Plastic "armor", long-stroke air suspension, two-stage transfer case on request for diesel versions - the first Audi Allroad was ready for any eventuality. But five years later, the Audi Q7 appeared, and the second Allroad became less "off-road": the maximum ground clearance decreased from 208 mm to 185 mm, the demultiplier disappeared from the list of options ... What will surprise the third one?

The new Audi A6 allroad quattro is also a variation of the A6 Avant station wagon: now with factory code C7. With the same lightweight, strong and rigid body made from 20% aluminum. With the same cozy and solid interior, reminding the driver of both BMW and Jaguar XJ. With the same spacious rear sofa. And with the same dimensionless trunk. And allroad (now just like that, with a small letter) is an air suspension and four-wheel drive with a cylindrical differential.

Externally, the allroad differs from the A6 Avant station wagon except in the wheel arch extensions, door sills and bumpers. But all this supposedly off-road paraphernalia is still an adornment. Thin stainless steel plates do not go under the bottom, but are made flush with the edges of the bumpers.

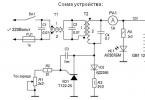

The diagram shows how Allroad's ground clearance changes depending on the selected air suspension mode and vehicle speed. In the rectangles next to the arrows - the time during which the suspension "inflates" and "deflates"

0 / 0

And the clearance? Audi engineers say only that the A6 allroad is 60 mm higher than a regular station wagon, while forgetting to add - in the lift position, when the car rises on air suspension by 45 mm. The maximum ground clearance I measured with a tape measure is 182 mm. And if you lower the car into the normal "transport" position of the comfort and automatic modes, you get only 137 mm.

In fact, the allroad rises above the Avant by only 17 mm. And in the dynamic mode, when the car "squats" by one and a half centimeters, there is no difference at all!

There is no it in the power units either: the allroad is the top version of the Avant, it has only three-liter six-cylinder engines. One petrol, 310 hp, with a mechanical supercharger. And three variations of the turbodiesel: 204, 245 and 310 hp. The latter is the newest version with two turbochargers. It was with her that I began our acquaintance.

In response to pressing the start button, there is a distinct uterine growl and diesel vibration. Sportversion?

Moved off softly. Paired with a powerful diesel engine is an eight-speed "automatic" ZF - the same as on the Audi A8. The preselective seven-speed "robot" that stands on all other modifications of Allroad is simply not designed for the giant super diesel torque of 650 Nm. Traction is unrealistic at any speed exceeding idle!

No additional handrails, no individual decor: the allroad is identical on the inside to the A6 Avant

The anatomy of passion is this. Up to 2500 rpm, the air is pumped mainly by a small turbine with an adjustable guide vane, and the large turbocharger installed before it, in which the inlet blades are fixed, actually rests. Then the distribution flap begins to rotate, directing some of the air from the larger turbine directly into the cylinders. At 3500-4000rpm, depending on the load, this damper completely "turns off" the small turbocharger. The result is fantastic! The avalanche of maximum torque rolls over from one and a half thousand and carries up to 4500 rpm. Switching - and it started again. At the same time, the "automatic" is controlled with a riot of Newton meters surprisingly smoothly and efficiently. And what an accompaniment! It is not for nothing that the superdiesel has an additional resonator next to the final muffler, which forms an unmatched low voice with a rolling "rrr".

A new word in entertainment electronics - pitch and roll indicators. The toy is as beautiful as it is useless

Passengers have two full-fledged seats in business class with optional four-zone climate control

0 / 0

Allroad's acceleration with a gasoline 310-horsepower engine is only slightly less dynamic (5.9 s according to the "passport" versus 5.6 s for a diesel biturbo), but not so dramatic. There is no additional resonator.

A diesel engine with one turbocharger (245hp), like a gasoline engine, is almost invisible at a constant speed. The average fuel consumption shown by the onboard computer is 8.6 l / 100 km. For comparison: on the same route and at the same driving speed, the biturbo diesel consumed 9.8 l / 100 km, and the gasoline engine consumed all 16 l / 100 km. The dynamics, by the way, with a "single-turbine" diesel engine is more than sufficient: acceleration to hundreds according to the "passport" takes 6.6 seconds. And it's a sin to complain about the S tronic preselective gearbox - at least until you drive off the pavement.

The handling does not depend on the choice of engine, but on the item in the Audi drive select menu. Dynamic is a little more sharpness and accuracy, the steering wheel is filled with a pleasant weight. Comfort - a little more rolls and softness, the steering wheel is lighter, but without loss of information content. But in any of the modes, the allroad remains one hundred percent Audi. Steadfast on the Autobahn, a little detached on the twists and turns of the Bundestrasse. And harsh on any road.

Eh, a field, a German field! Ideally, you are plowed, sown, in some places shoots are already visible. The narrow passages are covered with gravel and rammed in such a way that even a Porsche 911 can be driven along them. Even the smoothness of the ride on a bad road cannot be appreciated. Why did I come here? Alas, people from Audi did not find any off-road track in the vicinity of Neckarsulm. Or did not want to find it. And the passability must be checked ...

Only at the entrance to the village was an obstacle worthy of Allroad discovered - not a very steep grassy slope. Off-road lift and allroad modes, in addition to raising the suspension, also mean a softening of the reaction to gas. Conveniently! You can crawl up the hill at snail's speed. And the electronics, when suspended diagonally (short-stroke suspension), with the help of brakes, rigidly grabs the slipping wheels, effectively redistributing torque.

Would you ask for more from such a machine? You can only strip beautiful bumpers.

Easy transformation, powerful load loops and more than one and a half cubic meters of volume with the sofa folded down - the cargo capacity is identical to the BMW five. But Mercedes E 350 and Skoda Superb Combi are more spacious

The carrying capacity of the branded towbar's folding hook has been increased by 20%. Now you can hook a trailer weighing up to two and a half tons to it!

0 / 0

On the Russian off-road, we will not be able to check this until June, when the first Allroads will come to us. Alas, diesel biturbo is not among them. The Russian office of Audi has not yet named the reasons, but the matter is most likely in the engine's excessive sensitivity to the quality of diesel fuel. Modification 3.0 TDI (245 hp) will cost from 2 million 530 thousand rubles, and the price list for the gasoline A6 allroad starts from 2 million 630 thousand. There are virtually no competitors. Volvo XC70 and Subaru Outback are significantly cheaper. The "five" BMW has no air suspension in the list of options. And the Mercedes E 350 4Matic station wagon with air suspension is much more expensive - from 2 million 950 thousand. So the real competition for Allroad will only be the usual A6 Avant station wagon: it is 180 thousand rubles cheaper. But trim leveling (the allroad is equipped with richer) will eat up all the benefits. So it turns out that with all the richness of choice, those who want to have a large dynamic station wagon with slightly increased cross-country ability have no alternatives to Allroad.

