What to do if the plastic molding or other part of the oldtimer made of plastic has lost its appearance, color, or completely cracked and began to collapse? Despite the strength of ABS plastic, it is highly susceptible to the negative influence of the external environment.

Plastic elements in the interior and exterior of cars began to appear in the second half of the 20th century. For example, in the American auto industry, the plastic era began to develop rapidly in the 1970s. From an economic point of view, this was a real discovery - the material was strong enough, durable, inexpensive to manufacture. However, nothing lasts forever, and time still takes its toll. Under the influence of ultraviolet rays, the plastic gradually burns out in the sun, becomes faded and "worn out", and in the case of external decorative elements of the body, there is another aggressor - reagents that are sprinkled and watered on roads in the cold season. In addition, in the process of active use, scratches and cracks will inevitably appear.

As a rule, plastic body elements are made of a material under the complex name acrylonitrile butadiene styrene, or simply ABS plastic. It is a shockproof resin that is resistant to moisture and oil. This polymer, which is very popular in the automotive industry, is also used for interior details. However, the material does not tolerate ultraviolet radiation well enough, and some types of this plastic are even destroyed by sunlight. In 1998, this led to one of the largest car recalls in US history - the seatbelt button, made of UV-resistant ABS plastic, broke and blocked the seatbelt buckle, preventing the seatbelt from being inserted or - much more dangerous - unfastening it. As a result, 8,800,000 vehicles were recalled.

It's good if the part has retained its integrity, but just faded from time to time. In this case, you can get by with updating the top layer. For this, a whole series of products have been developed that restore the color of the part and extend its service life. Some of them even add details of flexibility that is lost over time, thereby reducing the risk of breakage. The American publication Consumer Reports conducted its own research, studying the characteristics of the products on the market. Depending on their characteristics (and, accordingly, cost), the drugs provide protection for parts for a period of two weeks to two years. It is worth noting that Consumer Reports analysts considered only means for black plastic elements, although it is not difficult to find the necessary color scheme today. The test was carried out in a rather amusing format: the plastic body lining was divided into several parts (according to the amount of funds that took part in the test), treated with test compounds and ... put on the roof of the building where the Consumer Reports editorial office is located for 10 weeks. Each week, the panels were removed, washed, dried and sent back to the roof.

Best of all, according to experts, the harsh test of the scorching sun and torrential rains withstood the samples coated with ReNu Finish and Wipe New - the parts covered with them retained a bright black color throughout the entire 70 days of the test. The disadvantage of both products is that they are sold in small bottles, and at the same time they are much more expensive than analogues. Although, the experts recognized the difference in the results as tangible. The rest of the products (Turtle Wax Premium Grade, Meguiar’s Ultimate Black, Mothers Back-to-Black) showed a vigorous start, but by the end of the test all the parts processed by them had faded.

The old color of the plastic can be restored with a building hairdryer: with accurate uniform heating, the color appears on the surface of the part. For black plastic parts, you can use bumper ink (for example, Hi Gear or Astrochem), however, judging by the reviews, the part quickly loses its attractive appearance again.

A blow dryer can help freshen up the look of the part, but unfortunately this is a temporary measure.

But what if the plastic element of your car has received a serious crack, and this is not a molding, but a whole body panel? In this case, welding will help, but here everything is much more complicated, and it would be better to turn to specialists. The fact is that ABS plastic unites a whole family of materials, the characteristics of which depend on the proportions of the constituents - acronitrile, butadiene and styrene. Depending on the proportion, each type of plastic also has its own melting point, and hence the welding temperature. If you select too high a temperature during welding and overheat the plastic, the material will begin to foam and solidify in a porous state, which will make the weld brittle and short-lived. It is logical to assume that if the temperature is insufficient, the plastic will melt very badly, and a strong seam will not work. Therefore, when welding, a special hair dryer is used, on which you can manually set the exact temperature value depending on the type of plastic.

However, if solid strength is not required from the part, then you can do with simpler methods, which are actually enough: for example, use epoxy resin, glue the damaged area with fiberglass or reinforce with a metal mesh. Soldering also belongs to a simplified recovery method, which must be distinguished from welding. Actually, the difference lies precisely in the fact that when soldering it is extremely difficult to "get" to the required temperature, so the seam turns out to be brittle and porous. Enough to visually hide the defect, but will not provide strength and durability. In any case, the first step is to thoroughly rinse the part using a cleaning agent designed to remove tar, salts and other dirt. For this, you can use a special bitumen stain cleaner. There are a lot of offers on the market: AC-395, Hi Gear Buster Bug, Pingo Tar Remover, Liqui Moly Teerentferner and others. By the way, you can use the old-fashioned way - "white spirit" or kerosene. Also, it will not be superfluous to walk over the part with a brush. A horsehair brush works best for this purpose.

