Все знают, что амортизатор смягчает удары при проезде неровностей. На самом деле, роль его в автомобильной подвеске несколько более специфическая – это демпфер, он предотвращает раскачивание автомобиля при наезде на препятствия. Сегодня изучим его типичну

Новые статьи

Биение руля при торможении, как устранить своими руками

Многие автовладельцы систематически сталкиваются с ситуацией, при которой в процессе торможения начинает вибрировать руль. Бесконтрольное и интенсивное вибрирование либо биение рулевой колонки в момент, когда автомобилист этого не ждет — ощущение довольно

Почему заливает свечи и что с этим делать?

Стартер крутит, а авто не заводится, многие автомобилисты начинают искать проблему в аккумуляторе. Но иногда не в нём дело. В зимний или осенний период, когда воздух влажный или холодный, пуск машины с утра может стать настоящей проблемой. Оказывается, чт

Каковы причины — авто не заводится, но стартер крутит

Автовладельцы нередко жалуются на то, что стартер крутит, но не заводится, или же стартер крутит плохо или не крутит совсем, и что из этого хуже – даже выяснить невозможно. Особенно распространена подобная ситуация зимой, когда на улице во всю властвует м

Заливает свечи зажигания: как завести двигатель

Большое количество автолюбителей в процессе эксплуатации транспортного средства периодически сталкиваются с трудностями запуска силового агрегата. При этом достаточно часто явные предпосылки в виде отчетливо проявляющихся неисправностей отсутствуют. Нео

Как очистить салон автомобиля от загрязнений своими руками?

26 августа 2016 Согласитесь, это очень приятно – сесть в салон автомобиля и ощутить неповторимые запахи, которые бывают только в совершенно новеньких авто. К сожалению, со временем от этих запахов не остается и следа, а еще совсем недавно новая обивка

Устройство рулевой рейки

Рулевая рейка - это силовой узел системы рулевого управления, благодаря которому водителю транспортного средства легче вращать рулевое колесо. Схема рулевой рейки: рис. 1 - без гидроусилителя (механическая); рис. 2 - с гидравлическим усилителем (с ГУР);

Почему плохо переключаются передачи

Когда плохо переключаются передачи, вождение авто становится не только неприятным, но и небезопасным. Рассмотрим основные причины того, почему плохо переключаются передачи или совсем не переключаются. А так как коробка автомат и мкпп слишком сильно различ

Популярные

Как перетянуть автомобильный руль кожей своими руками

Рулевое колесо - элемент машины, с которым водитель контактирует чаще всего. Это приводит к износу покрытия руля и появлению потёртостей, которые не только портят внешний вид, но и делают вождение менее комфортабельным и удобным. Для того чтобы восстано

Ремонт сидений автомобиля своими руками

А знаете ли вы, дорогой читатель, что сидений автомобиля сегодня очень высокая. Чтобы ремонтники в автосервисе взялись заменить сиденья вашего автомобиля, они прежде выставят вам предварительный счёт, который вряд ли вам понравится. Что же делать, если си

Как самому перетянуть руль кожей

Ни один уважающий себя автовладелец не станет терпеть в своем авто облезлые чехлы на сидениях или потрепанный руль! Однако не стоит забывать, что, в отличие от тех же чехлов, рулевое колесо - это не столько деталь интерьера салона, сколько важный элемен

Как завести авто без стартера

Пожалуй каждый автолюбитель сталкивался с ситуацией, когда его авто не желал заводиться из-за поломки стартера. и как правило по закону "подлости" эта поломка происходит как раз в самый неподходящий момент, когда нужно срочно куда-то ехать. В этом случае

Причина плохого переключения передач / О горном велосипеде

Велосипеды для начинающих оборудованы самой дешевой трансмиссией, а передачи на них слабо переключаются и заедают. Владельцы в этих случаях ничего не могут поделать, поскольку осознают, что управляют дешевым мусором. Но через определенное время столкнувши

Регулировка привода сцепления, как отрегулировать свободный ход педали сцепления

При эксплуатации автомобиля в результате износа элементов может возникнуть большой свободный ход педали сцепления, причиной чего, как правило, является стирание фрикционных накладок диска либо нарушение регулировок рычагов кожуха. Самостоятельно устранить

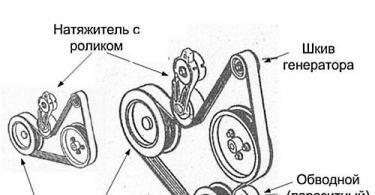

Замена ролика натяжителя ремня генератора

Чтобы чувствовать себя за рулем гораздо более уверенным, необходимо не только иметь представление о строении автомобиля, но и уметь, при необходимости, совершать определенные манипуляции с его составляющими, например, поменять колесо, и так далее.Замена р

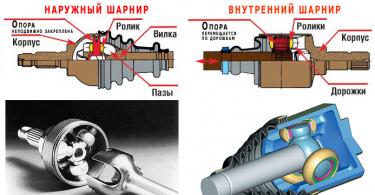

Шарнир равных угловых скоростей (ШРУС) - устройство и принцип работы

Переход от заднего к переднему приводу потребовал от автопроизводителей разработки новых технических решений, которые бы позволили эффективно передавать вращение на колёса даже при максимальном угле поворота. Традиционный карданный вал, применявшийся на а