| Passport data | ||||

|---|---|---|---|---|

| Automobile | Audi A6 allroad quattro | |||

| Modification | 3.0 TDI S tronic | 3.0 TDI tiptronic | 3.0 TFSI S tronic | |

| Body type | 5-door station wagon | 5-door station wagon | 5-door station wagon | |

| Number of places | 5 | 5 | 5 | |

| Trunk volume, l | 565/1680* | 565/1680* | 565/1680* | |

| Curb weight, kg | 1855 | 1910 | 1855 | |

| Full weight, kg | 2505 | 2560 | 2505 | |

| Engine | turbodiesel, with one turbocharger | turbodiesel, with two turbochargers | gasoline, with a mechanical supercharger | |

| Location | front, longitudinally | front, longitudinally | front, longitudinally | |

| Number and arrangement of cylinders | 6, V-shaped | 6, V-shaped | 6, V-shaped | |

| Number of valves | 24 | 24 | 24 | |

| Working volume, cm3 | 2967 | 2967 | 2995 | |

| Cylinder diameter / piston stroke, mm | 83,0/91,4 | 83,0/91,4 | 84,5/89,0 | |

| Compression ratio | 16,8:1 | 16,0:1 | 10,3:1 | |

| Max. power, hp / kW / rpm | 245/180/4000-4500 | 313/230/3900-4500 | 310/228/550-6500 | |

| Max. torque, Nm / rpm | 580/1750-2500 | 650/1450-2800 | 440/2900-4500 | |

| Transmission | 8-speed automatic | 7-speed robotic | ||

| Drive unit | permanent full, with a cylindrical center differential | |||

| Front suspension | ||||

| Rear suspension | independent, pneumatic, double wishbone | |||

| Front brakes | disc, ventilated | disc, ventilated | disc, ventilated | |

| Rear brakes | disc, ventilated | disc, ventilated | disc, ventilated | |

| Tires | 235/55 R18 | 235/55 R18 | 235/55 R18 | |

| Maximum speed, km / h | 236 | 250** | 250** | |

| Acceleration time 0-100 km / h, s | 6,6 | 5,6 | 5,9 | |

| Fuel consumption, l / 100 km | urban cycle | 7,4 | 7,9 | 11,8 |

| extra-urban cycle | 5,6 | 6,0 | 7,1 | |

| mixed cycle | 6,3 | 6,7 | 8,9 | |

| CO2 emissions in g / km | 165 | 176 | 206 | |

| Environmental class | 65 (75)*** | 65 (75)*** | 65 (75)*** | |

| Fuel tank capacity, l | diesel fuel CN-51 | diesel fuel CN-51 | AI-95 gasoline | |

| Fuel | ||||

| * With rear seats folded ** Limited by electronics *** Option | ||||

The four-level air suspension of the Audi Allroad Quattro is a logical development of the self-leveling system implemented in the Audi A6.

Introduction

Designing a car ideal for good driving conditions and off-roading sounds like squaring a circle. Usually good SUVs are not very pleasant to drive for everyday use on good roads. The high ground clearance - a decisive advantage off-road - determines the vehicle's high center of gravity.

However, this turns out to be a disadvantage when it comes to fast cornering or stability at high speeds. In addition, a higher seating position means greater air resistance and higher fuel consumption.

On the contrary, the shorter the suspension travel, the better the vehicle will "hold the road". However, the same quality significantly impairs off-road passability. Variable ground clearance is the optimal solution for operating a car on any type of road - this design solution is called a 4-level air suspension.

The air suspension in the Allroad Quattro is based on the family system from the Audi A6.

System Description

The 4-level air suspension includes full body level control with conventional spring-loaded front axle dampers and load-adaptive dampers (PDC) on the rear axle. The vehicle body height is monitored individually for each side - using four level sensors.

Each suspension mount has a gas-filled "spring" and a so-called "cross-valve". Thus, each axis can be individually controlled.

The 4-level air suspension is designed as a pneumatic accumulator system. This design improves system performance, reduces noise levels and increases compressor protection.

One of the features of the suspension is the ability to change the vehicle's ground clearance by 66 mm in 4 stages. All four stages can be controlled manually or automatically.

The body position levels are indicated as follows:

- Level 1 = low level (LL)

- Level 2 = normal level (NL)

- Level 3 = high level 1 (HL1)

- Level 4 = high level 2 (HL2)

- Parking PL = high level 1

The latest full-control air suspension has been developed specifically for the Audi Allroad Quattro. In addition to the advantage of automatically controlling and maintaining the level of the body above the road, as described for the Audi A6, this suspension system has additional advantages:

- The 4-level air suspension contains sophisticated, electronically controlled suspension components on both axles. The system allows you to change the level of the body by 66 mm and offers four options for ground clearance (from 142 to 208 mm);

- Depending on road conditions and personal preference, you can choose a higher ground clearance or a lower vehicle stance to improve handling and reduce drag;

- 4-level air suspension automatically maintains a constant level of the body, regardless of the load and weight distribution within the body;

- Setting any of the 4 levels of ground clearance can be carried out manually or automatically within the specified limits;

- Individual automatic functions or the whole system can be disabled using the control unit;

- LED indication on the control panel clearly informs about the current operating mode of the suspension;

- The pneumatic accumulator system ensures maximum driving comfort.

Functioning

The E281 automatic level control unit is used to control the 4-level air suspension and monitor / signal the system status. A certain level change occurs automatically during normal driving. Depending on road conditions, the driver can use the "Raise" or "Lower" buttons to force the appropriate ground clearance at any time.

A single press of the "Raise" button immediately switches the suspension to the next higher level. When you press it again, you can "jump" through the levels - for example, from "Low level" directly to "High level 1". However, "High Level 2" cannot be selected immediately - only if the suspension is already at "High 1".

The transition to low levels is performed in the same way - using the "Down" key. By pressing repeatedly, you can go directly from the “High 2” level to the lowest level.

Note:

- it is possible to raise the body to a higher level only when the engine is running or when there is sufficient air pressure in the pneumatic accumulator;

- it is possible to reduce the height of the body even when the engine is not running.

Indication

One of the four control panel LEDs, which are stacked one on top of the other, glows continuously to indicate the current suspension level.

Only a level change procedure (automatic or manual) will cause one or more LEDs to flash. After the suspension reaches a new level, the indicators stop flashing and light up again with a continuous light.

The LEDs inside the "Raise" and "Lower" keys indicate the execution and verification of the command. If the LED is flashing, then the command to change the suspension level has been rejected (for example, if the driving speed is too high).

If the actual suspension level deviates significantly from the optimal level, the corresponding LEDs will flash, "prompting" the driver for the best option for adjusting the level.

“Significant deviations” means:

- when at least one axle is lower than the next lowest suspension level relative to the current value;

- both axles are higher than the next highest suspension level.

Assigning other keys

Each of the buttons has its own purpose, let's consider what each of them is for.

Automatic switching

The so-called "manual mode" can be switched on or off by pressing the "Raise" or "Lower" buttons (they must be held for at least 3 seconds). A yellow light marked "man" indicates to the driver that the suspension is in manual mode. Parking Level Control and Highway Mode are disabled in manual mode.

Switching off the control system

The control system is turned on or off by pressing the "Level" button (you must hold it for more than 5 seconds). When the control system is off, the LEDs of the operating unit for manual mode, as well as both level buttons and the K134 indicator lamp are activated. The level indicator LEDs show the current level. The corresponding indicator is constantly on.

The control system, which has been deactivated, is automatically activated when the vehicle speed exceeds 10 km / h (unless the "lifting platform" mode is recognized). The control system can also be disabled using diagnostic testers.

Control algorithm

There are two types of control units (depending on the importing country of the vehicle). The control algorithms described below refer to control unit 907 4Z7 553A. Differences in the operating parameters of control units with numbers 4Z7 907 553B are described below.

If the car is on the highest off-road "Level 2", it will automatically "squat" to "Level 1" at a speed of more than 35 km / h. The control system will only allow an increase to "Level 2" at speeds below 30 km / h.

If the vehicle's suspension is at "Level 1", the control system will automatically lower the body to the normal level at speeds over 80 km / h. The system will respond to a manual body up command to “Level 1” only if the speed is less than 75 km / h.

While driving, automatic transition to off-road "Level 1" and "Level 2" is not available. This command must be manually selected by the driver. The Parking level is an exception. In this mode, the vehicle automatically rises to the off-road "Level 1" when it is stopped and locked.

