What materials will you need if you are going to do it yourself?

it construction hair dryer(required, no home hair dryer will work), stitching roller(for rolling up soundproofing material, I advise you to buy it, the cost is low, but the benefits are tangible), scissors(for cutting material), solvent(you can use white spirit as a degreaser before applying soundproofing) and the desire to make "Shumka".

Materials for car noise insulation

Vibroplast Silver

Flexible and elastic vibration-absorbing material representing a self-adhesive backing with aluminum foil. The layout drawing (squares 5x5 cm) allows you to cut the sheet into parts of the desired size. The material does not absorb moisture and does not decompose under the influence of the environment, has anti-corrosion and sealant properties. Easily mounts on surfaces with complex reliefs and does not require heating during installation. Weight 3 kg / m2. Thickness 2 mm.Processing areas: doors, roof, body sides, hood and trunk lid, bulkhead on the passenger side.

Vibroplast Gold

The same as the vibroplast Silver, but thicker, which means it has greater vibration isolation. Weight 4 kg / m2. Thickness 2.3 mm.BiMast Bomb

Vibration-absorbing material. Represents a multilayer structure from a face layer (aluminum foil), a sheet based on a bitumen composition, a sheet based on a rubber composition. During installation, it requires heating up to 40 - 50 ° С. The material does not absorb moisture. The best vibration-damping material. Has the highest efficiency. Ideal for audio speaker preparation. Thickness: 4.2mm. Weight: 6 kg / m2.Processing zones: bulkhead, tunnel, wheel arches, area above the muffler, propeller shaft.

Spleen 3004

Sound insulating material with an adhesive layer. Possesses high heat-insulating properties. It does not absorb moisture and does not degrade when exposed to the environment. Weight: 0.42 kg / m3. Thickness - 4 mm. It can be operated at temperatures from -40 ° С to + 70 ° С. Processing zones: front panel of the passenger compartment, wheel arches, doors, tunnel. There is splen 3008, which is 8 mm thick, and splen 3002, which is 2 mm thick.

Sound insulating material with an adhesive layer. Possesses high heat-insulating properties. It does not absorb moisture and does not degrade when exposed to the environment. Weight: 0.42 kg / m3. Thickness - 4 mm. It can be operated at temperatures from -40 ° С to + 70 ° С. Processing zones: front panel of the passenger compartment, wheel arches, doors, tunnel. There is splen 3008, which is 8 mm thick, and splen 3002, which is 2 mm thick. Splenna is glued with a second layer on vibration-absorbing material, it is glued to doors, front, rear arches. To create a strong bond, the surfaces to be bonded must be clean and dry. White spirit or acetone can be used to clean the bonded surfaces.

The optimum application temperature is 18-35 ° C, which guarantees the preservation of adhesive properties at temperatures from -40 ° C to + 70 ° C. At temperatures below +10 ° С it is not recommended to apply "Splen" due to the low initial adhesion force. The adhesive tape should be applied without tension. The protective layer is removed immediately before application.

Bitoplast 5 (antiskrip)

Sound absorbing and sealing material(eliminates squeaks and bounce in the cabin) based on polyurethane foam with a sticky layer, protected by a gasket, with a special impregnation. Waterproof, durable, not subject to decomposition, has thermal insulation properties. Odorless. Retains properties at low temperatures (down to -50 ° C).

Sound absorbing and sealing material(eliminates squeaks and bounce in the cabin) based on polyurethane foam with a sticky layer, protected by a gasket, with a special impregnation. Waterproof, durable, not subject to decomposition, has thermal insulation properties. Odorless. Retains properties at low temperatures (down to -50 ° C). Thickness 5 mm. Weight 0.4 kg / m2. It also comes in a thickness of 10 mm (Bitoplast 10).

Accent 10

Sound absorbing material. Consists of a metallized film, flexible polyurethane foam and an adhesive mounting layer. It has good heat-shielding properties. Extended operating frequency range. Absorbs up to 90% of noise. Thickness 10 mm. Weight 0.5 kg / m2. The material is efficient at temperatures from -40 ° C to + 100 ° C.Processing areas: hood and trunk lid, engine compartment bulkhead.

