It may seem that making an ATV out of the Ural is quite difficult, but it is not. You will need to prepare the necessary parts and tools, as well as review the assembly instructions. From one old, but working motorcycle, you can make a universal four-wheeler, which will be used both for off-road driving and on the farm.

It is worth noting that it is rather difficult to assemble an ATV from the Ural 4x4 with your own hands. For its high-quality study, you will need to seek help from a team of professionals; you will need a turner, an electrician and a welder. It is more expedient to make the front suspension independent than to assemble a homemade ATV from the Ural 4x4. Otherwise, management can be difficult. The fact is that to provide all-wheel drive, it will be necessary to supplement the system with a gearbox, which will lead to an increase in the weight of the ATV. To assemble a rear-wheel drive structure, you need to prepare the following:

- Working motorcycle "Ural".

- Tie rod of transverse type.

- One pair of front hubs from a RWD vehicle.

- Front suspension arms.

- Axle shaft or cardan shaft.

- Thick-walled light alloy tube.

- Rear axle.

It is worth noting that the rear axle and front hubs must be taken from the same vehicle. This will avoid the procedure for fitting the discs to the fixing holes. These parts are recommended to be taken from Moskvich or VAZ. The work will require a set of hand tools, as well as a grinder and a welding machine.

How to make an ATV from a Ural motorcycle?

The first step in creating an ATV is to make a suspension. First, the old vehicle will need to be disassembled. The frame of the device must be freed from all elements, the master needs to remove the shock absorbers and the steering wheel. It is advisable to determine in advance what type of suspension will be installed for an ATV from the "Ural", for example:

- Suspension on springs.

- Rigid construction without shock absorber.

- Suspension with shock absorbers on springs.

Of course, it is best to opt for a spring-loaded suspension. They can be taken from an old motorcycle. Since the device will have 4 wheels, the missing mechanisms will have to be purchased. The pendant in this case will have the shape of the letter "A". You need to correctly calculate the weight of the future ATV. In this case, the shock absorbers will provide a smooth ride when driving on hard off-road.

Frame

The frame for the ATV will have to be built from scratch. It is assembled from metal pipes, which must be both strong and lightweight. Some blanks can be taken from the Ural. Its frame is suitable for such purposes, since the weight of the structure is low. At the same time, pipes taken from a motorcycle are distinguished by good flexibility and strength.

Engines and transmission

The motor from "Ural" is most often used when creating homemade ATVs. This engine is powerful enough and durable, which provides motor vehicles with high functionality. Such an ATV can be operated both for off-road driving and for household purposes.

It should be noted that the Ural's engine is quite powerful. It is a four-stroke two-cylinder engine with a volume of 750 cm³ and a capacity of 41 liters. With.

When assembling, it is recommended to use not only the engine from the Ural motorcycle, but also its transmission. In this case, the system will work smoothly. In the presented motorcycle, the gearbox has 4 gearshift stages, as well as reverse. The standard equipment also contains a cardan drive for the rear wheel.

Steering wheel

The steering wheel from the "Ural" is also used in the design, but some modifications will need to be done. It is necessary to add drives that will now turn two wheels. Levers, ball joints, which are taken from the car, are added to the design. Additional parts can also be purchased from a specialist store. When assembling, you need to achieve high accuracy and comfort of the steering wheel of the future ATV.

Wheels

It is also advisable to take the wheels from the old car. They are wide enough to provide good stability and flotation, even on very poor road conditions. The diameter of the wheels can be quite large, since the engine from the "Ural" is powerful. It will allow you to develop good speed even under increased load.

Body and wiring

Attachments, a gas tank and other structural elements are attached to the assembled frame. Each node must be firmly fixed on the prepared platform. It is important that the vehicle remains stable after assembly.

For many motorcycle owners, it is important that the appearance of the ATV is spectacular. Therefore, the design must be thought out in advance, before the assembly begins. You will need to install a driver's seat, lighting. The turn signals and headlights are also removed from the donor motorcycle.

ATV from "Ural": assembly

Before starting work, a drawing is developed that displays all the details, assemblies and mechanisms of the structure. First, the frame is assembled from the pipes by welding. It is necessary to control that the structure is even in all areas. The rear and front axles are then attached to the frame.

After that, the engine is firmly attached to the metal frame, which can be located both in the front and rear of the structure. The motor is secured with bolts, which must be tightened securely with a wrench.

A transmission with a drive is installed on the rear wheels. This element of the system is installed immediately after fixing to the motor frame. All connections must be very strong, as backlash is unacceptable.

At the last stage, the steering wheel is mounted, followed by the fuel tank. Wheels with disks are put on the seats, and then tires are put on. A gearbox is installed on the rear axle, with which the engine is subsequently connected. It is necessary to stretch a chain from the motor to this part, after which the system is checked for operability.

After that, attention is paid to the design of a homemade ATV, attachments, a seat, headlights, etc. are installed. An electrical system is being installed, the quality of its work is being checked.