Highway mode

If the car moves faster than 120 km / h for more than 30 seconds and the suspension is at the "Normal" level, then the body will automatically lower down to the "Highway" mode. This lowers air resistance to save fuel and lowers the vehicle's center of gravity for better handling.

The car body is automatically raised to the normal level in the following modes:

Algorithm of the "Parking" mode

The "Parking" mode guarantees the maintenance of the vehicle body height after stopping for a long time. A decrease in the level is possible only due to air cooling in the pneumatic bellows or natural diffusion of the working fluid. The mode makes it easier for passengers to enter / exit and load luggage, and also improves the appearance of a stationary vehicle. The parking level corresponds to the high suspension level - "Level 1" (HL1).

Parking mode is activated:

- when the system is in standby mode and the car is locked from the outside;

- when there is sufficient air pressure in the accumulator;

- when the system is not in manual mode.

Please note: the "Parking" mode (PL = HL1) is canceled only when the speed reaches 80 km / h or when manually switching to a lower level.

If the suspension is already in Off-Road Level 2 (HL2) mode, the body will not lower to Park mode.

Manual mode

Levels "Highway" and "Parking" are available in manual suspension mode.

Differences from the device 4Z7 907 553A described above are:

- lack of parking level control;

- automatic level up to HL

Conditions for automatic lifting of the body to "Level 1" (HL1):

- the system should not be in manual mode;

- Between turning the ignition on and off during the current trip, the driver must select the "Level 1" or "Level 2" suspension mode at least once.

The vehicle body is automatically raised to "Level 1" under the following conditions:

If the system has reduced the height of the body to the minimum level ("Highway" mode), the suspension will automatically rise to "Level 1" when the speed drops below 60 km / h after 30 seconds of movement.

Safe automatic shutdown of the ESP system

For technical reasons, it is not possible to change the level / position of the body when cornering. If cornering is detected, the suspension control functions are disabled. However, the control commands are stored in memory and are implemented as soon as the car switches to straight-line motion.

In the Audi Allroad Quattro, you can influence the algorithm of the ESP stabilization system using the "ESP" button of the suspension control unit of the same name. If the ESP operation has been changed by pressing the ESP button while the ESP LED is on, the skid dynamics control goes into passive mode, but not during braking.

If, for example, the vehicle's suspension is in Level 2 with ESP activated and the driver accelerates sharply on a very winding road, speeds in excess of 35 km / h can be reached even at this suspension level. In order to guarantee maximum safety in these driving conditions, ESP is automatically deactivated at speeds over 70 km / h, despite the high center of gravity. This is called ESP Safe Auto Shutdown.

The normal ESP functions will become available again and the ESP lamp will go out. ESP "Safe Auto-Off" occurs at 70 km / h for the suspension mode "Level 2" and at 120 km / h for "Level 1". ESP is not provided for a normal or low level suspension.

Please note: turns are recognized by the self-leveling control unit J197 by evaluating the signals from the four body level sensors.

System components

Let's take a closer look at each component of the air suspension of the Audi Allroad Quattro.

Pneumatic supports

The front suspension struts feature a completely new design. As with the rear axle, the air springs are mounted coaxially with the shock absorbers in a single suspension strut. The rear air mountings are identical in design and function to those used on the Audi A6 suspension (also equipped with a self-leveling function).

Design

As for the C-pillar, the connection with the simultaneous sealing of the pneumatic support (piston) with the shock absorber is made using a double bayonet seal (for the A-pillar it is made as a single sealing connector No. 17). The differences in design required a change in the type of assembly.

Front suspension strut

The connection of the front air support to the shock absorber is carried out without lubrication. During installation, the No. 17 connector and O-ring must be absolutely dry and free from grease. Before assembling the air mount, make sure the o-ring is on the second shoulder of the shock absorber and is pressed evenly across the entire surface. The pneumatic support (piston) is installed on the shock absorber and pressed by hand. The O-ring is pulled on the collar 3 when the piston moves, where it is held and seals the pneumatic support.

Rear suspension strut

Before installation, the joints must be cleaned and lubricated with a special grease. For installation, the air support is pushed outward and slightly rotated.

Working air pressure in pneumatic mounts

Note: Always check the O-rings for tightness. The surface must be clean, free from rust and pitting (for aluminum parts). The rings should also be lubricated as needed.

Attention! Do not touch the piston when installing or transporting the suspension strut assembly, as the piston can be easily damaged if there is no internal air pressure. If the O-ring is pushed out of the air support, then the rack is not tight.

The pneumatic mounts must not be compressed if there is no working air pressure inside, as this will prevent the cuff from deploying correctly and will be damaged. After servicing the suspension, be sure to fill it with air from an external source using a diagnostic tester before raising or lowering the vehicle on a lifting platform or jack.

The air supply system consists of separate components. Each of them is described in detail below.

Compressor

The design and operation parameters of the compressor fully correspond to the device described for the self-leveling suspension of the Audi A6. Below are the differences only for the 4-level air suspension of the Audi Allroad Quattro:

- The inlet fitting is installed outside the vehicle in front of the spare wheel and is not soundproofed;

- The working pressure is increased to 16 atm. due to the presence of a pressure accumulator;

- Reduced speed to reduce noise;

- The suction connection and the discharge section are placed in the spare wheel area and are equipped with a filter, which is also a noise damper for the passenger compartment;

- The optional suction / discharge valve ensures minimal noise, especially during air bleeding;

- Temperature control is carried out using a sensor on the cylinder head, as well as calculations of the control unit in real time using a special temperature model.

Please note: In normal operation, the compressor is only switched on when the engine is running.

Exceptions:

- final diagnostic procedures;

- basic system setup;

- preliminary start at an excessively low level of pressure in the system.

Special fasteners, consisting of coil springs and rubber damping elements, prevent the transmission of vibration to the body.

Air filter / noise damper

Due to the location of the damping element (in the recess under the spare wheel), its maintenance during operation is not required.

Pressure accumulator

The receiver allows you to change the level of the car body quickly and with minimal noise in the operation of the air suspension, since the receiver can be refueled while the car is moving, when the compressor noise is not so noticeable.

Provided there is sufficient air pressure in the receiver, the body level can be changed without activating the compressor. "Sufficient pressure" means that before lifting the body in the suspension system there must be a pressure difference between the receiver and the pneumatic supports of at least 3 atm.

The receiver is made of aluminum and holds about 5 liters of air. The maximum working pressure is 16 atm.

Air inflation procedure

When driving at a speed of less than 36 km / h, air is pumped primarily into the air suspension mounts (and only when the operating pressure is reached, into the receiver). The pressure accumulator is only filled when driving at a speed of over 36 km / h. Above 36 km / h, the working air is supplied primarily from the compressor.

The described algorithm provides the best economy, including energy savings for powering the compressor, and the lowest noise level.

Pneumatic system diagram

- Additional noise damper;

- Check valve 1;

- Air Dryer;

- Check valve 3;

- Check valve 2;

- Pressure relief valve;

- Pneumatic release valve;

- Compressor V66;

- Electrical outlet valve N111;

- Receiver valve N311;

- Valve for front left strut N148;

- Valve for front right suspension strut N149;

- Valve for strut rear left N150;

- Valve for strut rear right N151;

- Receiver;

- Front left pneumatic support;

- Front right pneumatic support;

- Rear left pneumatic support;

- Rear right pneumatic support.

