It has become an integral part of most cars. Russian-made vehicles are no exception. The hydraulic booster was initially installed on the VAZ-2110, and then on all subsequent models. In a power steering system, the weakest link is the pump. Unification has a positive effect on the maintainability of cars. The power steering pump of VAZ models (ZF brand (ZFLS 7691 955 339) is used on other models of the plant, as well as on Wolksvagen Passat or Transporter, Audi A6. Its cost is relatively low and, if necessary, you can replace it yourself. About replacing the power steering pump and will be discussed in this article.

Power steering problems begin to manifest themselves in the form of heaviness when the steering wheel is turned, especially at low speeds; a hum may appear and a whistle may appear. When the device finally broke down, it stopped helping to steer even when not warmed up. Since the venerable age of the car left no hope for official warranty service, I decided that the replacement of the power steering would be done on my own.

Looking ahead, I would like to note that replacing parts yourself in order to save money on repairs showed the excessive optimism of such an idea. The work of replacing it was quite laborious. However, for those for whom working with a car is a kind of vacation, repairing a hydraulic drive will not seem like anything special.

Before starting work, it is worth assessing the general condition of all power steering components in order to replace them if necessary.

It is worth assessing the need to purchase a pump, pulley, oil seal, Teflon ring for high-pressure pipes and a belt. I get to work, having removed the protection, the mudguard on the belts. Next, the coolant tanks are removed. I remove the GUR belt or simply cut it, depending on its condition. Next comes the disconnection of the power steering tubes, both inlet and outlet, attached to the nuts.

On the right side of the radiator, I take out the gland that feeds the tube, which is held by a simple retainer, and then drain the liquid from the tube. To completely remove fluid from the system, it is advisable to ask someone to spin the wheels of the car. After this operation, I disconnect the flange of the power steering high pressure pipe. The next step is to unscrew the clamp securing the supply tube. The pump mount is held in place by four bolts. I unscrew three of them immediately, and access to the fourth opens after unscrewing the bolts of the timing belt cover. Now you can remove all four bolts holding the pump in place.