Madeleine

Madeleine - sealing and decorative material on a black fabric base. Material 1-1.5 mm thick with an adhesive layer, which is protected by a release liner.

Madeleine - sealing and decorative material on a black fabric base. Material 1-1.5 mm thick with an adhesive layer, which is protected by a release liner. Application:

- gaps between decorative elements of the passenger compartment and the car body

- instrument panel gaps

- duct seal

Noise insulation for bonnet and bonnet

Do not think that by making the hood soundproofing you can get rid of engine noise. This is not true. Bonnet soundproofing is done for. To do this, you will need the following materials - accent (10 mm) and vibroplast silver.When soundproofing the hood lid, we take into account the weight of the material, if you make the hood too heavy, then soon the hood shock absorbers will flow and they will have to be changed.

As a vibration-insulating material, we use vibroplast silver (or an analogue), which is lightweight. A special material is used as a heat-insulating material - an accent that designed to keep warm inside the engine compartment in winter, resistant to high temperature and will not ignite from engine heat. Thickness - the more the better.

As a vibration-insulating material, we use vibroplast silver (or an analogue), which is lightweight. A special material is used as a heat-insulating material - an accent that designed to keep warm inside the engine compartment in winter, resistant to high temperature and will not ignite from engine heat. Thickness - the more the better.

Let's pay attention to the presence of factory heat-insulating material. His in no case should be thrown away and our hood insulation should be a help, not a replacement. So when choosing the thickness of the "accent" one should be guided by the principle, so that later it would be easy to put on the standard soundproofing of the hood.

On some cars there is no factory hood "noise", then hood sound insulation is necessary, and the thickest material is used as heat insulation material - 15 mm. Together with vibration damping material, this will give the best effect in terms of bonnet insulation.

Soundproofing car doors

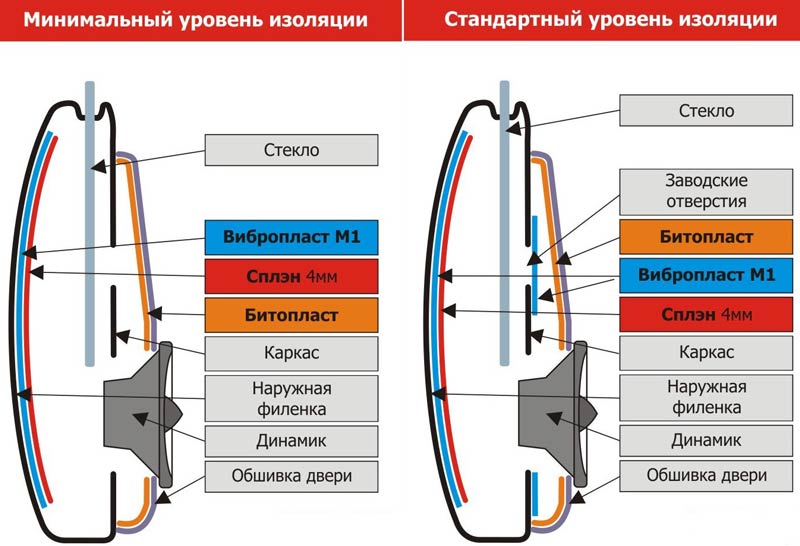

Soundproofing of doors is done to get rid of external noise and to improve the sound of music in the car. From my own experience I can say that even a simple "noise" of the door works wonders, and the music after it starts to play better. For minimum noise insulation of doors, only vibration-insulating material is required, such as vibroplast "Silver" or "Gold". You need to glue it on the inside of the door opposite the column. The larger the coverage area of the vibration-insulating material, the better, and the thinner the metal, the greater the amount of vibration-insulating material required - vibroplast.

For minimum noise insulation of doors, only vibration-insulating material is required, such as vibroplast "Silver" or "Gold". You need to glue it on the inside of the door opposite the column. The larger the coverage area of the vibration-insulating material, the better, and the thinner the metal, the greater the amount of vibration-insulating material required - vibroplast.

