ATVs have many advantages over a car or motorcycle, which is why they are so popular today. It is not difficult to buy an ATV today, but it is not quite a cheap purchase, so many can only dream of such an acquisition or make an ATV with their own hands.

If before this time you did not have the necessary skill, then you will have to be patient, since making an ATV with your own hands is not very easy. But on the other hand, if you still achieve your goal and design an ATV with your own hands, a video where you drive around in your unit can become an adornment of the Internet.

The process that you will have to go through to assemble the ATV is quite laborious, but if you put in the effort, all your efforts will be rewarded a hundredfold.

The first thing to consider when designing an ATV is that at the exit, it should be a lightweight, maneuverable and mobile unit that is not very bulky, but at the same time durable. It is worth remembering that the main quality of a good ATV is its cross-country ability, which must be taken into account when assembling it.

Homemade ATVs do it yourself

If you decide - the drawings become the starting point for starting work. On the Internet, you can find a variety of drawings of ATVs, based on different equipment. Here you can also see photos of ATVs that our craftsmen made with their own hands.

Craftsmen do, "IZH", "Ural" or other equipment. For example, if you are planning to make an ATV from Oka with your own hands, you can take a motor - it will cope well with a light ATV. The gearbox can also be loaded from the Oka. If you can turn the engine along the frame and direct the input shafts straight out of the gearbox to the axles, you can get a DIY 4x4 ATV without a transfer case.

The main stages of work on an ATV

A good unit can be obtained on the basis of Soviet-made motorcycles. For example, if you are planning to create an ATV from the "Ural" with your own hands, you can conditionally divide all the work into four stages:

- Frame modernization;

- Installation of the engine and transmission;

- Suspension equipment;

- Equipment and installation of the dashboard.

By the way, you need to immediately decide on the type of control - it will be steering or motorcycle. In the case of choosing a motorcycle control, you already have the necessary parts from the "Ural", but if you have conceived a steering for your horse, take care of the necessary details in advance.

At the first stage of working out the "Ural" into an ATV, you will have to play with the frame. Although it is the Ural frame that is most suitable for ATVs, it almost always remains unchanged, although this already depends on your drawing. More often it is only scalded with a system for mounting a suspension.

Next, you need to think about the rear suspension and rear axle. There are two solutions to this problem. The first is the creation of a design based on a native cardan and a gearbox. The end result is a lightweight design without a differential. And the second warrant is a design based on an automobile bridge. But if you do not want to have an ATV, you will have to shorten it as wide as the car. Naturally, the process is not easy, but you will get a differential that will not get in the way on the roads.

But still the most time consuming process is the creation of the front suspension. Although you can make it from anything, the ATV is lightweight and therefore reliable levers can be created in any size.

Optional equipment

ATVs are used not only for walking trips, but also as a reliable, hardy assistant in the farm. They are used to transport goods, crops, or are used instead of a small tractor in the garden. And for these needs, it is necessary to somehow place a lot of things on the ATV. If you need an ATV mainly for personal needs or for picnic trips, you can make your own ATV case, in which you can place the necessary things. But for a subsidiary farm, it is better to make a trailer for an ATV with your own hands. If you have already mastered the assembly of an ATV, then it will take you very little time for a small trailer, but it will bring a lot of benefits.

Today, four-wheeled units are gaining more and more popularity. But not everyone can afford to buy such a device. Then the question arises of how to make an ATV with your own hands. The process of creation itself is very exciting, and it is not at all difficult to find components. Therefore, if you have a desire, feel free to get to work.

Before starting work, a clear visual representation of the future structure is required. The drawings of homemade ATVs vary in accordance with the tasks of the owner and the features of further use (transporting goods, passing through rough terrain, etc.). After exploring the basic diagrams and structures, draw your own four-wheeled bike project. An illustrative example will serve as a basis for the work and will help explain to specialists what is required of them.

Of course, homemade work loses to established brands. However, if you choose the right materials and assemble compatible parts, then you get a completely powerful unit that can compete with competitors. Moreover, you will save a lot.

