Camshaft position sensor (Other name - phase sensor, English abbreviation - CMP) is designed to determine the angular position of the camshaft at a certain period of time. Information that the sensor forms is needed to control the injection and ignition system. In particular, the injection takes place only in one cylinder, which is in the upper "dead" point.

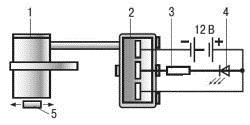

1 - switching switch of the switchgeal sensor, 2 - Hall sensor

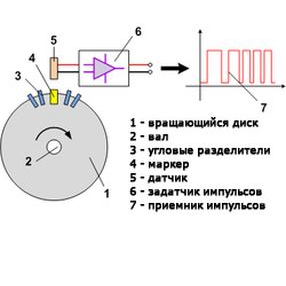

The camshaft lines sensor transmits information on the recognition of the cylinder and / or the number of revolutions of the camshaft on the control unit. It is also used for injection systems with a serial injection mode and / or for ignition systems without a distributor with single-bar ignition coils. The sensor probes the pins, teeth, gear discs of a pulse sensor or a sensor discs, reinforced on the camshaft or on the camshaft drive.

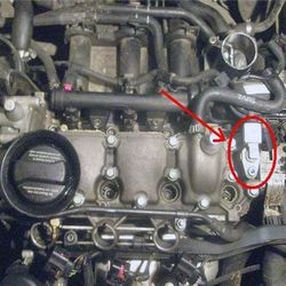

Where is the camshaft position sensor

On most DPRV machines are in the area of \u200b\u200bthe cylinder head. To find it, you need to focus on the position of the camshaft. It can be on the left or right side of the engine. The location of the camshaft sensor varies depending on the brand and model. It is usually located near the top of the belt location or in the protected parts of the wiring located in the front of the engine. Also, sometimes the sensor is installed in the rear of the GBC. Some automakers install the sensor in a special compartment under the hood (Examples of the GENERAL MOTORS cars).

Below are some examples of the location of the DPRV on different machines.

DPRV on Opel Astra

DPRV on VAZ 2114

DPRV on VW Polo

Principle of operation of the camshaft position sensor

There are three types of camshaft position sensors:

- Magnetic (inductive type). The principle of operation is based on passing in a constant magnetic field of a metallic subject (teeth). Magnetic sensors usually have two outputs.

- Hall effect. Fixes the change in the magnetic field around the sensor. Such sensors usually have three outputs.

- Optical. The principle of operation is based on fixing the reception and interruption of the photocell of the beam of light emitted by the source.

The most common DPRV of the first two types. Optical sensors are used only in some brands of cars (for example, Mazda GE platform machines). Some models of cars can be installed two or more DPRV. Moreover, perhaps different types.

Integral sensor

Hall Sensor

Optical sensor scheme

Together with the distribution shaft rotates a rotor of ferromagnetic material. Hall is located between the rotor and the permanent magnet, which creates a magnetic field vertically relative to. When the tooth passes by the sensitive element of the sensor, the voltage of the magnetic field changes. Due to this, the voltage is induced and a digital signal occurs in the Hall. Thus, the rotation of the gear disk of the pulse sensor of the camshaft changes the voltage of the hall in the Hall IC in the sensor head. The changing voltage is transmitted to the control unit and analyzed.

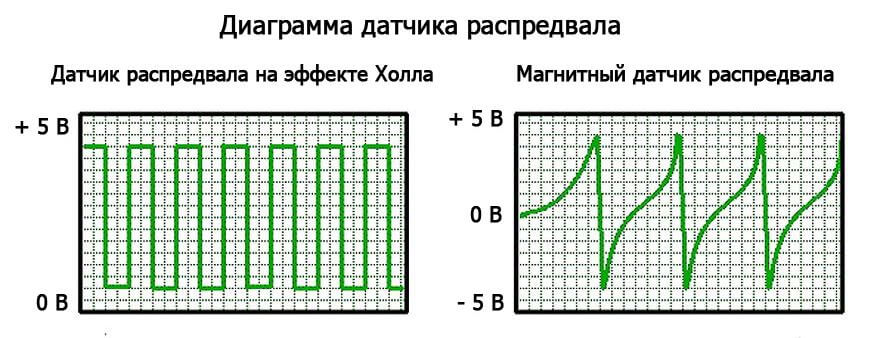

Diagrams of various sensors

The sensor is integrated, that is, includes a sensitive element and a secondary signal converter. The main function of the sensor consists in fixing the cylindrical phases of the intake and release. That is why it has a second name -.

