Engine oil viscosity- the main characteristic by which a lubricant is selected. It can be kinematic, dynamic, conditional and specific. However, most often, kinematic and dynamic viscosity indicators are used to select a particular oil. Their permissible values are clearly indicated by the car engine manufacturer (often two or three values are allowed). Correct selection viscosity ensures normal engine operation with minimal mechanical losses, reliable protection details, normal flow fuel. In order to select the optimal lubricant, you need to carefully understand the issue of engine oil viscosity.

Classification of viscosity of motor oils

Viscosity (another name is internal friction), in accordance with the official definition, is the property of fluid bodies to resist the movement of one part relative to another. In this case, work is performed, which is dissipated in the form of heat into the environment.

Viscosity is not a constant value, and it changes depending on the temperature of the oil, the impurities present in its composition, the service life value (engine mileage per given volume). However, this characteristic determines the position of the lubricating fluid at a certain point in time. And when choosing a particular lubricating fluid for an engine, you must be guided by two key concepts- dynamic and kinetic viscosity. They are also called low-temperature and high-temperature viscosity, respectively.

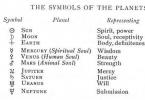

Historically, car enthusiasts around the world determine viscosity by the so-called SAE standard J300. SAE is an acronym for the Society of Automotive Engineers, an organization that works to standardize and unify various systems and concepts used in the automotive industry. And the J300 standard characterizes the dynamic and kinematic components of viscosity.

In accordance with this standard, there are 17 classes of oils, 8 of them are winter and 9 are summer. Most oils used in the CIS countries are designated XXW-YY. Where XX is the designation of dynamic (low temperature) viscosity, and YY is the indicator of kinematic (high temperature) viscosity. The letter W stands for the English word Winter. Currently, most oils are all-season, which is reflected in this designation. Eight winter ones are 0W, 2.5W, 5W, 7.5W, 10W, 15W, 20W, 25W, nine summer ones are 2, 5, 7.10, 20, 30, 40, 50, 60).

According to the SAE J300 standard, engine oil must meet the following requirements:

- Pumpability. This is especially true for engine operation when low temperatures. The pump should pump oil through the system without problems, and the channels should not become clogged with thickened lubricant.

- Work at high temperatures. Here the situation is the opposite, when the lubricating fluid should not evaporate, burn away, and reliably protect the walls of the parts due to the formation of a reliable protective oil film on them.

- Protection of the engine from wear and overheating. This applies to work in all temperature ranges. The oil must provide protection against engine overheating and mechanical wear of the surfaces of parts during the entire operating period.

- Removing fuel combustion products from the cylinder block.

- Ensuring minimal friction force between individual pairs in the engine.

- Sealing of gaps between parts of the cylinder-piston group.

- Removing heat from the rubbing surfaces of engine parts.

Dynamic and kinematic viscosities each have their own influence on the listed properties of motor oil.

Dynamic viscosity

According to the official definition, dynamic viscosity(aka absolute) characterizes the resistance force oily liquid, which occurs during the movement of two layers of oil, separated by a distance of one centimeter, and moving at a speed of 1 cm/s. Its unit of measurement is Pa s (mPa s). It is designated by the English abbreviation CCS. Testing of individual samples is carried out using special equipment - a viscometer.

In accordance with the SAE J300 standard, the dynamic viscosity of all-season (and winter) motor oils is determined as follows (essentially, the cranking temperature):

- 0W - used at temperatures down to -35°C;

- 5W - used at temperatures down to -30°C;

- 10W - used at temperatures down to -25°C;

- 15W - used at temperatures down to -20°C;

- 20W - used at temperatures down to -15°C.

Also worth distinguish between pour point and pumpability temperature. In the designation of viscosity we are talking specifically about pumpability, that is, condition. when the oil can spread unhindered throughout oil system within acceptable temperature limits. And the temperature at which it completely hardens is usually several degrees lower (5...10 degrees).

As you can see, for most regions of the Russian Federation oils with a value of 10W and higher cannot be recommended for use as all-season. This is directly reflected in the tolerances of various automakers for cars sold in Russian market. Oils with a low-temperature characteristic of 0W or 5W will be optimal for the CIS countries.

Kinematic viscosity

Another name for it is high-temperature, which is much more interesting to deal with. Here, unfortunately, there is no such clear connection as with the dynamic one, and the values have a different character. In fact, this value shows the time during which a certain amount of liquid is poured through a hole of a certain diameter. High-temperature viscosity is measured in mm²/s (another alternative unit of measurement is centistokes - cSt, there is the following relationship - 1 cSt = 1 mm²/s = 0.000001 m²/s).

The most popular SAE high temperature viscosity ratios are 20, 30, 40, 50 and 60 (the lower values listed above are rarely used, for example, they can be found in some Japanese cars, used on domestic market this country). To put it in a nutshell, then the lower this coefficient, the thinner the oil, and vice versa, the higher it is, the thicker it is. Laboratory tests are carried out at three temperatures - +40°C, +100°C and +150°C. The device used to carry out the experiments is a rotational viscometer.

These three temperatures were not chosen by chance. They allow you to see the dynamics of changes in viscosity with different conditions- normal (+40°С and +100°С) and critical (+150°С). Tests are also carried out at other temperatures (and corresponding graphs are constructed based on their results), however, these temperature values are taken as the main points.

Both dynamic and kinematic viscosities directly depend on density. The relationship between them is as follows: dynamic viscosity is the product of kinematic viscosity and oil density at a temperature of +150 degrees Celsius. This is fully consistent with the laws of thermodynamics, because it is known that as the temperature increases, the density of a substance decreases. This means that at a constant dynamic viscosity, the kinematic viscosity will decrease (as indicated by its low coefficients). And vice versa, as the temperature decreases, the kinematic coefficients increase.