When soundproofing car doors, take into account the weight of the materials. If you heavily weight the door, then over time the door will sag and you will have to change the hinges. Here you need a reasonable approach from the set goals. If you are going to improve the sound of an audio system, then you will not get off with small funds. We need an integrated approach and sound insulation of at least 4 layers (!).

The first layer - insulation is glued inside the door. Vibroplast-silver (gold) or a small amount of bimast bombs in the place behind the speaker is used as a material. The second layer - on top of the vibration-insulating material, a splenium of 4-8 mm is laid.

The first layer - insulation is glued inside the door. Vibroplast-silver (gold) or a small amount of bimast bombs in the place behind the speaker is used as a material. The second layer - on top of the vibration-insulating material, a splenium of 4-8 mm is laid.

Next comes the soundproofing of the door outside, under the door cards and will suit lovers of high-quality car sound. It is necessary to completely seal the technological holes in order to make the volume of the door, in which the speaker plays, airtight. In addition, after this operation increase the rigidity of the door, which will have a positive effect on the sound of music... Outside, we glue it over with a vibroplast with a silver and on top with a spleen for sound insulation.

The next step - soundproofing door cards - we do so that they do not creak and make unnecessary sounds. Useful anti-creak and noise-insulating material "Bitoplast". The thicker the bitoplast, the better. Do not forget about the "crickets" inside the door and additionally glue the rods and handles with the "Madeleine - antiskrip" material.

Noise insulation for rear doors performed in the same way as the front ones. Only if there are no speakers in the door, the number of layers is reduced and the type of vibration damping material is used more easily.

Soundproofing the roof and ceiling of the car

Roof soundproofing is done to reduce outside noise, mainly from rain, and also to remove "crickets". After soundproofing the ceiling, the effect during the rain is amazing - when it is raining heavily, there will be no loud "drumbeat" in the cabin, there will be slightly muffled beats that do not cause discomfort.Vibroplast gold or silver is used as a material. Weight is important, because the heavier the ceiling, the higher the center of gravity of the car, which will negatively affect handling. As a sound-absorbing material we use 4 or 8 mm splenitis, possibly in 2 layers. The possibilities for soundproofing the roof are limited so that the ceiling sheathing can then be properly installed in its place.

Soundproofing the car floor

Soundproofing the floor is done to protect the noise from the roadway, as well as impacts from small stones on the bottom of the car. You can use the best quality vibration and noise materials. Vibration isolation "bimast bombs" (the best in performance, but also the heaviest) is usually placed on the floor of the car, and a layer of noise-heat insulation "splen" 4 or 8 mm is placed on top.It is inconvenient to lay splenas of large thickness, therefore, it is better to take a material of lesser thickness, but lay it in 2 layers. Be sure to lay the spleen on the entire floor surface, without gaps. The larger the coverage area, the better.

Pay particular attention to the places of the wheel arches on the side of the passenger compartment - these are important places in terms of sound insulation. It is better to glue them in 2 or 3 layers of thicker material, and use "bimast bombs" as vibration isolation. If it is not there, then glue it, for example, with vibroplast gold in 2 layers.

Soundproofing of a trunk, wheel arches, arches

Attention should be pointed at the spare wheel well and, if possible, completely glue it over with vibration-insulating material. And "noise" the plastic lining of the trunk with the anti-creak material "Bitoplast". Soundproofing the wheel arches is necessary to improve the comfort in the passenger compartment. If done correctly, the noise from the wheels and the roadway will be minimal. In winter, there will be no noise from the spikes on winter tires.The sequence of actions for soundproofing the wheel arches: remove the wheel arches (you cannot throw them out, since they are good insulators in themselves). Then we clean it from dirt and apply vibration-insulating material "vibroplast gold" to the inner layer of the arch. Also it is useful to treat wheel arches with anti-gravel, on the one hand, it is protection against corrosion, and on the other hand, it is also sound insulation.

You can soundproof plastic wheel arch liners. We glue vibroplast Silver on the reverse side and Bitoplast as sound insulation. Next, we put the fender liners in place. After the impact of pebbles on the wheel niche will not be heard.