Greeting the Lord! If you consider yourself a real driver, repair skills must be extremely high, well, the maximum average. The experienced motorist is equivalent to anything that the punched wheel is that engine repair. Of course, even an experienced, but minimum, how to pull the screws on the heads of the cylinder head is not always decided to get into the motor - it should know!

In this procedure, a key success factor is the moment of tightening the bolts of the cylinder block head, it must be chosen correctly! Agree, all regards the repair of the engine is mainly the topic that is difficult to express, but I still will try. Today, on examples of different power units, I will try to explain all the nuances in an affordable language: an effort, a tightening order of bolts, etc.

Main signals to action

It is extremely important to establish the need for suspenders! If oil is seeping between the head and block, it can mean several "diagnoses":

- GBC gasket was worn - This is mainly due to the periodic engine overheating.

- The deformed head of cylinders.

- Incorrectly tightened screws - It all depends on the qualification of the repairman.

- Bolts just glorified a little - Summates their tightening them, but only correctly performed.

Today, modern cars (from 2010 from 2010) do not need such a procedure, before during the USSR, everything was completely different, and the cars were others!

Just think: then the process of pulling the GBC was a mandatory debut item in our state.

From this, you can conclude that you are most susceptible to weaken the head bolts of the old generation machine, then you mean a classic and it concerns not only "Zhiguli"!

So, if you are the happy owner of Muscovite, UAZ, Volga or ordinary VAZ, do on the mustache!

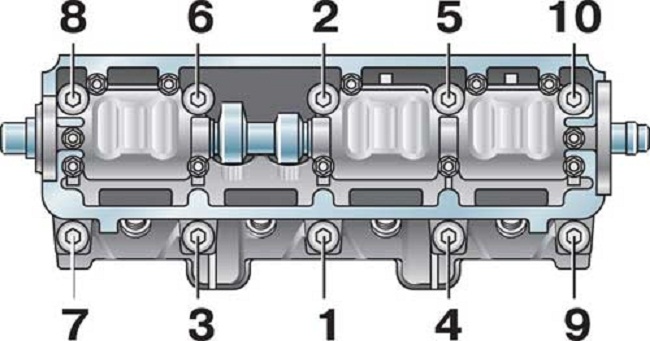

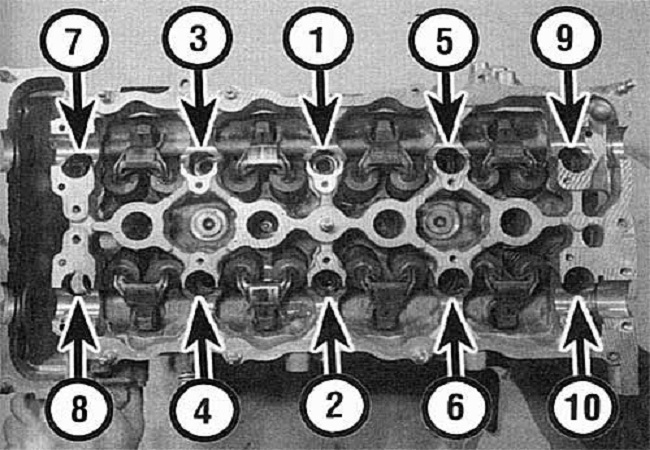

If you are lucky and the bolts need only tighten, you need to know the correct order of their twisting. Otherwise, the metal will be unnecessary, and this means that without distortion, which depreciate the entire procedure, can not do. On the engines of classics, as well as 402 and 406 models, the suspension is carried out in 2 approaches:

- Reception number 1 - Screws from 1 to 10 are delayed by a moment 3.5-4.1 kgf.m.

- Reception number 2 - the same elements are amenable to force with a moment of 10.5-11.5 kgf.m.

- Bolt 11 Tighten the last with the moment 3.5-4.0 kgf.m.

In the photo, you can see a clearer motor tightening sequence with 8 valves, which you need to repeat.

Procedure for tightening bolts VAZ 2108-09 Samara

Everything is almost also here, start from the middle, but instead of two, we perform 4 approaches:

- Approach number 1 - all bolts in the sequence, as in the picture are delayed with a moment of 2.0 kgf.m.

- Approach No. 2 - the force of tightening bolts of the cylinder head of the cylinder is equal to the moment in the range of 7.5-8.5 kgf.m.

- Approach №3 - we are in collapse bolts by 90 degrees.

- Approach №4 - Repeat the previous paragraph.

I draw your attention that before the beginning of such a procedure, it is desirable to clear the power unit, I already talked in one of the past publications. There you can find the technology, so there should be no problems.

The owners of the 16-valve priory, as well as the VAZ 2114 and VAZ 2112 with a similar power plant, must be performed almost the same actions:

- Step number 1 - broach on the sequence specified in the photo by a moment in 2.0 kgf.m.

- Step number 2 - reinstall the bolts by 90 degrees.

- Step number 3 - scroll through a bolt to 90 degrees again.

Please note: the reuse of old bolts on such motors is allowed, but only those whose length does not exceed 95 mm. Measures of the bolt are carried out together with the washer.

Main tool

Of course, the entire operation is not to complete the usual wrench, or rather, you can, but only the end. However, the tightening torque cannot be set. Therefore, before proceeding, be sure to separate the dynamometer key. The price hesitates within 600 - 3000 rubles - you can buy a time!

It is not difficult to use it:

- Set the holder to zero (The instrument readings should be equal to the initial position of the holder.

- Controlling the key readings start twist holderIf the numbers do not change - the bolts are stretched, which is the norm. When the readings sharply went uphill, it means insufficient stretching. In this case, only after stabilization is adjusted.

Of course, do not forget - begin to work without the original manual to a specific car whether it is a prior or any other car - it is extremely undesirable, but if it did not turn out to be at hand at hand, I provided you at least the necessary data. Long life to your car and tranquility of his owner! And let's rather get any model and there will be no problems !!! Subscribe to my blog, follow the updates ahead of a lot of cognitive and interesting, see you in the next article!