Work process

The first step is to make drawings of the ATV with your own hands. Make the most of your sketching efforts. They will be needed to determine the required parts and calculate the costs.

After creating the drawing, start buying components. Usually their main structure includes:

- frame - the main structure on which the entire unit will be held;

- pipes of various lengths and diameters to ensure the operation of the system;

- rolled metal, for the installation of shields, protection and other things;

- shock absorbers;

- engine and its components.

The ATV is easiest to make with special equipment. If one is not available, the best option would be to contact specialists with ready-made drawings. They will not only do the job well, but they will also be able to adjust inconsistencies parts and mechanisms.

The frame should be made individual, according to the dimensions of the planned device. However, if you wish, you can take a simple frame from a motorcycle or a Russian-made car. The easiest way is to make an ATV from the Oka with your own hands. Because Oka's wheelbase is not great, this simplifies the sizing work.

Suspension and shock absorbers from cars and bikes are also great for future crafts. Considering that ATVs are designed for movement on difficult terrain, shock absorbers from a moped Minsk or Dnepr will be an excellent option.

The brakes are a very important part of the design. You shouldn't save on them. Create an ATV with your own hands, 4x4 drives, better with a VAZ brake system. Their durability is designed for cars, so a lightweight four-wheeled bike will respond well to such a system.

The steering wheel can be taken from any motorcycle. It is desirable that weights be installed on it to reduce vibration from the operation of the motor and movement on rocky terrain. This will reduce hand pressure and fatigue while riding.

Depending on which way of operation you choose, you need to select wheels with a wear calculation. For trips on normal roads, simple wheels from the Oka are suitable. However, if you want to achieve good off-road ability, it is worth investing in specialized wheels and tires from manufacturers.

And the most important thing is the engine. The best option for the role of a motor will be engines from motorcycles IZH Jupiter or Planet. Not a new motor will do quite well. Their simple design will help you to easily replace worn out and broken parts. At the same time, don't forget about cooling. It is necessary to find the ideal option for different climatic conditions. Active cooling, which unfortunately hasn't been used on motorcycles, is great.

A homemade ATV from Oka, the drawings of which, depending on the operating conditions, must contain additional equipment, can be equipped with fog lights, a tool box (very useful in case of a breakdown) or a winch.

Assembling the structure

After creating drawings and selection of material, you can start creating the unit. First of all, a frame is created, on which all the details will be installed later. It is advisable to use the strongest and most corrosion-resistant materials during work. When driving off-road, the sturdy construction will keep your engine from breaking down more than once.

Next comes the installation of the chassis. Here it is necessary to show the accuracy of assembly, since the coordinated work of all wheels and shock absorbers will provide good dynamics and stability of the apparatus.

Then proceed to the installation of the engine and its components. If the mechanisms are not aligned, never use brute force. This will lead to subsequent operational problems. After connecting the engine to the box, connect the fuel system. The fuel tank can be made with a margin, which will ensure the possibility of long journeys.

Now you need to install the electrical equipment. At this stage, wires are laid, headlights, signal lights and other consumer elements are installed.

After completing the main work, you can proceed to the cladding and body kit. It is up to you to use metal or plastic sheets when installing the body kit, but it is recommended select based on the weight load on the engine... With sufficient power, a couple of kilograms will not be noticeable. It is better to install seats with a hydraulic cushion, but you will have to pay extra for this, because when driving for a long time on a bad road, vibration mitigation will provide additional comfort.

This is the easiest way to make a homemade ATV from Oka 4x4. The main thing in work is the correct balance of finances and opportunities. After all, if you want to create an equal four-wheeled bike without calculating the costs, you risk leaving your work unfinished.

Power unit homemade ATV became the engine from the car "Oka" - 32-strong, two-cylinder, four-stroke, liquid cooling. And if for a car its power was often not enough, then for an ATV it should have been more than enough.

And this is just the dream of every man !!! I want this !!!

Homemade ATV frame- spatial, welded. Its main elements (two pairs of spars: upper and lower) are made of round pipes of the VGP-25 type (water and gas pipes with a diameter of 25 mm and a wall thickness of 3.2 mm), auxiliary (struts, crossbars, etc.) are made of VGT-20. The side members are bent: the lower ones are in the horizontal plane, the upper ones are in the vertical plane. He bent pipes on a pipe bender, "cold". I welded the lugs (pairs of lugs) for fastening the levers and shock absorbers to the frame at once, and welded various brackets as the assemblies and assemblies were mounted (in place).

Homemade ATV ATV:

1 - front wheel (from the Chevrolet-Niva car, 2 pcs.);

2 - engine (from the car "Oka");

3 - front wheel drive transmission;

4 - a gearbox (from the Oka car);

5 - rear wheel drive transmission;

7 - rear wheel (from the Chevrolet-Niva car, 2 pcs.);

8 - fuel tank (20 liter canister);

9 - rear trunk;

10 - muffler;

11 - backrest of the passenger (headrest from the car "Oka");

12 - saddle;

13 - clutch basket (from the Oka car);

14 - gear fixing lever;

15 - body kit (fiberglass);

16 - steering wheel (from the Ural motorcycle);

17 - instrument panel (from the car "Oka");

18 - front trunk

Homemade ATV transmission- kind. Although the car is all-wheel drive, there is no transfer case in it. As you know, in "Oka" the engine is located across, and on the ATV it is installed along. This made it possible to direct the output shafts from the gearbox (gearbox) not to the right and left wheel (as in a car), but to the front and rear axles. Here are just the power unit itself, interlocked with the "basket" of the clutch and the gearbox, had to be shifted relative to the longitudinal plane of symmetry slightly to the left in order to reduce the horizontal angle of the longitudinal joint shafts of the transmission. Well, their vertical angles turned out to be insignificant.

The transmission has been assembled from units of various domestic cars, mainly "VAZ" models. But the finished industrial units also had to be refined. For example, from the checkpoint (from "Oka") to ensure the optimal (reduced) speed and increase the torque, he removed the main gear pair and replaced it with a chain transmission. The gearshift rod was also made different - lengthened, with outlets on both sides of the gearbox. The stem can be fixed in three positions: to engage 1st and 2nd gears, 3rd and 4th and reverse. The lever for selecting these positions is on the right side, and the gearshift lever is on the left.

Interwheel reduction gears are from the rear axles of the VAZ "classics", only their axle shafts together with the "stockings" were removed and replaced with shafts with CV joints from the front-wheel drive models. CV joints are used as hinges in the rest of the transmission intermediate shafts.

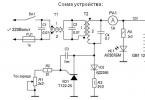

Kinematic transmission diagram of a homemade ATV from Oki

1 - motor (from the car "Oka");

2 - clutch (from the Oka car);

3 - gearbox;

4 - CV JOINT (from the VAZ-2108 car, 12 pcs);

5 - main gear reducer with differential (from VAZ-2105, 2 pcs.);

6 - shaft (from the car VAZ-2108, 6 pcs.);

7 - wheel (from the car "Chevrolet-Niva")

There are no low gears and no differential locks.

Steering - motorcycle type (lever and shaft) at the top and car type (with steering rods) - at the bottom, only simplified, without a steering mechanism, with one bipod. At first I used the steering wheel from a motorcycle "Minsk", with a pipe diameter of 22 mm, but it turned out to be a little thin. Later I found and delivered it from a Ural motorcycle. The steering shaft is made of a tube with a diameter of 20 mm and a wall thickness of 2.8 mm. It has a travel stop at its lower end. At the bottom, the shaft rests on a thrust bearing, and in the middle part it turns in a split nylon bracket-sleeve.

The bipod is made of steel sheet 8 mm thick and shaped like the letter "T". At the edge of the "rack" a hole with a diameter of 20 mm is made - the steering shaft is inserted and welded into it, and in the ears there are tapered holes for the ball ends of the steering rods. These holes are reinforced with matching welded washers. The bipod ears are slightly bent down so that they are almost parallel to the rods.

