We will tell about the main composite power steering, how to replace the pump and pump the system.

Who had to go to the domestic car without a waterwater and then transfer to a foreign car, immediately say that the difference is essential and sensitively others when driving. No need to strain your arms, think about the turn path, as well as the hydraulicel helps to keep maneuverability, driving a car and softens blows.

Much more pleasant when such a hydraulicel is installed on the car, but sooner or later the moment comes when it fails. The characteristic breakdowns of the hydraulicel is considered to be the manifestation of noise during the rotation of the steering wheel, the reduction of the liquid, turning the steering wheel with the jerks or the tight rotation of the steering wheel, the manifestation of various sodes when driving around the uneven road, or worse than this is a decrease in car manageability.

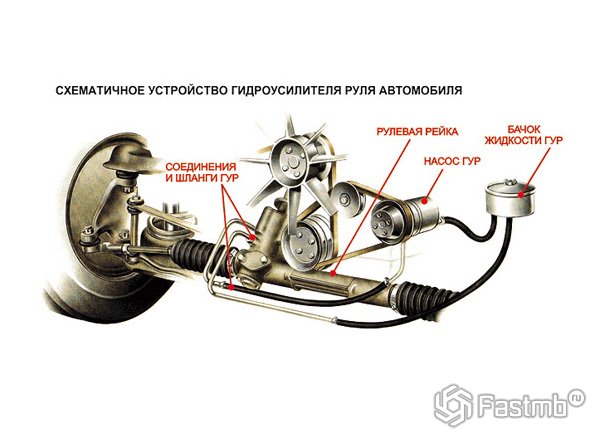

Major composite hydraulic

Depending on the model and brand of the car, the design of the hydraulicer may differ, but still, there are always the main details. First of all, it is a pump that is designed to maintain pressure and fluid movement in the system. The distributor - supplies fluid according to certain system cylinders, it does not touch the engine cylinders. A hydraulic cylinder that helps, by means of pressure, moves the piston, which in turn transmits an effort on the wheels to facilitate the rotation. And of course, do not do without connecting hoses that help circulate fluid in the system and transfer the liquid of one part to another.

If you have discovered a malfunction in the hydraulicel, do not postpone the repair or replacement parts for later. Sometimes repairs can correct the situation, but it happens when you only need to replace the damaged item.

Replace the entire steering power plate is not so simple, you have to remove the car engine and disassemble half the front running part. In new foreign cars, a much more complex mechanism and better contact the service center immediately.

The average replacement price per service station is from 30 dollars, as the complexity depends on the car. In service centers are much more expensive, as the original parts are used.

For example, consider the replacement of the pump hydraulic power supply, since it most often it comes in disrepair.

Replacing the pump hydraulic

The first thing worth to do when replacing is to remove the belt from the hydraulic agent. Immediately I want to warn that before removal, we recommend remembering the power of the belt tension, if you do not like to pick up at random, as it was before repair. If you do not know how to do it properly, then put the labels before you begin to take it.

To remove the belt, you need to let the roller of the hydraulic tensioner roller, and then weaken the belt with the tensioner. Then remove the protection against the belt, usually one bolt is turned off completely, and the second is close to the protection. Now we can remove the belt.

They advise you to watch the tensioner's roller and the tensioner itself, sometimes there is nothing wrong with the view, but by srolling it, we can see how he goes eight. In this case, it is worth replacing, as it will very much to affect the wear of the hydraulic belt.

Now, as it should be, the safety technique is de-energizing the power supply of the machine, removing the terminals from the battery. Then disconnect the sensor terminals from the hydraulic agent and unscrew the fuel hoses. Prepare the container in advance, as the liquid flows from these tips, it is best not to merge, but to close the plug. The next step is unscrewed by the high pressure tube of the hydraulic plug.

In order to remove the tube, you need to move it a bit clockwise and counterclockwise. But you need to be very careful, since the tip of the tube is aluminum and can easily break. The case is left for the removal of the hydraulic pocket, it is not cunning, the bolts are damaged behind the belt pulley, for this we unscrew the bolts alternately, scrolling the pulley for each.

The collection occurs in the reverse order, it is not worth tightening the bolts through the power so as not to break the hats. We stretch the belt on the labels that we did earlier, but also it is not worth the overpatch, as it will lead to a rapid erasure of the belt.

Pumping power steering system

Replacing the Pump of the Hydrauscitel, this is not a complete process, it is necessary to still make a system without air, plus it will be necessary to top up the fluid in the tank. It is best to change the liquid to a warm engine, but since we changed the pump of the hydraulicel, it is clear that everything was cooled.

Warm tag and all possible channels for which liquid will be merged using a technical hair dryer. But it is not necessary to diligently so as not to overheat and do not hit the tubes. Pre-prepared transmission fluid is also better to warm up, as it will be better to pour. Each uses the one that is recommended by the car manufacturer, most of the manufacturers recommend DextRon II. Do not forget about the minus temperature, in the cold, the main thing is not to penetrate, so when you choose a liquid, pay on the label on the label.

After disconnected the loose hose from the hydraulic tank, lower it into an empty bottle. The hole itself in the tank, where there was a return, it is worth it to close something. The process passes as follows: Pour the transmission fluid into the hydraulic tape tanks, scroll the starter, which in turn turns the pump pump and it pumps the grinding in the return tube, then in turn into an empty bottle.

In color, it will be possible to understand when the fluid is pumped in the hydraulicel, then it is worth stopping the pumping. Next, connect the return hose with a tank and scroll through the starter again and move the steering wheel in parallel, somewhere 25% of its turnover, left and right. This is to feel the steering wheel. In no case do not start the engine, since the fluid in the pressure hydraulicel will fly out.

On this pumping and replacing the hydraulic pumper pump ends, we collect everything in the reverse process, connect the fuel pump. We look at the transmission fluid in the tank to the maximum level. Sit into the car and drive a couple of circles. At the same time, and pump it on the working engine.

During the ride, try to extrude the steering wheel in a state of movement of the machine, this is how you will feel if there are some more shortcomings or crunch. There should be no failures during turn or noise. It is even better to put on a man street and whatever he looked at and listened to, how the front wheels behave during work and does not give extraneous sounds of the new pump of the hydraulic agent.

Video about the principle of operation of the power steering: