If you want to know everything about the work of your car, it is worth starting with learning open space. Perhaps you will find a lot of new things for yourself, because modern cars It is not necessary to work as vehicle worked a dozen years ago. Classic knots and vehicles of cars have become complex, productive and economical. Complex design pursues two goals at once. The first is to create a real economy of all units, minimal consumption of fuel and electricity. The second is to teach car owners from independent repair And attempts with their own hands to change the aggregate failed. IN modern machines without skills I. professional instrument It looks unreal.

Starter is one of the elements of the electrical equipment of gasoline or diesel cars. On electric motors, such a device is not used, since the start of the electric motor does not need additional promotion. To start the OBS, you need to apply the torque of another device. Then fuel begins to flow into the combustion chambers and continues to twist the main shaft of the unit without the help of electricity. The principle of the starter is extremely simple, but in the current technologies there are many interesting differences. Today we will consider the action of the starter under the hood of modern cars.

How does a classic starter in gasoline or diesel engines work?

A classic device for starting the engine is an electric motor with a constant current. This unit works from the car battery, because manufacturers do not stop to invent possible schemes Reduced electricity consumption. The classic starter works simple enough. It is connected to the power unit through the gear system. A small gear at the starter itself connects to a large engine gear that runs the unit operation system. The starter works as follows:

- when moving the ignition key to the extreme position, the starter turns on and starts to twist the power unit;

- the gear gear ratio is equal from 1:10 to 1:20, which allows to obtain the desired speed of rotation;

- after launch power aggregate The retractor is triggered, the starter gear moves away from the engine gear;

- when the power unit is unhappy, the starter is again connected to the engine for the future of the car launch;

- classic starters are equipped with retracting relays, which determines the point of separation of gears;

- the speed of rotation of the starter is crucial, most of the engines can only be launched when this condition is met.

If the starter does not match the desired engine parameters, the car cannot be launched without harm for the design of the unit. Therefore, when replacing the starter, it is recommended to use an exceptionally model that is intended for the engine of your car. Using the correct rotation frequency, it will be possible to avoid various problems, including increased wear Engine. If the unit needs overhaulAnd the starter will be installed with inappropriate parameters, the engine can jam.

Major problems of the classic starter

Standard equipment for starting the engine is quite simple and securely, but the electric motor is also susceptible. certain breakdowns. Given the Spartan conditions for using this peripheral device, you can imagine how often too high-quality starters have to be repaired. Too frequent breakdowns Also may mean the availability of problems with the engine or electrical connection. For example, if the powered gear of the power unit rotates with a large force, the starting device will be too long load. The most common problems are the following versions of equipment breakdown:

- failure of the winding, literally combustion of the starter from constant excessive loads;

- crash associated with incorrect work permanent magnetswhich is treated only by replacing the device;

- incorrect operation of the retractor relay or other device responsible for disconnecting the starter from the engine;

- gear wear on the main starter mechanism, which leads to a torque slippage;

- the failure of electrical connections is one of the cheapest problems in the sense of the cost of repair;

- deformation of the starter case from impact or breaking the device from attachments with accidents and departures to high obstacles.

In any of these cases it will be necessary quality repairs and recovery. In most situations, problems with the starter are solved quite simply - the usual replacement. In some cases, you can partially change the starter devices. For example, the retracting relay is much smaller than the entire assembly unit. In the case of its breakdown, you can save and replace the relay only, without changing the entire starter assembly. You can also change the gear that is responsible for the engine launch. In other cases, when the breakdown is associated with winding or magnets, a full replacement of the starter occurs.

Performance of repair work - independently or professionals

The complex starter design practically eliminates the possibility of repairing the device. Therefore, all repair work is to replace Bendix and retracting relays. You can change these two elements yourself, but in the case of the gearbox, you will have to pretty try. This process requires disassembly of equipment that in the absence of skills to work with electric motors can very easily lead to the impossibility of subsequent assembly. Therefore, it is better to trust this task to professionals and do not try to make everything with your own hands. The process of dismantling and base repair starter is as follows:

- you must disable the starter from the electrical connection for subsequent disassembly;

- next, you should unscrew the fastening bolts that different models There may be different shapes and quantities;

- then the starter is removed from the laid place and the detailed study of the body for damage;

- next, the replacement of the necessary parts should be replaced and, if necessary, disassembling the case to study the nature of the problems;

- the starter assembly may take a certain time, because the mechanism inside is quite complex;

- after assembly, check the starter, connecting it to the battery before installation on the car;

- the next step is to set the starter to the former place and check its work under normal conditions.