There were a lot of ideas in my head, but finances were not a lot, and therefore I decided to limit myself to building a rear-wheel drive ATV, and not an all-wheel drive one. I also thought through the basic technical requirements for the future design: among them - the presence of reverse gear, the absence of a chain drive - after all, I assumed to use the ATV not on asphalt, but mostly on country roads, as well as decent power and maintainability. And, of course, a low price.

Do-it-yourself ATV from the Urals in detail

I couldn't find a more suitable "donor" than the Ural motorcycle, with a reverse gear and a mileage of 12,000 km, I bought it for an acceptable amount, and from him I began to "dance, that is, collect an ATV with my own hands."At first, the lack of experience with motorcycle equipment affected and things did not go as quickly as we would like. But experience is a gain.

It is clear that the engine, or rather the power unit (in the block with the gearbox and clutch), used the Ural ones together with the frame.

Frame of the future ATV in the rear part has changed slightly - only the tubes of the seatpost (vertical) struts, to which the same Ural pendulum is attached, only now with a welded Zhiguli bridge, have been shifted 40 mm back.

Bottom fork(duplex frame arms) are cut off immediately behind the seatpost tubes along with the C-pillars. From the tubes of the struts, I made a pair of struts, which I welded to the seat posts next to the bushings of the pendulum suspension and the feathers of the upper seatpost (in front of the shock absorber mounting brackets). In addition, he later covered the resulting triangles on both sides of the frame with kerchiefs made of 2-mm steel plates. At the joints of the beams and struts, I also welded consoles (from a water pipe with a diameter of 20 mm) - footrests for the passenger.

But at the front, a whole structure of steel thin-walled pipes with a diameter of 30 mm is welded to the frame - an additional subframe for attaching the front suspension. Looking ahead, I note that from the same pipes I welded a curly front bumper and a rear trunk (front - from a pipe with a diameter of 20 mm).

Rear axle- from the good old "penny" (VAZ-2101), only shortened. This was necessary to ensure compactness and narrowing of the track, in order to reduce the turning radius and, as a result, increase maneuverability. To shorten the bridge, I cut off, separated the spring support cup and the bracket from it, and pulled the end flange (bearing seat) out of the "stocking".

Then he shortened the "stocking", reinserted the flange into it and fastened the parts by welding the plate overlays to them. I shortened the semi-axle to the appropriate length (about 185 mm). I also cut off the wheel flange from it (immediately behind the locking ring) and drilled a through axial hole in it. I also made the end of the semi-axle rod under this hole. Having inserted the rod into the flange, drilled a blind hole on their mating circle so that there were holes in each of the parts, and “hammered” a wire key into it. After that, I welded the joint “in a circle”.

The native Ural driveshaft did not fit the main gear of the drive axle, and the Zhiguli driveshaft did not fit the motorcycle transmission. In addition, the angles between these transmission units turned out to be quite significant. Therefore, the shaft was made with my own hand from the axles of the Oka car using a constant velocity joint.

Front suspension- self-made, on double transverse A-arms made of square pipes with a section of 25x25 mm and a wall thickness of 2 mm. The steering knuckles are from the "classic" (rear-wheel drive) "Zhiguli". The upper ends of the levers are fastened to the lugs on the subframe, and the lower ends to the corresponding ball joints of the steering knuckles.

Front shock absorbers- from the VAZ-2101 are combined with a spring from the "Ural". The relatives of the Urals were left behind in order to subsequently identify which ones are better: motorcycle or automobile.

Brake system used from "Zhiguli", only without a vacuum booster and a parking brake. The main brake cylinder is driven by a familiar motorcycle pedal.

The engine cylinders are equipped with forced air cooling from the fan of the stove of the VAZ-2108 car. It turns on with a toggle switch as needed in conditions of reduced heat transfer from the motor.

The wheels and tires of the ATV are also Zhiguli, only the front tires have a road tread pattern, and the rear driving wheels have an all-terrain (more "toothy").

Steering- mixed type: automobile and motorcycle.

The steering wheel itself- from the motorcycle "Ural", lever arm. And then - everything automotive (from the VAZ-2105): a column, a bipod, thrust to the levers of the wheel fists and the fists themselves.

The DIY ATV is equipped with two trunks: front and rear. Their configuration is a figment of the author's imagination, and manufacturing does not cause difficulties - it is like a warm-up for an athlete.

Onboard electrical network ATV, like the base motorcycle, - 12 volts. From the electrical equipment, I have installed headlights and a rear brake light. I also plan to mount direction indicators.

After the very first sea trials of the homemade ATV, it became clear that it needed large fenders with mudguards. The wings were made with my own hands from 1.5 mm thick duralumin sheet, and the mudguards were made of 5 mm rubber. Consoles for fastening the wings, made of pieces of thin-walled steel pipe with a diameter of 16 mm, were welded to the frame "in place". He fastened the wings to them with self-tapping screws.