Wheels - 15-inch, from the car "Chevrolet-Niva". Tires with the corresponding rim dimensions 205/70 (width / height as a percentage of the width) with an off-road tread pattern. The wheel roll-in diameter is about 660 mm.

Homemade ATV frame drawing:

1 - lower spar (pipe d25x3.2, 2 pcs.);

2 - upper spar (pipe d25x3.2, 2 pcs.);

3 - stand (pipe d25x3.2, 2 pcs.);

4 - support of the rear upper suspension arm (pipe d25x3,2,2 pcs.);

5 - rear strut (pipe d20x2.8, 2 pcs.);

6 - support of the front upper suspension arm (pipe d25x3.2, 2 pcs.);

7 - front strut (pipe d20x2.8, 2 pcs.);

8 - the upper support of the front shock absorber (corner 35 × 35);

9 - rack of the upper support of the front shock absorber (sheet s5, 2 pcs.);

10 - front engine mounting support (sheet s3, 2 pcs.);

11 - rear engine mounting support (sheet s3,2 pcs.);

12 - lugs for fastening levers and shock absorbers of suspensions (sheet s5, 18 pairs);

13 - saddle mounting bracket (sheet s3, 2 pcs.);

14 - upper transverse link (pipe d20x2.8);

15 - lower transverse link (pipe d20x2,8,2 pcs.);

16 - radiator support (pipe d25x3.2 cut in half lengthwise, 2 pcs.);

17 - front console of footrests (pipe d20x2);

18 - rear console of footrests (pipe d20x2);

19 - connection of the front and rear footrest consoles (pipe d20x2);

20 - footboard cross member (sheet s5, 4 pcs.);

21 - an eyelet for attaching a fiberglass body kit (sheet s5, set)

Wheel suspensions are independent, on two triangular wishbones each (upper and lower) with shock absorbers from the Oka car (front). Levers are welded from round pipes of the VGP-20 type. Elastic elements (springs) and shock absorbers - from the car "Oka" (rear). Wheel hubs and steering knuckles are welded into the wheel ends of the front levers - from the VAZ-2109 car. Both those and others had to be finalized. In the hubs I installed studs under the wheels from the "Niva", and in the front fists - homemade swivel levers.

The muffler is homemade, two-piece. To protect it from temperature warping, the body kit covered it with a remote cover, and insulated the inlet pipe with asbestos.

ATV body kit - fiberglass. I pasted it for the first time, and therefore first studied the recommendations for performing the relevant work. But as it turned out, this process is painstaking, although the result is worth it.

Wheel suspension arms

(a - upper arm of the front suspension; b - lower arm of the front suspension; c - lower arm of the rear suspension; d - upper arm of the rear suspension; all parts, except those noted specially, are made of VGT-20 pipe):

1 - beam (2 pcs.);

2 - cross member;

3 - bushing (pipe d37x32, 2 pcs.);

4 - shock absorber mounting eye (steel, sheet s3);

5 - ball joint (from the steering rod of the car "Zhiguli")

First, I made the required contours of the body kit from a steel square pipe with a section of 10x10x1 mm. Fortunately, this pipe bends easily even with hands over the knee. The contour was welded to the frame with the help of jumpers from the same pipe, in places where later (after gluing the body kit), it would be easy to cut the "tacks". Then he bent the "wings" from hardboard (fiberboard) and fixed them with self-tapping screws to the contour and lintels. Where the bend turned out to be steep, I fastened separate strips of the same hardboard. The front end was taken out with styrofoam purchased from a hardware store. It was possible to use polystyrene or the same polyurethane foam, but expanded polystyrene turned out to be a more suitable material - it is cut well with a sharp thin knife. I glued individual elements from it into a general structure on polyurethane foam.