Before moving on to a description of the correspondences of the described coefficients, let us dwell on the concept of High temperature/High shear viscosity (abbreviated as HT/HS). This is the ratio of engine operating temperature to high temperature viscosity. It characterizes the fluidity of the oil at the test temperature of +150°C. This value was introduced by the API in the late 1980s to better characterize manufactured oils.

High Temperature Viscosity Table

Please note that in new versions of the J300 standard, oil with a viscosity of SAE 20 has a lower limit of 6.9 cSt. The same lubricating fluids for which this value is lower (SAE 8, 12, 16) are separated into a separate group called energy saving oils. By classification ACEA standard they are designated A1/B1 (obsolete after 2016) and A5/B5.

Viscosity index

There is another interesting indicator - viscosity index. It characterizes the decrease in kinematic viscosity with an increase in the operating temperature of the oil. This is a relative value by which one can roughly judge the suitability of a lubricating fluid to work at different temperatures. It is calculated empirically by comparing properties at different temperature conditions. IN good oil this index should be high, since then its operational characteristics depend little on external factors. And vice versa, if the viscosity index certain oil small, then this composition is very dependent on temperature and other operating conditions.

In other words, we can say that with a low coefficient, the oil quickly dilutes. And because of this, the thickness of the protective film becomes very small, which leads to significant wear on the surfaces of engine parts. But the oils from high index capable of working in a wide range temperature range and fully cope with your tasks.

Viscosity index directly depends on the chemical composition of the oil. In particular, it depends on the amount of hydrocarbons in it and the lightness of the fractions used. Accordingly, mineral compounds will have the worst viscosity index, usually in the range of 120...140, semi-synthetic lubricating fluids will have a similar value of 130...150, and “synthetics” can boast the most best performance- 140...170 (sometimes even up to 180).

The high viscosity index of synthetic oils (as opposed to mineral oils with the same viscosity according to SAE) allows the use of such compositions in a wide temperature range.

Is it possible to mix oils of different viscosities?

A fairly common situation is when a car owner, for some reason, needs to add oil to the engine crankcase that is different from the one that is already there, especially if they have different viscosities. Is it possible to do this? Let us answer right away - yes, it is possible, but with certain reservations.

The main thing worth saying right away is: All modern motor oils can be mixed with each other (different viscosity, synthetics, semi-synthetics and mineral water). This will not cause any negative chemical reactions in the engine crankcase, will not lead to the formation of sediment, foaming or other negative consequences.

Decrease in density and viscosity with increasing temperature

This is very easy to prove. As you know, all oils have a certain standardization according to API (American standard) and ACEA (European standard). Some and other documents clearly state safety requirements, according to which any mixing of oils is allowed in such a way that it does not cause any destructive consequences for the car engine. And since lubricating fluids meet these standards (in in this case it doesn’t matter which class), then this requirement is met.

Another question is whether it is worth mixing oils, especially those of different viscosities? This procedure is only allowed as a last resort, for example, if at the moment (in the garage or on the track) you do not have suitable (identical to what is currently in the crankcase) oil. In that emergency you can add lubricant until the required level. However, further operation depends on the difference between the old and new oils.

So, if the viscosities are very close, for example, 5W-30 and 5W-40 (and even more so, the manufacturer and their class are the same), then it is quite possible to drive with such a mixture until the next oil change according to the regulations. Similarly, it is possible to mix neighboring dynamic viscosity values (for example, 5W-40 and 10W-40. As a result, you will get a certain average value, which depends on the proportions of both compositions (in the latter case, you will get a certain composition with a conditional dynamic viscosity of 7.5W -40 provided they are mixed in equal volumes).

Also allowed to long-term operation a mixture of oils with similar viscosity values, which however belong to neighboring classes. In particular, it is allowed to mix semi-synthetics and synthetics, or mineral water and semi-synthetics. You can travel on such trains for a long time (although it is undesirable). But although it is possible to mix mineral oil and synthetic oil, it is better to drive it only to the nearest car service center, and then do it there. complete replacement oils

As for manufacturers, the situation is similar. When you have oils of different viscosities, but from the same manufacturer, feel free to mix them. If, however, to a good and proven oil (which you are sure is not a fake) from a well-known global manufacturer (for example, such as or) you add one that is similar in both viscosity and quality (including API and ACEA standards), then In this case, you can also drive the car for a long time.

Also pay attention to the car manufacturers' approvals. For some car models, their manufacturer directly states that the oil used must necessarily meet the approval. If the added lubricant does not have such approval, then you cannot drive with such a mixture for a long time. It is necessary to carry out the replacement as quickly as possible and fill in lubricant with the required tolerance.

Sometimes situations arise when you need to fill in lubricating fluid on the road, and you drive up to the nearest auto shop. But its range does not contain the same lubricating fluid as in the crankcase of your car. What to do in this case? The answer is simple - fill in the same or better. For example, you use semi-synthetic 5W-40. In this case, it is advisable to choose 5W-30. However, here you need to be guided by the same considerations that were given above. That is, oils should not differ much from each other in characteristics. Otherwise, the resulting mixture must be replaced as quickly as possible with a new one suitable for of this engine lubricating composition.

Viscosity and base oil

Many car enthusiasts are interested in the question of what viscosity the oil has. It arises because there is a common misconception that a synthetic product supposedly has better viscosity and that is why “synthetics” are better suited for a car engine. On the contrary, supposedly mineral oils have poor viscosity.