Technical characteristics of an ATV from a Ural motorcycle approximately the same as those of the base Ural motorcycle. The speed has slightly decreased due to the smaller diameter of the wheels, but the traction power has noticeably increased.... The stability has also improved, especially when cornering and sloping.

The ATV fulfills its purpose completely with its own hands. But in fairness, it should be noted that the rear dependent pendulum suspension has a number of disadvantages: such as stiffness, high torsional loads on the unit. But on the other hand, it is easy to manufacture, and on a slope it keeps it from falling on its side, which is important with a small track. And its inelasticity is compensated by the soft front suspension. Automotive shock absorbers are undoubtedly better than motorcycle shock absorbers. And yet - to control the car, man's strength is still required.

In general, with a relatively modest investment in this project, I am satisfied with the result.

We will share with you for free information on how to make a homemade ATV.

It is not a rare case when an old motorcycle is in the garage, somewhere in the country. In such cases, the thought arises, and not to make an ATV out of it? By and large, any engine is suitable for a quadric, but I must note that a car of very large dimensions will turn out from a too powerful car engine, and it will be inconvenient to drive.

We will not bother too much, the good old Soviet motorcycle Ural will be enough. A homemade ATV based on a motorcycle is a great solution. If you have a different model, it's okay, do what you have.

The first problem that will stand in our way is the cooling of the motor. Since we have it with air cooling, in the summer there will be a problem with overheating, in order to prevent this, you need to make forced airflow. The question is how to blow air on a Soviet motorcycle. Since the cylinders will be found behind the wings, this is not so easy to implement. Shifting the seat closer to the steering wheel is not an option, in which case the legs will be very close to the boilers. It may not affect in any way in winter, but in summer you can easily get burned. In addition, it can cause overheating. The good news is that oppos have some really amazing traction and the potential to pull off a loyal and undemanding driveshaft with ease. This option caught our attention, especially knowing that liquid cooling is possible in mass production. There are a lot of articles on its installation on the Internet. A video on the topic of ATVs with your own hands can also help you in the manufacture of a four-wheeled vehicle based on the Urals.

As for the frame, there isn't much to experiment with. The obvious choice fell on sturdy round steel pipes and metal profiles. Usually the best solution is to build an extra frame around the frame itself. But I must admit, this does not always lead to perfect problem solving. Here it is already necessary to look at each individually.

Gradually we come to the suspension and transmission. The ideal solution for the rear suspension, without question, will serve as a dependent suspension with the exception of the differential.

You absolutely don't need it, and since you are building an ATV it will not be very useful either. It is not worth changing anything if your motor is driven by a chain standard. We do it. In this case, the implementation process is simplified, the subordinate ratio is quickly selected, and the power loss is much less, since the weight is less.

Not everything is as smooth as it seems, because the chain needs an eye and an eye. If the chain breaks, it will be necessary to re-fit a new one in length, since it is extremely difficult to find an analogue.

Of course, it would not be bad to install an independent suspension back. But since we make an ATV with our own hands, this option disappears due to the complexity of the implementation.

The front suspension is usually made by yourself, the ATV drawings will help you with this. We advise you to do it on the basis of the Oka car. If you got down to business even more seriously and decided to make an all-wheel drive model, then front-wheel drive VAZs will help you.

If we somehow helped you in creating a four-wheeled homemade iron horse, then this is a big plus for us. But remember that when creating homemade ATVs from drawings, you will need at least a little experience of a welder, locksmith and electrician.

And if you made an all-wheel drive motorcycle with your own hands, you can consider that you have accomplished a feat at all. Indeed, in this case, you have to manually produce a large number of parts. Only a turner with extensive experience is capable of this. And if you buy all these parts in a store, then, in my opinion, it is easier to buy a used ATV and not suffer.

Homemade ATV.

Many requests to publish the drawing of the ATV. There are many different designs presented at the forum, but Sergey Pletnev's ATV seems to me the simplest, besides there are his drawings. Drawings and description of the ATV are taken from the forum and from the magazine "Modelist - Constructor" # 6 for 2010.

This device has already been described earlier on our website, but now there are drawings of it.

Ready ATV

The idea to build an ATV (four-wheeled motorcycle) arose a long time ago - a technique was needed with which it would be possible to drag a cart with a load, go fishing on light off-road, and just go for a ride to family members. And, of course, to get satisfaction from creation.

There were a lot of ideas in my head, but finances were not a lot, and therefore I decided to limit myself to building a rear-wheel drive ATV, and not an all-wheel drive one. I also thought through the basic technical requirements for the future design: among them - the presence of reverse gear, the absence of a chain drive - after all, I assumed to use the ATV not on asphalt, but mostly on country roads, as well as decent power and maintainability. And, of course, a low price.

I did not find a more suitable "donor" than a motorcycle "Ural", with a reverse gear and a mileage of 12,000 km, bought for an acceptable amount, and from it I began to "dance".