Often, by changing the elements failed, you can restore the starter operation. But the diagnosis of equipment at home is not always available. Therefore, most car owners prefer to access specialists to obtain the necessary conditions for the equipment. it optimal solutionSince a specialist will diagnose and identify a problem without your participation. You do not have to disassemble the equipment, search qualitative spare partsand also independently perform the repair process. Experts will provide you with all required services Repair equipment and allow you to enjoy high-quality and impeccable work of the electrical equipment of your car. We offer to look at the starter work scheme in a short video:

Let's sum up

Starter is a fairly complex device among peripheral equipment in the car. This mechanism is responsible for the high-quality start of the engine if necessary. Often the breakdown of the device is associated with electrical part Equipment work. However, often the breakdown is associated with the global failure of the winding or magnets. In this case, it will be necessary to simply change the equipment to the new one. If you want to operate a car without problems and fears for possible absence Starting the engine, it is worth thinking about constant tracking of the starter's work and perform all the tasks of repair and maintenance.

It is also worth remembering that in some situations only professional services will help get the necessary working conditions. In most cases, use qualitative services Car workshops will help prevent problems with the starter, because the diagnosis shows all the problems in the state of the embryos. They manage to eliminate even before you start feeling negative consequences. Despite the complexity of the design, all necessary maintenance and repair processes will be easily in the professional workshop. Did you ever have problems with the starter?

As you know, to start the car engine you need to turn several times crankshaft. In the first cars they were engaged in hand. But now all cars are equipped with starters that allow you to rotate the shaft without any effort. The driver only needs to insert the key into the lock and turn it into third position. Next, the motor will be launched without any problems. What is this element, what is the purpose and principle of the starter? We will talk about this in our current article.

Purpose

Due to the rotation of the crankshaft, the engine produces the energy necessary for the movement of the car. But the problem is that the motor cannot issue any energy in a fixed state.

From here there is a question about its launch. For this purpose, the starter was invented. The principle of work will consider it a little later. This element is able to promote the shaft using an electric motor and external source Nutrition. The battery is used as the latter. Depending on the model and type of car, the starter power may be different. But for the majority passenger cars There is enough 3-kilodate electric motor.

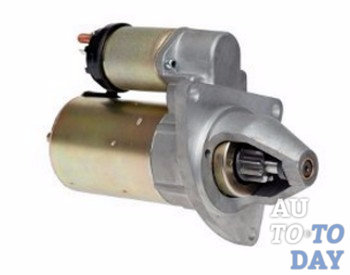

Device

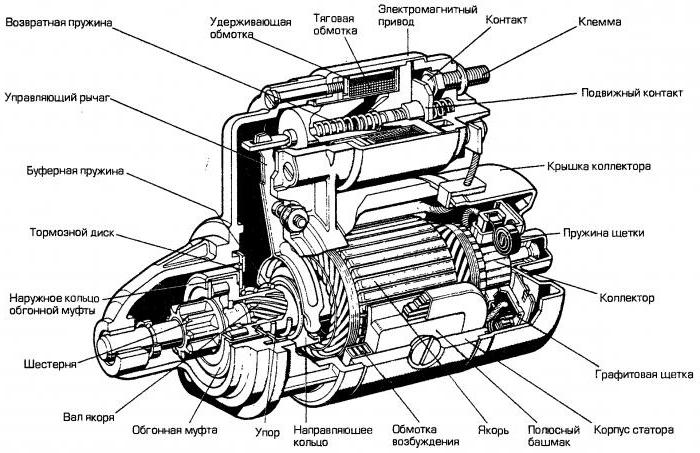

The design of this item includes several parts:

- Anchor starter. It is made from alloy steel. Collective plates, as well as the core, will be pressed on it.

- Retractor starter relay. The principle of work is extremely simple. The relay serves to supply power to the electric motor in case of turning the ignition key. Also, the relay pushes the overtook coupling. In the design of the element there is a movable jumper and power contacts.

- Overpona coupling (in commoner - "Bendix"). It is a roller mechanism that transfers through the gear of the engagement torque on the crown of the flywheel.

- Brushes. Serve to supply current on the plates of the anchor of the starter. Thanks to the brushes, power increases electric engine At the time of his engagement with the flywheel.

- Case. It is in it that all the above elements are combined. Typically, the housing has a cylindrical shape. Inside it is also the core and the excitation winding.

This design has all modern starters. Differences can only be minimal. So, on cars with automatic box The starter is equipped with holding windings. They serve so that the car does not start on the "Drive" and other modes except "neutral".

Types

Distinguish several types of mechanisms:

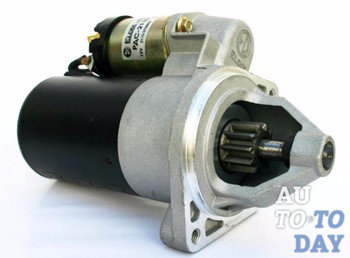

- With gearbox.

- Without him.

The principle of the latter type starter is direct contact with the rotating gear. The main plus of such a design is high maintainability and resistance to high loads.

But on most cars, an element with a gearbox is installed. The principle of operation of the starter of this type will be discussed below. Compared with its analog, the gearbox has more high efficiency, consumes less current, has small size and saves high performance features Throughout the period of work.