Solenoid valves

The 4-level air suspension has 6 solenoid valves. The discharge valve N111 forms a functional unit: the pneumatic valve together with the discharge valve are integrated into a single dryer body. The outlet valve N111 is a 3/2-way valve that closes automatically without an electric actuator. The pneumatic outlet valve acts as a pressure limiter and residual pressure holding device.

In the four air springs, the valves N148, N149, N150, N151 and the accumulator valve N311 are combined in a single block. They are designed as 2/2-way valves and are self-closing. Accumulator-side pressure on the air springs further assists in closing.

The pressure lines are color coded to avoid confusion when connecting. The valve blocks are also color-coded to match the connector colors.

Temperature sensor G290 (overheating protection)

To improve the maintainability of the system, the temperature sender G290 is attached to the compressor cylinder head. The J197 control unit operates on a special temperature pattern to prevent overheating of the compressor while ensuring continuous operation.

To do this, the control unit calculates the maximum permissible compressor temperature, depending on the operating time and the temperature sensor signals, and switches off the compressor or blocks it from switching on when certain limit values are reached.

The pressure sender G291 is integrated in the valve block and is used to monitor the pressure in the accumulator (receiver) and the air suspension mountings. Information from the receiver sensor is required for additional verification of the correctness of functions and for self-diagnostics. The individual pressure value in each of the pneumatic supports and the receiver can be set using the appropriate control of the solenoid valves.

The measurement of "personal" pressure is performed during the discharge or filling of the pneumatic supports. The fixed values are stored and updated in the memory of the control unit. The pressure in the accumulator is additionally monitored every 6 minutes while the vehicle is in motion. The G291 transmits a signal (voltage) proportional to the physical air pressure.

The level sensors are so called "angle sensors". With the help of the linkage, the change in the height of the vehicle body is converted into a change in the angle of the sensor element. The angle sensor used in the Audi Allroad Quattro is inductively contactless.

A feature of this type of sensors is the presence of two types of output signal proportional to the angle of rotation of the sensing element. This allows the sensor to be used both for providing four levels of vehicle ground clearance and for monitoring / adjusting the headlight angle.

One output signal provides a voltage proportional to the sensor angle (for headlamp leveling), and a second output signal provides information for the operation of the 4-level air suspension itself.

Please note: the body level sensors are identical in design, only the brackets for their installation and the mechanical connection to the body are different for the rear / front axle and starboard / port side.

Thus, the rotation of the sensor drive arm, as well as the output signal, will be opposite for the left and right side of the body. For example, the amount of stress during suspension compression increases on the sensors on one side and decreases on the other.

For technical reasons, the voltage for the left side level sensors (front left G78 and rear left G76) is supplied from the headlight bulb control unit J431. The power supply for the right side level sensors (front right G289 and rear right G77) is supplied by the 4-level air suspension control unit J197. This arrangement ensures that if the J197 control unit fails, the headlamp control circuit will continue to operate.

Pin assignment for level sensor

J431 - J431 control unit for headlight range control;

J197 is a self-leveling block.

Design and function

An angle sensor essentially consists of a stator and a rotor. The stator is a multilayer printed circuit board that includes field coils, three receiver coils and control electronics. The three take-up coils are angular and phase-shifted. The excitation coils are mounted on the back of the printed circuit board.

The rotor consists of a closed conductive loop connected to an arm that oscillates with a mechanical drive arm. The turns of the conductor have the same geometric shape as the receiving coils.

Functioning

The excitation coils are exposed to an alternating magnetic field, which induces EMF induction in the rotor turns. The current induced in the rotor produces its own alternating electromagnetic field around the rotor winding. Both alternating fields act on the receiving coils and induce two types of alternating current in them.

While the induction of the rotor is independent of its angular position, the induction of the receiving coils is determined by their distance from the rotor, so that its angular position can be determined.

When the rotor, depending on its angular position, "blocks the road" to the secondary current in the receiving coil, the voltage amplitudes change in strict accordance with the angle of the rotor position.

The electronic unit evaluates the AC compensation in the receiving coils, amplifies this signal and generates a proportional output voltage (dynamically varying). The output voltage is the receive signal for the body level sensors and is used / processed by the suspension control unit.

Voltage amplitudes depending on the position of the rotor in relation to the receiving coil (example of determining the position of the rotor).

Level sensors (short description)

The advantages of "angle sensors" are in their design - contactless signal reception reduces interference.

Receiving a relative signal proportional to the angle of rotation makes it sensitive to mechanical tolerances, such as distance from the sensor, position / tilt error of the sensor, and the like. At the same time, electromagnetic interference is largely compensated for by obtaining a relative signal.

Thus, the design of the sensor does not impose strict requirements on the magnetic characteristics of the material, operating temperature and the "age" of the components. Deviations in the measured signal can only be caused by "aging" or heating of permanent magnets and the associated decrease in the magnetic field strength.

- Lights up for one second when terminal 15 is on (self-test);

- Lights up continuously when there are system errors or when the system is turned off;

- Lights up continuously during system calibration when the basic settings have not been performed correctly;

- Flashes at an extremely low or high position of the body relative to specific driving parameters;

- Flashes during control diagnostics.

The J197 unit is connected via the K-wire interface. The control board, integrated into the general unit, evaluates the signals from pressing the buttons for changing the body level on the dashboard and transmits them in the form of an appropriate data protocol via the K-wire interface to the J197 control unit.

The J197 control unit transmits information about the vehicle height and the current system status back to the E281 via the K-wire interface as well. Then the electronic unit turns on the corresponding indication LEDs.

To increase the reliability, the "Raise" key performs the backup functions of the additional interface.

Please note: the connection via the K-wire interface of blocks E281 and J197 is not related to the self-diagnosis K-wire functions between the block J197 and the diagnostic tester.

Interface

CAN data bus

The design of the four-level air suspension provides for the exchange of data between the self-leveling unit J197 and the control unit via the CAN bus (with the exception of several interfaces).

The diagram shows the algorithm for the exchange of information between the transmission control unit and the control control unit via the CAN bus.

Additional algorithms

The control unit also has additional algorithms, we will also consider them.

Signal from door limit switches

- This is the ground from the central locking control unit, which signals the opening of the rear doors and / or the trunk lid;

- Also used as a "wake-up pulse" to bring the system from sleep to on-line.

Signal from terminal 50

- signals the inclusion of the starter and serves to turn off the compressor during start-up.

If low body position is detected after the wake-up pulse, the compressor is immediately activated so that the vehicle can start moving as quickly as possible. The compressor shuts down during engine start to conserve battery power and provide adequate starting power.

Car stop signal

- Used as information to control the parking mode;

- Received as a ground signal from central locking unit J429;

- Not taken into account in self-diagnostics. In the absence of a signal, the parking level control is not performed.

Vehicle speed signal

- Represents a "square wave" generated by the instrument panel. Its frequency changes in accordance with the speed of the vehicle;

- It is used to assess the state of the car (movement / stop) and, accordingly, to select the control algorithm.

The speed information is superfluous, since this information is duplicated over the CAN bus.

K wire

The interface is used for system diagnostics (communication between the J197 control unit and the diagnostic tester connector). The K-wire communicates with the system through normal information messages.

The K wire self-diagnosis interface should not be confused with the K-wire connection of the E281 operating unit to the J197 control unit.

Power supply for the headlight range adjustment system

For the 4-level air suspension in the Audi Allroad Quattro, the position of the headlights is controlled by the control unit J197.

Please note that the central locking signal is not required for vehicles without a parking level control system.

Trailer connection signal

Supplied from contact switch F216 of the trailer coupling. When the plug is inserted, contact switch F216 connects J197 to ground.

