The head of the cylinder block or GBC is one of the most important parts of the engine. And during the repair of the engine, it is often necessary to replace its gasket. I believe that the correct replacement of this auto parts implies an indispensable replacement of cylinder poles. About what is needed to be tightened, how to determine its moment, about the cylinder head bolts of the cylinder head and the general rules of the protraction, I will tell further in the article.

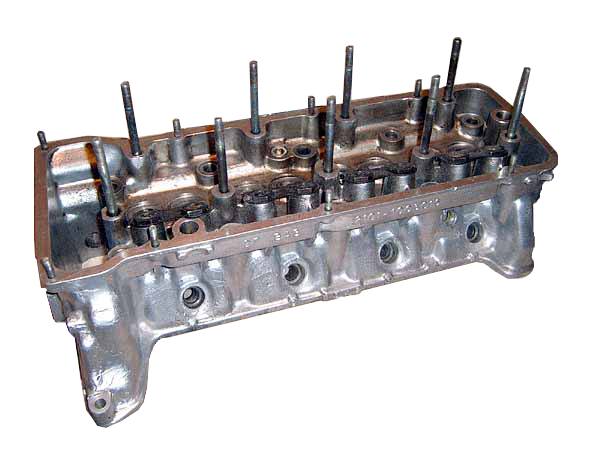

Before starting work, let's get acquainted, which represents this mechanism. Materials for the production of CFCs can be: alloyed cast iron or aluminum alloy. This is a lid that closes the cylinders. Performs the following functions:

- Protective. It protects the cylinder block;

- The CFCs provide cavities for: valve sleeves, puil valve springs, for fastening intake and exhaust manifolds;

- In the front of it, there is a hole for placing the chain tensioner and camshaft drive;

- There are threaded holes for spark plugs.

The tightening of the cylinder head bolts must be carried out in order to prevent the formation of sputum on the connection site of the elements under consideration. It happens, as a rule, due to oil leakage.

How to determine the torque

Alas, not all motorists know that today's automotive models do not need to tighten the cylinder block bolt. Previously, this operation was necessary for the successful passage of the first technical inspection. But these times have already been rushed into the fly and today even on the engines of the vase is not needed to produce. The only models that need to be tightened - Moskvich, UAZ and similar models.

As already mentioned, tightening time is the appearance of sputum on the site of connecting the head and the cylinder block. This happens for several reasons:

- because of the breakdown, we need a mechanism;

- curvature it due to engine overheating;

- initially incorrectly prolonged cylinder head.

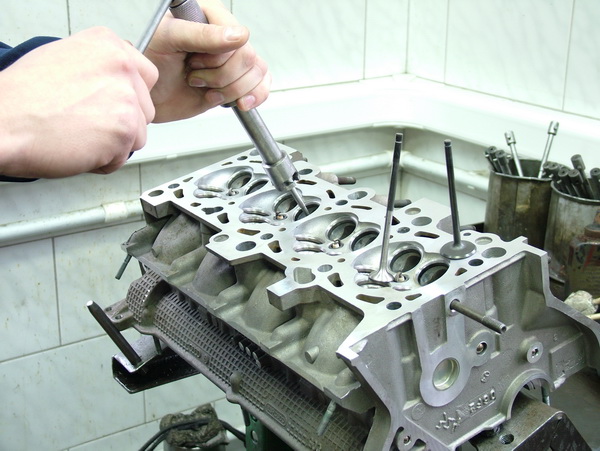

Tightening GBC Bolts

Tightening bolts GBC pass in two stages.

- The first stage: 1-10 is fixed with a moment of 3.5 - 4.1 kgf * m;

- The next stage involves the use of the same pins, but the tightening torque is 10.5 - 11.5 kgf * m;

- Moment 3.5 - 4.0 kgf * m. The last (eleventh) screw is delayed;

- Next, I will describe the fixing schemes of the pins of VAZ 2108 - 09, SAMARA and 16 valve engines of VAZ.

In the first case, the order of work is similar to the classical, but it takes place in four stages:

- Screws are tightened with a moment of 2.0 kgf * m.

- They are fixed with the point of 7.5 - 8.5 kgf * m.

- Reliable by 90 0.

- Read more on 90 0.

In the second, the course of work is carried out in three stages:

- tightening torque - 2.0 kgf * m.;

- next to trust screws by 90 0;

- reception is once again trust screws by 90 0.

General delay rules

The beginning of the process should occur with learning the operation and repair manual.

To work you need to get acquainted with:

- algorithm for tightening bolts of this device;

- the right time for tightening the bolt of fastening the head of the cylinder blocks;

- recommended for fixing pins.

General tightening rules exist if there are various parameters and are used in working with all types of engines:

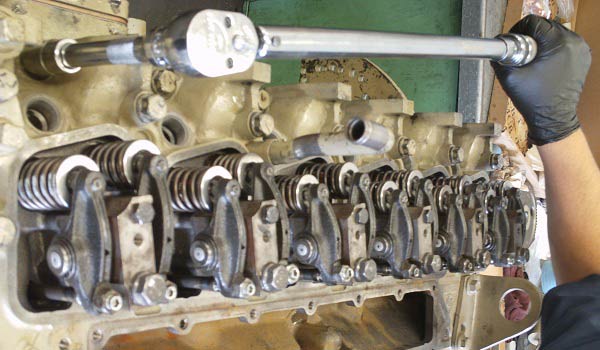

- As for monitoring the moment of tightening the screws of the mechanism under consideration, it is necessary to use a special dynamometric key here.

- Simple wrench are not used in this case.

- It is necessary time equal to the start of the screw movement to apply to the tightened screw.

- It should be remembered that before the process you need to carefully check the threads of the pins.

- Do not use the spring screw again - this will lead to oil leakage through the installation of the element under consideration.

- TTY type bolts should not be used for tickling or tightening the head of the cylinder block, since this type of bolts is used for aluminum cylinder heads. All information on TTY screws can be found in the manual of the manufacturer of the machine.

- The numbers of tightening the gasket and the engine tightening time should also be taken into account, and at the same time, prevent discrepancies in them. Detailed information is placed in the layout specification for the instrument head.

- When running with screws fastening the head of the cylinder blocks with a dead-end hole, it is necessary to monitor the fill of the oil. You need to pour it carefully, in order not to pour, as this will lead to the fact that the screw will not reach the end.

- When working with threads with through hole before screwing the threads, it is necessary to lubricate with plastic sealant.

- The fastening bolts should be in perfect condition. Old, converted pins or pins, already once used in no case are not suitable.

And all those who decided to still make the recession of CHC screws, I want to give a couple of tips.

- application in the engine with cast iron CPC should only be done on a hot engine;

- but in a cold state, the broach is produced in the engine in which the aluminum head of this device is applied.

So I introduced you to the rules and techniques of tightening the pins of this mechanism. I hope this information benefits you and your car! And let the tightening of CHC screws pass successfully using a minimum effort!

Video "Tightening of automotive bolts"

Looking at the entry, you will learn how to tighten the GBC bolts.