What to do when the “thrust” suddenly drops in the car or it starts to consume gasoline at a too high rate? An experienced technician will tell you that the problem is in the lambda probe and it needs to be repaired or replaced. Owners of foreign cars are especially susceptible to this problem. And the truth is - what to do in such a situation? After all, you yourself understand that nowadays auto parts are not cheap. Is it possible to prevent the breakage of the lambda probe, what are the signs of a malfunction of the lambda probe, and what is it like? Let's take everything in order.

What does a lambda probe look like?

Simply put, a lambda probe, also known as an O2 sensor, is a sensor that estimates the amount of unburned fuel and oxygen in a car's exhaust system. Although lambda probes are also used in other areas, in this article we will talk exclusively about automotive oxygen sensors.

What is this oxygen sensor for? The so-called catalysts that reduce the proportion of harmful substances in the exhaust are currently in every more or less modern car. The lambda probe monitors the amount of oxygen in the catalysts, thus prolonging their life. It also significantly affects the amount of fuel consumed by your car and improves engine performance.

If you mention specific facts, then it is known that fuel burns efficiently only with the correct ratio of fuel and air in the fuel mixture. Otherwise (if there is less or more air) the catalysts will wear out and become unusable. Therefore, the lambda probe directly affects the vehicle's exhaust system.

Defective lambda probe: causes and symptoms

The main reasons that cause the lambda probe to malfunction are as follows:

- Overheat;

- Mechanical damage;

- Connection problems;

- Wear.

As you can see, all these reasons do not immediately affect the oxygen sensor, which is why inexperienced drivers may not understand the reason for the unstable behavior of the car and will not take appropriate measures in time. Therefore, in order to avoid common mistakes, we will tell you about several stages of an oxygen sensor failure.

- First stage. At the initial stage, the lambda probe starts to "junk" - from time to time the signal ceases to arrive, the data goes in a very wide range, which significantly deteriorates the quality of the fuel mixture and the idle speed deteriorates. At this stage of the lambda probe malfunction, the car jerks violently, the engine emits strange pops and a warning light on the panel comes on.

- Second phase. At the second stage, when the engine is cold, the sensor stops working altogether. In this case, the same, but even more pronounced signs of malfunction will be visible. Added to this is a significant drop in engine power and a slower accelerator pedal action. In one of the worst cases, the engine will overheat very much, which will lead to more significant malfunctions and, accordingly, costs.

- Stage three. The third stage is usually a breakdown of the lambda probe. In this case, you will find an even greater decrease in the car's power (this will be especially noticeable when driving at high speed), as well as a sharp and unpleasant toxic smell from the exhaust pipe.

How to check a lambda probe

If you notice the symptoms of a malfunction of the lambda probe described above, then you need to check it immediately. It is best to check the lambda probe on professional equipment. Often the check is carried out using an electronic oscilloscope. The process itself takes place when the engine is running, since otherwise, the data cannot be received. Many service stations will be able to provide you with such a relatively inexpensive service.

Although you can check the sensor with a voltmeter at home, if the sensor is not warmed up, then you may receive incorrect data.

Video about malfunctions and checking the lambda probe

It leads to increased fuel consumption, a decrease in the dynamic characteristics of the car, unstable operation of the engine at idle speed, an increase in the toxicity of exhaust gases. Usually, the reasons for the malfunction of the oxygen concentration sensor are its mechanical damage, a break in the electrical (signal) circuit, contamination of the sensitive part of the sensor with fuel combustion products. In some cases, for example, when a p0130 or p0141 error occurs, the check engine warning light is activated on the dashboard. It is possible to use the car with a faulty oxygen sensor, but this will lead to the above problems.

Purpose of the oxygen sensor

An oxygen sensor is installed in the exhaust manifold (the specific location and quantity may differ for different cars), and monitors the presence of oxygen in the exhaust gases. In the automotive industry, the Greek letter "lambda" stands for the excess oxygen ratio in the air-fuel mixture. It is for this reason that an oxygen sensor is often referred to as a "lambda probe".

The information provided by the sensor about the amount of oxygen in the exhaust gas by the electronic engine control unit (ECU) is used to adjust the fuel injection. If there is a lot of oxygen in the exhaust gases, it means that the air-fuel mixture supplied to the cylinders is poor (the voltage at the sensor is 0.1 ... 0.3 Volts), and if there is a lot of oxygen, it means that it is rich (the voltage at the sensor is 0.6 ... 0.9 Volta). Accordingly, the amount of supplied fuel is corrected as needed. This affects not only the dynamic characteristics of the engine, but also the operation of the catalytic converter of exhaust gases.