At first, the lack of experience with motorcycle equipment affected and things did not go as quickly as we would like. But experience is a gain.

It is clear that the engine, or rather the power unit (in the block with the gearbox and clutch), used the Ural ones together with the frame.

The frame in the rear part has changed slightly - only the tubes of the seatpost (vertical) struts, to which the same Ural pendulum is attached, only now with a welded Zhiguli bridge, have been shifted 40 mm back. The lower fork (the arms of the duplex part of the frame) immediately after the tubes of the seatpost along with the C-pillars are cut off. From the tubes of the struts, I made a pair of struts, which I welded to the seat posts next to the bushings of the pendulum suspension and the feathers of the upper seatpost (in front of the shock absorber mounting brackets). In addition, he later closed the resulting triangles on both sides of the frame with kerchiefs made of 2-mm steel plates. At the joints of the beams and struts, I also welded consoles (from a water pipe with a diameter of 20 mm) - footrests for the passenger.

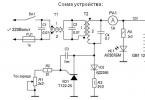

ATV based on the heavy motorcycle "Ural-2" (IMZ 67-36):

1-front steered wheel (from a Zhiguli car, 2 pcs.); 2 - the lower arm of the front suspension (pipe 25x25.2 pcs.); 3-upper arm of the front suspension (pipe 25x25.2 pcs.); 4-front shock absorber (from the Zhiguli car, reinforced with a spring from the shock absorber of the Ural motorcycle, 2 pcs.); 5-front buffer (pipe 030); 6-pillar of the front rack (pipe 020); 7 - front trunk (pipe 020); S-electric ventilator (from the VAZ-2108 car); 9-air duct (rubber corrugated hose 0100, 2 pcs.); 10-fairing (duralumin, sheet s2); 11-steering wheel with a steering shaft (from the Ural motorcycle); 12-fuel tank (from the Ural motorcycle); 13 - power unit (from the Ural motorcycle); 14 kick starter; 15-battery; 16-brake light; 17-rear shock absorber (from the Ural motorcycle, 2 pcs.); 18-muffler (from the Ural motorcycle, 2 pcs.); 19-rear drive wheel (from a Zhiguli car, 2 pcs.); 20-rear driving axle (from the Zhiguli car); 21 - half-axle (from the Zhiguli car, 2 pcs.); 22 - pendulum suspension (from the Ural motorcycle); 23-cardan shaft (semi-axle from the car "Oka"); 24-joint (CV joint from the car "Oka"); 25 - steering bipod (from the Zhiguli car); 26-tie rod with a tip (from the Zhiguli car); 27-brake pedal; 28-carburetor throttle control handle; 29-lever brake; 30-strut rear rack (pipe 020); 31 - clutch release lever; 32 - gear shift pedal; 33 - saddle (from the Ural motorcycle); 34-rear trunk (pipe030); 35 - front wing (duralumin, sheet si, 5.2 pcs.); 36-rear wing (duralumin, sheet si, 5, 2 pcs.); 37-headlight (2 pcs.)

But in front, a whole structure of steel thin-walled pipes with a diameter of 30 mm is welded to the frame - an additional subframe for attaching the front suspension. Looking ahead, I note that from the same pipes I welded a curly front bumper and a rear trunk (front - from a pipe with a diameter of 20 mm).

The rear axle is from the good old "penny" (VAZ-2101), only shortened. This was necessary to ensure compactness and narrowing of the track, in order to reduce the turning radius and, as a result, increase maneuverability. To shorten the bridge, I cut off, separated the spring support cup and the bracket from it, and pulled the end flange (bearing seat) out of the "stocking". Then he shortened the "stocking", reinserted the flange into it and fastened the parts by welding the plate overlays to them. I shortened the semi-axle to the appropriate length (about 185 mm). I also cut off the wheel flange from it (immediately behind the locking ring) and drilled a through axial hole in it. I also made the end of the semi-axle rod under this hole. Having inserted the rod into the flange, drilled a blind hole on their docking circle so that there were holes in each of the parts, and “hammered” a wire key into it. After that, I welded the joint “in a circle”.

The native Ural driveshaft did not fit the main gear of the drive axle, and the Zhiguli driveshaft did not fit the motorcycle transmission. In addition, the angles between these transmission units turned out to be quite significant.

Continuation...

Levers of the front suspension (a-upper arm; 5-lower arm; the number of parts is indicated for one arm): 1 -beam (pipe 25x25.2 pcs.); 2-intermediate cross member (tube 25x25); 3-end cross-piece (pipe 25x25); 4 - bushing of the silent block (2 pcs.); 5-eyelet for shock absorber mounting (steel, sheet s5, 2 pcs.

The front suspension is self-made, on double transverse A-arms made of square tubes with a section of 25x25 mm and a wall thickness of 2 mm. Rotary fists - from "classic" (rear-wheel drive) "Zhiguli". The upper ends of the levers are fixed in the lugs on the subframe, and the lower ends to the corresponding ball joints of the steering knuckles.