How to change the pump

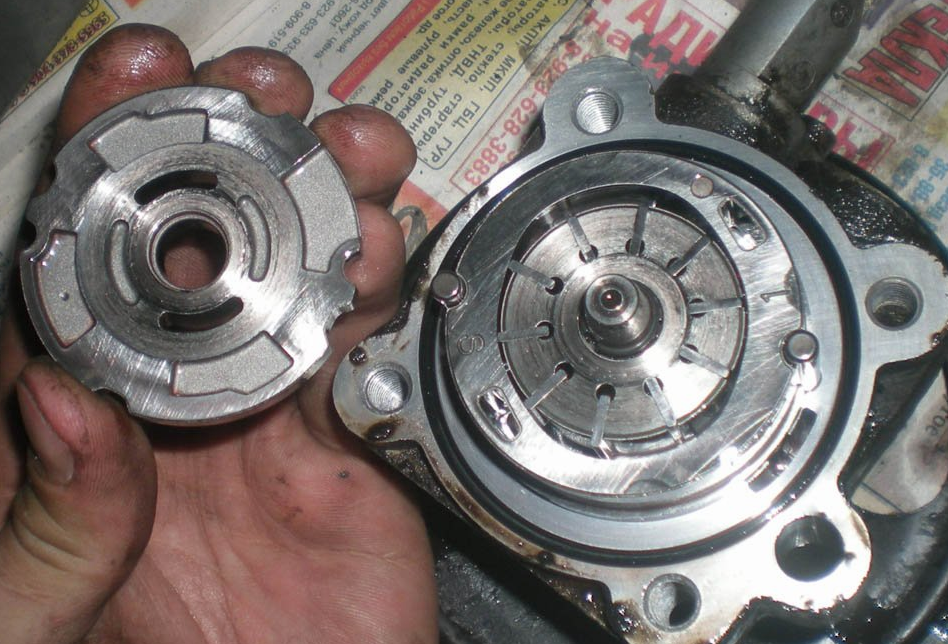

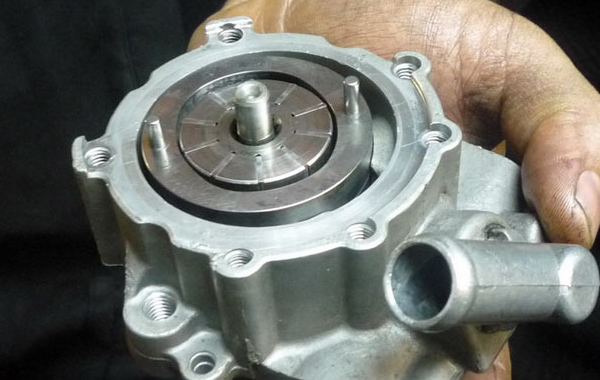

Disassembly of the pump and dismantling of the power steering must be carried out according to the instructions. Further, I recommend that it be cleaned of dirt and inspected in order to identify the causes of the malfunction. Often the cause of the breakdown is the development in the internal cavity of the pump housing. Visually it is perceived as a step. You can deal with the defect using a drill with an attachment. However, difficulties may arise if a non-collapsible pump model is caught, which has neither retaining rings nor covers.

I broke the clamps for attaching the pipes to the tank, because in my case the clamps turned out to be disposable. After which I drained the remaining fluid from the tank. When using it again, you should definitely look inside and check the cleanliness of the mesh located there. If necessary, the tank should be washed or a new one should be bought, since its cost is low. Cleaning the system does not end there. It is desirable to clean all the insides with compressed air under a pressure of eight atmospheres. After this, the pump pipe clamp is disconnected.

Teflon gaskets are durable, but on high pressure tubing flanges, they should be replaced with new ones. Even in comfortable conditions - a garage, a pit - replacing the pump took me about three hours of work. In general, the job of replacing the pump takes about six hours of careful work. If the design of the pump allows it to be repaired, then pressing out the pulley and oil seal takes a special place.  But in order to save time and effort, it is better to replace it with a new one. If replacement is not possible, you will have to press a new pulley onto the shaft of the new pump. The structure is fixed with a screw and nut. The pump shaft has an M6 thread inside. To put the flange on the shaft, it must be preheated. After cooling, it will sit tightly on the shaft. Inside the pump, the power steering bearing is secured with a curved edge.

But in order to save time and effort, it is better to replace it with a new one. If replacement is not possible, you will have to press a new pulley onto the shaft of the new pump. The structure is fixed with a screw and nut. The pump shaft has an M6 thread inside. To put the flange on the shaft, it must be preheated. After cooling, it will sit tightly on the shaft. Inside the pump, the power steering bearing is secured with a curved edge.

Installation of the power steering is carried out in the reverse order. I tensioned the belt using a cone. Sometimes a special tin device is used for these purposes. Or another option is possible, when the power steering mount is not fully tightened and the belt is loosely put on the pulley. Only after this is the entire structure secured with the required degree of belt tension.

Bleeding the pump after installation

The power steering pump is assembled in reverse order. After assembly, the power steering may make a buzzing noise, but you should not be afraid of this, since the parts will wear in after 300-500 kilometers. Some car owners keep it, but I would recommend adding new fluid.  Usually it is filled until the tank is completely filled. The system is filled with the engine running. It is important to prevent air from entering the system. If this could not be avoided, as happened to me, then after the fluid had foamed, I stood for about thirty minutes with the reservoir open, constantly adding it to the power steering. And even after that, for two hours the power steering jerked at times.

Usually it is filled until the tank is completely filled. The system is filled with the engine running. It is important to prevent air from entering the system. If this could not be avoided, as happened to me, then after the fluid had foamed, I stood for about thirty minutes with the reservoir open, constantly adding it to the power steering. And even after that, for two hours the power steering jerked at times.

Video “Replacing the power steering pump at home”

In the video below you will learn how to replace the power steering pump at home.