In most cases, the range of effective operation of the catalyst is 14.6 ... 14.8 fractions of air per one fraction of fuel. This corresponds to a lambda value of one. Thus, the oxygen sensor is a kind of controller located in the exhaust manifold.

Some vehicles are designed to use two oxygen concentration sensors. One is located before the catalyst, and the second is located after. The task of the first is to correct the composition of the air-fuel mixture, and the second is to check the efficiency of the catalyst. The sensors themselves are usually identical in design.

Does the lambda probe affect the launch - what will happen?

If you turn off the lambda probe, there will be an increase in fuel consumption, an increase in toxicity of gases, and sometimes unstable engine idling. However, this effect occurs only after warming up, since the oxygen sensor begins to work under conditions of an increased temperature up to + 300 ° C. For this, its design implies the use of a special heating, which turns on when the engine is started. Accordingly, immediately at the moment of starting the engine, the lambda probe does not work, and in no way affects the start itself.

When the protective cap has been completely dismantled, then argon welding will have to be used to restore it in its seat.

The recovery procedure is performed according to the following algorithm:

- Pour 100 ml of phosphoric acid into a glass container.

- Immerse the ceramic element of the sensor in acid. Do not completely immerse the sensor in acid! Then wait about 20 minutes for the acid to dissolve the soot.

- Remove the sensor and rinse it under running water from the tap, and then let it dry.

Sometimes it takes up to eight hours to clean the sensor using this method, because if the soot is not cleaned the first time, it makes sense to repeat the procedure two or more times, and you can use a brush to perform mechanical surface treatment. You can use a toothbrush instead of a brush.

Method two

Assumes formation of carbon deposits on the sensor. To clean the oxygen sensor with the second method, in addition to the same orthophosphoric acid, you will also need a gas burner (as an option, use a home gas stove). The cleaning algorithm is as follows:

- Dip the sensitive ceramic element of the oxygen sensor in acid, wetting it abundantly.

- Take the sensor with pliers from the side opposite to the element and bring it to the burning burner.

- The acid on the sensitive element will boil, and a greenish salt will form on its surface. However, along with this, the soot will be removed from it.

Repeat the described procedure several times until the sensing element becomes clean and shiny.

Most cars manufactured from the late 70s - early 80s are equipped with catalytic converters of exhaust gases (in common parlance -), which can significantly reduce the toxicity of waste materials, reducing the damage to the environment. An interesting enough fact is that the catalyst can maintain functionality only under conditions of ideal mixture formation, in which 1 part of the fuel accounts for 14.6 to 14.8 parts of atmospheric air with a normal oxygen content. So that the mixture does not turn out to be over-enriched or over-depleted, it is necessary to use electronic control of the fuel supply - in such a system, the quality of the combustible composition is controlled by a lambda probe. Despite its location in a hostile environment, this device is quite fragile and unstable, and prone to frequent. If the lambda probe stops working in your car, the symptoms of a malfunction can be detected without specialized equipment - it is impossible to continue operating the vehicle.

Mechanism of action

The lambda probe determines the chemical composition by looking for oxygen in them and determining the percentage. In the normal state of the mixture, this indicator is 0.1–0.3% - small fluctuations are allowed due to the fact that the mode of fuel supply to the engine cannot be stable for a significant period of time. The lambda probe is installed directly into the exhaust manifold - usually its installation is carried out at the junction of the pipes extending from various cylinders (in common parlance - "pants"), although there are other options.

There are various modifications of lambda probes - as well as vehicles of previous years of production, the device has a two-channel layout. They can only detect the presence of a deviation of the oxygen content in the positive or negative direction, which is accompanied by a change in the voltage of the electrical signal transmitted to the electronic unit. However, all modern cars of the middle and elite classes are already equipped with broadband lambda probes, which are already designed to determine the percentage deviation of the content of the desired element from the norm. Thanks to this, a significant improvement in the characteristics of the motor is achieved:

- The stability of the retention of revolutions is increased;

- Reduced fuel costs;

- The resource of the vehicle increases.

If you are interested in the electrical side of the lambda probe, then it is worth mentioning that this device cannot generate a uniform signal. Due to the fact that the standard lambda probe is located in the exhaust manifold, several operating cycles may already have passed when the exhaust gas reaches the point of its location. In this case, the quality of mixture formation deteriorates by 3-5%, which is accompanied by some destabilization of the motor. The lambda probe reacts to this by changing the voltage supplied to the central injection control unit, which takes the necessary measures.

Determine the breakdown

External signs

In the event of a malfunction of the lambda probe, a significant deterioration in the quality of the fuel mixture occurs, which outwardly manifests itself in a deterioration in engine performance. It is worth saying that there can be many - among them the following main ones can be distinguished:

- Depressurization of the sensor housing, penetration of atmospheric air and exhaust gases;

- Overheating of the lambda probe as a result of inept engine tuning;

- Failure as a result of prolonged exposure to an aggressive environment (aging);

- Blocking the working surface of the lambda probe by combustion products of low-quality fuel;

- Disruption of normal power supply and interruption of the line leading to the control unit;

- Severe impact on the lambda probe housing, destroying internal components, for example, when actively driving on bad roads.

In all cases, except for mechanical damage accompanied by depressurization, lambda probe malfunctions appear gradually, with a stepwise deterioration. Another exception is a broken wiring - however, it cannot be considered a malfunction of the lambda probe itself, so it should be considered in a separate topic for discussion. For all the rest, the following stages of the development of faults can be distinguished.

Video on how to check a lambda probe:

At first, the device ceases to normally perform its functions in the extreme operating modes of the engine, when its electrical characteristics have already deteriorated so much that the sensor cannot form. A malfunction of the lambda probe manifests itself in the destabilization of the idle speed, which begins to "float" in a fairly wide range, the length of which is 300-600 rpm. When reaching very high revs, which do not belong to the critical level, a sharp change in the quality of the fuel mixture can occur. At the same time, the car can twitch violently, in some cases jerky pops are heard from under the hood, and a control lamp flashes, signaling abnormal engine operation. With a decrease in speed, all signs of a breakdown of the lambda probe disappear, but they cannot be ignored.

At the second stage, the device stops working on a cold engine - until the temperature reaches the maximum possible, the car will show all signs of a malfunction of the intake system or gas distribution mechanism. In particular, you will notice a significant decrease in power, extremely slow reactions to changes in the position of the gas pedal, as well as jerks and pops. In the event of a malfunction of the lambda probe, the car can jerk, slow down sharply as a result of a complete stop of the fuel supply, as well. After about 5-10 minutes of driving in such an unpleasant mode, a visible stabilization of the vehicle condition occurs - however, it is extremely temporary.

If you do not take any measures regarding the malfunctions of the lambda probe at the previous stage, the device will finally fail, which will cause many negative consequences. In addition to a significant deterioration in dynamics and the impossibility of normal driving in continuous mode, you will encounter an increase in fuel consumption by 15-30%, as well as a significant increase in exhaust toxicity, which can be determined by a clearly noticeable shade of fuel. Modern cars can generally block all driver actions in the event of a faulty lambda probe by switching to emergency mode.

Worst case

If the above-mentioned depressurization of the lambda probe occurs, it is impossible to continue operating the car, since this can become a prerequisite for a complete failure of the engine with subsequent expensive repairs. In this phenomenon, the exhaust gases enter the duct, which is used to draw in atmospheric reference air in order to compare the two types of gases and determine the optimal oxygen content. If engine braking occurs, atmospheric air with a minimum amount of impurities passes through - therefore, the lambda probe sees that there is much more oxygen in the manifold than in the environment! The result of this is the formation of powerful negative signals that completely disrupt the normal operation of the injection control unit.

Electronic diagnostics

If you want to know what signs of a malfunction of a lambda probe can be detected during a professional inspection, you should find specialized equipment. When examining the lambda probe, an electronic oscilloscope is used - some experts recommend using a multimeter, but it can only state the fact that the device has failed. The device is checked on a running engine, heated to a circuit temperature of 80-90 degrees. In a cold state, the sensor can give readings that significantly deviate from the norm.

There can be many signs of a device malfunction. They are represented by flat signal characteristics or an increase in the level not exceeding 0.1 V. In addition, it is worth paying attention to the shape of the curve - the changes should be quite steep, not allowing a smooth increase in voltage. Experts say that the lambda probe must change the signal level every 120 ms, otherwise it is possible to talk about its malfunction.