Shock absorbers in the front - from the VAZ-2101 are combined with a spring from the "Ural". The relatives of the Urals were left behind in order to subsequently identify which ones are better: motorcycle or automobile. The braking system is used from "Zhiguli", only without a vacuum booster and a parking brake. The main brake cylinder is driven by a familiar motorcycle pedal.

The engine cylinders are equipped with forced air cooling from the fan of the stove of the VAZ-2108 car. It turns on with a toggle switch as needed in conditions of reduced heat transfer from the motor.

The wheels and tires of the ATV are also Zhiguli, only the front tires have a road tread pattern, and the rear driving wheels have an all-terrain (more "toothy").

Steering is a mixed type: automobile and motorcycle. The steering wheel itself is from the Ural motorcycle, lever-operated. And then - everything automotive (from the VAZ-2105): a column, a bipod, thrust to the levers of the wheel fists and the fists themselves.

The ATV is equipped with two racks: front and rear. Their configuration is a figment of the author's imagination and manufacturing does not cause difficulties - it is like a warm-up for an athlete.

The on-board electrical network of the ATV, like that of the base motorcycle, is 12 volts. From the electrical equipment, I have installed headlights and a rear brake light. I also plan to mount direction indicators.

After the very first sea trials of the ATV, it became clear that it needed large fenders with mudguards. The fenders were made of 1.5 mm thick duralumin sheet, and the mudguards were made of 5 mm rubber. Consoles for fastening the wings, made of pieces of thin-walled steel pipe with a diameter of 16 mm, were welded to the frame "in place". He fastened the wings to them with self-tapping screws.

The technical characteristics of the ATV are approximately the same as those of the base Ural motorcycle. The speed has slightly decreased due to the smaller diameter of the wheels, but the traction is noticeably especially felt on turns and slopes.

The ATV fulfills its purpose completely. But in fairness, it should be noted that the rear dependent pendulum suspension has a number of disadvantages: such as stiffness, high torsional loads on the unit. But on the other hand, it is easy to manufacture, and on a slope it keeps it from falling on its side, which is important with a small track. And its inelasticity is compensated by the soft front suspension. Automotive shock absorbers are undoubtedly better than motorcycle shock absorbers. And yet - to control the car, man's strength is still required.

ATV frame (welded construction):

1 - cross member of the additional subframe (pipe 020); 2-arch of the stretcher, right, left-mirrored (tube 030, 2 pcs.); 3-bracket for fastening the upper end of the front suspension shock absorber (stamped channel # 3); 4-eyelet for attaching the upper end of the suspension arm (steel, sheet s5, 16 pcs.); 5-passenger footboard (steel tube 020, 2 pcs.); 6-seat post (from the frame of the Ural motorcycle, moved back); 7-brace (from the rear rack of the Ural motorcycle frame, 2 pcs.); 8-bracket for attaching the upper end of the rear shock absorber (steel, sheet s5, 2 pcs.); 9-bracket for fastening the seat (steel, sheet s5,2 pcs.); 10-horizontal link of the subframe (tube 030); 11-motorcycle frame; 12-power unit

There are many options for how to make an ATV with your own hands. It is important to decide what you want to get as a result of your work, and what funds you have. Consider a simpler rear-wheel drive option.

From the Ural motorcycle, or from IZH

For the base you will need:

- the motorcycle itself;

- two front hubs from a rear-wheel drive passenger car (Zhiguli classic, Moskvich);

- rear axle (preferably from a car of the same brand from which the hubs were taken, so that the disks coincide in the mounting holes);

- cardan shaft, or semiaxis (depending on the design);

- front suspension arms (if you wish, you can make completely homemade ones);

- tie rod;

- pipe (square thick wall, or round plumbing about ¾ inch);

From the tool:

- welding machine;

- Bulgarian.

This is basic. A bunch of little things will be needed along the way.

We disassemble the motorcycle completely. We want a clean frame with no handlebars or shock absorbers.

We draw drawings, or use ready-made ones and decide which version of the rear suspension suits us:

- hard without shock absorbers (cheaper and less laborious, but more suitable for high soft rubber);

- on springs with shock absorbers;

- on springs.

Without shock absorbers

Cut off the rear part of the frame along with the swingarm mount. We lengthen the frame and rigidly weld the bridge using gussets and jibs.

It is important to consider the following points:

- the axle gearbox, in case of replacement, must be removed without problems;

- the direction of rotation at the exit from the Ural transmission is the opposite. Those. during installation, the road bridge must be turned over, otherwise it will go back.

Homemade ATV video

On springs with shock absorbers

We leave the rear suspension swingarm together with the original silent blocks. We weld the bridge to the fork, be sure to reinforce the seams with wide kerchiefs, otherwise it will vomit along with the metal of the bridge. Instead of a universal joint, in this case, you need to use a semi-axle from the Oka, or VAZ 08, 09, etc. Because when using a native rear fork, it requires a torque transmission at a large angle, which the universal joint shafts cannot provide. With this design, springs with shock absorbers can be left in their old place.