Signs of malfunction

At the failure of the DPRV, each nozzle works twice as often (once each crankshaft turnover). In this case, the following camshaft position sensor faults arise:

- Sharp.

- Unstable work of the car while driving. She begins to twitch jerks, lose speed. Sometimes the car will not be able to accelerate faster 60 km / h. Also, the engine can stumble during the ride.

- On some cars at the failure of the DPRV the gearbox can be fixed in the same position.. So it will continue until you restart the engine. If such a situation is repeated regularly - it means that the camshaft position sensor has failed on your machine.

- When the sensor malfunction can completely absor the spark spark. As a result, you will get problems with the start of the engine.

- Possible failures in the work of the self-diagnosis system.

- Lamp "Check engine" unsystemantly lights up At idle engine speeds, and with elevated revolutions it goes out.

The signs that appeared will be enshrined with a yellow engine light bulb on the dashboard. Since when the control unit detects the incorrect operation of the SMR sensor - writes an error code into memory. To decrypt, you must use special equipment. The most frequent error codes are:

- - irregular / multiple skipping ignition in the ignition system;

- P0340 - no signal from the camshaft position sensor;

- P0341 - irregular phase of gas distribution;

- P0342 - Low signal of the camshaft position sensor signal;

- P0343 - a high level of the camshaft position sensor signal;

- P0344 is an unstable (intermittent) signal from the camshaft position sensor;

- P0365 - There is no camshaft position sensor chain signal.

Possible causes of sensor malfunction

The causes of the malfunction of the DPRV may be very much. At the same time, it is not necessarily indicating that the sensor has failed. Often problems arise with wiring and other elements of the scheme. The causes of the output of the sensor or problems in its operation may be the following factors:

Garbage and chips on the sensor housing

- the sensor is not connected to the signal wires;

- the presence of moisture in the sensor connector;

- circuit on the "mass" of the signal wire;

- breaking the signal wire;

- circuit on the onboard network of the signal wire;

- breaking the shielding shell of wires or harness;

- break or damage to the power supply of the sensor;

- invalid connection of power wiring;

- malfunction of high-voltage ignition circuits;

- malfunction of the engine control unit;

- a large or small gap between the sensor and the checkbox;

- increased ending camshaft gear;

- the presence of chips on the sensor housing.

How to check the camshaft position sensor

Check inductive DPRV and sensor based on the Hall effect, similar to each other. In the process, the voltage value between their conclusions occurs. To do this, you will need a multimeter capable of measuring constant voltage. Checking the operation of the sensor should be started with the following procedures:

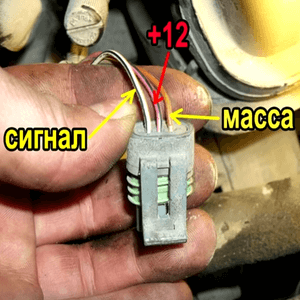

DPRV with three conclusions

- Check the sensor connection to the signage wiring harness. It should be approached +12 V and "Mass" (see Figure).

- If the power and "mass" on the sensor is, it is necessary to start the engine and check the presence of pulses on the signal wire.

- Check the availability of moisture in the connector. To do this, you must disconnect a plug from the sensor with signal wires and check dryness of the fork itself and the socket. If there is oxidation or contamination, clean and dry.

- Check the signal wires insulation. Its damage to statistics is the most common cause of a malfunction. The fact is that the sensor is in close proximity to the engine. Therefore, the insulation is heated and over time breaks and crept, leading to the circuit closer.