Steering column assembly:

1 - steering shaft (pipe d20x2.8);

2 - rudder connection plate (steel, sheet s6);

3 - brace of the plate (steel, sheet s6, 2 pcs.);

4 - split bracket-sleeve of the steering shaft (nylon, sheet s18);

5 - support washer (steel, sheet s6, 2 pcs.);

6 - bipod (steel, sheet 18);

7 - rudder travel stop (steel, sheet s6);

8 - bearing housing;

9 - a persistent tip (steel, circle 15);

10 - thrust bearing

The false tank is of a complex shape. It was not possible to bend it out of hardboard. Therefore, having wrapped the engine with plastic wrap, I began to fill the space intended for it with layers of polyurethane foam. After each layer, drying is mandatory, otherwise a thick foam volume may not dry out inside. I filled it until the layers went beyond the outline. Finally, after the foam was completely dry, I began to draw the desired shape with a knife. The edges were smoothed out with coarse sandpaper.

A part of the “Oka” dashboard was used under the dashboard. I also fixed it on the disc with the help of polyurethane foam. Since the foam is coarse, the pores were filled with gypsum and then processed. When the shape of the blank began to respond to the conceived design and its surface became more or less smooth, I covered the blank with PF-115 paint. Since I was not going to make a matrix for gluing the body kit on the dummy, but immediately glued the body kit on it, followed by finishing the surface to an ideal state, then plastering with plaster and painting the dummy could be neglected.

An ATV is virtually any four-wheeled vehicle, since the Latin word for "quadro" is "four". In the CIS, this name most often means four-wheel drive, representing the symbiosis of a motorcycle and a car. From a motorcycle, the ATV took over mobility, maneuverability, lightness, speed, and from the car - excellent characteristics of cross-country ability, power and controllability. The result is a unique vehicle designed for a variety of purposes.

The domestic market provides only foreign models of ATVs, the cost of which is often transcendental. At the same time, on the secondary transport market, you can easily find used motorcycles and cars at an extremely low price.

For example, a motorcycle "Ural" - large, bulky, heavy and "gluttonous" has an excellent four-stroke engine with reverse gear and costs "a penny". For this reason, it is much cheaper and more fun for enthusiasts to create their own designs for these SUVs.

The quintessential factory ATV is shiny, neatly built, sturdy and powerful.

Its homemade cousin, which is not much inferior in appearance, and even more so in terms of power.

How to make an ATV with your own hands

Before starting the assembly, it is necessary to draw up a detailed list of units and parts that will be needed to create your own brainchild, develop a work plan and a design drawing.

Engine: the best choice

It is logical that first of all it is necessary to find the "heart" of the future "beast" - the power unit. Absolutely anything will do, from a conventional walk-behind tractor to a six-liter V12 - there are such precedents. In most cases, motorcycle engines are used - they are economical and small-sized.

.jpg)

To use high gear ratios under normal operating conditions, a Minsk or Ural engine will suffice. In the summer, the issue of overheating arises, so air-cooled models should be chosen. Another good option is the Soviet-made boxer engines, the indisputable advantage of which is powerful traction and a completely unpretentious cardan drive.

Suspensions: rear and front

There are two common ATV rear suspension solutions.

- Gear-cardan system. The design turns out to be as lightweight and simple as possible, but there is no differential, which, in principle, can be sacrificed for the sake of the previously mentioned advantages.

- Using a road bridge. The construction turns out to be extremely heavy, and if there is no desire to have an ATV with a car base, it is necessary to shorten the bridge, which is a very non-trivial task. Of the advantages, it is worth highlighting only the presence of a differential, which is useful when driving on highways.

The possibilities for front suspension and steering are tremendous. The suspension arms of an ATV carry a significantly lower load than automobile ones, respectively, they can be made independently using available tools. The best option is to create a suspension based on the existing Ural motorcycle.

Frame: drawings and alternatives

The best solution is a robust construction made of pipes or profiles welded together.

It is ideal to remove the frame from the donor motorcycle and add the necessary elements - this eliminates a number of problems, but the design can turn out to be unnecessarily complicated.