On springs

If you need a cargo ATV with a body for your needs, it is better to use springs for the rear suspension. In this case, a frame for a body is welded from a square thick-walled pipe (with a section of approximately 70 × 40). The length is not shorter than the spring, but the width is equal to the size of the bridge. This body frame is connected to the motorcycle frame by means of jibs, which must be correctly positioned to provide sufficient torsional rigidity.

The base of such an ATV is larger than the above structures, since the rear axle is located further away. But it becomes possible to use the cardan shaft of a car: serial, or shortened. The cardan is connected to the box with a Ural rubber coupling, and with the bridge - with a native flange, through the crosspiece of the hinge.

If an IZhevsky donor is used for an ATV, it is more convenient to refuse the differential. In this case, a large driven sprocket is installed on the axle, and the drive is carried out by the native chain.

Front suspension

The design of the front suspension is almost the same for an ATV from IZH and from the Urals. To attach the swing arms, the motorcycle frame is extended at the front. It is important to ensure that the turning wheels do not hit the engine cylinders. Therefore, on the Ural frame, the wheels should be further forward.

To increase the geometric flotation, the suspension arms should be as long as possible. Therefore, it is better to make them yourself, and not use serial ones from the car.

The steering column can be made from the Ural universal joint. At the bottom, two steering bipods are welded to it, located side by side, each for its own steering link: on the right and left wheel. The hubs are attached by means of native ball.

Four-wheel drive ATV from Oka

Using the power unit from the Oka, you can make an all-wheel drive ATV. It is better to cook the frame for it from scratch, taking into account the mount and the size of the engine. In the front suspension, more space is left for the installation of the front wheel drive gearbox, which can be made independently from the "classic" rear axle. To do this, cut off the "stockings" of the bridge and remove the suitable axle shafts from the VAZ 08, 09 from the differential.

It is important to think over every detail so that as many standard parts as possible are used, which will greatly facilitate subsequent repairs.

The power unit is deployed in motion. The axle shafts now become cardan shafts that transmit torque to the front and rear axles.

The checkpoint is more convenient to operate manually.

Finishing

First of all, these are the wings! Still, the technique is extreme, they must be strong and wide. With sufficient metalworking skills, you can give the ATV such an appearance that a homemade one will look no worse than a factory one. Some shapes can be shaped using polyurethane foam. After hardening, it is easily processed, puttyed and painted. A reliable trunk will add rigidity to the bodywork. By fixing a wardrobe trunk on it, you can increase the size of the usable area for the carriage of goods.

Blade, trailer

The ATV is an excellent base for installing all kinds of attachments that are useful in the household. A homemade ATV can be equipped with a snow blade. The size of the blade depends on the dimensions and weight of the ATV. If the quad is made on the basis of the Urals, it will pull a knife 1.5 m wide and half a meter high. The material for the shovel is steel 3 mm.

Even a children's ATV has an enviable cross-country ability; all the more, large and heavy, the strength to tow a car trailer.

The time, money and effort spent on making a homemade ATV will pay off with interest. Indeed, in addition to adrenaline, you get a hard worker on the farm who can replace a small tractor.

- news

- Workshop

Research: car exhaust is not a major air pollutant

As the participants of the energy forum in Milan calculated, more than half of CO2 emissions and 30% of solid particles harmful to health enter the air not at all due to the operation of internal combustion engines, but due to heating of the housing stock, La Repubblica reports. Currently, in Italy 56% of buildings are classified in the lowest ecological class G, moreover ...

Roads in Russia: even children could not stand it. Photo of the day

The last time this site, located in a small town in the Irkutsk region, was repaired 8 years ago. The children, whose names are not named, decided to fix this problem on their own so that they could ride bicycles, reports the UK24 portal. The reaction of the local administration to the photo, which has already become a real hit on the network, has not been reported. ...

AvtoVAZ has nominated its own candidate to the State Duma

The official statement of AvtoVAZ says that V. Derzhak has worked for more than 27 years at the enterprise and has gone through all stages of career development - from an ordinary worker to a foreman. The initiative to nominate a representative of the workforce of AvtoVAZ to the State Duma belongs to the collective of the enterprise and was announced on June 5 during the celebration of the city of Togliatti. Initiative ...

Self-driving taxis to appear in Singapore

During the tests, six modified Audi Q5s, capable of driving in autonomous mode, will be released on the roads of Singapore. Last year, such cars smoothly covered the path from San Francisco to New York, according to Bloomberg. In Singapore, the drones will move along three specially prepared routes equipped with the necessary infrastructure. The length of each route will be 6.4 ...

The regions of Russia with the oldest cars are named

At the same time, the youngest car fleet is listed in the Republic of Tatarstan (average age - 9.3 years), and the oldest - in the Kamchatka Territory (20.9 years). Such data in its research are cited by the analytical agency "Autostat". As it turned out, apart from Tatarstan, only in two Russian regions the average age of passenger cars is less than ...

Private cars will be banned in Helsinki

In order to make such an ambitious plan a reality, the Helsinki authorities intend to create the most convenient system in which the boundaries between private and public transport will be erased, Autoblog reports. Sonia Heikkilä, a transport specialist at the Helsinki City Hall, said that the essence of the new initiative is quite simple: the townspeople must have ...

Limousine for the president: more details revealed

The website of the Federal Patent Service continues to be the only open source of information about the "car for the president." First, NAMI patented industrial models of two cars - a limousine and a crossover, which are part of the "Cortege" project. Then the namishniki registered an industrial design called "Car dashboard" (most likely, namely ...

GMC SUV turned into a sports car

Hennessey Performance has always been famous for its ability to generously add extra horses to a "pumped" car, but this time the Americans were clearly being modest. GMC Yukon Denali could turn into a real monster, fortunately, that the 6.2-liter "eight" allows you to do this, but Hennessey minders limited themselves to a rather modest "bonus" by increasing the engine power ...

Acura NSX: new versions are being prepared

In May this year, the second generation Acura NSX supercar was launched at the Honda plant in the American city of Marrysville. It took the Japanese several years to decide on the type of power plant Acura NSX, and, in the end, the choice was made in favor of the six-cylinder 3.5-liter gasoline turbocharged engine, which they work with ...

Russian assembly of Mazda: now they will also make motors

Let us remind you that the production of Mazda cars at the facilities of the Mazda Sollers JV in Vladivostok started in autumn 2012. The first model that the plant mastered was the Mazda CX-5 crossover, and then the Mazda 6 sedans got onto the assembly line. By the end of 2015, 24,185 cars were produced. Now Mazda Sollers Manufacturing LLC ...

Luxury cars of the stars

Luxury cars of the stars

Celebrity cars must match their star status. It is simply impossible for them to come in something modest and generally accessible. Their vehicle must match their popularity. The more popular a person is, the more sophisticated the car should be. Globally Popular Stars Let's start this review with ...

2018-2019: rating of CASCO insurance companiesEach car owner seeks to protect himself from emergencies associated with road accidents or other damage to his vehicle. One of the options is the conclusion of a CASCO agreement. However, in an environment where there are dozens of firms on the insurance market that provide services for ...

HOW to choose the color of the car, choose the color of the car.

How to choose a car color It is no secret that the color of a car primarily affects road safety. Moreover, its practicality depends on the color of the car. Cars are produced in all colors of the rainbow and dozens of its shades, but how to choose “your” color? ...

HOW to order a car from Germany, how to order a car from Germany.

How to order a car from Germany There are two options for buying a used German car. The first option involves an independent trip to Germany, selection, purchase and driving. But this method is not suitable for everyone due to lack of experience, knowledge, time or desire. The way out is to order a car ...

Rating of reliable cars 2018-2019Reliability is by far the most important requirement for a car. Design, tuning, any "bells and whistles" - all these ultra-fashionable tricks in their degree of importance inevitably fade when it comes to the reliability of the vehicle. The car should serve its owner, and not cause him problems with its ...

Rating 2018-2019: DVRs with a radar detectorThe requirements for additional equipment in the passenger compartment are growing at a rapid pace. Up to the point that the cabin simply does not have enough space to accommodate all the necessary equipment. If earlier only video recorders and air flavors interfered with the review, today the list of devices ...

TOP-5 rating: the most expensive car in the worldYou can treat them as you like - admire, hate, admire, feel disgust, but they will not leave anyone indifferent. Some of them are just a monument to human mediocrity, made of gold and rubies in full size, some are so exclusive that when ...

Review of the most popular crossovers and their comparison

Today we'll be looking at six crossovers: Toyota RAV4, Honda CR-V, Mazda CX-5, Mitsubishi Outlander, Suzuki Grand Vitara, and Ford Kuga. To two very fresh new products, we decided to add the debuts of 2015, so that the test drive of 2017 crossovers was more ...

What colors of cars are most popular

Compared to reliability and technical characteristics, the color of the car's body is, one might say, a trifle - but a rather important trifle. Once upon a time the color range of vehicles was not particularly diverse, but these times have long sunk into oblivion, and today the widest range of ...

- Discussion

- In contact with

Motorcycles produced back in the Soviet era are already considered a rarity. It is unlikely that he will be able to interest any of them in the quality of a vehicle. A museum exhibit, nothing more! Such equipment is sold very cheaply, a little more expensive than scrap metal. Despite the fact that the old "horse" has already served its purpose, it's time, as they say, to retire, but you don't want to part with it. Familiar situation? Often such a vehicle does not have documents, you cannot go far from home on it - trouble from the police is guaranteed.