Actually this is not true. The fact is that usually mineral oil itself is much thicker, so on store shelves such a lubricating fluid is often found with viscosity readings such as 10W-40, 15W-40, and so on. That is, low-viscosity mineral oils practically never happens. Synthetics and semi-synthetics are another matter. The use of modern chemical additives in their compositions allows for a reduction in viscosity, which is why oils, for example, with the popular viscosity 5W-30 can be either synthetic or semi-synthetic. Accordingly, when choosing an oil, you need to pay attention not only to the viscosity value, but also to the type of oil.

Base oil

The quality of the final product largely depends on the base. Motor oils are no exception. In the production of car engine oils, 5 groups of base oils are used. Each of them differs in their extraction method, quality and characteristics.

U various manufacturers in the assortment you can find a wide variety of lubricating fluids related to different classes, but having the same viscosity. Therefore, when purchasing one or another lubricating fluid, the choice of its type is a separate issue that must be considered based on the condition of the engine, the make and class of the car, the cost of the oil itself, and so on. As for the above values of dynamic and kinematic viscosity, they have the same designation according to the SAE standard. But the stability and durability of the protective film different types oils will be different.

Oil selection

Selection of lubricant for specific engine machines is a rather labor-intensive process, since you need to analyze a lot of information to make the right decision. In particular, in addition to the viscosity itself, it is advisable to inquire about the motor oil, its classes according to API and ACEA standards, type (synthetic, semi-synthetic, mineral water), engine design and much more.

What oil is better to pour into the engine?

The choice of engine oil should be based on viscosity, API specifications, ACEA, tolerances and those important parameters that you never pay attention to. You need to select according to 4 main parameters.

As for the first step - choosing the viscosity of the new engine oil, it is worth noting that you must initially proceed from the requirements of the engine manufacturer. Not oil, but engine! As a rule, the manual (technical documentation) contains specific information about what lubricating fluids of what viscosity can be used in the power unit. It is often possible to use two or three viscosity values (for example, ).

Please note that the thickness of the protective oil film formed does not depend on its strength. Thus, a mineral film can withstand a load of about 900 kg per square centimeter, and the same film formed by modern synthetic ester-based oils can already withstand a load of 2200 kg per square centimeter. And this is with the same oil viscosity.

What happens if you choose the wrong viscosity?

Continuing the previous topic, we list the possible troubles that may arise if an oil with an inappropriate viscosity is selected. So, if it is too thick:

- The operating temperature of the engine will increase as thermal energy is less efficiently dissipated. However, when driving high speed and/or in cold weather this may not be considered a critical phenomenon.

- When driving at high speeds and/or high load The temperature on the engine can increase significantly, causing significant wear of both individual parts and the engine as a whole.

- High engine temperatures lead to accelerated oxidation of the oil, which causes it to wear out faster and lose its performance properties.

However, if you fill the engine with very liquid oil, then problems may also arise. Among them:

- The protective oil film on the surface of the parts will be very thin. This means that the parts do not receive adequate protection from mechanical wear and exposure to high temperatures. Because of this, parts wear out faster.

- A large number of lubricating fluid usually goes into a frenzy. That is, it will take place.

- There is a risk of the so-called motor wedge appearing, that is, its failure. And this is very dangerous, since it threatens complex and expensive repairs.

Therefore, to avoid such troubles, try to select oil of the viscosity allowed by the car engine manufacturer. By doing this you will not only extend its service life, but also ensure normal mode its operation in different modes.

Conclusion

Always follow the car manufacturer's recommendations and fill in lubricant with the values of dynamic and kinematic viscosity that are directly indicated by them. Minor deviations are allowed only in rare and/or emergency cases. Well, the choice of one oil or another needs to be made according to several parameters, and not just by viscosity.

Choosing engine oil is a serious task for every car enthusiast. AND main parameter, according to which selection should be carried out, is the viscosity of the oil. Oil viscosity characterizes the degree of thickness of the motor fluid and its ability to maintain its properties under temperature changes.

Let's try to figure out in what units viscosity should be measured, what functions it performs and why it plays a huge role in the operation of the whole motor system.

Engine operation internal combustion involves the continuous interaction of its structural elements. Let's imagine for a second that the engine is running dry. What will happen to him? First, the frictional force will increase the temperature inside the device. Secondly, deformation and wear of parts will occur. And finally, all this will lead to a complete stop of the internal combustion engine and the impossibility of its further use. Properly selected motor oil performs the following functions:

- protects the motor from overheating,

- prevents rapid wear of mechanisms,

- prevents the formation of corrosion,

- removes soot, soot and fuel combustion products outside the engine system,

- helps to increase the resource of the power unit.

Thus, the normal functioning of the motor department without lubricating fluid is impossible.

Important! Pour into the engine vehicle You only need oil whose viscosity meets the requirements of car manufacturers. In this case the coefficient useful action will be maximum, and wear of working units will be minimal. You should not trust the opinions of sales consultants, friends and car service specialists if they differ from the instructions for the car. After all, only the manufacturer can know for sure what to fill the engine with.

Oil viscosity index

The concept of oil viscosity implies the ability of a liquid to be viscous. It is determined using the viscosity index. Oil viscosity index is a value indicating the degree of viscosity oily liquid with temperature changes. Lubricants with a high degree of viscosity have the following properties:

- during a cold engine start, the protective film has strong fluidity, which ensures quick and uniform distribution of lubricant over the entire working surface;

- heating the engine causes an increase in the viscosity of the film. This property allows you to maintain a protective film on the surfaces of moving parts.

Those. oils with a high viscosity index easily adapt to temperature overloads, while a low viscosity index of a motor oil indicates less ability. Such substances have a more liquid state and form a thin protective film on the parts. In conditions of negative temperatures, motor fluid with a low viscosity index will make it difficult to start the power unit, and at high temperatures it will not be able to prevent high friction forces.

The viscosity index is calculated according to GOST 25371-82. You can calculate it using online services on the Internet.

Kinematic and dynamic viscosity

Degree of ductility motor material is determined by two indicators - kinematic and dynamic viscosity.

Engine oil

Kinematic viscosity of an oil is an indicator that reflects its fluidity at normal (+40 degrees Celsius) and high (+100 degrees Celsius) temperatures. The method for measuring this value is based on the use of a capillary viscometer. The device measures the time required for the oil fluid to flow out at given temperatures. Measured kinematic viscosity in mm 2 /s.

The dynamic viscosity of the oil is also calculated empirically. It shows the resistance force of the oil fluid that occurs during the movement of two layers of oil, spaced 1 centimeter apart and moving at a speed of 1 cm/s. The units of measurement for this quantity are Pascal seconds.

The determination of oil viscosity must take place under different temperature conditions, because the liquid is not stable and changes its properties at low and high temperatures.

A table of motor oil viscosity by temperature is presented below.

Explanation of the engine oil designation

As noted earlier, viscosity is the main parameter of a protective fluid, characterizing its ability to ensure vehicle performance in various climatic conditions.

According to the international SAE classification system, motor lubricants can be of three types: winter, summer and all-season.

Oil intended for winter use, marked with a number and the letter W, for example, 5W, 10W, 15W. The first symbol of the marking indicates the range of negative operating temperatures. The letter W - from the English word “Winter” - winter - informs the buyer about the possibility of using the lubricant in harsh low-temperature conditions. It has greater fluidity than its summer counterpart to ensure easy starting at low temperatures. The liquid film instantly envelops the cold elements and facilitates their scrolling.

The limit of negative temperatures at which the oil remains operational is as follows: for 0W - (-40) degrees Celsius, for 5W - (-35) degrees, for 10W - (-25) degrees, for 15W - (-35) degrees.

Summer liquid has a high viscosity, which allows the film to “stick” more firmly to the working elements. At too high temperatures, this oil spreads evenly over the working surface of the parts and protects them from severe wear. This oil is designated by numbers, for example, 20,30,40, etc. This figure characterizes the high-temperature limit in which the liquid retains its properties.

Important! What do the numbers mean? The summer parameter numbers in no way mean the maximum temperature at which the car can operate. They are conditional and have nothing to do with the degree scale.

Oil with a viscosity of 30 functions normally at temperatures environment up to +30 degrees Celsius, 40 – up to +45 degrees, 50 – up to +50 degrees.

It is easy to recognize universal oil: its marking includes two numbers and the letter W between them, for example, 5w30. Its use implies any climatic conditions, be it harsh winters or hot summers. In both cases, the oil will adapt to changes and maintain the functionality of the entire engine system.

By the way, the climatic range of universal oil is determined simply. For example, for 5W30 it varies from minus 35 to +30 degrees Celsius.

All-season oils are convenient to use, which is why they are found on the shelves of car dealerships more often than summer and winter options.

To give you a better idea of what motor oil viscosity is appropriate in your area, below is a table showing the operating temperature range for each type of lubricant.

Average oil performance ranges

Having figured out what the numbers in oil viscosity mean, let’s move on to the next standard. The classification of motor oil by viscosity also affects API standard. Depending on the engine type, API designation starts with the letter S or C. S means gasoline engines, C means diesel engines. The second letter of the classification indicates the quality class of the motor oil. And the further this letter is from the beginning of the alphabet, the better the quality of the protective fluid.

For gasoline engine systems, the following designations exist:

- SC – year of manufacture before 1964

- SD – year of manufacture from 1964 to 1968.

- SE – year of manufacture from 1969 to 1972.

- SF – year of manufacture from 1973 to 1988.

- SG – year of manufacture from 1989 to 1994.

- SH – year of manufacture from 1995 to 1996.

- SJ – year of manufacture from 1997 to 2000.

- SL – year of production from 2001 to 2003.

- SM – year of manufacture after 2004

- SN – cars equipped modern system neutralization exhaust gases.

For diesel:

- CB – year of manufacture before 1961

- CC – year of manufacture before 1983

- CD – year of release before 1990

- CE – year of manufacture before 1990 (turbocharged engine).

- CF – year of manufacture since 1990, (turbocharged engine).

- CG-4 – year of manufacture since 1994, (turbocharged engine).

- CH-4 – year of production: 1998

- CI-4 – modern cars(turbocharged engine).

- CI-4 plus is a much higher class.

What's good for one engine may be in danger of repair for another.

Engine oil

Many car owners are sure that it is worth choosing more viscous oils, because they are the key to long-lasting engine operation. This is a serious misconception. Yes, experts pour oil with a high degree of viscosity under the hoods of racing cars to achieve maximum service life of the power unit. But ordinary Cars are equipped with a different system that will simply choke if the protective film is too thick.

What oil viscosity is permissible to use in the engine of a particular machine is described in any operating manual.

After all, before launching mass sales of models, automakers conducted a large number of tests, taking into account possible modes driving and operation technical means in various climatic conditions. By analyzing the behavior of the motor and its ability to maintain stable operation under certain conditions, engineers established acceptable parameters for motor lubrication. Deviation from them can provoke a decrease in the power of the propulsion system, its overheating, an increase in fuel consumption and much more.

