A load plug is a device that is necessary to check and determine the degree of charge of each battery can. It is a powerful load resistor with a voltmeter direct current, as well as two probes. For many car enthusiasts, a load fork for testing batteries is an excellent assistant when servicing batteries. However, this device is quite expensive in stores. Therefore, we will provide instructions on how to make a load fork with your own hands.

The first thing you need to find out is what voltage one fully charged cell of a particular battery should have. This is indicated in the user manual. You should also make sure that the battery has access to individual banks.

Now a microammeter is taken and connected in series with the resistor. Its resistance should be slightly greater than the voltage of one cell in the battery. Now we change the scale of the device to a new one, which must now be calibrated by applying a varying DC voltage in the required polarity to the resulting voltmeter. The voltage supplied during calibration must be monitored with a reference device.

Next, from the instructions for the battery, you need to find out the nominal or maximum current loads. Now we translate all the indicators of quantities into the SI system, our result will be obtained in the same system. Next, we calculate the resistance of the load resistor in this way: R=U/I - where R is the resistance in Ohms, the value of U will be the voltage in units of Volts and finally I will be the current strength in Amperes. In this formula it is necessary to substitute the voltage value of one bank, and not the entire battery.

After this, we calculate the power that is released on the resistor using the formula P = UI. Here P is the power in Watts, U will be the voltage in units of Volts and finally I will be the current strength in Amperes. Choose a load resistor rating greater than that available from the standard range. The resistor must be a wirewound resistor.

Now we take probes that will be able to withstand the current flowing through the resistor. We connect them to it using wires that can also withstand the specified current. Be sure to solder the connections well.

At this stage, the load fork is not yet ready. We connect a voltmeter (microammeter with a small resistor connected in series) in parallel with the load. Now you need to mark the polarity on the probes, similar to the polarity of the switched on voltmeter. Next, you need to isolate the connection points.

After all this, we fix all the parts on a fireproof, dielectric, rigid frame, which will be equipped with a handle. It is necessary to arrange the probes so that there is a distance between them equal to the distance between the can terminals.

The load plug must not be connected to the battery being charged. Also, do not do this near other charging batteries. If the process has stopped recently, it is necessary to ventilate the room well. Now the load fork is connected to each bank in turn.

Drivers who independently maintain their car are often interested in how to make a battery load fork with their own hands. It should be said right away that to perform such work you need to have at least a little experience working with electrical equipment. Today no one will argue that this device plays important role in the proper maintenance and operation of the car battery. From proper care This device largely depends on its service life on the car.

How to make a battery load plug with your own hands, all interested car enthusiasts will find out, and then decide what to do, make it yourself or purchase a finished product in retail chains. In any case, such a device will be a useful acquisition for your garage and car. If you have a certain supply of radio components, know how to hold a soldering iron in your hands and want to have such a device at your disposal, then read the article to the end and get down to business.

For what purposes is this device used?

It is simply impossible to carry out a complete and high-quality check of the working condition of the battery without this device. The load plug is used to determine the degree of charge of the battery without a load, as well as with a load corresponding to the battery being tested. Such checks are not done very often, since when checking under load, a significant amount of current is consumed, which can affect the condition of the battery.

The industry produces such plugs with a set of different loads in order to be able to test batteries different containers, but at self-production load fork It is enough to select it in accordance with the battery being tested. Passenger cars do not have a very wide range of battery parameters, so such a device will be useful even after replacing the car with another model.

A few words about its use

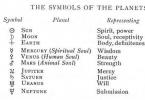

The load fork usually consists of several elements, these can be the following parts:

- Handle for holding it;

- Voltmeter for measuring the voltage of the battery being tested;

- Probes for connecting to the terminals of the battery being tested;

- Additional resistance.

There are simple rules for its correct use:

- The battery should be checked without load after it has been left “settled” for at least 6 hours;

- First of all, you should connect the positive terminal and only then the negative terminal. During such a connection, sparking is possible, so the battery plugs must be closed;

- To carry out a full load test, you need to connect an additional resistance. The measurement is carried out for approximately 5 seconds, after which you need to compare the obtained data with the recommendations in the battery operating instructions.