Assembling the ATV

Having prepared the necessary tools, donor vehicles and freeing up time, you can start creating your own ATV:

Thanks to its reliable, time-tested design, excellent power and traction, the Ural motorcycle is the most popular donor for homemade ATVs.

Video clip: "Wasp" 4x4

The video below describes the design of a homemade ATV, its characteristics, properties and features.

Photo review

Photos of ATVs based on domestic motorcycles and cars:

.jpg)

As you can see, using the outdated and inexpensive achievements of the Soviet car industry, you can create amazing devices that will amuse your vanity and satisfy most transport tasks.

Quite a lot of hunters, fishermen, and just lovers of outdoor activities dream of their ATV. But the prices even for used equipment are too expensive for most, not to mention new equipment. Do not despair, because today we will learn how to make an ATV with our own hands! It is an excellent vehicle for household needs, for transporting trailers, with high maneuverability due to a short wheelbase, as well as easy to operate. But right away we want to say that it will take a lot of time to make a homemade ATV. As practice shows, a project can take from 6 to 12 months on average.

Preparatory stage

So let's get started. Prepare your tools and equipment first. It will take a lot of welding work, for which manual arc welding is quite suitable. Choose electrodes for welding critical and vibration-loaded structures, which will be the ATV frame. By the way, this very frame can be cooked with your own hands from ordinary water pipes. These are easy to find at the nearest scrap metal reception, or metal warehouse. Choose a pipe diameter from 25 to 32mm, and the wall thickness should be around 3mm. To bend such pipes, it is desirable to have a pipe bender, but if it is not there, then you can also manually bend the pipes for the frame frame using a lever, heating the desired bend with a gas burner, or better with a gas-oxygen torch.

Selection of main parts

The next step will be the selection of the necessary parts in the first place, namely:

- engine

- wheels

- shock absorbers

- rear axle

If you want to build a simple lightweight quadric with a drive only to the rear axle, then it is preferable to choose an engine from a motorcycle of an average cubic capacity, from 250 cubic meters and above. Depending on the construction budget, this can be almost any motor from a Soviet motorcycle, preferably with a chain drive, due to which it will be quite easy to make a rear axle drive. The axle can be made from a structural steel tube. In the center, weld the flanges for attaching the driven star and disc brake, and on the sides, install wheel bearings from the car, having previously pressed them into the housings made in advance.

The housings are used to fasten the complete axle to the pendulum. The swingarm can be left as standard by further strengthening it and making a new mount for the disc brake caliper. Also, do not forget to make the brake hose mounts along the swingarm.

Our next task is the choice of wheels. And the ideal option not only in terms of accessibility, but also in size will be the wheels from the Oka. The main feature is that such stamped discs are very light, will perfectly fit into the proportions of a home-made ATV, and most importantly, rubber from factory ATVs is perfect for them, which will significantly improve cross-country ability. How it looks can be seen below:

Donor selection for a new frame

How to make an ATV even easier to manufacture? You can simply use a donor frame, for example, from the Ural motorcycle by welding the rear axle to the standard swingarm and just slightly change the front suspension! The thick frame of the Urals is made of good steel and has an excellent margin of safety. And an engine with a high torque is just right for such a purpose. As for the gearbox, it is better to use it from the Dnepr motorcycle. It is designed for good loads, is characterized by precise gear changes, and the most important thing is the presence of a reverse speed, which is an indispensable function of a full-fledged ATV. Photo example of a homemade ATV from the Urals below:

Steering

Do-it-yourself ATV assembly is not an easy task. And, perhaps, the most difficult thing is to make the steering. To do this, first weld the frame of the front of the ATV, then you will need steering knuckles from the car, for example from the Niva, but any others will do. Then you need to build the suspension arms. Pay special attention to the design of the attachment of the levers, since they are coupled with the frame, heavy loads arise, so additional stiffeners will not be superfluous. Levers are usually bolted through silent blocks. This is a rubber-to-metal hinge that is an indispensable link in the suspension. It dampens wheel vibrations, preventing vibration from being transmitted to the frame. Levers can be made according to these drawings.

