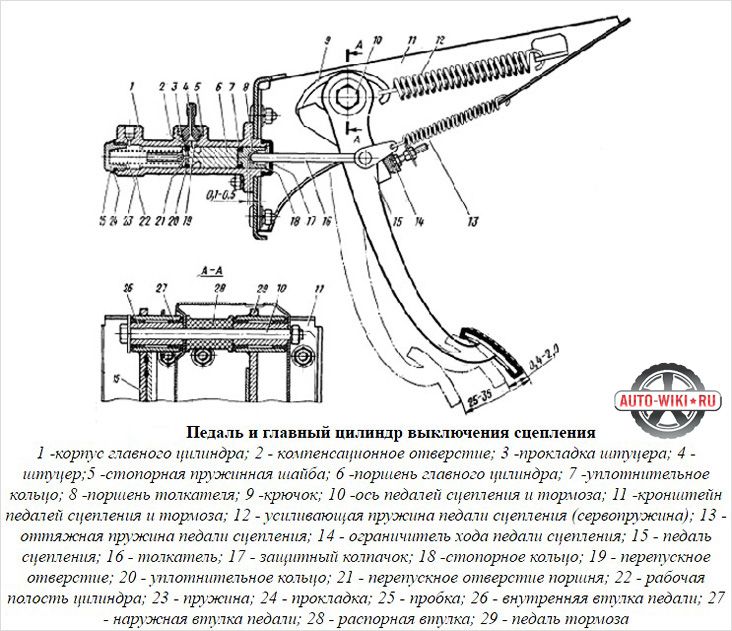

In the clutch drive in the VAZ-classic with an original basket, a native clutch release and with a conventional slave cylinder, there must be a gap between the pusher (rod) of the slave cylinder and the clutch fork. This clearance is required as the release bearing is not designed for continuous operation and constant rotation. In the absence of a gap, the bearing will constantly rest against the basket petals, rotate, which over time will lead to the release of its lubricant and overheating. After a short time of such work, the bearing will jam. If there is a gap, the bearing only works when we squeeze the clutch. When releasing the clutch pedal, the bearing should stop. That is why it is important to know how to adjust the VAZ clutch.

Clearance check

- Before checking the clearance, the retraction spring must be removed. If the clutch pedal is too tight, this spring can be completely removed. This spring serves to retract the clutch fork, which prevents the release bearing from contacting the basket. But, of course, it is more correct that this spring is in its place.

- Correct clutch adjustment is achieved with a clearance of 4-5 millimeters. Of course, extreme precision is not required, the main thing is that the fork must be in a free position. For example, so that when starting off, the pedal engages the clutch at the very bottom of the pedal, this gap can be increased slightly. And, accordingly, on the contrary, in order for the pedal to work earlier, the gap must be reduced. But the pusher and the fork must be in a free position, in no case in a taut position, otherwise the release bearing will soon become unusable.

If the clutch is incorrectly adjusted (if the fork is constantly pulled by the pusher, and the release lever rests on the basket).

In this case, the first thing to check is the clutch adjustment, but if this does not help, we change the ferodo disc.

Adjustment

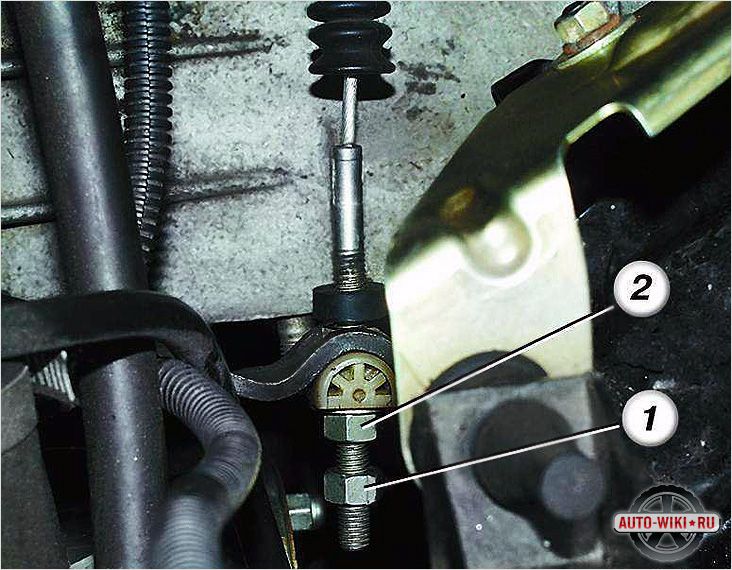

- In order to set the stem, it is necessary to unlock two nuts 17 and 13.

- Holding the stem, we tighten the nut - we increase the gap, unscrew it - we reduce it.

- We adjust the gap with one nut, with the other we counter the structure in the desired position.

- If necessary, return the spring to its place.

- We check the operation of the clutch when starting off and in motion.

The main task in this procedure is to maintain free play, that is, clearance, so that the release bearing does not burn out during constant rotation. Modern baskets already go without a gap, they have a different design, and it is simply not needed there, since it is replaced by a working self-feeding cylinder. But this option does not come from the factory and is not common.

Video

For helpful tips on adjusting the clutch on a classic, see the following video: