A clutch is a mechanism designed to transmit rotation from the engine to the gearbox, which can be switched on and off smoothly. Main function this mechanism lies in touching vehicle from a standstill without any jerks and silent gear changes. Currently there are many different types clutches, but the operation of most of them is ensured by one or more friction discs, which are tightly compressed with each other or with the flywheel using springs.

The material used in the manufacture of discs is very similar to the material used in brake pads. Today, materials that do not contain asbestos are becoming increasingly popular. Smooth gear shifting is guaranteed due to the slippage of the continuously rotating master disk, connected to the internal combustion engine shaft, relative to the driven disk, which is connected to the manual transmission using spline connection. The force generated when you press the clutch pedal is transmitted directly to the mechanism through a hydraulic drive or through a cable. When the pedal is depressed, the discs unclench. As a result, there appears between them free space. The result of releasing the clutch pedal is the tight compression of the driven and driven discs between each other.

Clutch is enough reliable mechanism, which usually does not cause any particular difficulties for car enthusiasts during operation, however, with intensive use of the car, sooner or later certain malfunctions may occur. In this case, repair of this vehicle unit becomes inevitable, which must be preceded by mandatory diagnostics necessary to determine the nature of the breakdown and find optimal solution to eliminate it.

To check the release function, you need to disengage the clutch during operation power unit on Idling. After approximately 3 seconds the transmission reverse should turn on silently. Before checking the clutch for possible slipping, it is necessary that the temperature of this mechanism reaches its operating value. To do this, before starting testing, drive the car a short distance, and the clutch should work at different modes. The verification includes several stages. After disconnecting parking brake turns on most high gear. Next, when clutch disengaged The gas is released until the engine speed reaches 2000, after which this value is maintained for a short period of time. The clutch is then quickly engaged. If the motor stalls after this procedure, then the transmitting torque is in in perfect order. To avoid overloads, this check should be carried out only once.

To check the release function, you need to disengage the clutch during operation power unit on Idling. After approximately 3 seconds the transmission reverse should turn on silently. Before checking the clutch for possible slipping, it is necessary that the temperature of this mechanism reaches its operating value. To do this, before starting testing, drive the car a short distance, and the clutch should work at different modes. The verification includes several stages. After disconnecting parking brake turns on most high gear. Next, when clutch disengaged The gas is released until the engine speed reaches 2000, after which this value is maintained for a short period of time. The clutch is then quickly engaged. If the motor stalls after this procedure, then the transmitting torque is in in perfect order. To avoid overloads, this check should be carried out only once.

Identifies malfunctions of the clutch mechanism and its drive. Clutch malfunctions include: wear of the surfaces of the pressure plate, flywheel, linings and splines of the driven disk, damper springs, weakening or failure of the diaphragm spring, sticking of the clutch release fork, etc. The drive is characterized by such “troubles” as damage to the lever system, elongation, jamming or damage to the cable (mechanical drive), as well as failure of the working cylinder due to damage to the cuff, failure of tightness due to leakage working fluid(hydraulic drive).

Identifies malfunctions of the clutch mechanism and its drive. Clutch malfunctions include: wear of the surfaces of the pressure plate, flywheel, linings and splines of the driven disk, damper springs, weakening or failure of the diaphragm spring, sticking of the clutch release fork, etc. The drive is characterized by such “troubles” as damage to the lever system, elongation, jamming or damage to the cable (mechanical drive), as well as failure of the working cylinder due to damage to the cuff, failure of tightness due to leakage working fluid(hydraulic drive).

Many clutch malfunctions are quite accurately determined by external signs, but one external sign can be evidence of several different failures at once. Therefore for precise definition the nature of the damage to the clutch mechanism often requires disassemble. It can be stated that some part of this unit is faulty if the clutch “slips” or “leads”, jerking is regularly observed during its operation, the clutch is engaged with vibration, and the clutch is disengaged with noise.