About the manufacturing stages

First of all, you need to prepare necessary materials. The main element of any load fork is measuring device, in this particular case, it will be a voltmeter. It’s good if you find or manage to purchase one with a scale of up to about 20 Volts, which is most convenient for taking measurements, otherwise you’ll have to calibrate it yourself.

When making a new scale, you will have to carefully disassemble the voltmeter. To determine the voltage, you need an additional tester or multimeter, which will be used to monitor the currents passing through a calibrated device. To do this, additional resistances are connected in series with it and measurements are taken. After plotting the readings on the new scale, it is carefully placed in the voltmeter.

From the battery characteristics, you should select the current and voltage parameters under load. This is necessary to determine the parameters of the additional resistance. They can be determined using formulas.

To determine the resistance, it will be R=U/I, where R is the resistance of the additional resistor, U will be the voltage, and I will be the current under load. After this, the dissipated power of this resistance is determined using the formula P=UI. The resistance power should be taken slightly higher than that obtained after calculations. The resistance must be wire.

Instructions

Find out what the voltage should be on a fully charged single cell battery from its owner's manual. Also make sure the battery is designed to allow access to the individual banks.

Take a micrometer. Connect a resistor in series with it of such resistance that at a voltage slightly higher than the limit for one can. Replace the instrument scale with a new one. Calibrate it by applying a changing voltage to the resulting voltmeter constant pressure in the correct polarity. Monitor the voltage supplied during calibration using a reference voltmeter.

Find out from the battery instructions the value of the rated (not maximum!) load current. Convert all quantities to the SI system, and the result will be in the SI system. Calculate the resistance of the load resistor using the formula R=U/I, where R is resistance, Ohm, U is voltage, V, I is current, A. Be careful: substitute the voltage of one bank, not the entire battery, into the formula.

Calculate the power allocated to the resistor using the formula: P = UI, where P is power, W, U is voltage, V, I is current, A. Select the rated power of the load resistor greater than that allocated from the standard range. It must be wire.

Get test leads that can withstand the current flowing through the load resistor. Connect them to the resistor with wires that can also withstand this current. Solder the connections well.

Connect a voltmeter, consisting of a microammeter and a small resistor connected in series with it, in parallel with the load. On the probes, indicate the polarity corresponding to the polarity of the voltmeter. After this, insulate the connections.

Secure all parts to a rigid dielectric and fireproof frame equipped with a handle. Position the probes so that the distance between them is equal to the distance between the terminals of the can.

Be sure to check that the battery is in this moment is not charging, and also that other batteries are not charging next to it. If the battery under test or adjacent batteries has recently finished charging, ventilate the room to ensure there is no hydrogen in the air before using the load plug.

Connect the load plug to the banks one at a time, observing polarity. Keep it connected to the jar for a few seconds, make sure that the readings do not change during this time. You cannot keep the plug connected for longer. Read the readings immediately before disconnecting the device from the jar.

In this article we will not talk about those forks that are used to eat, but about those with which you can knit beautiful things. These are knitting forks. They resemble the shape of the English letter U and are made of metal or plastic. The distance from one end of the fork to the other is not fixed and can be 20-100 mm. The width of the braid knitted with a fork depends on this.

Instructions

Knitting forks are sold in special stores; there are universal models that allow you to adjust the distance between the ends of the fork. But you can make such an item yourself and immediately try it in practice.

For this we need a regular knitting needle, its number depends on what products you are going to knit. Using wire cutters we remove one of the sharp ends of our knitting needle blank. We treat the “biting off” area with sandpaper to avoid injury and to prevent the thread from catching. We bend the workpiece in the shape of the letter U. You just need to position the ends of our fork strictly parallel. The quality of knitting directly depends on this.

You can also make a collapsible knitting fork. To do this, we are already preparing two knitting needles, identical. In addition to the knitting needles, we will need: small bolts with nuts, a piece of brass or tin, a drill, sandpaper.

We cut out a strip of metal (the width of the strip is 1.5 - 2 cm), and process the sharp edges. After this, we bend the resulting workpiece three times.

We drill holes for the bolts that will be secured in the spoke coupling. We insert the spokes into the bends of the spoke holder and secure them with bolts and nuts. WITH reverse side You can use an eraser instead of a holder. To do this, you will need to cut it into 2 equal parts lengthwise and insert knitting needles into it. Knitting needles can be regular knitting needles or from a sock knitting kit. Our fork is ready.