Finally, a very "hard case" - if the part cannot be easily restored, and it is easier to replace it than to restore it. It is good if we are talking about a mass car model for which it is easy to find the necessary parts. But what if you have a rare specimen, for which it is almost impossible to find components? Today, in addition to fiberglass, 3D printers are gaining popularity. Over the past two years, a host of industrial and scientific initiatives have been applied to master 3D printing technology in the automotive industry. Recently, polymer modification company Techmer PM presented even a full-fledged copy of the legendary Shelby Cobra, fully printed on a 3D printer. In this way, the company has demonstrated that this technology can be easily applied in the restoration of old cars. True, in this case, the authenticity of the car is lost, which is undesirable when working with autoclassics, and the technology itself is still only developing and therefore is a rather expensive pleasure. However, the increasing percentage of 3D printing in the automotive industry gives hope that this option will become more affordable over time.

This Shelby Cobra is fully 3D printed

The plastic parts of the passenger compartment are not easier: the interior is protected from road reagents, but it suffers from the sun, bulky goods and sloppy passengers, earning scuffs, scratches and cracks.

However, it is possible to update the plastic parts and return them to their former novelty with budgetary funds. If the car is no longer young and represents a certain historical value, with a competent approach, you can increase its value by 500 dollars, while spending ten times less. Although, of course, everything depends on the scale of the problem.

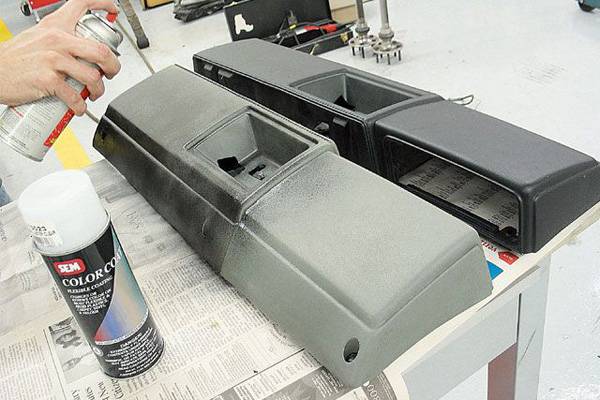

To begin with, the surface of the plastic part of the interior must be thoroughly cleaned. A number of American experts, in particular, American restorer and presenter Stacy David, advise using trisodium phosphate, a compound that forms the basis of various detergents and cleaning agents. The next step in preparation for painting is to ensure sufficient adhesion of the surface to the paint you intend to apply. This can be done with a special adhesion promoter (Stacy David recommends Duplicolor), which will provide a secure adhesion by acting as a primary primer coat before applying the base paint. If this is not done, then the new coating will fall on the old paint and will not adhere well - pretty soon the part will have to be repainted again. The first, rough layer of paint is also used as an additional bonding agent. In the case of interior plastic, a very popular tool is vinyl paint (the so-called liquid vinyl) such as Plasti-Kote or the same Duplicolor. Which of these brands is better is a controversial issue, and the opinions of Western restorers on this issue differ. The paint is applied in several layers for a secure fixing. It is at this moment that the magic happens: the old part turns into a new one, as if from a factory, and all the years of its service are hidden under a layer of fresh paint. The final touch is the treatment of the part with a special reducing agent to give shine and additional protection. Armor All and Black Magic are in demand.

You can refresh the detail without painting. To do this, after the washing stage, the part is dried, and then treated with sandpaper, sanding all small irregularities. However, do not get too carried away - the most "delicate" of the coarse-grained, 6-H, which is usually used for the final sanding of soft woods, is enough. After that, the part is gently and evenly heated with an ordinary hair dryer, while wiping the element with a clean rag without much pressure. After such processing, the part will noticeably rejuvenate, however, with severe abrasions, the homogeneous texture of the plastic cannot be completely restored.

If, among other things, there are still cracks on the parts, they can be dealt with with a simple superglue, which is applied along the entire length of the crack. For additional rigidity and durability, you can walk along the same place from the inside with a glue gun - this will guarantee that the crack will not disperse. Excess dried glue is sanded with sandpaper.

The situation is somewhat different with steering wheels with plastic rims. A layer of varnish is sanded off, after which all cracks and scratches are drilled out and expanded to make it easier to fill the damaged areas with epoxy. Many people use a standard two-component epoxy at this stage, but you can use, for example, a filler called Bondo, a brand from 3M. He has become almost a household name in America, in fact - automobile grinding mastic. When the mastic hardens to the state of melted cheese, the author recommends to process the pouring area with coarse sandpaper 25-H. The main thing here is not to waste time and not miss the right moment: fully hardened Bondo mastic is very problematic to sand with sandpaper.

Andrey Shuldeshov