Not everyone will think that an old motorcycle "Ural", gathering dust idle in the garage, can be turned into a practical unit. Such a homemade product from the Urals does not require huge financial investments, but a certain amount of patience and a few hours of free time will be very useful.

Homemade tricycle from the Urals

The main advantages of a tricycle based on the "Ural":

The predominant part of the component parts belongs to the motorcycle, the engine for the trike is suitable from the ZAZ-968. The most time consuming process is the manufacture of the frame. In the design, it is a kind of connecting link on which all assemblies and parts are installed.

Design features

For inexperienced designers, when assembling a tricycle, the drawing will be an excellent guide to action. It is important to think carefully about sizing.

Rear shock absorbers are mounted on the upper beam, which are similar to automobile counterparts. When driving on a road with irregularities, the shock absorbers will react sensitively to them. Glasses are welded to the beam, which provides the desired comfort. The pipes are welded to the end together with reinforcing kerchiefs - the fastening will be reliable.

Due to the fact that the power unit is installed at the rear, the center of gravity is also there. With a sharp increase in engine speed, the front wheel comes off the road, the tricycle rears up. The elimination of this effect is facilitated by placing the balance closer to the front wheel.

If the engine is slightly tired, it needs to be slightly repaired. The exhaust system in this case is home-made, and the cooling system can be chosen water or oil type.

Since the right hand is busy adjusting the "throttle", then the gear lever, of course, should be on the left side.

Assembly sequence

- The frame is constructed according to the drawing. Everything that is made of ferrous metal must be covered with a layer of primer, and then with paint.

- The rear axle must be in good condition. It can be removed from a Zaporozhets or Moskvich car.

- All major components and assemblies represented by the engine, filters, exhaust system and oil cooler are mounted on the rear axle.

- To have free access to all parts and to ensure ease of assembly, it is recommended to use a jack or lift. The frame must provide a secure connection between the front fork, rear axle and engine.

- When fixing the elements, backlash should not be allowed, there should be no clinking. To avoid vibrations, make the connection with lock nuts.

- The most reliable is considered to be fastening by welding. This must be taken into account when fixing on the frame, rear axle and cross members.

- Attaching the fuel tank, seats, trunk and other accessories is done at the very end of the assembly, when the homemade trike is already on the wheels.

Homemade ATV from the Urals

Heavy motorcycles "Ural" are not very popular. One of the reasons is the huge consumption of gasoline. Many motorcyclists and bikers are not satisfied with the large dimensions of the Urals. Despite this, craftsmen are interested in such motorcycles. Moments such as the presence of a reverse gear, a rather powerful four-stroke engine are very tempting in terms of converting an old Ural into an ATV. As a result, its cost is much lower than that of its European congener, and the engine power is much higher. Such homemade products from the Ural motorcycle will appeal to everyone who loves to create with their own hands.

Design features

Craftsmen from the city of Barnaul received a successful version of a homemade ATV:

- The Ural motorcycle was taken as a basis, in particular, the frame with the engine was left.

- The reinforced gearbox was removed from the motorcycle of another model of the domestic motorcycle - "Dnepr".

- The drive had to be made of a cardan type, due to the fact that the options with sprockets and chains are less reliable.

- Two pairs of wheels fit well from the Gazelle car. At the same time, the appearance of the ATV turned out to be rude, uncouth.

The management of Russian car factories should think about the issue of producing domestic ATVs and tricycles, taking advantage of the excellent experience of, for example, Barnaul craftsmen. Moreover, most of the components have already left the conveyors of these enterprises in due time!

Homemade Ural motorcycles can look different. In any case, this technique is impressive.

Homemade snowmobile from the Urals

Most craftsmen who have tried to design a snowmobile with their own hands are faced with the problem of choosing a light engine with high power. It is also difficult to find a track track.

Important criteria a homemade snowmobile must meet:

- I would like to simplify the scheme as much as possible so that the manufacture of the unit at home is not accompanied by difficulties. The product should be as cheap as possible, otherwise it is more profitable to buy a ready-made factory analogue.

- The inventor is accountable to customers by offering them a hazardous vehicle.

- Minimize the naming of parts that require processing on a lathe or other machine. Otherwise, the process of manufacturing the unit becomes more complicated, because in modern conditions, finding the necessary machine and a specialist who knows how to handle it is not easy.

Features of a homemade snowmobile

- When choosing and modifying the chassis, you can use the Buran snowmobile diagram. The track system is in the form of rollers, but only one of them was needed for the homemade unit.

- The implementation of the power train from the gearbox to the drive shaft is made possible by means of a chain.

- In the front there are a pair of racks that are designed to have skis instead of wheels. The struts are equipped with springs from the rear shock absorbers of the Izh-Planeta motorcycle.

- The run of the homemade snowmobile over 3 thousand km did not affect the engine's operation - there was no overheating. Traveling a distance of 90 km, the snowmobile consumes almost 10 liters of gasoline.