Car repair

Almost all manufacturers of vehicles and individual components for them claim that the lambda probe cannot be repaired - only a complete replacement of the unit is required. That being said, its cost can be quite impressive - especially if you own a luxury car. A common way out of this situation is to purchase a universal sensor equipped with a special adapter for a specific type of vehicle. These devices are made by Bosch - using its services, you can even purchase used remanufactured parts, which are distinguished by a reduced cost and limited duration. In addition, you can buy a used exhaust manifold with a pre-installed lambda probe.

If you are absolutely sure that the lambda probe is not functioning correctly as a result of the deposition of combustion products on it, you can try it. To do this, the device is dismantled at a surface temperature of 40-50 degrees, the protective cap is removed from it and the contacts are immersed in orthophosphoric acid. After several washes, the lambda probe is washed with clean water, dried thoroughly and installed in place, not forgetting to lubricate the threads with a special sealing paste. The tightening torque is set by the manufacturer - usually it varies between 40-60 Nm. A similar procedure helps in 80% of the described faults.

The main thing is timely diagnosis

If you find out in time that the car malfunction lies precisely in the breakdown of the standard lambda probe, then you can carry out the necessary repairs even before the consequences touch the engine, leading to its significant breakdown. In addition, by eliminating such a problem, you can keep the most important characteristics of the vehicle at the same level, which will help you to use it as fully and profitably as possible. Which troubleshooting method to choose is up to you, but it is worth remembering that working with car electronics without the appropriate qualifications is very dangerous.

Many car enthusiasts have faced the problem of increased fuel consumption. This can be due to many engine problems: faulty sensor and idle drive, ignition problems, decreased compression, high pressure pump malfunction.

But, if the fuel consumption has increased significantly (up to 50%), you should immediately check the oxygen sensors, in automotive practice they are often called "lambda probe".

What is a lambda probe in a car

The lambda probe informs the engine control unit about the amount of oxygen that has not entered the ignition reaction in the working cylinders of the engine. For complete combustion of oxygen, the mixture must be formed in a ratio of one to fifteen (more precisely 1: 14.7).

The engine control unit monitors the formation of the mixture (eliminates the causes of the formation of a rich or a lean mixture) based on the readings of the sensors, including the oxygen (lambda probe).

Video - faulty oxygen sensor:

The name "lambda probe" was taken from the qualitative characteristics of the excess air ratio in the air-fuel mixture, denoted in the automotive industry by the letter of the Greek alphabet "lambda".

Oxygen sensor malfunction symptoms

The main symptoms of an oxygen sensor malfunction include:

- significantly increased fuel consumption;

- uneven engine operation, especially when the accelerator pedal is pressed;

- increased emission of toxic waste from the engine;

- malfunction of the catalyst.

The principle of operation of a lambda probe and common reasons for its failure

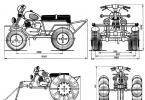

The most common reason for the failure of lambda probes is wear. Typical probe design is shown in the figure:

The weakest points of the design are the ceramic tip and the electric heater. A burnout of an electric heater does not completely damage the sensor.

The lambda probe is installed in the exhaust manifold in front of the catalyst, and as the manifold heats up with the exhaust gases of the engine, the oxygen sensor itself heats up to a high temperature.

The electric heater is mainly used to correct the readings of the oxygen sensor in the first few minutes after starting a cold engine.

There are one- and two-wire sensors in which there is no electric heater at all.

The ceramic tip is made of special porous ceramics, on which thin zirconium dioxide is applied, the electrodes are made of platinum using vacuum deposition technology (which is why lambda probes are expensive).

During operation, exhaust gases of a very high temperature pass through the micropores of the sensor. A thin layer of dioxide burns out over time, oxidizes, and its electrical properties change.

As a result of this, the readings of the lambda probe become unreliable, in fact, it becomes unusable. In this case, all kinds of flushing, cleaning, and other methods of restoring performance are pointless.

Structurally, the principle of operation of a lambda probe can be depicted:

In the diagram: 1 - zirconium dioxide, 2,3 - electrodes (sometimes platinum), 4 - negative ground, 5 - output signal contact. The zirconium oxide probe acquires the properties of a solid electrolyte at temperatures between 300 and 400 degrees Celsius (which is why the probe is preheated). Then the lambda probe begins to register the voltage in accordance with the oxygen concentration.

As can be seen from the graph, the dependence has a pronounced jump-like characteristic, which is very beneficial when processing signals by digital methods.

The following factors can accelerate the premature failure of the lambda probe:

- ingress of impurities into the exhaust system (antifreeze in case of cylinder head gasket violations, residual ether when using “quick start” sprays when starting the car, oil with reduced engine compression, etc.);

- high concentration of lead in fuel;

- cleaning the exhaust system with means not intended for these purposes;

- getting into the exhaust manifold of dust, impurities not removed by the fuel cleaning filter.

Many vehicles are equipped with two lambda probes, before and after the catalytic converter. This allows you to more accurately control the quality of the mixture, as well as check the effectiveness of the catalyst.

How to check a lambda probe with a multimeter and in other ways

It is easier to start checking the performance of the four-outlet lambda probes installed on most modern cars by monitoring the performance of the heating element.

To do this, switch the multimeter to the resistance measurement mode and "ring out" the leads of the electric heater. They are usually made of larger wire. The resistance should be less than 10 ohms. If the resistance is greater, this indicates a malfunction of the electrical heater.

After 10,000 km the vehicle has been driven, it is advisable to visually check the probe. For this, the sensor must be removed from the manifold.

Many people use WD sprays or, even worse, brake fluid. The ingress of these liquids into the working area of the lambda probe can lead to its malfunction.

Even if special tools are used to loosen the coked threaded connection, they should be removed immediately before removing the sensor.

In the working area of the sensor, pay attention to its color and condition. The presence of soot (a sign of a rich mixture) leads to contamination of the sensor, for better performance, the soot must be removed.

White or gray deposits are evidence of the presence of additives in the oil or fuel, they can also lead to a malfunction of the lambda probe. A shiny coating is a sign of excess lead concentration in fuel. In case of intense plaque, the sensor must be replaced.

Contact leads of the most common zirconium oxygen sensors (b, c - lambda probe with a heater; a - without; * the colors of the leads may differ from those indicated):

In order to check the lambda probe using a multimeter, it is necessary to connect its probes to the signal wires, switch to a measurement limit of 2 Volts. Further, artificially create situations of an enriched mixture, for example, by gas re-gasings, or by removing the pressure regulator connector. In this case, the readings of the multimeter must be more than 0.8 Volts, then the probe is serviceable.

Then a lean mixture situation is created (you can artificially create air leakage by slightly unscrewing the air duct clamp). The multimeter reading should be less than or equal to 0.2 Volts.

Video - how to check a lambda probe with a tester:

Allows you to see the parameters of the lambda probe in real time. This can also be done with a conventional oscilloscope. The time dependence of the voltage at the signal output of a working lambda probe will have an approximate form:

If the lower limit drops to 0 Volts, the sensor is pretty "tired", if the curve is smoother, the sensor must be replaced without fail.

Replacing the oxygen sensor

The mechanical difficulty of replacing a lambda probe is unscrewing a coked threaded connection. Here you may have to use special equipment. After removing the faulty sensor, carefully wipe the sensor installation site from any residual liquids.

Video - replacing the lambda probe on the Audi A4 B5:

The original lambda probe is usually expensive (up to 6,000 rubles, sometimes more). For some car models, the original sensor cannot be found, it makes no sense to buy from disassembly. In this case, it is better to install a universal lambda probe.

Universal lambda probe

The installation dimensions of the probes (thread, embedment depth) are usually the same, it is better, of course, to check so as not to damage the threaded connection or the new probe.

Universal lambda probes are sold without a connector, only with wires (usually four-wire, two signal and two for the heating element). Next, cut off the connector with wires from the old faulty native sensor and make a high-quality connection with the universal sensor in full accordance with the electrical connection diagram.

The electrical connection is best done by twisting + soldering + heat shrink insulation. Since the typical characteristics of all lambda probes made using the same technology are almost identical, the universal probes work correctly on engines of all modifications.

Video - installing a connector on a universal lambda probe:

When installing the sensor, pay attention to the tightness of the connection with the manifold, the safety of the thread.

Cleaning

Cleaning the lambda probe is a last resort. It is performed only in the case when there is confidence that the sensor accurately shows incorrect data and the last hope before sending it to the trash can is cleaning.

First things first, in case of failure and malfunctions several tangible consequences appear in the behavior of the car:

- Unstable operation of the car engine (jerking)

- The operation of the catalyst is disrupted (toxicity increases)

Then, to check the lambda probe, you can first unscrew and carry out a visual check (just as it can tell a lot).

Several types of lambdas are installed on cars, sensors can be with one, 2, 3, 4 even five wires, but it is worth remembering that in any of the options one of them is a signal (often black), and the rest are intended for heater (they are usually white).

How and how you can check the lambda

To check, you will need a digital voltmeter (preferably an analog voltmeter, since it has a much shorter "sampling" time than a digital one) and an oscilloscope, if possible, measurements will be more accurate. Before checking, you should warm up the car since the lambda works correctly at temperatures over 300C °.

First, we are looking for a heating wire:

We start the engine, do not disconnect the lambda connector. We connect the minus probe of the voltmeter (a regular shop) to the car body. With the positive probe of the chain we "poke" on each contact of the wire and observe the reading of the voltmeter. When the positive wire of the heater is found, the voltmeter should show constant 12 V. Next, with the negative probe of the voltmeter, we try to find the negative wire of the heater. We turn on the remaining contacts of the sensor connector. If a negative contact is detected, again the voltmeter will show 12 V. The remaining wire, signal wires.

Checking the lambda probe with a tester

We take an electronic DC voltage millivoltmeter and connect it in parallel with the LZ ("+" "-" to the LZ, - to the ground), and the lambda probe must be connected to the controller.

When the engine warms up (5-10 minutes) then you need to look at the voltmeter needle. It should periodically go between 0.2 and 0.8 V (i.e. 200 and 800 mV, moreover, if less than 8 cycles occur in 10 seconds - it's time to change the LZ. Also, to replace if the voltage "stands" at 0 , 45 B.

When the voltage is 0.2 or 0.9 V all the time - something is wrong with the injection - the mixture is too lean or too rich. Since the voltage of the oxygen sensor must change all the time and jump from ≈0.2 to 0.9V.

There is another quick way to check the lambda probe... It should be done like this:

Gently pierce the positive contact of the tester (black lambda wire), the other contact to ground. With the motor running, the readings should fluctuate from 0.1 to 0.9V. Constant readings (for example, all the time 0.2) or readings outside this range, or fluctuations with a lower amplitude indicate a probe malfunction.

Exceptions:

- all the time 0.1 - little oxygen

- all the time 0.9 - a lot of oxygen

- The probe is OK, the problem is something else.

If you have time and desire to pozamorachivatsya, you can conduct several tests for a rich and poor mixture and additionally.

- Disconnect the oxygen sensor from the shoe and connect it to a digital voltmeter. Start the car, and, pressing the gas pedal, increase the engine speed up to 2500 rpm. Using the device for enriching the fuel mixture, set the speed reduction to 200 per minute.

- Provided your vehicle is equipped with an electronically controlled fuel system, remove the vacuum pipe from the fuel pressure regulator. Look at the voltmeter reading. If the arrow of the device approaches 0.9 V, it means that the lambda probe is in working order. This is evidenced by the lack of response of the voltmeter, and its readings are within the limits of less than 0.8 V.

- Do a lean mixture test. To do this, take a vacuum tube and provoke an air leak. If the oxygen sensor is good, the digital voltmeter reading will be 0.2 V or less.

- Check the operation of the lambda probe in dynamics. To do this, connect the sensor to the fuel supply system connector and install a voltmeter parallel to it. Increase engine speed to 1500 rpm. The voltmeter readings with a working sensor should be at a level of 0.5 V. Another value indicates a failure of the lambda probe.

Checking the voltage in the heating circuit

A voltmeter is needed to check the presence of voltage in the circuit. We turn on the ignition and connect it with the probes to the heater wires (you cannot disconnect the connector, it is better to pierce it with sharp needles). Their voltage should be equal to that of the battery when the engine is not running (about 12V).

If there is no plus, you need to go through the battery-fuse-sensor circuit, since it always goes directly, but the minus comes from the ECU, so if there is no minus, we look at the circuit to the block.

Checking the lambda probe heater

In addition to measuring the voltage with a multimeter, you can also measure the resistances to check the health of the heater (two white wires), but you will need to switch the tester to Ohms. In the documentation for a specific sensor, the nominal resistance is necessarily indicated (usually it is about 2-10 ohms), your task is only to check it and draw a conclusion. The video shows this method:

Oxygen sensor reference voltage test

We switch the tester to the voltmeter mode, then turn on the ignition and measure the voltage between the signal and ground wire. In most cases, the reference voltage of the lambda probe should be 0.45V.