Engine oil in the engine

Why is viscosity grade so important in the operation of mechanisms? Imagine for a moment the inside of the engine: there is a gap between the cylinders and the piston, the size of which should allow possible expansion of parts due to high temperature changes. But for maximum efficiency, this gap must have a minimum value, preventing exhaust gases generated during combustion from entering the engine system fuel mixture. To ensure that the piston body does not heat up from contact with the cylinders, motor lubricant is used.

The oil viscosity level must ensure the performance of each element of the propulsion system. Manufacturers of power units must achieve an optimal ratio of the minimum gap between the rubbing parts and the oil film, preventing premature wear of the elements and increasing the operating life of the engine. Agree, trust official representatives car brand It is safer to know how this knowledge was obtained than to trust “experienced” motorists who rely on intuition.

What happens when the engine starts?

If your “iron friend” stood in the cold all night, then the next morning the viscosity of the oil poured into it will be several times higher than the calculated operating value. Accordingly, the thickness of the protective film will exceed the gaps between the elements. When a cold engine starts, its power drops and the temperature inside it rises. Thus, the engine warms up.

Important! During warming up, you should not give it increased load. Too thick lubricant composition will impede the movement of the main mechanisms and lead to a reduction in the service life of the vehicle.

Engine oil viscosity at operating temperatures

After the engine has warmed up, the cooling system is activated. One engine cycle looks like this:

- Pressing the gas pedal increases the engine speed and increases the load on it, as a result of which the friction force of the parts increases (since the too astringent liquid has not yet had time to get into the gaps between parts),

- the oil temperature rises,

- the degree of its viscosity decreases (fluidity increases),

- the thickness of the oil layer decreases (leaks into the gaps between parts),

- friction force decreases,

- The oil film temperature is reduced (partially with the help of the cooling system).

Any motor system works on this principle.

Viscosity of motor oils at a temperature of – 20 degrees

The dependence of oil viscosity on operating temperature is obvious. Just as it is obvious that the high level of motor protection should not decrease throughout the entire period of operation. The slightest deviation from the norm can lead to the disappearance of the motor film, which in turn will negatively affect the “defenseless” part.

Each internal combustion engine, although it has a similar design, has a unique set of consumer properties: power, efficiency, environmental friendliness and torque. These differences are explained by the difference in engine clearances and operating temperatures.

In order to select the oil for the vehicle as accurately as possible, we have developed international classifications motor fluids.

The classification provided for by the SAE standard informs car owners about the average operating temperature range. API, ACEA, etc. classifications give a clearer idea of the possibility of using lubricating fluid in certain vehicles.

Consequences of filling high viscosity oil

There are times when car owners do not know how to determine the required viscosity of engine oil for their car, and fill in the one recommended by sellers. What happens if the ductility is higher than required?

If oil with high viscosity “splashes” in a well-heated engine, then there is no danger for the engine (at normal speeds). In this case, the temperature inside the unit will simply increase, which will lead to a decrease in the viscosity of the lubricant. Those. the situation will return to normal. But! Regular repetition of this pattern will significantly reduce motor life.

If you suddenly “give on the gas”, causing an increase in speed, the degree of viscosity of the liquid will not correspond to the temperature. This will result in exceeding the maximum permissible temperature in engine compartment. Overheating will cause an increase in friction force and a decrease in the wear resistance of parts. By the way, the oil itself will also lose its properties in a fairly short period of time.

You will not be able to immediately find out that the oil viscosity is not suitable for the vehicle.

The first “symptoms” will appear only after 100-150 thousand kilometers. And the main indicator will be an increase in the gaps between parts. However, it is definitely associated with increased viscosity and rapid decline even experienced specialists will not be able to maintain the engine life. It is for this reason that official auto repair shops often neglect the requirements of vehicle manufacturers. In addition, it is profitable for them to repair power units of cars that have already expired. warranty service. That is why choosing the degree of oil viscosity is a difficult task for every car enthusiast.

Viscosity too low: is it dangerous?

Engine oil

Destroy gasoline and diesel engines may have low viscosity. This fact is explained by the fact that at increased operating temperatures and loads on the motor, the fluidity of the enveloping film increases, as a result of which the already liquid protection simply “exposes” the parts. Result: increased friction force, increased fuel consumption, deformation of mechanisms. It is impossible to operate a car for a long time with a low-viscosity liquid filled in - it will jam almost immediately.

Some modern engine models require the use of so-called “energy-saving” oils with reduced viscosity. But they can only be used if there are special approvals from car manufacturers: ACEA A1, B1 and ACEA A5, B5.

Oil density stabilizers

Due to constant temperature overloads, the viscosity of the oil gradually begins to decrease. And special stabilizers can help restore it. They can be used in engines of any type whose wear has reached a medium or high level.

Stabilizers allow:

Stabilizers

- increase the viscosity of the protective film,

- reduce the amount of soot and deposits on engine cylinders,

- reduce emissions of harmful substances into the atmosphere,

- restore the protective oil layer,

- achieve “silence” in engine operation,

- prevent oxidation processes inside the motor housing.

The use of stabilizers allows not only to increase the period between oil changes, but also to restore the lost beneficial properties of the protective layer.

Types of special lubricants used in production

Spindle machine lubricant has low-viscosity properties. The use of such protection is rational on motors that have a light load and operate at high speeds. Most often, such a lubricant is used in textile production.

Turbine lubrication. Its main feature is to protect all working mechanisms from oxidation and premature wear. The optimal viscosity of turbine oil allows it to be used in turbocompressor drives, gas, steam and hydraulic turbines.

VMGZ or all-season hydraulic thickened oil. This liquid is ideal for equipment used in the regions of Siberia, the Far North and the Far East. This oil is intended for internal combustion engines equipped with hydraulic drives. VMGZ is not divided into summer and winter oils, because its use only implies low-temperature climates.

The raw materials for hydraulic oil are low-viscosity components containing mineral base. In order for the oil to reach the desired consistency, special additives are added to it.

Viscosity hydraulic oil presented in the table below.

OilRite is another lubricant used for the preservation and treatment of mechanisms. It has a waterproof graphite base and retains its properties in the temperature range from minus 20 degrees Celsius to plus 70 degrees Celsius.

conclusions

A clear answer to the question: “what is the best viscosity of motor oil?” no and cannot be. The thing is that the required degree of ductility for each mechanism - be it a weaving loom or a racing car engine - is different, and it cannot be determined “at random”. The required parameters of lubricating fluids are calculated by manufacturers empirically, so when choosing a fluid for your vehicle, you are primarily guided by the instructions of the developer. And after that, you can refer to the table of motor oil viscosity by temperature.

The introduction of exhaust gas recirculation has led to new requirements for motor oils.

Recirculation - feeding part of the exhaust gas back into the engine - has made it possible to reduce the content of nitrogen oxides in the exhaust gas. However, due to recirculation, the crankcase oil temperature increased, from an average of 120 to 130°C. Therefore, motor oil must have increased antioxidant properties. Otherwise, as nitrogen oxides decrease, soot emissions will increase. The solution was found in the form of ashless additives - based on nitrogen and manich bases. Their use made it possible to maintain the required amount of metal-containing additives without harm to exhaust gas cleaning systems.

Extremely important indicators of engine oil quality are its sulfate ash content and high-temperature shear viscosity. .

Sulfate ash content - this is an indicator that determines the amount of metal-containing additives in the oil. The more such additives, the higher the ash content. However, an excess, as well as an insufficient amount of additives, harms motor oil, as it becomes a source of additional low-temperature deposits on the engine: sludge, tar, coke. Today, in the production of motor oils, there is a clear trend toward decreasing sulfate ash content– below 1.5%. In the meantime, most modern cars use fuel with low content sulfur.

Ash content, as well as sulfur and phosphorus contained in exhaust gases (EG), severely damage the exhaust gas converter and clog the cells particulate filters. SAPS oils were developed to solve this problem. In this abbreviation, the letters indicate the limitation of sulfated ash (Sulphated Ash), phosphorus (Phosphorus) and sulfur (Sulfur) in the oil. The use of SAPS oils allows you to increase the service life of cleaning and neutralization systems up to 100 thousand kilometers. This is especially important due to the fact that a catalyst containing expensive metals (platinum, ruthenium, palladium) is not cheap.

As you know, the main wear and tear is on the cylinder-piston group and the crankshaft. The CPG accounts for 60% of wear, the crankshaft - 40%. That is why another fundamentally important indicator of oil quality is HTHS, or high-temperature shear viscosity. In an engine, this oil parameter is essentially similar to the operation of crankshaft bearings. HTHS is measured in millipascals per second.

Today there is a trend towards a decrease in shear viscosity from the usual value of 3.5 mP/sec. If the engine oil has a reduced HTHS, it can only be used in new engines prepared for this purpose. The use of oil with low HTHS in engines not intended for this purpose can lead to accelerated wear. This is explained simply. In engines adapted for oil with low HTHS, the distance between the rubbing surfaces is extremely reduced, the parts fit so tightly that the gap is minimal. If the contact pairs are of a traditional type (i.e., the gap is larger than necessary), the oil film breaks and metal-to-metal contact occurs. Currently, oils with reduced HTHS are used in a number of VW models, as well as in some BMW models and MB. This contributes to additional fuel savings. However, most modern models still use oils with a standard HTHS value.

In the modern world, environmental standards are becoming increasingly stringent, since cars account for up to 60% of all harmful emissions into the atmosphere. Car exhaust contains up to 200 chemical compounds, the most harmful of which are carbon monoxide, hydrocarbon compounds, sulfur, phosphorus and finally particulate matter, i.e. soot. Soot is produced mainly by heavy diesel engines. Formally, this is pure carbon, which, it would seem, is not dangerous for the environment. But when exhausting gases, it acts as an absorbent of harmful compounds: absorbing them, it accumulates carcinogens.

An important indicator of lubricating properties is the viscosity of the oil. It is determined by the chemical composition and structure of compounds in the lubricant. In fact, the degree to which the liquid lubricates the surfaces of the rubbing parts of the power unit depends on this characteristic. Its properties are influenced by external factors such as temperature, load and shear rate. That is why the test conditions are indicated next to the specific value.

What is kinematic and dynamic viscosity of oil?

In order to understand the difference, let's look at their characteristics.

The kinematic viscosity of a motor oil, whose units are mm2/s (cCT), shows its fluidity at normal and high temperatures. To measure this indicator, a glass viscometer is used. The time it takes for the lubricant to flow down the capillary at a given temperature is measured. In this case it is used low speed shear, and the kinematic viscosity of the oil is measured at 100 0C.

Dynamic viscosity is measured with a rotational viscometer, which simulates conditions as close as possible to real ones.

Methods that determine the viscosity of motor oil are predefined in the SAE J300 APR97 specification. Following this certification, all lubricating fluids are divided into 3 types:

- summer;

- winter;

- all-season.

If the name uses only numbers, for example, SAE 30, SAE 50, etc., then these liquids refer to summer motor lubricants. If a number and the letter W are used, for example, SAE 5W SAE 10W are winter lubricants. When 2 of these types are used in the class designation, such a liquid is called all-season.

Let's look below at what SAE oil viscosity means.