Headlight range control

When the vehicle height changes, that is, both axles are raised / lowered at once, this leads to a short-term decrease in the headlight range. To compensate for this effect, the Allroad Quattro is equipped with an automatic headlight range control (with the exception of discharge headlamps).

The Automatic Dynamic Headlight Height Control maintains the beam of light at a constant angle to the road regardless of vehicle height / level changes.

In order to prevent errors in headlight correction from oscillation of the suspension on irregularities, it is carried out only with some continuous uniform movement of the vehicle (with little or no acceleration).

If a change in body level occurs, for example in highway mode, the 4-level air suspension control unit J197 transmits a voltage pulse to J431. This immediately activates the HRC to control the body change algorithm:

- to raise the level - first the rear axle, then the front;

- to lower the level - first the front axle, then the rear.

Control algorithms

Now more about air suspension control algorithms.

The central element of the air suspension system is the control unit, which, in addition to the control functions, allows monitoring and diagnostics of the entire system. The control unit receives signals from the height sensors and uses them to determine the current position of the body.

If it differs from the "reference" for the given mode of movement, the unit issues a command for correction taking into account other monitored values, including the response time and the actual value of the level deviation.

Depending on the driving conditions, the unit controls the suspension by implementing the appropriate algorithms. Comprehensive self-diagnosis function facilitates air suspension inspection and maintenance. Two suspension control units are fitted on the Audi Allroad Quattro, depending on the importing country.

Control units numbered 4Z7 907 553A and 4Z7 907 553B implement different control algorithms. A unified algorithm for both blocks (index "B") is planned to be implemented in the future.

Please note that the system can be tested using built-in self-diagnostic routines. Or test apparatus 1598/35.

Power supply for headlamp leveling system

As described in the "Level sensors" section above, the left-hand side sensors are supplied with voltage from the headlight control unit J431. The headlamp leveling mechanism does not need to be permanently energized; therefore, power is supplied via control unit J431 (terminal 15) with the ignition on.

However, all left and right side level sensors must be online even with the ignition off. To enable the left-hand level sensors to provide information, the 4-level suspension of the Audi Allroad Quattro has a J431 (HRC) control unit connected to J197. This ensures that voltage is applied to all level sensors when control unit J197 is active.

Modes

The suspension system of the Audi Allroad Quattro has various modes. The following is a description of each mode and how they can be controlled.

Off-road mode / Normal mode

Reaction time when level changes

Algorithm of control when changing the level

The change in level is mainly carried out from axle to axle, as a result of which the level difference between the left and right sides of the body is compensated, for example, if the load in the car is unevenly placed - closer to one side.

Level change process:

- Raise - first the rear axle, then the front;

- Lowering - first the front axle, then the rear.

Starting and stopping

The "Start of motion" mode is designed to compensate for body deviations after parking, for example, when one of the passengers leaves or unloads the car, and before a trip due to a decrease in the air temperature in the pneumatic bellows, natural air leakage, etc. These modes help reduce waiting before starting to move to a minimum.

After switching off the ignition, the control unit goes into standby mode and remains active for a maximum of 15 minutes (power is supplied via terminal 30) until it goes into sleep mode.

To save battery power when the engine is not running, the polling of sensors and the set of functions of the unit are limited both in number and in duration.

"Sleep" mode

To minimize power consumption, the control unit switches to "sleep mode" after 15 minutes. The duration of "sleep" is not adjustable. And the inclusion of the block is activated by the impulse of the door limit switch.

When there is a signal from the door open sensor, the unit "wakes up" and is ready to start working immediately as soon as the ignition is turned on or a signal from the speed sensor appears (the car will move).

The system can switch between sleep and ready mode up to 15 times. For the next 15 wake-up procedures, the system will go to sleep in just 1 minute. The system can then only be activated via terminal 15 and / or a signal from the speed sensor.

Lift mode

The air suspension control unit evaluates the signals from the level sensors for a stationary vehicle. If in this case the body "spontaneously" rises, the unit initiates the "lift" mode. The "Lift" mode is designed to protect the pneumatic supports from excessive stretching in the absence of a load, when the car body is raised on the platform.

Please note: in order for the control unit to correctly recognize the "Lift" mode, the vehicle must be raised as quickly as possible.

Using a trailer

The correct hitch position must be determined for a "Normal" body level. The connection of the switch F216 to the 13-pin trailer connector is used to recognize its connection.

If the presence of a trailer is detected, manual suspension mode is automatically activated, the "man" diode on the instrument panel lights up. The automatic suspension control is then canceled. The body level is set to the normal level by the E281 control unit.

Please note: when towing a trailer, the normal suspension mode must always be selected.

It is necessary to ensure that the system switches to manual mode (for example, there is no automatic switch to manual mode if the signal about connecting a trailer is not recognized).

In difficult road conditions, the off-road modes (level 1 or 2) can be activated, but the normal suspension mode must be re-selected at speeds up to 35 km / h. Driving with a trailer on a low suspension level or in automatic mode is not allowed!

Additional tools

The 1598/35 adapter cable from the 1598/14 tester is used for troubleshooting and testing four-level air suspension sensors. Since the pin assignment of the tester is not compatible with that of the J197 control unit, template VAG 1598 / 35-1 must be used. The pin assignment can only be found using the VAG 1598 / 35-1 template.

The basic setting of the "reference" air suspension level system is carried out by entering the ground clearance value with the body position at the "Normal" level. The measured value from the center of the wheel to the lower edge of the wheel arch must be entered into the control unit using the diagnostic tester - function 10 "Adaptation".

The codes are used to determine the reference value for the normal level (Audi Allroad Quattro - 402 mm). This means that the value of the specific values of the body level sensors will be taken into account, corrected for the "reference" value.

Due to the tolerances of the components of the measuring system, there will be a discrepancy between the actual (measured) and reference values. If there is data on the actual body level, control unit J197 detects a discrepancy with the reference values, on the basis of which the readings of the specific level sensors are corrected.

The advantages of the described measuring method:

- no influence of a fixed basic setting due to ...

… Different tread depths and tire pressures.

… Minor irregularities in the road surface.

… Different sizes of tires.

- ease of customization.

Codes for AllroadQuattro

Self-diagnosis. Keyword: 34 Self Leveling Suspension

Both generations of the diagnostic tester (VAG 1551/1552 and VAS 5051) are suitable for connection to a 4-level air suspension control unit. Due to the limited capabilities of the software maps, there are textual display restrictions for V.A.G. instruments. 1551 and 1552.

Control unit 4Z7 907 553A / B. Control algorithms for the 4-level air suspension of the Audi Allroad Quattro, including the range.

General information about the model

The first generation Audi Allroad (C5) is a premium all-wheel drive station wagon. The SUV is a 5-door modification of the Audi A6 Avant with permanent all-wheel drive. The Allroad C5 was assembled at the company's plant in Germany. The first generation of the model was produced from 1999 to 2005.

The German automobile concern Audi has long been famous for its four-wheel drive cars, but until 1998 they remained just city cars with good handling. However, German engineers, driven by competitors, primarily the Japanese, decided to gain fame in the class of "off-road" cars. Thus, the flagship of the Audi A6 Avant line has undergone a modernization, and the first SUV from Audi, the Allroad C5, saw the light.

The car was first shown in 1998 at the Detroit Motor Show. By the end of the 90s, interest in such hybrids of an SUV and a passenger car especially increased, primarily in the United States, which explains the choice of the presentation location. Having received the most flattering comments from the public, German engineers brought the prototype to mind and in 1999 the first production samples of the Audi Allroad C5 rolled off the assembly line.

Undoubtedly, the developers of the new model did not disregard the successes of Japanese competitors in this field, therefore, in many ways, the Allroad resembles the Subaru Outback. But they took as a basis only the concept - a light off-road vehicle, or simply a SUV.

Interestingly, the C5 was produced unchanged until the second generation Allroad was released. Compared to its predecessor Avant, the Allroad is 15 mm longer, half a centimeter wider and 140 mm taller. In terms of design, the Audi Allroad C5 retains its premium features, but a number of elements such as large wheel arches, rims and aluminum trims on the doors and radiator grille add some sportiness and aggressiveness to the exterior.

In 2005, it was replaced by the second generation model - C6. Nevertheless, along with the updated Allroad, the C5 is still quite popular today.

Technical features

Audi Allroad C5 cars were equipped with the following engines: six-cylinder petrol engines of 2.7 and 4.2 liters, and diesel 2.5 liters. The increased power was achieved thanks to five valves for each of the six cylinders and an injection system with a modified geometry of the manifold. Despite the fact that the engine is tuned primarily for high torque, acceleration and top speed are also decent - less than 8 seconds to 100 km / h, a very good result for a massive station wagon.

Perhaps the main advantage of the Audi Allroad is the electronic suspension tuning system. The car driver can choose 4 driving modes. For each mode, a clearance is provided in the range from 142 to 208 mm. It is important to note that if the driver has chosen not the most suitable mode, or simply forgot to switch it after driving off-road onto a flat surface, the electronic control unit will automatically change the suspension settings based on the data from numerous sensors. A similar idea became widespread on sport-touring bikes in 2008, while Audi has been using it since 1998.

Since the Germans encroached on the off-road element, it was impossible to do without a number of low gears. The Audi Allroad C5 was equipped with a so-called range multiplier, which can be switched on using a button on the gearbox selector. The speed of movement in this mode is limited to 70 km / h, but it is very difficult to imagine a madman who wants to drive through the forest at a higher speed, and even in a premium car.

The renowned company Pirelli has produced special tires for the Allroad C5. On the side of the tire there is an inscription "Allroad", and the tread of the wheel is slightly deeper than the universal "rubber" from Pirelli.

The Audi Allroad is one of the first models to give birth to a new class of cars - SUVs.

The luxury car's sliding sunroof is equipped with a solar panel, which has enough charge to operate the cooling system.

Competitive advantages

The main competitors of the Audi Allroad C5 are the Subaru Outback and BMW X5. The competitors are very serious, but Audi can compete with dignity even with them.

First of all, the difference between SUVs and SUVs is their fuel consumption. For obvious reasons, there cannot be SUVs among Audi's competitors, but in comparison with Subaru and BMW, the Allroad C5 has an order of magnitude higher efficiency indicators. When driving outside the city and in mixed mode, the fuel consumption of the Audi is 7% lower.

The maximum speed indicator is unrivaled - the 2.6-liter Allroad C5 petrol engine allows the car to reach speeds of up to 234 km / h, while the X5 and Subaru Outback limit does not exceed 220 km / h.

Audi's main trump card is the very decent off-road qualities of the Allroad C5. An important role here was played by the air suspension with the ability to adjust the clearance. But do not forget that one of the most important indicators for cars such as the X5 and Allroad is the level of comfort.

Awards

According to the EuroNCAP crash test, the Audi Allroad C5 received three stars for the safety of adult passengers.

In 2001, the Allroad C5 entered the top 10 best cars of the year according to the American magazine Car and Driver.

In the row of fast Audi station wagons, a vacancy appeared by the beginning of the 2000s. SUVs began to come into vogue at that time, and the company decided that it was time to do something like that. Sports station wagons RS by that time were already the hallmark of the company. Their powerful motors, all-wheel drive, dynamics and handling, which do honor to any sports car, have already become legend. And Audi has made another RS, but for those who don't drive on asphalt. The first Audi Allroad Quattro was built on the basis of the Audi A6 station wagon in the back of the C5.

The most important change relative to the base model was the introduction of air suspension, which made it possible to combine both cross-country ability and excellent handling. Aggressive "off-road" body kit and widened track completed the image of an off-road vehicle.

In the photo: Audi Allroad 4.2 quattro "2000-06

Only the most powerful motors could be found under the hood. True, the power of the magnificent 2.7 biturbo was reduced to 250 forces, and the 4.2-liter engine develops "only" 300, while on other models this series also had 15-20 more horses.

Inside the driver was a magnificent salon and excellent equipment, the "poor" Allroads simply do not exist in nature. Well, all-wheel drive, of course, was a must. Moreover, for cars with a manual transmission, it was even possible to order a transfer case with a reduction gear. But we have a large part of the Audi - it's all the same cars with automatic transmission.

The first generation was produced from 2001 to 2005, and it gained considerable popularity. But the second turned out to be “not right”: in order to eliminate internal competition with the Audi Q 7 and the platform-based Touareg, the car was made much more “on the road”, and it did not repeat the success of its predecessor. Yes, and it was no longer positioned as a separate model, but as a top-end version of the A6, and nothing more.

The first generation remains one of the best "niche" models in its class. It is ideal for those for whom an SUV is uncomfortable or does not fit in image (although this is difficult to imagine in Russia) or simply need a powerful and not too defiant car. She especially liked tuning lovers, because the potential of the 2.7 biturbo engine is over 500 horsepower, and in stock on the RS it develops about 380. And the atmospheric 4.2 liter is also an excellent option for improvements.

Body

It is difficult to expect from a car ten or seventeen years old from the ideal condition of the body. But other examples may surprise you.

I already wrote that high-quality paintwork on VAG machines at the beginning of the century, combined with high-quality galvanizing and elaboration of details, are capable of a miracle. Cars in "native paint" without any special remarks are found, especially in the price category "above 450", fortunately, the body is not the most problematic part of the car.

In the photo: Audi Allroad 4.2 quattro "2000-06

In the photo: Audi Allroad 4.2 quattro "2000-06 Windshield

price for original

22 721 rubles

But there are also enough "drowned", "guests" and other options in a state of disrepair. They are strongly given away by peeling moldings and corrosion, swelling paint on the rear and side doors. In principle, there are quite a few points in the body where corrosion can feel at ease, but they are all covered with plastic or hidden from view, so during an external examination you can only take a closer look at the seams and in the engine compartment. The seam between the mudguard and the wing is a potentially problematic spot and often gives out cars with a difficult fate.

Cars that have stood still for a long time usually have a rusty "aquarium" - an over-engine niche. Here, all cars on this platform like to accumulate water due to the not very successful design of the drain. In addition, acid fumes from the battery do not add health to the metal. In general, check carefully. By the way, the VIN number is printed on the same panel, only from the side of the engine compartment, so corrosion in this area also threatens with purely legal problems.

On the side of the windshield, there is a welded seam in this place and there is a battery platform, the paint on which is often damaged.

If possible, you should carefully inspect the car from below. Like any SUV, the Allroad can be clogged with mud, side members, hidden cavities, the space between the pipes in the arches and on the bottom with the usual consequences for such cases - rapid corrosion in this vulnerable zone.

Also carefully examine the front panel: this part is replaceable, but responsible and loves to corrode. If you take the car for many years, then check the sealant on the windshield pillars, in this hidden area debris accumulates under the plastic cover, and if the car was washed irregularly, corrosion climbs out.

In the photo: Audi Allroad 2.5 TDI quattro "2000-06

In the photo: Audi Allroad 2.5 TDI quattro "2000-06 On the way, listen for squeaks in the rear of the body on the pits. If present, remove the rear wheel arch liners and check the condition of the seams. Allroad is noticeably heavier than its progenitor, and sometimes they load it with all their hearts, they drive on a primer, so welding may not withstand. If the seams diverge, then in this place the corrosion immediately begins to sharpen the metal. Fortunately, she does it extremely slowly, thanks to galvanizing.

Surprises are also possible under the plastic parts. Plastic does not so much protect the metal as it creates a favorable environment with poor ventilation and accumulation of debris. Particularly dangerous is the area in the rear of the threshold, where even on very good outwardly cars, there may already be decent holes in the area of the clips.

In the photo: Audi Allroad quattro 4.2 (2002)

In the photo: Audi Allroad quattro 4.2 (2002) Pay attention to the doors: their lower edge is covered with plastic, but it is worth looking under it. Early examples suffered from corrosion in the area of the door hinges.

Externally, the body holds up well. Of course, the headlights wear out a lot with age, and the installation of more common headlights from the "simple" A6 is somewhat detrimental to the appearance, so you will have to look for Hella Classic lenses and polish the surface.

Numerous bumper grilles suffer primarily from small impacts, and the quality of their Chinese counterparts forces them to be installed on clamps, so take care of the original parts.

The rear bumper is often damaged underneath, look for tears. It is better to replace the plastic anthers of the engine compartment with a full-fledged protection covering the automatic transmission crankcase and aluminum anther sheets. Anyway, plastic usually does not last long: the oil dripping from the motor corrodes it, and frequent contacts with the surface will safely finish off the weakened plastic.

In the photo: Audi Allroad quattro 2,7T (2000)

In the photo: Audi Allroad quattro 2,7T (2000) Cracking fog lights are a sign of those who like to turn them on for no reason: they are afraid of water, so use them strictly for their intended purpose, and there will be no problems. But the wheel arch extensions and door linings are scarce parts, and their cost is appropriate. The original ones are expensive, at 3-7 thousand per item, and you will have to wait a lot. You can look for homemade ones, but their plastic is usually much worse than the original.

Beautiful aluminum roof rails corrode at the junction with the body and peel off as a result of the use of aggressive chemicals when washing the car. Often they are simply painted with "rubber", but pay attention to the state of the paintwork in the contact zone: often oxides damage the paint on the steel roof and very bad foci of corrosion appear, due to which the aluminum is literally "eaten away".

Another "sore spot" among the hinged parts is the "frill" plastic panel. Here it is with a cover for the battery, and therefore, if the latter is carelessly removed, it easily breaks in half. However, you should still check the over-engine niche, so at the same time pay attention to the condition of the plastic in this area. As a last resort, a panel from the Passat B 5 will do.

It is worth checking the condition of the boot floors. They are often broken by heavy loads, especially if the machine has an optional "pull-out floor". It can withstand only 80 kilograms, and the average weight of a Russian is usually more, so the mounts just give up. And it does not hurt to inspect the side niches for moisture, sometimes water flows there due to the leaky seals of the rear lights or jammed ventilation louvers under the bumper.

Salon

The salon is doing well. Good build quality and workmanship pays off.

Yes, the leather of the seats is usually cracked, the driver's seat is often squashed, and the steering wheel is worn down to the base. But this is with typical runs "over 300". Do not believe the small numbers on the odometers, an inspection of several cars showed that "on average" about 180 thousand kilometers were coiled. A good master and attentive "ringing" of the blocks will tell the truth, since there is well-developed electronics of a completely modern sample. A rare specimen has a real mileage of less than 200 thousand, the interior of such a car is usually almost in perfect condition, as well as the body with a motor.

In the photo: the interior of the Audi Allroad quattro "2000-06

In the photo: the interior of the Audi Allroad quattro "2000-06 Traces of harsh exploitation by "clawed barbarians" will have external and internal door handles, a light switch and a climate system. On cars before 2003, armrest mountings were often broken, it did not differ much in strength, and the installed "from Superba" clearly speaks of a creative approach to repair and the outlook of the owner.

Doors and their fillings are the cause of the owners' headaches. The unsuccessful design of locks on Audi cars at the beginning of the century causes minor, but massive breakdowns on older cars. Failure of the lock itself usually manifests itself in poor operation of the lock interlocks and the failure of the outer door handle. Less often, the inner handle drive cable breaks. On European cars with a "safe" (with double locking), the "quest" to remove the lock, if it is locked in the closed position, can take many hours of work. Or a few thousand rubles, if the service is nearby. This problem is very common, which occurs more often on the driver's or rear doors. The repair procedure in any case will be very non-trivial: the door design is surprisingly inconvenient. You cannot do without a manual and the skills of an octopus locksmith.

In addition to locks, mirrors, in which the supporting structures are corroded, and window lifters, in which guides in the front doors often fly off or cables break, are troublesome. But this is already a relatively rare malfunction.

The interior systems are generally in fair condition. The climate is quite reliable, except that with regular overheating, the heating radiator begins to flow: it is often the weakest point in the cooling system here. Failures of the damper drives of the automatic climate control, which is mandatory here, also happen, but these are very rare breakdowns. But the souring of the trapezoid of the wipers is, on the contrary, a typical malfunction, and in advanced cases it is extremely unpleasant. A fairly powerful motor can simply burn out, or it can "drag" the fuse socket in the fuse box and a piece of wiring behind it.

In the photo: the interior of the Audi Allroad quattro 4.2 (2002)

In the photo: the interior of the Audi Allroad quattro 4.2 (2002) Windshield and headlight washer motors cost a lot, but you can see similar ones from VW Touareg: for some reason, there are noticeably more non-original codes on it, and parts are twice as cheap.

The hatch requires minimal care, except that you have to regularly blow through the front drain holes and lubricate the guides and edges of the seals with special silicone: it will slide easier, and the rubber will not crack in the sun.

Electronics

In principle, as with any age car, the number of minor problems is quite high, but they are easy to solve.

Somewhat more often than usual, you will have to change lambda sensors in gasoline engines, they do not run more than a hundred thousand mileage, and any overheating or prolonged "annealing" can kill them immediately. The result is poor traction and an extra couple of liters of fuel consumption in the city and a liter on the highway.

A fairly expensive mass air flow sensor can pass twice as much, but its malfunction affects the dynamics even more, and in some cases the piston group can be damaged.

Headlight xenon

price for original

54 855 rubles

Door end switches, like locks, are a sore spot of a car. Almost everyone goes through it.

A weak gasoline pump, most likely, has died a long time ago, and you have a more or less successful Chinese copy. If you're lucky, the tank is converted to a thick and powerful Bosch 044, if not, then to a buzzing Walbro or something else.

Many cars with 2.7T do not really drive, because there is not enough fuel pressure on the boost: remember this and find out what is under the seat. By the way, the tank itself is bad, like on other all-wheel drive Audi. Problems with the fuel gauge and the operation of only one "half" of the tank are problems typical for older cars. The best solution is careful assembly with original components and no dirt. But in practice, it turns out that the gas tank of these cars is too complicated for the average car service. Contact real professionals.

In the photo: Audi Allroad 2.5 TDI quattro "2000-06

In the photo: Audi Allroad 2.5 TDI quattro "2000-06 Headlight halogen

price for original

16 373 rubles

Body level position sensors are a problem for the Allroad. Here, not only optics depend on them, but also the air suspension system. Fortunately, there are Chinese boards in the well-known Chinese online store, and there are repairmen. But sometimes the sensor simply breaks in half with a sour lever or rod, and then you have to buy a new part. Less often, the connector turns sour, in which case its replacement can help if the insides of the board have not yet corroded. The codes for the required connectors are 1-967616-1 and 7M 0 973 119. This is not VW, but BMW and Mercedes, don't be confused by that.

Burning radiator fan connectors are a more serious problem, here it is not far from a fire, and the motor can overheat, especially if the viscous coupling is already half-dead or its fan has burst, which happens quite often. The connectors must be monitored, and the heatsinks must be washed regularly so that the fans do not thresh in vain.

Not very good connectors for parking sensors and other little things, perhaps, you can not mention, on cars over 15 years old, such problems are inevitable. So just check all trunk and door corrugations for fractures, and all headlights and external electrical devices for operability.

Brakes, suspension and steering

The braking system of the car is excellent. Moreover, the front brakes here are multi-piston, but normally they have a floating caliper and 330 mm discs. A small upgrade of the brakes is a common thing for the forced 2.7T. They are equipped with slightly more serious "brakes" from 4.2 or from a heavier Touareg, since 350 mm mechanisms and even more fit into 18-inch rims.

In the photo: Audi Allroad 2,7T quattro "2000-06

In the photo: Audi Allroad 2,7T quattro "2000-06 The ABS block is quite fragile. A typical Bosch problem is a power failure of the unit or an error in a sensor or solenoid. Of course, all sensors are in good working order, they rarely break. The problem lies in the soldering of the ceramic board of the ABS unit. This is repaired in specialized services, at home it is unrealistic to solder the thinnest gold wires, just spoil the board. And you can tear off a lot of excess together with the compound. Fortunately, there are a lot of blocks, although they don't fit very well from the "regular" A6: the firmware differs, and the ESP system starts to malfunction. And, of course, you need to closely monitor the condition of the brake pipes and hoses. The pipes corrode, especially if the underside of the machine has not been washed. And the hoses are often worn out due to the peculiarities of the suspension, which is reflected in the excessive "cottoniness" of the brakes. In general, it is worth installing reinforced brake hoses on such a car, and the length for the front wheels should be taken a couple of centimeters longer than that of the standard ones. And it will be useful to keep an eye on their mountings, which is very important for long travel suspension.

The suspension here is strictly pneumatic, unless, of course, it has already been converted to ordinary springs. Don't be afraid of pneumatics, they are nowhere near as expensive as they were five or ten years ago. The cost of repairing a cylinder is 11-15 thousand rubles, it can be "corked", thereby greatly extending its service life on primers.

The suspension sensors have learned to reanimate, like the pump. But the number of knots that can break is certainly impressive. The cylinders themselves leak over time, especially if you do not wash off the sand from them, moving the suspension to the "upper" position. System fittings also occasionally leak, but rarely. The valve block is corny wears out and malfunctions. Maintenance is often forgotten, and the old dehumidifier and moisture freeze it in winter. In case of leaks, the compressor runs "for wear" and can damage both the cylinder with the piston and the electric motor. Fortunately, both components are commercially available, and the kit can go for less than 5 thousand rubles.

Front shock absorber

price for original

18 320 rubles

Shock absorbers are also a bit pricey. You can choose from either the original or Arnott, which is essentially the same Bilstein B 6 with a cropped base plate. It is rather difficult to put something else. In principle, any shock absorber from the A6 in the C6 body can be put on the "pipe" from Arnott, and if it is sealed, it will work fine, but the issue with the shock absorber diameter will have to be resolved, the standard ones are not very suitable for this.

The air suspension hose does not like non-standard wheel sizes. In some positions, the pneumatics may touch the wheel and the machine will "fall". A hernia or detachment of a piece of cord can cause the same effect. Be carefull.

Steering is pretty straightforward. It is not very successful, the rail with Servotronic usually works at the limit and often flows at the slightest opportunity, so the habit of turning the steering wheel in place and focusing on "cold" should be immediately forgotten. Unless, of course, you want to spend 11-16 thousand rubles each time on repairs.

In the photo: Audi Allroad 4,2 quattro "2000-06

In the photo: Audi Allroad 4,2 quattro "2000-06 The pump does not like the same, which is also extremely "well" located on the motor. The cost of replacement work will be rather big. In case of special luck, you can still get the current pipes of the pressure line or damage to the "power steering radiator" due to the curve of the front fans. But in general, all the parts for this machine are not very expensive, it will just be expensive, or you will have to do it yourself.

Of course, some of Audi's problems will have to fight. Ten-year-old cars simply do not exist in nature without problems. Is it worth it? It seems that the body here is not bad, the interior is quite decent, and parts for the suspension can be found without difficulty today. But will the motors and gearboxes please not new "German women"? About this - in.

The "third in a row" all-terrain wagon Audi A6 allroad quattro entered the Russian market in April 2012 and since then has firmly held the leading position in its segment, offering owners not only a high level of comfort, but also excellent crossover cross-country ability. This year (September 2014) the Audi A6 allroad quattro wagon has undergone a planned update, becoming more attractive in appearance and more powerful in technical terms.

The exterior of the Audi A6 Olroad Quattro "in the back of the C7" is built on the basis of the Audi A6 Avant, but the off-road station wagon received a characteristic plastic body kit (door sills, fenders), bumper protection, a different radiator grill and a slightly tweaked front bumper. All this splendor has been neatly transformed within the framework of the current restyling, making the exterior even more brutal and attractive. The length of the Audi A6 allroad quattro station wagon is 4940 mm, the width is 1898 mm, and the height is 1452 mm. The wheelbase is 2,905 mm, which is 7 mm less than the Audi A6 Avant. The curb weight of the A6 allroad quattro is 1,855 kg.

The 5-seater salon of the A6 allroad quattro provides comfort at the level of a business-class car, for which many appreciate the station wagon, which compares favorably with crossovers in this regard.

The interior design of the A6 allroad quattro is practically no different from the Audi A6 sedans and the A6 Avant station wagon, but the list of basic equipment is much wider. The trunk holds 565 liters in the base and 1680 liters with the second row of seats folded.

Specifications. Before restyling, the Audi A6 allroad quattro all-terrain wagon was equipped with two power plant options: a diesel V6 with turbocharging and direct injection, developing 245 hp, or a gasoline V6 with a compressor and direct injection, capable of producing 310 hp. power.

After the restyling of the motors, there are also two left. Diesel migrated to the updated station wagon without changes, but the power of the gasoline engine increased to 333 hp. (similar to the Audi A6 sedan).

Both engines, as before the restyling, are aggregated with a 7-speed S-Tronic "robot" with a double clutch.

The Audi A6 allroad quattro already gets a fully independent adaptive air suspension with adjustable ground clearance (ground clearance varies in the range of 135 - 185 mm), as well as a permanent all-wheel drive system based on a central self-locking center differential and a traction vector control system on the rear axle. All wheels of the station wagon are equipped with ventilated disc brakes, the parking brake of the Audi A6 allroad quattro is electric. The rack and pinion steering mechanism of the car is supplemented by an electromechanical amplifier with a variable gear ratio. In the base of the Audi A6 allroad quattro is equipped with ABS, EBD, BAS, ESP, ASR systems and an uphill start assist system.

Equipment and prices. The Audi A6 allroad quattro has a list of basic equipment similar to the A6 Avant station wagon, but additionally receives 18-inch alloy wheels, bi-xenon optics, leather interior, more expensive interior details, heat-shielding glass tinting and other "chips". The cost of pre-styling cars starts at 2,630,000 rubles. After restyling, the cost of the Audi A6 allroad Quattro will be 2,645,000 rubles for the version with a 245-horsepower diesel engine and 2,775,000 rubles for the modification with a 333-horsepower gasoline engine. The updated station wagons will appear at dealerships at the end of October 2014.