- Check the value of the insulation resistance of the inductive sensor. As a rule, it is about 0.5 ... 1 com. Some sensors will have several com (specify detailed information in the manual to your machine). The main thing is that the insulation is not broken.

Scheme for checking DPRV

Check work sensor based on Hall Effect, in the following way. To do this, collect the scheme shown in the figure. In the Scheme: 1 - the sensor housing, 2 is a plugging block, 3 is a resistor with a resistance value of 0.5 ... 0.6 com, 4 - LED brand al307, 5 - metal object (for example, a screwdriver). A car battery is taken as a power source. To check, you need to move the metal object near the sensor. If it is working, the LED should shine briefly. If this does not happen - it means that the sensor is faulty.

There is another way to check hall Effect Sensor. We disconnect the sensor from the connector, and to its outputs, connect the multimeter in the mode of measuring constant voltage. Turn on the ignition. The voltage value between the "mass" of the sensor and the overall mass should be 0 V. And the voltage between the total "mass" and the contact of the sensor's power should be within 10 ... 12 V. near the body it is necessary to move a metal object. If at the same time the values \u200b\u200bat the multimeter will change - the sensor is working. Otherwise - no.

Checking a two-wire (inductive) sensor

If your machine has a two-wire DPRV (inductive type), it must be carried out in such a sequence:

- Set the multimeter to the variable voltage measurement function.

- Turn the ignition key without starting the engine.

- Check the availability of voltage in the chain. To do this, connect the multimeter contact to "mass", and to the other to check each wire in the sensor connector. If there is no voltage on any of them - the sensor is completely faulty.

Another way is as follows:

- Run the car engine.

- One Multimeter Contact Connect to one sensor wire, the second contact is to another. If the sensor is working, then you will see the oscillating voltage on the tester in the range of 0 ... 5 V (specify the exact value to check your car's manual). If there is no voltage - the sensor is faulty.

Checking three-wire DPRV.

Check the sensor based on the Hall effect is carried out according to the following algorithm:

- Set the multimeter to the DC measurement mode.

- Turn the key in the ignition, but without starting the engine.

- Connect one contact to "mass". Another contact is to the power of the sensor. Compare the received voltage with the manual specified in your manual.

Another way:

- Run the engine.

- Connect one multimeter pin to the black sensor wire, the second contact to the red (power wire). The resulting voltage value must coincide with the machine indicated in the manual. If there is no electricity contacts - the sensor has failed.

As a rule, the camshaft position sensor is not repaired. Therefore, if it fails to buy a new one. Its price is about 4 ... $ 10, depending on the brand of the sensor and the car.

Replacing the camshaft sensor

The sensor is attached to the housing using one bolt. It usually has a head for 10. To unscrew it, you need an end key. Previously from the sensor you need to remove the chip. After you unscrew the bolt, gently pull the sensor up to pull it out of the landing site.

Before that, do not forget to remove the minus terminal from the battery, this will allow not only to avoid accidental closure, but also reset information about the error (when the terminal was removed within 3-5 minutes).

The assembly occurs in the reverse order. The seat of the sensor is sealed by a rubber ring. Also note that the assembly gap between its end and the upper edge of the pin point must be within 0.5 ... 1.2 mm. The sensor is installed in place, fasten the bolt and connect the chip.

The process of replacing DPRV by car "Lada"

Specialists are recommended to replace the sensor through every 100 thousand kilometers of run or every 5 years (Depending on what will come faster). Such a recommendation is caused by the fact that the sensor operates in constant change in the temperature regime. In this regard, there is a temperature difference between the semiconductor filling of the sensor, which is very "does not like" this.

Now, I hope to learn the nuances of the principle of operation of the camshaft position sensor and its signs of malfunction, you will not be difficult to independently check DPRV, and in two accounts to replace it in case of failure. And the question of a friend: "What are the signs of a faulty camshaft sensor" or "how to check the PV position sensor", answer with confidence - I know, I read it, now I will tell you.