When knitting using a fork, you can use the following types of yarn: cordone - for finishing linen, alsation - for decorating furniture with fringe, double-folded wool yarn for shawls. And in order for the knitting quality to be high, you need the quality of the thread. It should be well twisted.

Table etiquette rules clearly describe how to properly hold a fork, spoon and knife. It's one thing to eat at home, where you are hidden from prying eyes. But it’s a completely different matter when you are visiting or at a social reception. If you don't handle your cutlery correctly, it can become your enemy instead of helping you.

Instructions

When you sit down at the table, you should pay attention to its setting. All cutlery and utensils ideally stand in their place and each play their role, which will help you avoid getting confused while eating. Correct and skillful use of serving items involves their use according to direct purpose. Remember that all cutlery, be it knives or forks, should be located to the right of the plate. Take them and hold them with your right hand while eating. Accordingly, the utensils located to the left of the plate are taken with the left hand. If dessert utensils are on the table with handles to the right, they should be taken with the right hand, and those with handles to the left should be taken with the left.

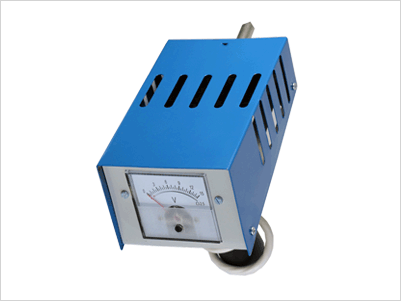

This is a device designed to test a car battery. The simplest version includes a voltmeter and a load resistance; a more complex version also includes an ammeter and the ability to carry out all kinds of measurements not only of the battery, but of the entire electrical circuit car. The most common option is this one.

Metal housing on the handle with a built-in voltmeter and one or more load coils. A thick wire on one side is connected to the “+” of the voltmeter, and on the other side there is a clamp that allows the load plug to be connected to the battery terminal.

The negative electrode of the voltmeter is connected to a metal pin located on the back of the case.

![]()

How to use a load fork and how to test a battery with a load fork? Checking the battery with a load fork is carried out in two stages. First, you need to measure the voltage at the battery terminals without connecting load resistors. To perform this operation, you need to wait 6-7 hours after you have turned off the car or after the battery has stopped receiving charging current from charger. Take the device without connecting the coils and connect the positive clamp to the positive terminal of the battery. Then touch the negative terminal of the battery with the negative pin located on the metal body of the device and monitor the readings of the voltmeter. So, the first stage is completed. Disconnect the device. If you find out that your battery is 100% charged, you can safely move on to the second stage - measurements under load. Now you must connect the necessary load and perform the same manipulations as in the first stage. The only difference is that you only need to hold the device for five seconds and take measurements at the fifth second. We warn you that the moment the pin touches the negative terminal of the battery, a working battery will “spark” a little, do not be alarmed, because the whole point is that you connected to it a load comparable to starting current engine.

Attention! When taking measurements, do not touch the load fork pin with your hands, as it can get very hot. Pause for 3-5 minutes. Check that the battery plugs must be tightened during all operations.

If at the second stage of measurements, the voltmeter value is more than 9.0 Volts, then your battery is in excellent condition. If it is below 9.0 Volts, you need to service and charge the battery, and take a control measurement. If this does not help, then the news is disappointing - the battery will have to be replaced.

Be careful: frequent testing of the battery with a load fork will cause harm general condition your battery, because it creates a load on the battery.

Nowadays there are various types of load forks, but we advise you to purchase

WHAT IS A LOAD FORK?

The load fork is a necessary device for any auto electrician, but the average driver, for the most part, does not even know about the existence of such a mechanism, which significantly reduces his capabilities when self-repair car.

The process of diagnosing a car battery using a load fork is quite simple. We must pay tribute to the manufacturers of such devices, because modern models have a number of different amenities: they are compact (some units can even be called pocket-sized), easy to operate and, finally, durable! As an example of how a load fork works, we use the creation domestic producers called "VIN-100". The specialization of the device includes such functions as assessing the overall performance of the battery, as well as monitoring the open circuit voltage of the battery at the exit points under load.

So, the load fork is a small device, the device of which includes the following elements:

- Load resistor - despite the small design of the load fork in its body, a resistor of exceptionally high power is installed.

- A voltmeter is also located in the device’s system, thanks to its presence it will be possible to test not only the battery, but also the entire on-board network(starter, generator, etc.).

- Ammeter - present in more expensive copies.

- Clamps built into the design are located on the back wall of the device and serve to connect it to the battery.

- Electrodes - there are two of them in the design, each of which allows measurements to be taken under two types of load.

- The negative cable is attached to a similar terminal on the battery using an alligator clip.

- Resistance coils - one copy is designed for a current of 100 Amps.

Clamps will help connect the device to the battery. The negative wire is connected to one of them, the one located on the voltmeter side, and the other end of the wire is connected to the battery. The electrode, which in most models is integrated into the body of the device, must be in contact with the positive terminal in different modes, thanks to which the parameters we need can be seen on the voltmeter.

There are a huge number of types of load fork, however, the device diagram does not differentiate them much. However, to check the alkaline car battery or, say, acidic, you will need two devices with different functions. After all, be that as it may, all testers measure different voltage, and also differ in rated load. In addition, with the help of some load fork models it will be possible to diagnose not only the entire battery, but also its individual elements. This is very useful feature, which is useful for identifying a closed jar.

HOW TO USE THE LOADING FORK?

Having figured out how to connect a small but very useful device for testing the battery, before starting the test, consider some necessary conditions.

The main requirement stated in the instructions is absolutely cold engine during diagnosis. More specifically, downtime vehicle should be at least 6-7 hours. The ideal option is to check after overnight parking. The electrolyte level should also be normal in each jar. All battery plugs in mandatory twist.

If you have a regular a car With a standard 12-volt battery, using one resistance coil is sufficient to test it. When the battery capacity is larger than standard, for example, models that supply power to freight car or productive traction batteries, then the second resistance is also activated.

By and large, knowing how to use a conventional charger, there should be no problems with the load plug - the same crocodiles, the same voltmeter, but a completely different specialization.

Testing the battery with a load fork is carried out in two ways: with and without a load.

Checking the battery without load. Using this test, we will determine whether the battery requires recharging or not.

Diagnostics are carried out with the engine turned off. First, experts advise turning on the headlights for a few minutes, then wait another minute and you can proceed directly to the test.

At the beginning of the procedure, it is necessary to thoroughly clean the battery terminals from oxidation and connect the load plug to the battery, strictly observing the correct polarity. The negative cable is connected to a similar terminal on the battery, and by connecting the electrodes to the positive terminal of the battery, the voltage will be measured. We simply press the electrode (the right one, to which the cable is screwed) to the terminal and look at the voltmeter readings:

- 5-11.8 W - the battery is faulty or completely discharged.

- 8-12.1 W - accumulator battery discharged by 25%.

- 1-12.3 W - by 50%.

- 3-12.6 W - up to fully charged 25% is missing.

- 6-13 W - battery is 100% charged.

By following these simple steps, you can easily set the charge level of your battery.

Checking the battery with a load. This is also carried out with the engine off, but with the load resistance. The process is not much different from the previous one, the only nuance is that contact with the positive terminal must be made with the left electrode for 5-10 seconds, after which you can watch the voltmeter readings. Be responsible when counting the time, as the load plug may well fail and keep in mind that the contact pin heats up and touching the battery terminal can cause sparking. The voltmeter will show you the following readings:

- 8 V and below - complete discharge or battery malfunction.

- 4 V - 25% charge.

- 9 V - battery is half charged.

- 6 V - 75% charges.

- 2 V and above - a fully charged, serviceable battery.

It is better to carry out repeated diagnostics only then (5-6 minutes) when the contact pin has cooled down and you should not abuse this method, because The battery is under high load.

If the diagnostics showed a complete discharge of the battery or a malfunction, follow the procedures for checking and restoring the electrolyte density, perform a full charge using a charger (ACU) and only after re-check and receive confirmation that the battery is unsuitable, make a decision to replace it.

When taking measurements, it happens that the percentage of battery charge under load is lower than without it. In this case, drivers say “the battery can’t hold the load.” Such a battery is clearly refurbishable and suitable for use.

HOW TO MAKE A LOAD FORK?

Currently various types There are a huge variety of “load fork” type testers and there are no problems purchasing these devices. For those who like to do everything with their own hands, this video will be useful: