When parsing and repairing the engine of the vehicle, there is a need for a tightening of bolts. But not every car enthusiast is aware that it is. What is the moment of tightening the GBC bolts, why is it needed and how does this process go?

In what cases is needed?

Some motorists do not have no idea why to comply with the sequence and adjustment of the moment of tightening the GBC bolts. The motorist should understand that the use of unsuitable technology as a result will cause problems in the operation of the motor. This is very important, and it means that he should pay attention. Especially if you used to engage yourself to repair your "iron horse", rather than seeking help for a hundred.

Until they started the question of the procedure for tensioning the elements of the GBC, we note that each engine has its own torque. Accordingly, for each car the coefficient is different.

Some motorists consider if they were engaged in the repair of the engine or tightening its screws, they have enough experience. But it should be borne in mind that this procedure should be carried out only in accordance with certain engine parameters. This information can be found in the manual for use for your car.

The tightening procedure is needed when condensate and moisture should be prevented in places of the CBC connection with the block.

Or, if oil leak occurs. This reason is common. In addition, the need to tighten the bolts occurs when the motorist performs the repair of the motor or replacing the gasket. Also, the adjustment is needed when the structure of the BC is broken.

Oil leakage is one of the reasons for the need to stretch component components

Oil leakage is one of the reasons for the need to stretch component components Note that several factors affect the tension. If you do it yourself, you need to know what affects:

- quality and lubrication of holes, as well as the screws themselves. If the holes are dry or practically not lubricated, then it should be done. For lubrication, it is desirable to use unusual engine fluids.

- Pay attention to the state of the thread and the element that includes it. If the components of the motor are deformed, and the thread is clogged, then it is better not to start the stretch. Sooner or later, this will lead to a decrease in the coefficient of the force of compression of the gasket, and as a result it can turn it very much deploy. Up to overhaul engine repair.

- Newly use bolt or old. If new, then its resistance rate and torque will be incorrect. Experienced specialists are recommended that when using new screws, the tightening process was carried out after two or three twisting cycles. To make it right, the element needs to attach a little effort and tighten the element by 50% after the tightening.

Tightening adjustment

So, if we decided to engage in the tightening screws of the GBC and the adjustment of the moment, then you need to observe a certain order and sequence. GBC mounting bolts should not be too tightened or not mety. Effort must be applied, but not carried away. If you have no experience, I'd better contact professionals for help.

Instruments

Despite the fact that this process of repair work requires a special individual approach, the preparation for it passes quickly. All because for this you do not need to prepare a whole set of tools. If you decide to do it yourself, you will need to prepare only a dynamometer key.

Tightening scheme

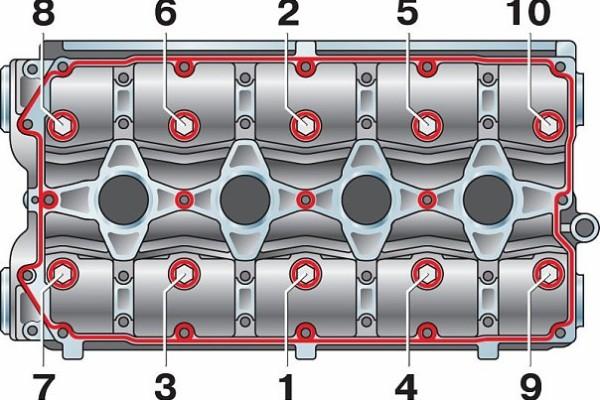

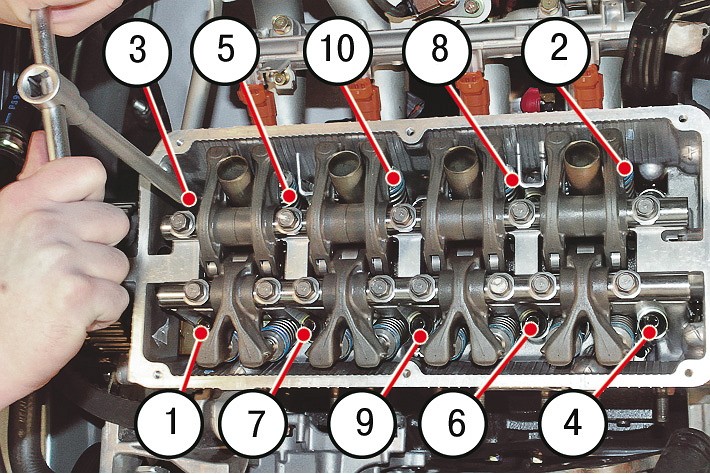

Consider the process circuit. Immediately note, the tightening procedure is carried out in several stages, each has certain steps. At the first stage, the procedure for such:

- If you do not know what should be the order of the tightening, then all the elements must be secured by the moment of 3.5 - 4.1 kgf * m;

- At the next stage, these elements need to be consolidated so that the moment is 10.5 - 11.5 kgf * m;

- The latter, the eleventh bolt needs to be tightened with a moment of 3.5 - 4.0 kgf * m.

As for the second stage of work, it is carried out in several steps:

- First, you need to observe the moment of tightness, it should be 2.0 kgf * m;

- After that, the elements of the CFC must be checked by 90 degrees;

- Then followed by 90 degrees again.

Stages

Consider the phased instructions for tightening bolts. As mentioned above, it will be individually for each vehicle. Therefore, if you want to do this case yourself, then you in any case require a service book to your car. In particular, you will need:

- get acquainted with the process and circuit of tightening the screws of the GBC in its car;

- it is also necessary to know the time for tightening the screws of the GBC;

- to familiarize yourself with the pins that are used for tightening, they may have a specific shape or other nuances that should be considered.

As mentioned above, the procedure for tightening the pole poles occurs in several stages. Consider this process on the example of the car VAZ 2109:

- All adjusting pins should be tightened in such a way that the moment is equal to 2.0 kgf * m.

- Then the same screws must be fixed. For this, the moment should be equal to about 8 kgf * m.

- All screws should be checked, but no more than 90 degrees.

- Then you need to trust the pins no more than 90 degrees.