External signs of incomplete disengagement of the clutch mechanism are: an increase in the amount of free play of the pedal, noise and crackling noise when shifting gears, as well as the appearance of difficulties in the process of shifting gears while the engine is running. Clutch slippage is characterized by: engine overheating, increased fuel consumption, deterioration of the vehicle's dynamic qualities, and the appearance of a specific odor due to significant overheating of the friction linings.

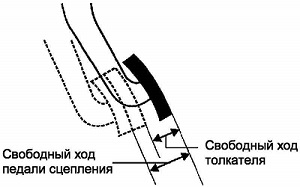

The clutch “drives” (does not disengage entirely) when the driven disk is deformed, its splines or linings are worn out, the diaphragm spring fails, the working cylinder breaks, the drive is clogged or sealed (in the case of a hydraulic drive), the lever system or cable is damaged (in the case of a mechanical drive). drive). In addition, the reasons for incomplete disengagement of the clutch may be increased freewheel outer end fork that disengages the clutch, too small pedal stroke, as well as air present in the hydraulic drive, jamming of the driven disk hub or misalignment of the latter.

Clutch slipping can be a consequence of damage or severe wear of the driven disk linings, oiling of the working surfaces of various parts, wear of the flywheel surface, jamming of the fork that disengages the clutch, lack of free play of the pedal, a decrease in the force of the pressure springs due to excessive overheating, or clogging of the compensation hole. clutch release master cylinder. The drive malfunctions discussed above can also result in the clutch not engaging fully.

Clutch slipping can be a consequence of damage or severe wear of the driven disk linings, oiling of the working surfaces of various parts, wear of the flywheel surface, jamming of the fork that disengages the clutch, lack of free play of the pedal, a decrease in the force of the pressure springs due to excessive overheating, or clogging of the compensation hole. clutch release master cylinder. The drive malfunctions discussed above can also result in the clutch not engaging fully.

Jerking during starting (non-smooth engagement of the clutch) is observed when the friction linings are oiled or significantly worn, as well as in cases of jamming of the driven disk hub, breakage of damper springs, diaphragm springs, and warping of the pressure plate. The clutch does not engage smoothly enough if the mounting supports of the power unit are loose, the pressure plate is warped, there are burrs on the working surfaces of the parts, the plate springs of the driven disk have lost their elasticity, or the clutch switch lever is stuck.

If you hear unusual noises when pressing the clutch pedal, you should first check the release bearing. If that's the case, then this part will have to be replaced. The cause of the noise may also be the beating of the driven disk during operation on the pressure plate. In this situation, the driven disk must be replaced. Noises that rise and fall during acceleration or braking (coasting or engine) indicate that the clutch rivets are loose or the imbalance is greater than the permissible value.

If you hear unusual noises when pressing the clutch pedal, you should first check the release bearing. If that's the case, then this part will have to be replaced. The cause of the noise may also be the beating of the driven disk during operation on the pressure plate. In this situation, the driven disk must be replaced. Noises that rise and fall during acceleration or braking (coasting or engine) indicate that the clutch rivets are loose or the imbalance is greater than the permissible value.

To the creaking engine not running usually caused by lack of lubrication and/or breakage of the plastic bushings of the pedal axle. The solution to this problem is to lubricate the bushings or replace worn parts with new parts. If you find that you have to apply excessive force to disengage the clutch mechanism, then most likely the reason for this phenomenon lies in jamming in the hinge joints, which are an integral part of the vehicle unit in question.

If during engaging the clutch vibration is felt, then you should check the splines of the driven disk, the driven disk itself (for deformation and oiling), the diaphragm spring, as well as the engine mounting supports. The pedal may shake at the very beginning of disengagement of the clutch due to increased runout of the heel of the release levers, which can be eliminated by adjusting the position of the heel. Determining a clutch malfunction is a difficult task that only true professionals in the field of transmission diagnostics and repair can do. Therefore, if you suspect a failure of any component of this mechanism, it is better to immediately contact service center , where diagnostics and subsequent repairs will be carried out in full compliance with technical regulations.

Clutch malfunctions are perhaps the most unexpected and unpleasant, because in most cases the car is completely immobilized. Read about what types of clutch malfunctions there are, as well as how to repair the clutch.

The most common clutch failures are:

- incomplete shutdown (in this case, gears are difficult to shift or do not shift at all);

- the clutch slips when the pedal is released (a burning smell is felt, the car does not develop speed, and has difficulty climbing hills);

- not smooth engagement of the clutch with jerking and vibration;

- noise in the clutch mechanism when pressing the clutch pedal;

- noise in the clutch mechanism when the pedal is released.

Clutch faults

So, now let’s look at them in more detail and determine how to eliminate them.

The clutch can be mechanically or hydraulically driven. Incomplete disengagement of the clutch may occur due to reduced level brake fluid in the feed tank, as well as incorrect adjustment. The fluid level must be periodically monitored, and if it is not within the normal range, brake fluid must be added. If the fluid level in the nutrient tank constantly decreases, this indicates a violation of the clutch hydraulic drive tightness (fluid is leaking), as well as possible wear of the clutch working cylinder. This problem can also occur due to air in the system hydraulic drive. To remove air, it is necessary to bleed the system.

Ideally, you need to drive onto a lift or overpass and carefully inspect the clutch slave cylinder for leaks. This is especially true in winter if the fluid has not been changed for a long time. In general, the brake fluid is very hygroscopic, which means it attracts moisture well. Therefore, it must be changed approximately every three years.

It happens that after long-term parking The car speeds refuse to turn on at all. This is due to the fact that the driven disk has become soured to the flywheel and pressure plate. In this case, you need to press the clutch pedal several times, and then try to turn on the speed again; if this does not help, you can turn off the engine, turn on the speed, press the clutch pedal, tighten the handbrake and carefully try to start the engine. If these procedures do not help, then you need to contact a service center to repair the clutch.

If the car does not pick up speed and has difficulty climbing hills, this indicates that the clutch is not completely disengaged. This happens due to wear on the linings on the clutch driven disc, wear on the drive disc, or improper adjustment of the clutch drive. When operating a car under normal conditions, replacing the clutch is required after 100 thousand kilometers.

Another clutch malfunction can be expressed in vibration and jerking when starting to move. The reason for this may be deformation of the driven disk, as well as oiling of its friction linings. The latter may occur due to wear of the crankshaft oil seal or input shaft boxes variable gears. In order to check this, you need to leave the car on a flat, clean place overnight, and in the morning look under it from the front. Detection of drops or puddles of oil may indicate the presence of this malfunction.

Another malfunction of the clutch mechanism can be determined by opening the window and pressing the clutch pedal. If you can hear them from under the car extraneous noise and a grinding noise that disappears when you release the clutch pedal, this indicates a malfunction release bearing. There is no point in delaying its replacement, because... in the event of a complete breakdown (if it jams), the clutch pressure plate will be destroyed, including other clutch parts, and the clutch casing and variable gearbox housing may also be damaged, which will entail large financial costs. Therefore, when replacing clutch parts, the release bearing must also be replaced.

It may work properly, but after several years of operation, the lubricant in it dries out and is expelled. Naturally, a dry bearing cannot work for a long time.

But if the clutch pedal is released and the noise does not stop, then most likely this indicates destruction of the driven or pressure plate, which in turn will require replacement of these parts. It is also, of course, rare, but it happens that one of the gearbox input shaft bearings is humming.

How to save your clutch

In order for the clutch to last as long as possible, you must adhere to following rules: at traffic lights and in traffic jams, turn off the speed and remove your foot from the clutch pedal, when shifting, release the gas pedal, do not move away abruptly, when the car is coasting, put the variable gear lever in the neutral position and remove your foot from the clutch pedal, try not to use the car off-road and as a tug.

If you neglect these rules, then replacing the driven disc, and possibly the entire clutch, may be required much earlier. To check the wear of the driven disk, it is necessary to sharply press the accelerator in direct gear. If the engine “roars”, and the car is reluctant to accelerate, and a specific burning smell is felt, then this is the first sign that it is time to think about replacing the driven disk. Typically, once a clutch is burned, it will wear out completely within a couple of weeks.

Conclusion

Thus, the clutch mechanism does not require much attention during operation, however, when the symptoms described above appear, it is necessary to replace worn parts as quickly as possible. And if the car’s mileage is more than 100 thousand kilometers and long trip, then it is better to take care in advance and inspect the car’s clutch mechanism.

Video: Clutch faults

Clutch problems can overtake a car owner right on the road, so every car enthusiast should know what the signs of a clutch malfunction are and how to solve the problem. Moreover, as a result of breakdowns, the vehicle may not move at all. You will learn from this article how to find out when it’s time to change the mechanism, what are the main breakdowns and how to fix them.

Signs of a bad clutch

Since this mechanism is quite important for the normal functioning of the car, you will probably be interested in knowing how to understand that it needs to be changed. Today, the main breakdowns in (hereinafter referred to as SS) are slippage and incomplete shutdown of the mechanism. Such signs of clutch malfunction indicate imminent failure of the mechanism. So how to determine clutch wear?

If the shutdown is incomplete when the pedal is pressed, then you will encounter problems with switching gears on a running engine. Clutch malfunctions occur when extraneous sounds and even cod when changing gears. In addition, if the mechanism does not work correctly, the free play of the pedal will be increased. If you notice slipping when you release the pedal, then these clutch malfunctions will be accompanied by a burning smell as a result of the burning of the linings. It should also be noted that with such a problem, the dynamics of the vehicle can significantly deteriorate, the engine will overheat, and gasoline consumption may also increase.

One of the main signs of malfunction is noise, which usually appears when the clutch is engaged or disengaged.

It will be very good if the motorist records such signs of problems in advance, so that he has time to get to the nearest service station or garage on his wheels. If the car allows you to drive, then you need to move carefully, you shouldn’t accelerate too much, the speeds should be switched carefully. If you shift to a higher gear, the pedal should be depressed and the gear selector should be held for a while neutral speed. Then the pedal is released and squeezed again, and only after that the speed is turned on.

If at this time it is necessary to switch to more low speed, then the box selector also needs to be delayed by neutral gear. The clutch pedal is released, after which the gas pedal is depressed (but not completely, but a little), and it turns on required speed. This way, the load on the mechanism elements is reduced, which will allow you to safely get to the service station if necessary.

Causes and main malfunctions

- Often the main reason for mechanism failure is improper operation of the vehicle. For example, if a car is stuck in snowdrift, and the driver continues to press on the gas, this significantly reduces the service life of the CC. The same goes for slippage.

- In addition to the CC disc itself, the one designed for smoothly engaging and disengaging the clutch can also fail. As a rule, before the actual breakdown, the driver may hear a strange squealing noise - this usually indicates a bearing failure.

- Another reason why you can understand that it’s time to change the CC is the natural wear and tear of clutches as a whole and their individual components. This is normal if the mechanism has already exhausted its service life. As a rule, as a result normal wear and tear Most often the driven pulleys fail. By the way, their service life on average is about 100 thousand kilometers. If you prefer an aggressive driving style, the service life of the disc can be reduced by two or even three times.

- A common cause of failure of the CC is considered to be low quality installed parts. As statistics show, today domestic market Auto parts sometimes contain up to 50% of low-quality products. The huge number of counterfeits and their sale have caused this problem. Therefore, when purchasing parts, pay attention to the manufacturer; we recommend installing only original spare parts on cars.

- If it gets on the friction linings motor fluid. Friction linings are very important for the vehicle and if they get dirty motor oil, this may cause the mechanism to break down. On practice similar problem occurs most often when the oil seals break or their service life expires. In any case, until the cause of the oil leak is eliminated, it is too early to talk about repairing the SS.

Ways to fix clutch problems

So, you know how to determine clutch wear and understand that it’s time to change it. Now let's talk about ways to fix this problem. There are several signs of failure; we will consider solving the problem with each of them separately.

If the clutch does not disengage

IN in this case eliminating the causes is accompanied by the need to:

- adjusting the drive itself;

- thorough cleaning and lubrication of the splines;

- adjusting or replacing the driven pulley;

- As a rule, another solution is to replace the friction linings.

Sooner or later, any CC will fail and will have to be replaced. Malfunctions in the hydraulic system can be corrected by bleeding the system to eliminate air trapped in it. Also in this case, you will need to check the tightness of the connections; the pipeline must also be intact. Sometimes to fix a problem you need to change the working and master cylinders, if all the working fluid has left them.

The flywheel of a car is the most important part of the engine. He is entrusted with many tasks, which he performs flawlessly for the time being. Nothing lasts forever, and this detail also has its resource. Let's find out what allowable wear flywheel.

About the flywheel and clutch

As you know, a serviceable cast-iron flywheel guarantees the normal functioning of the internal combustion engine. The element is also intended as a coupling stronghold. AND valid values element wear must be calculated in conjunction with other clutch elements.

ATTENTION! A completely simple way to reduce fuel consumption has been found! Don't believe me? An auto mechanic with 15 years of experience also didn’t believe it until he tried it. And now he saves 35,000 rubles a year on gasoline!

For this reason, if we talk about the flywheel, we will mean the entire clutch system. Obviously, this part is directly connected to the clutch and is its support.

Let's look at the operation and location of clutch elements in more detail.

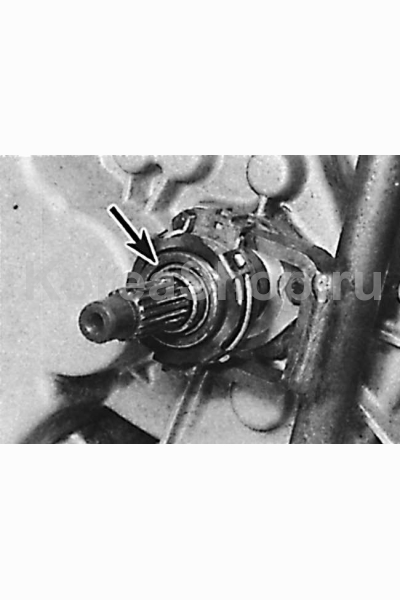

- A metal hoop is placed along the entire outer border of the flywheel, the teeth of which engage with the starter part when starting the engine. The hoop is steel and durable. To increase strength properties, the crown is hardened high voltage. It is initially put on the crank shaft balancer after previous and uniform heating to a temperature of 180 degrees.

- The flywheel sphere in contact with the clutch disc is subject to heavy load. The part is fixed with bolts to the end of the crank shaft, and the bolts must be secured with a special washer so that the fasteners can withstand such a load.

Attention. Flywheels must undergo a mandatory static balancing process (in this case, the imbalance should not exceed more than 0.1 Nm).

Important points:

- the flywheel is also adjusted after seating on the crank shaft assembly;

- during operation, the reverse plane of the flywheel, which is in direct contact with the clutch disc, is mostly subject to abrasion;

- The metal hoop that wears out most often is the crown.

If the rear plane of the flywheel wears out, it is ground on a machine in compliance with the basic rules. If the crown wears out, it must be replaced. The hoop is replaced as follows: the crown is knocked out of the part.

