View of a newborn man longer than others is delayed on the brightest and large toys. The attention of adult "children", that is, men and women, attract fashionable, bright, unusual things. Most motorists want to make the facade of their "four-wheeled" friend more stylish, for example, by installing. However, branded linings from brands Reef or ARB are expensive. For drivers who know how to work with their hands, it is proposed to solve the problem on how to make a power bumper with their own hands.

This article discusses the process of decorating the car on the example of the front of the bumper, although there are options for amplifying thresholds, roofs, rear bumpers, radiator and other parts of the car.

Sequence of production of power bumpers

The most common place in which the lining assemble is a cottage or a garage. As the basis, sheet metal (2-3 mm thick), a round tube or a box beam (similar to the carcass) is used.

In order to change the appearance of the body, it is necessary to hold a number of events.

Part 1. Preliminary preparation

1. Disassembling the front of the car body.

From the place scheduled to install the power bumper, all overhead elements belonging to the factory configuration are removed.

2. Making layout.

In order to accurately develop a complex spatial design, programmers can use the Solid Works complex (or simpler software: Katina, AutoCAD or Compass). However, most car enthusiasts prefer to apply the "Scientific Tick" method, that is, fitting "on the eye".

For the manufacture of patterns, a piece of cardboard of suitable size and tape is taken. Technology does not represent difficulties: try, cut, assemble on the segments of the tape, apply to the intended place again. Make the final version and deploy a sketch. Especially carefully check the size and coordinates of the elements located symmetrically.

3. Strengthening spars.

You should keep in mind the following. Depending on the intended form, the power bumper will refuse the design of the car by 15-25 kg (and sometimes more, it depends on the number of pipes). It is worthwhile to ask the steadyness of the frame of its car. For example, the car brand Niva needs to enhance the hardness of the power structure.

Special plates required to prevent deformation during screed are attached to the protruding part of the spars. Previously, they are covered with anti-corrosion composition, also protect the drilled holes from the destruction. By means of plates, hold the collected power bumper by car.

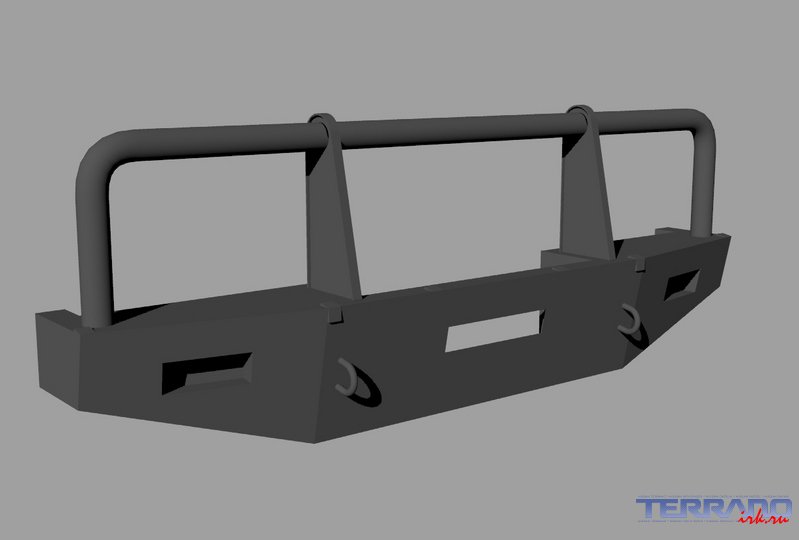

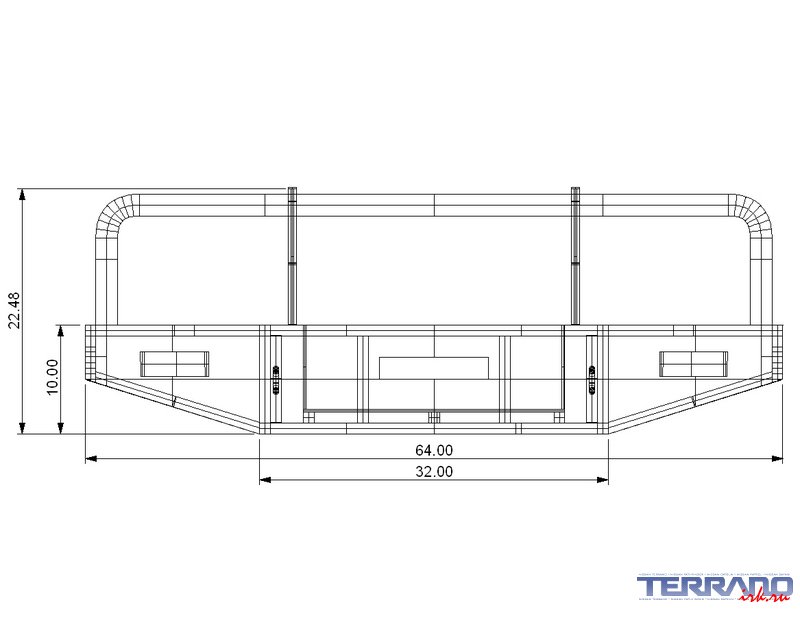

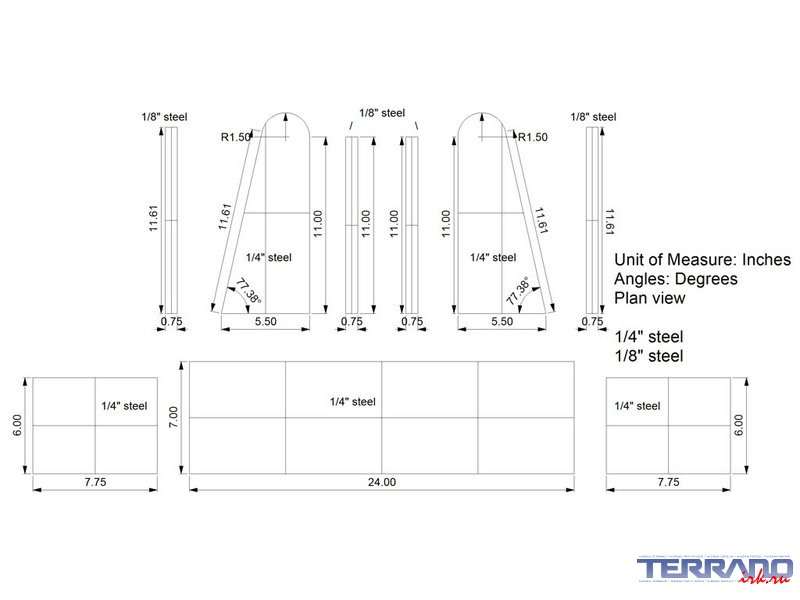

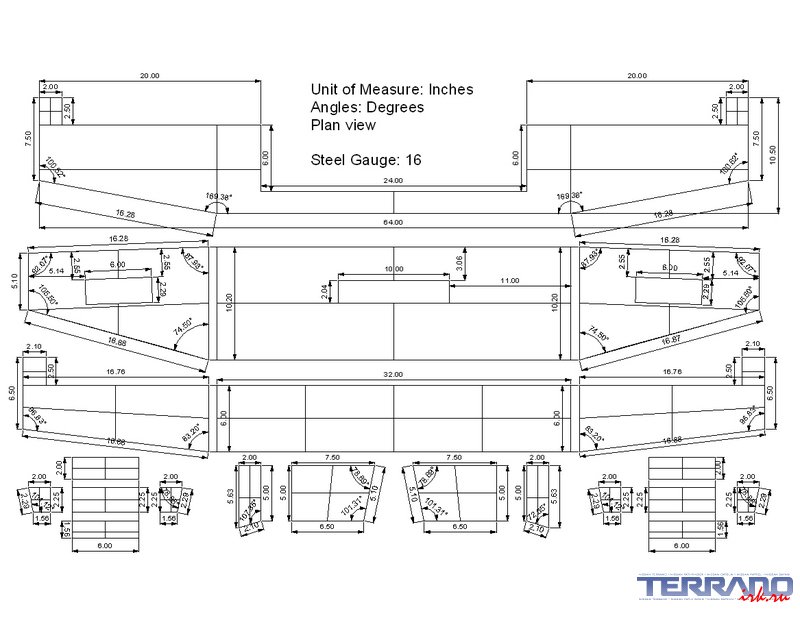

Example of the drawing of the power bumper:

Part 2. Mounting work

1. Assembling a frame frame.

According to a pre-made paper pattern from a metal sheet, a frame is cut out, the sides, the side of the board is cut. Depending on the thickness of the source material, scissors for metal, drill or gas burner are used for slots and holes. The final form of the invoice is acquired after applying the welding machine.

If the frame is collected only from rectangular pipes, they are cut from the inside, bend in size according to the paper pattern. First connect the parts of the central crossbar, then the sides. Weld.

Subsequently, the frame is fixed to the plates (see clause number 3 "Strengthening of the spars").

2. Production of additional elements from pipes.

The best equipment in order for the metal of the circular section to give a neat shape, is a pipe bender. In the absence of such, along the fold axis, the design is neatly so as not to burn the hole, heated by gas burner. At the same time, one of the ends of the pipe is gradually sent to the desired side.

The best equipment in order for the metal of the circular section to give a neat shape, is a pipe bender. In the absence of such, along the fold axis, the design is neatly so as not to burn the hole, heated by gas burner. At the same time, one of the ends of the pipe is gradually sent to the desired side.

3. Welding frame for elements and its assembly.

In the event that the P-shaped components protect the radiator are provided, the holes at the base of the frame burn. Then they are welded at the place.

Part 3. Degreasing and painting of the finished product

In order to bring the power bumper to the presentable form, it is necessary to produce the process of staining (according to traditional technology). Upon completion of the process, the power bumper, made by their own hands, will take its place on the front of the car.

It should be borne in mind that all the places where the holes are drilled in the factory structure, should be appropriately treated with anti-corrosion compositions, and then covered with paint, varnish, preservative. Otherwise, very soon, the look of passersby will attract the original power bumper, but rust stains, corrosive design.

Keep up with modern fashion trends, equip your car with fashionable installation. Production of power bumpers forces by many motorists!