The SAE (Association of Automotive Engineers) classification divides all oils according to their ability to remain in a liquid state (to flow) and to lubricate all parts of the power unit well at different temperatures.

Above are temperature indicators, depending on the value that determines the viscosity of the engine oil. The table shows at what temperature indicators the fluidity of a particular liquid will not lose its lubricating properties.

Why do you need to consider oil viscosity when changing lubricant and what do the numbers mean?

A simple example for clarity. As is known, low viscosity of engine oil contributes to their normal operation in winter (SAE 0W, 5W). If the fluidity is low, the oil film covering the parts of the power unit will be thin. The manufacturer indicates in the technical manual the permissible values, as well as tolerances for each type of engine. If you fill in a lubricant with high fluidity, the motor will operate with a load at elevated temperature. This sharply reduces its service life.

And now it's the other way around. You are pouring liquid with fluidity below the designated level. In this case, during operation, breaks in the lubricant film occur, and the motor may jam. Oil viscosity depending on temperature. You don’t need to think that if you fill the engine with “super lubricant”, which is used on sports cars, your car will start to “fly”. You need to fill in the liquid recommended by the manufacturer.

Another misconception is that some car enthusiasts do not distinguish the type of lubricants from their fluidity. For example, the viscosity of synthetic oils can be the same as mineral or semi-synthetic ones. In this case, they differ in composition, not physical properties.

What oil viscosity to choose for your car engine.

First of all, you need to look at the technical manual. The manufacturer indicates in the manual what oil viscosity is best suited for the engine to ensure it long lasting performance. If it is not possible to look at the recommended oil viscosity, then it is important to determine several points:

- at what minimum and maximum temperature will your car be operated;

- will the load be used (trailer, additional load or off-road driving);

- what is the condition of the engine (new or used).

Following these indicators, you must select the viscosity of the automobile oil that will ideally lubricate the parts of the power unit.

A few words about other types of lubricants

Transmission fluids

Transmission fluids meet SAE J306 classification. The viscosity of transmission oil depends on the operating temperature conditions. Just like engine fluids, transmission fluids are conventionally divided into:

- winter (SAE 70W, 75W, 80W, 85W);

- summer (SAE 80, 85, 90, 140, 250);

- combined (for example, SAE 75W-85).

To understand what lubricant to use in your car’s gearbox, you need to look at the recommendations and approvals of the gearbox manufacturer.

Hydraulic lubricants

In addition to its main function - transmitting pressure, hydraulic fluids lubricate parts of hydraulic pumps. Based on this, they are divided into classes. Hydraulic oil viscosity can be low, medium or high. Below is a table showing the possible classes of hydraulic lubricating fluids.

The world of motor oils is filled with a variety of parameters responsible for different properties and qualities of lubricants. There are several classifications of motor oils alone, and each automotive market gives preference to its own classification. With the viscosity index, things are also not so simple. We have all long been accustomed to classifying oil viscosity according to SAE. This classification is quite easy to understand and any car owner can easily use it to select oil for summer and winter use or “all-season use”. But in last years A new “viscosity index” - HTHS - has come into use among auto mechanics. Since the controversy around this term does not subside to this day, we decided to dedicate this abbreviation new article on motor oils.

To begin with, HTHS is not a “viscosity index,” as it is often called. If we decipher the abbreviation and literally translate it into Russian, then HTHS is “high temperature viscosity at high speed shift." HTHS is measured in millipascals per second. The most common test method is ASTMD 4683. This method involves determining the viscosity of the oil at a high temperature (150 ° C) and a high shear rate of 106 s-1. Essentially, this indicator determines the thickness of the oil film over time - that is, at high oil temperatures and high shear rate.

All oils according to this parameter can be divided into two groups: full-viscosity and low-viscosity. The most common full-viscosity motor oils have an HTHS of 3.5 mPa/s and higher. For low-viscosity oils according to HTHS, this indicator is in the range of 2.6 to 3.5 mPa/s. The higher this indicator, the thicker the protective film on lubricated parts at engine operating temperature, and therefore the higher the engine protection. Consequently, full viscosity oils provide much better engine protection than oils with low HTHS viscosity. Why did oil manufacturers and, most surprisingly, engine manufacturers create oils with a thinner protective film at high oil temperatures? We will find the answer in the European environmental requirements of the EU countries and Japan. In recent years, Japan and the European Union have very strictly regulated the level of harmful emissions into the atmosphere. The fight is to cut every fraction of a percent in government annual reports. Naturally, the most stringent requirements are imposed on motor transport, as the main air pollutant. And often these requirements conflict with consumer expectations. The same happened with motor oils. The use of low-viscosity oils leads to a significant reduction in engine friction, which leads to a reduction in fuel consumption and harmful CO2 emissions into the atmosphere. It is no coincidence that these oils are also called “energy-saving”. Although fuel savings have not been very noticeable, the number of engines designed to use low HTHS motor oils has increased dramatically over the past few years.

Lower HTHS viscosity ensures energy-saving properties of the oil, which reduces fuel consumption and, as a result, reduces the level of emissions of harmful substances into the atmosphere. Strict requirements of environmental standards for engines, which legislators insist on Western countries, is the main motivator for automakers to reduce the HTHS viscosity of modern motor oils. This is what explains such a rapid increase in sales of oils of this type and a further trend towards a decrease in HTHS viscosity. For example, from April 1, 2013, the Association of Automotive Engineers SAE introduced a new summer viscosity class 16, which corresponds to an HTHS viscosity of 2.3 mPa*C.

It is worth noting that engine manufacturers do not insist that engines designed for low HTHS viscosity oils must only be filled with such oil. The choice remains with the consumer and the service company that services the cars. In most modern engines, regular full-viscosity oil can be used if it meets all other vehicle manufacturer specifications or ACEA specifications.

“In general, this is purely technical parameter, which is not familiar even to many car mechanics, not to mention end consumers,- speaks Georgy Gorshkov, Technical Specialist Sibindustritekhmash company (official distributor of Shell lubricants). - But it just so happens in our country that there is a certain category of car owners who are accustomed to independently delving into all the features of not only servicing, but also car repairs, which is why this parameter has recently been given a certain importance on the Russian Internet in various forums. People argue about how important it is and what HTHS index an oil should have for a particular engine model.”

Low HTHS oils. Good or bad?

Of course, it is impossible to answer this question unambiguously. Even if we do not take into account the environmental and resource-saving properties of such oils, which are an absolute benefit for the environment, oils with low HTHS have many advantages. Oils of this type can reduce fuel costs. Savings, according to various sources, range from 3 to 5%, however, this figure greatly depends on driving style. There is also a slight increase in engine power (“throttle response”), as energy consumption for friction is reduced.

But unfortunately, there is also back side. This type of oil protects the engine less well. Skeptics argue that the use of such oil is not always justified, and the small fuel savings and reduction in harmful emissions due to the use of such oils in no way compensate for the increased risk of premature engine wear that low HTHS oils carry.

“Using low HTHS oils is a double-edged sword. On the one hand, the performance characteristics of the engine are increased: efficiency, throttle response. On the other hand, there is a certain risk that in an emergency the engine will not be sufficiently protected from friction. Using oil with high HTHS, you deprive the car owner of fuel economy, but increase the reliability of engine protection, comments Georgy Gorshkov.“But what you definitely cannot do is use low-viscosity HTHS oil in an engine that is not designed for this.”

The fact is that in engines designed to use oils with low HTHS, there are a number of significant differences:

The gaps between the rubbing surfaces have been reduced, and higher precision has been applied to the assembly and fitting of engine parts to each other.

High flow oil pumps are used to provide the required pressure when using thinner oil.

Wide surface bearings are used, in which oil high viscosity arrives more slowly.

A special micro-profile (micro-analogue of honing) is applied to the surfaces of the rubbing parts, which holds low-viscosity oil on the walls for as long as possible.

Naturally, if the engine does not have such “preparation”, you cannot use low-viscosity oil on it. This will lead to very rapid wear. In 1997, research Toyota center A study was conducted of the effect of HTHS viscosity on the wear of parts of the cylinder-piston group when operating in different temperature conditions. Oils were tested for Toyota engine 1.6 DOHC. The study showed that when using oils with HTHS below 2.4 mPa*C and at an oil temperature of 90 o C, piston wheel wear increases only if the engine speed exceeds 5000 rpm. But at an oil temperature of 130 o C there is a sharp increase in wear piston rings occurs when using oil with HTHS from 2.6 mPa*C, starting from 2000 rpm, while oils with HTHS viscosity from 3 mPa*C and above continue to protect the rings even at such high temperatures.

Such oils are most dangerous for engines that already have some wear. The fact is that abrasive particles (soot, dust, etc.), which, as a rule, are present in a not new engine, can cause the thin oil film created by oil of this class to break, and unprotected friction, local overheating is formed, which then leads to very rapid failure of parts. Too large gaps and suboptimal operating conditions fuel system, engine operation at low speeds and in warm-up mode leads to fuel entering the oil, reducing the already low viscosity and worsening its lubricating properties. Subsequently, the fuel evaporates from the oil, but its original characteristics are no longer restored.

In the Russian market, according to Georgy Gorshkov, the share of oils with low HTHS viscosity is still quite small. This is related to both general condition car park, and with the fact that environmental requirements in our country are not yet as stringent as in Europe.

From energy-saving oils The most popular in Russia today is the SAE summer class with HTHS viscosity of 2.9 mPa*C. A small market share is occupied by oils with SAE class 20 and HTHS viscosity of 2.6 mPa*C. Sales volumes of such oils are small, this is due to the characteristics of the market. At the moment, the share of such engines on the Russian market is not so high.

It is worth noting that in Europe not all automakers are ready to take risks. For example, if we look at the fairly recent specifications of leading European automakers - BMW LL-04, MB 229.51, VW 504 00/507 00, Renault 0710/0720, we will make sure that they insist on using oils whose HTHS viscosity is not less than 3.5 mPa/s.

How are the SAE and HTHS classifications of oils related?

HTHS viscosity is directly related to SAE viscosity grades, since this type of viscosity determines the stability of the oil at high temperatures and is one of the parameters for determining the summer viscosity grade according to the SAE J300 standard for motor oils.

For example, if the HTHS viscosity is 2.6 mPa*C, then this motor oil will correspond to the SAE Xw20 class. And if the HTHS viscosity is 3.7 mPa*C, then this motor oil will already belong to the SAE Xw50 class. In both cases winter viscosity grade can be any.

Future prospects

Despite existing concerns from automakers, SAE is now committed to continuing to reduce HTHS further. Already announced summer classes viscosities: 12, 8 and 4 with even lower HTHS viscosities to achieve maximum energy efficiency, but only when requested by car manufacturers. But such requests have not yet been received.

The main fleet of vehicles requiring low HTHS viscosity are hybrids, the engines of which are two combined power plants: ICE working in tandem with an electric motor. If this market segment shows significant sales dynamics, then soon we may witness the appearance on the market of oils whose HTHS viscosity has been reduced to 2.0 mPa*C. But at the moment the market does not have such a need.