Do-it-yourself ATV assembly is not an easy task. And, perhaps, the most difficult thing is to make the steering. To do this, first weld the frame of the front of the ATV, then you will need steering knuckles from the car, for example from the Niva, but any others will do. Then you need to build the suspension arms. Pay special attention to the design of the attachment of the levers, since they are coupled with the frame, heavy loads arise, so additional stiffeners will not be superfluous. Levers are usually bolted through silent blocks. This is a rubber-to-metal hinge that is an indispensable link in the suspension. It dampens wheel vibrations, preventing vibration from being transmitted to the frame. Levers can be made according to these drawings.

Go ahead. What is the front suspension without shock absorbers? Here you can apply 4 motorcycle shock absorbers, one for each arm in the front, and two for the swingarm to shock the rear axle. Rear shock absorbers from Izh are suitable, but if you are ready to fork out for gas-oil with pumping, then this will give you the opportunity to adjust the suspension to road conditions, which is very handy for such equipment as an ATV!

Four-wheel drive and car engine

How do you create a 4-wheel drive ATV yourself? Above, we have considered the simplest option. But an option is possible not only with an engine from a motorcycle, but also with a car engine! And then we will tell you how to make an ATV with an Oka engine. In the case of an all-wheel drive ATV with a car engine, things are much more serious. Here it is no longer possible to use a motorcycle frame as a basis; it will have to be welded completely from scratch for a car engine. By the way, it can be not only from Oka, but also any other, depending on your desires and capabilities. Don't forget about the liquid cooling system right away. Calculate the frame design so that the radiator and fan are located in a protected area from forest branches. The engine with the gearbox should be mounted along the frame so that the drive shaft from the gearbox is directly directed to the rear axle. To distribute the rotation of the wheels to each wheel, you will need 2 identical axles, for example, from the Zhiguli. But for installation you have to shorten them. To increase the cross-country ability, if desired, a lowering chain reducer can be made, combining with a standard gearbox. In this case, the driving gear should be slightly smaller than the driven one. By simple calculations of the ratio of the diameters of these gears, you can find out by how much the maximum speed will decrease and the thrust will increase. If the ATV is not planned to be used for driving on public roads, then this will be a very significant technical solution.

Increased functionality

Now that the frame and chassis are assembled and the engine is installed, you need to think about the secondary structures that will make the technique practical. The fuel tank will fit well from a Ural motorcycle. Its impressive capacity will be enough even for a car engine. An important modification will be the snorkel installation. Since the engine is located quite low in the frame, the air filter also draws air from the bottom accordingly. To prevent water from getting into it when overcoming the fords, it is highly recommended to do this. The exhaust system also needs to be completely redone, with the exhaust gas outlet at a fairly high level so that water does not get inside either. Also, for an ATV you need a large wide seat, moving the body weight, it will be possible to achieve better control while driving. Aluminum sheet metal can be used for underbody protection to protect the front suspension arms and engine. A winch installed in the front will not be superfluous in the forest. Car fog lights can be used to illuminate the road.

Work on the appearance

In conclusion, you need a body to get a proper ATV look and feel. To do this, you will need ED-20 epoxy and fiberglass. These components can be purchased at a hardware store or hardware store.

To give this shape, first you need to cut out a blank from dense foam, which is also sold in large hardware stores in the form of 1 m2 plates, which is very convenient for creating such projects. Then fiberglass is applied in several layers, while each layer is coated with resin. The more layers, the stronger the case. Do not forget about the metal fasteners, which must be inserted between the layers, in the future for which the body will be attached to the ATV frame. After drying, it can be primed, sanded and painted. This fiberglass body is lightweight and very durable.

With a serious approach to business, such an ATV will be little inferior to the factory one, and in terms of assembly costs, it turns out to be many times cheaper. Despite the fact that you can assemble such a thing for yourself and get a lot of driving pleasure.