The clutch is one of the main components of a car's transmission. Thanks to it, gears are switched, the loads are removed from the engine and oscillations are damped. The quality of driving a car depends on its correct adjustment. The article describes the device of the node, its functions, principle of operation, recommendations are given on how.

Clutch structure and function

The link between engine and transmission is the clutch. Its purpose is to disconnect and connect the input shaft of the gearbox from the crankshaft flywheel. In cars with manual transmission, gears are switched only when the clutch pedal (PS) is fully depressed. At this point, there is no communication between the flywheel and the gearbox and no torque is transmitted.

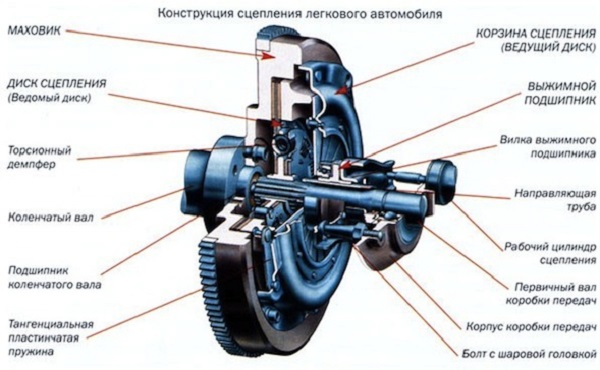

This vehicle unit consists of the following components:

- Flywheel. This element takes over the torque and transfers it through the gearbox to the gearbox. The basket is attached to the flywheel.

- Driven and pressure plate. These details are closely related. Their contact depends on the position of the vehicle located in the passenger compartment.

- Shutdown plug. With its help, the disks are disconnected.

- Input shaft of the gearbox. Torque is transmitted to this element.

Vehicle assembly design

Vehicle assembly design These are the main details. In addition to them, the unit includes:

- vibration damper springs;

- casing;

- friction pads fitted to the driven disc to soften friction between the flywheel and basket.

The pressure plate is interconnected with the flywheel and constantly rotates with it. To transmit rotation, there is a splined clutch in the driven disk, into which the gearbox input shaft is inserted.

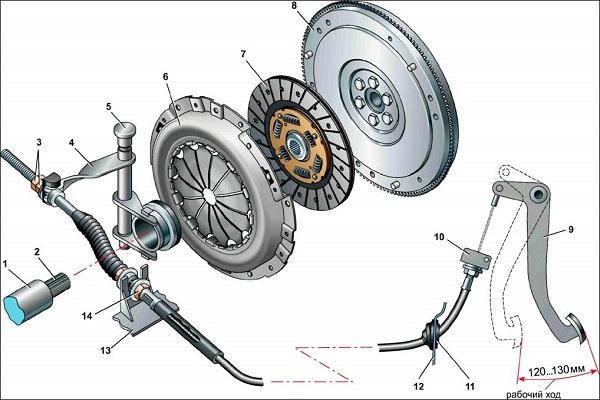

Gear shifting is carried out via the pedal as follows:

- pressure is transmitted to the release fork through the drive system;

- the fork pushes the release bearing and its clutch to the release springs of the pressure plate;

- under the pressure of the bearing, the legs (release springs) of the basket disconnect it for a while from the flywheel;

- after switching the speeds, the pedal is released, the bearing stops pressing on the springs and the basket again contacts the flywheel.

Nodes can be single-disk or multi-disk. Multi-disc assemblies are usually mounted on automatic transmissions.

Drive circuit and adjustment

Drive circuit and adjustment The following types of drives can be installed on cars:

- mechanical;

- hydraulic;

- electrical.

For a manual transmission to last longer, you must smoothly release the pedal when shifting gears.

When do you need to adjust the clutch?

The clutch is adjusted periodically. Over time, the pedal travel increases and the shutdown does not occur completely. Thus, when the PS is maximally squeezed out, the shafts are not completely disconnected, and they remain in contact with the engine, which increases the load on the teeth and shortens the service life of the unit.

With insufficient free stroke of the PS, the driven disk does not turn on completely. As a result, not all of the torque is transmitted when driving, in which case the car loses power. In addition, even with a smooth release of the PS, the driven disk may turn on abruptly, while noise in the transmission will be heard, the car will jerk.

You can diagnose that adjustment is required by the following signs:

- jerks or blows when starting to move;

- the PS sinks;

- PS has insufficient free play;

- fluid leaks from the drive system;

- there is extraneous noise when shifting gears.

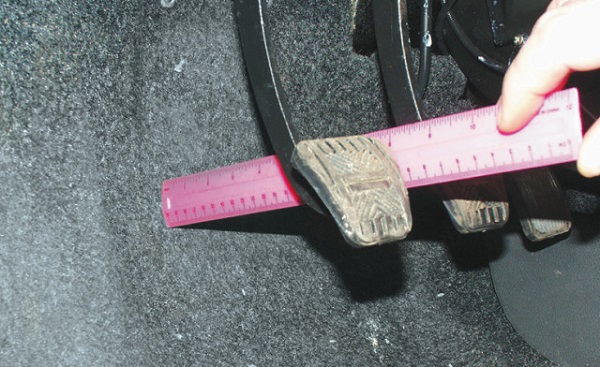

It is easy to determine the need for PS regulation. You need to measure the distance from the floor to the pedal, it should be about 16 centimeters.

Practical guide to adjustment

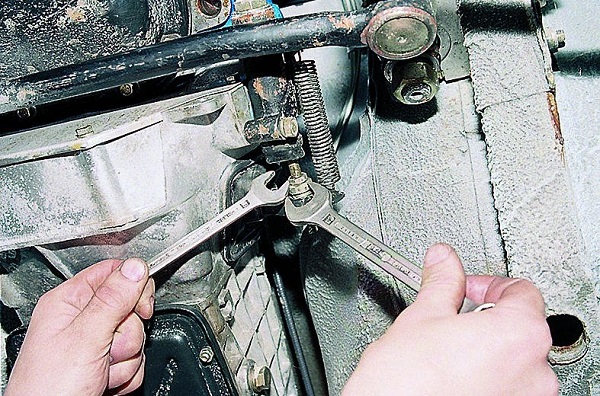

The mechanical clutch is adjusted by means of its actuator. To do this, in the engine compartment, you should find a cable, at the end of which there is a bolt with a lock nut. Turning the adjusting nut, it is necessary to ensure that the pedal free travel is 12-13 cm. To increase the PS travel, the nut should be tightened, to reduce the travel, the nut must be unscrewed. Then press the PS three times and measure the distance between the pedal and the floor. The clutch is adjusted until the required distance is reached.

Adjusting the drive cable

Adjusting the drive cable If the procedure is performed after replacing the unit, then it is necessary to check that there is no air in the hydraulic drive system. If present, it must be removed by purging the system.

The essence of the regulation is to establish the necessary clearances between the rod and the piston of the master cylinder of the unit. In addition, the required distances are set between the friction ring of the pressure plate and the release bearing.

In order to adjust the hydraulic actuator, it is necessary to remove the spring from the bracket of the master cylinder and fork. Next, you should measure the gaps between the pusher and the release fork. This distance should be approximately 5 mm. By unscrewing or tightening the adjusting nut on the cylinder rod, it is necessary to ensure that the free travel of the fork is 5 mm.

This procedure is carried out on simple systems and is shown as an example. There are other clutch drive systems. To properly adjust the unit, it is best to refer to the vehicle's operating instructions. The quality of movement of the car depends on the correctness of the adjustment.