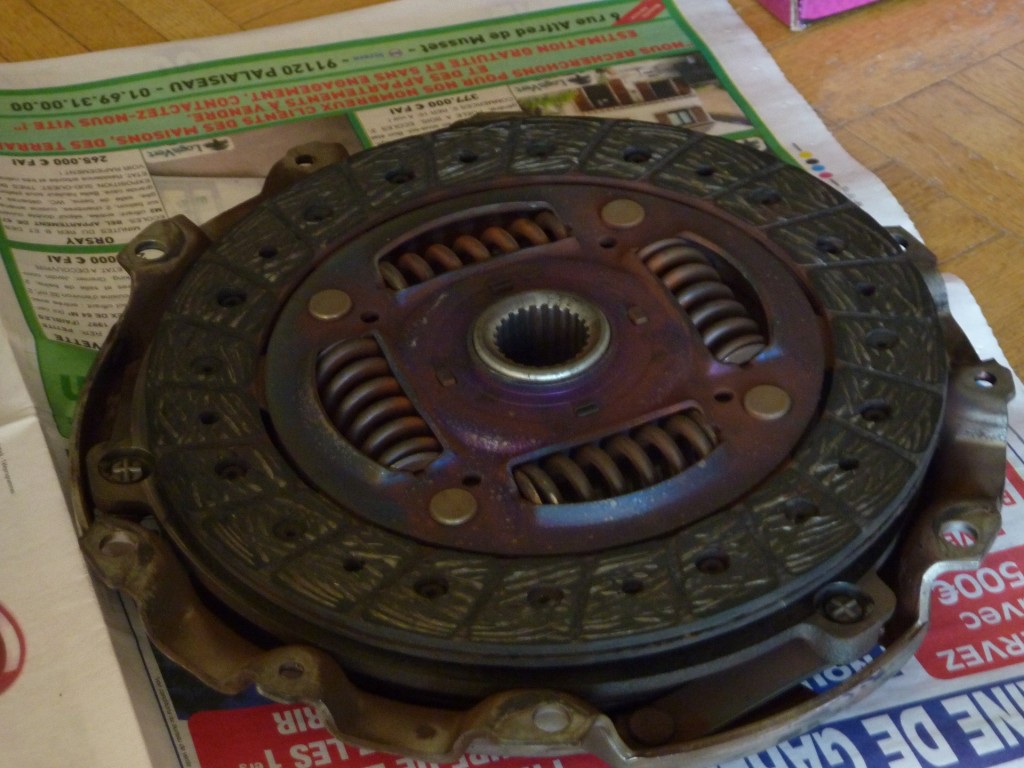

The main element of the clutch is a basket in which the drive disk is located. This disc is spring-loaded, but it has the ability to longly move through these springs, as well as levers. In passenger cars, the membrane spring is connected to the levers.

A basket with a bolted joint is rigid to the flywheel. A slave disk is placed between them. The PPC shaft protrudes the axis for this disk, while they are associated with the help of slots along which the disk moves.

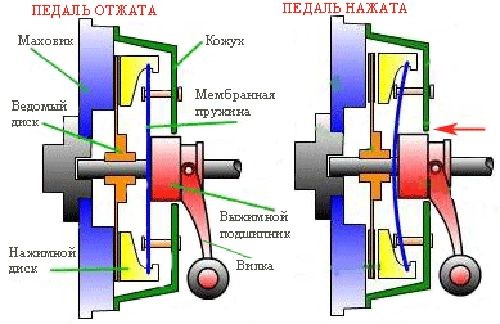

The principle of clutch work

Since the basket is firmly fixed on the flywheel, it perceives the torque of the motor in full. However, it is not connected with the box, as a result of which it does not transmit this moment. But the driven disk is connected with the checkpoint, as it is planted on the leading shaft. To transfer the moment, it is necessary to strongly clamp the slave disk between the flywheel and the drive disk, for which the springs are replied, which are pressed the drive disk.