In some cases, if the crown sits very tightly, you should do this. Drill several holes in the base of the hoop so that the hoop splits. In this case, you must try not to damage the cast iron material of the flywheel itself.

The new hoop is installed either “cold” or “hot”. Both methods have their pros and cons. A crown placed “cold” will last much longer, but such installation can be difficult. On the contrary, it is much easier to put the crown “on hot”, but this must be done with great care, otherwise the heating will be uneven.

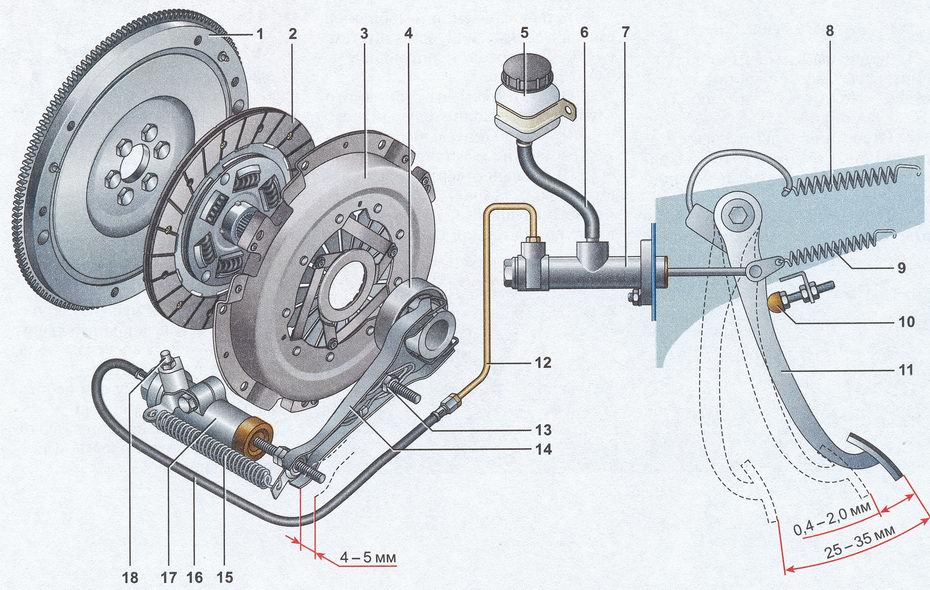

So, here is how the flywheel and clutch elements are located in the diagram (we are talking about a single-plate clutch):

- clutch pedal lever;

- a shaft that transmits pressing energy;

- clutch release fork;

- pressure disk;

- driven disk;

- damping system consisting of drive disk springs;

- release lever;

- thrust bearing;

- ferodo or overlays;

- gearbox input shaft.

Table of factory permissible dimensions and clearances of the main coupling parts

| Designation and name of associated parts | Nominal size and tolerance, mm | Gap, mm | Permissible wear limit, mm |

|---|---|---|---|

| 2141-1701030 - gearbox input shaft | 1,595+0,046+0,029 (shaft tooth height) | 0,02 - 0,132 | 0,3 |

| 2141-1601142 - driven disk hub | 1,661+0,066+0,033 (hub cavity) | ||

| 2141-1601036-10 - guide sleeve | 31-0.080-0.180(diameter) | 0,08 - 0,219 | 0,4 |

| 2141-1602055 - pedal roller | 20-0,033 (diameter) | ||

| 2141-1601242 - clutch release shaft | 20-0,033 (diameter) | 0,04 - 0,325 | 0,6 |

| 2141-1601222 - large shaft sleeve | 3,48-0,12 (wall thickness) |

Signs of flywheel wear

The main sign of component wear is the clutch pedal jerking when pressed. “Jerking” of the car is the first sign that something is wrong with the flywheel or clutch.

One more a clear sign wear and tear are visible external damage. But it is impossible to see them without disassembling the car. For this reason experienced drivers advise: if a car is being repaired, the gearbox is removed, be sure to check the condition of the flywheel and clutch.

Secondary signs of wear are considered to be difficult gear shifting, vehicle slipping, abrupt or too slow start, etc.

Signs of clutch wear are different from signs of flywheel wear. In this case, if the clutch disc has outlived its useful life, a burning smell will be clearly noticeable in the car interior and under the hood.

Another sign of disc wear is incomplete engagement of the mechanism. The solution to the problem in this case is to replace the part or gasket. If this is not done on time, the owner will face major and expensive repairs in the future.

Modern cars are often equipped with non-standard mechanical boxes, but by robots. At such gearboxes, the need for clutch repair will be indicated by the unexpected activation of the protective system.

Also on a robot, a sign of clutch failure is difficulty shifting gears.

How is the check carried out?

If the operation of the flywheel or clutch disc is in doubt, the following diagnostic procedures must be carried out:

- diagnose the condition of the flywheel plane (mirror) for the presence of burrs, scratches or other signs of wear;

- check for runout - it should not exceed two tenths of a millimeter (in case of increased runout, urgent measures are taken, otherwise the driven disk will wear out, jerking and jerking will be observed during the clutch engagement process);

- distortion of the clutch disk (VDC) and flywheel is diagnosed (if warping is observed, it is eliminated by grinding).

Note. The smallest permitted thickness of the VAT must be at least 20-21 mm. The disc should not be thinner than this, otherwise the clutch damper system will deteriorate.

Here's something else to check:

- diagnose the VAT mirror for smoothness (in this case, a concavity of no more than 0.08 mm is permissible, and there should be no convexity at all);

- the cleanliness of the mirror is checked (must be at least 1.6 microns);

- carefully diagnose the first shaft bearing (no seizures are allowed);

- separately check the friction linings, which must be changed if cracks appear on them or significant wear of the material (the heads of the locking rivets should not sink more than 0.2 mm relative to the working surface of the material).

Knowing the permissible wear of the flywheel and clutch elements, it will be possible to prevent the main problems and difficulties that are of a fundamental nature.

Incorrect adjustment and excessive wear of the clutch elements can lead to failure of the entire assembly. Consider what is meant when they say “the clutch is moving”, and also in what cases the malfunction can be corrected with your own hands.

A little about the device

It is difficult to understand the cause of the malfunction if you do not have a minimal understanding of the design and principle of operation of the clutch. It is enough to understand that pressing the pedal provokes movement of the fork and release bearing. The release lever, pressed by the fork, presses on the petals of the diaphragm spring, moving the pressure plate away from the driven disc. The latter, in turn, moves away from the flywheel, thereby stopping the transmission of torque from crankshaft to the gearbox input shaft.

The shutdown drive can be mechanical or hydraulic. In the first case, the pedal and the release fork are connected cable drive. The second type of inclusion requires the presence of a clutch master cylinder. By pressing the pedal, you initiate the movement of the rod, which presses on the piston inside the clutch cylinder. Repressed brake fluid, moving in the line, presses on the piston inside the working cylinder. The piston, moving, presses the shutdown rod.

What does "lead" mean?

They say that the clutch is engaged if the clutch does not disengage completely. In other words, after pressing the pedal, the driven disk and the engine flywheel do not disengage completely, which leads to partial transfer torque to the transmission input shaft.

Symptoms

You can assume that the clutch is slipping based on one symptom - difficulty engaging and disengaging gears. Most often, problems begin with the inclusion of reverse and first gears. The term “difficult” means both the need to apply more force to the gearshift knob and the inclusion with a crunch.

Difficulty shifting gears may also be associated with a faulty gearbox, which should also be taken into account during diagnosis.

Causes

DIY repair

If, after adjustment, problems with gear shifting have not disappeared, it is necessary to disconnect the gearbox and fully diagnose the clutch mechanism. cannot be called easy work, but with proper theoretical preparation and availability the necessary tool you can do it yourself.