If necessary, in the separation of the engine and the checkpoint, it is necessary to affect the springs that the drive disk is pressed. As a result, the effort is reduced, and the disc, departing, ceases to press the slave disk to the flywheel - the moment transfer is no longer produced.

In other words, to disconnect the motor from the PPC, you must act on the spring of the drive disk, for which the design bearing is suitable. And it is located behind the basket on the drive shaft of the checkpoint. Navigating the flange, the release bearing affects the springs of the basket, however, for this, it is necessary for this effort to overcome their resistance. This effort is taken from the foot of the driver, pressing the clutch pedal. Its effort is transmitted to the bearing by the drive system and it enters work.

Clutch disk wear, reasons

At the heart of the clutch work is the strength of friction between different materials, and in the case of cars - friction linings and metal. However, where friction exists, there is also elevated wear. In particular, it increases at the start of the car when the CAT connection is made gradually.

All this over time leads to the wear of the main elements of the clutch, especially the disks, there is a decrease in their thickness, and the movement of the output bearing and disks increase. As a result, the grip is experiencing enhanced wear, which leads to the absolute wear of the slave disk and, accordingly, to the need for its replacement.

When changing the clutch

To know exactly whether the clutch is worn out, turn on the third or even fourth transmission, after which when 50-60 kilometers per hour moves and with a squeezed clutch strongly push the gas pedal. If the motor will gain momentum, and the speed of the car, and it will not match, then the grip is worn out. The motor will issue excessive revisions due to the weak contact of the clutch with the flywheel.

It is not recommended to get behind the wheel of a car with a worn clutch, as an increase in fuel consumption and a significant loss of power will be observed. In addition, the worn clutch at any time can break it completely, which does not exclude the probability of breakage at the most inability time.

Clutch adjustment, why do you need to do clutch adjustment

As a result of disks wear, a change in the bearing stroke and disks are changed. That is why it should be periodically adjusting the clutch to remove the formed clearances.

The free stroke of the clutch pedal, what is the magnitude of the free turn in the normal car

Even with optimal clutch operation, the froze the free move of the pedal must be performed at least once a year. With a working clutch, this move should be 30-35 millimeters, regardless of the type of drive - hydraulic, cable or mechanical.

The change in the size of this progress, as a rule, depends on the manner of driving a motorist. With an aggressive manner when the clutch is actively used, the wear of friction linings and disks are carried out faster.

The free move of the clutch pedal, how to measure the free course of the pedal on your car, in detail

Checking free travel is carried out by the usual line. One of her edge rests in the floor, the second is substituted to the pedal. Next, slightly click on the pedal, performing a sample of all gaps. The pedal, while moving without resistance. When the gaps are selected, the movement of the pedal will begin to prevent the springs of the basket and resistance will appear. This turn and must be measured before the start of resistance, it should be 30-35 millimeters.

Adjusting the free move, step-by-step instruction

On all cars with different clutch drives, adjustment is carried out in one place - the point of connection of the drive and the bearing plug, for which there is a thread with two special nuts on the pins of the working cylinder, thrust or cable. With this pin, the drive enters the plug and fastened with nuts.

Therefore, the adjustment of the free move is produced by changing the length of the entrance to the eye of the fork. It is enough to weaken the lock nut and with the help of the second nut to change the length of the pin input by unscrewing or twisting the nut. After that, one more measurement of the length of the free stroke is carried out. If it corresponds to the norm, the adjusting nut should be plugged. If the gap is inconsistent, it is necessary to further be adjusted.

To check the clutch operation, press the clutch pedal several times, the motor, wherein it must be turned on. Pedal should not eat. Extraneous noises should be absent - creaking, grind, knock and more.

Next, run the motor, maintaining it at idle. Then squeeze the clutch and turn on the rear gear. If a crunch is observed or any other sharp distinct sound, it means that the pressure or driven dick clutch is faulty. If the transfer does not turn on at all, then the adhesion failed and need urgent repairs.