Principle of operation

Since this element runs from the battery, mandatory condition To start it is the presence of 12V voltage and higher. As a rule, when starting the starter, the voltage "sends" by 1-1,5V, which is very significant. In this regard, it is not recommended for a long time to twist the starter (more than five seconds), since you can easily discharge the battery. The principle of the car starter is pretty simple. At first, the driver places the key into the lock and turns it into the extreme position. So he will launch the ignition system. To start the starter, you need to check the key again. At this time, the contacts will be closed, and the voltage goes through the relay on the retracting winding. The relay itself can make a characteristic click. This suggests that contacts are closed.

Next, the anchor of the retractor element moves inside the housing, thereby putting forward the bendix and introducing it into engagement with the wedding of the flywheel. When anchor reaches the end point, the contacts are closed. The voltage enters the winding of the starter electric motor. All this leads to the rotation of the engine's flywheel. At the same time, the crankshaft of the motor rotates with it. The cylinders themselves begin to flow a combustible mixture, and candles light up. Thus, the motor is activated.

After the speed of rotation of the flywheel exceeded the rates of rotation of the starter shaft, Bendix comes out of the engagement. He, due to the return spring, is installed in initial position. Simultaneously with this, the key in the lock returns to its original position. The electricity supply is stopped at the starter.

Thus, the principle of operation of the starter (vase including) is aimed at short-term rotation of the flywheel, thanks to which it is produced launch of DVS. The element stops its work as soon as the motor has been successfully started.

What will happen if you do not turn off the starter on the engine running?

Often such problems are observed when the return spring has failed. If the starter continues to rotate with the flywheel, you will hear the characteristic loud grinding. It occurs because the rotational speed of the crown does not coincide with the one that the starter gear issues (the difference is 2 or more times). This may be happening and due to the broken ignition lock.

Note that such a process is very harmful to the gear and for the starter as a whole. Even short-term crunch can entail serious problems with an electric motor.

Requirements for the starter

This mechanism must comply with several requirements:

- Reliability. The absence of breakdowns in the next 60-80 thousand mileage kilometers) is implied.

- The ability to run in conditions low temperatures. Very often, the starter turns badly at a temperature of -20 and lower. But it is usually a cold electrolyte in the battery. To heat it, before launching it is recommended a couple of times to "frody" with distant light.

- The ability of the mechanism to a reusable launch for a short period of time.

Conclusion

So, we found out what is the starter, its principle of work. As you can see, this is an integral element of any modern car. If it fails, it will be possible to start the motor only "from the pusher" (and on machines with automatic transmission - and it is impossible at all). Therefore, you need to monitor its condition and do not ignore the breakdowns.

Before carrying out the repair of electrical equipment, it is necessary to know the design of all the most important components. Each driver must know the car starter device, as it is one of the most vulnerable structural elements. The starter is necessary in order to facilitate the start of the engine. internal combustion. Used both on gasoline and diesel engines.

But it is possible to start the engine with the help of muscle strength, an electric motor or an aggregate on pneumatics. In passenger cars, most often you can meet the start of the engine, carried out using an electric starter. The battery is used as a power source.

What are the starters?

Of the total mass of these mechanisms, two large groups can be distinguished: gear and illegal. How work happens as well internal organizationIt is clear from the very name. If there is no gearbox inside the electric motor, then such a starter can develop a small frequency of rotation. The presence of the planetary gearbox allows you to achieve greater speed Rotor. At the same time, the electric motor can be relatively small power, but it is enough for spinning crankshaft Motor.

But there is one big drawback in such mechanisms - the reliability is extremely low, can be very quickly to wear and fail. But do not think that the outer starters differ big resource. They also fail, and even possess one weighty disadvantage - with a weak battery charge, the crankshaft is not able to promote.

Basic components of the starter

In essence, a car starter device, a diagram of its connection to on-board networkThe same practically from any manufacturer. Regardless of which country is a car and for what standards. Different devices can only be an option for execution, product quality, but common design It will be the same type. Several main components can be distinguished:

- Rotor - moving part of the car starter. It has a winding on which an electric current is supplied.

- The stator is a fixed part. Some manufacturers of electric motors for savings are installed permanent magnets. But this is unreasonable, since the power of the electric motor is significantly reduced.

Usually such a design is used in without additional gears, the electric motor is not capable of developing the torque required for the rotation of the crankshaft. There are advantages in such mechanisms, and quite significant shortcomings. The main plus is that when starting the engine, the starter consumes a very small current. But the design of the node is much more complicated.

Bendix and overtaking coupling

These are two components that are mounted on the starter rotor. They are needed in order to transmit torque from the starter rotor to the flywheel rotor. And the gear, which is located on the overtook coupling, can only rotate in one direction. Therefore, when diagnosing this mechanism You just need to try scrolling the gear in both directions.

At the top of the starter case, a retractive relay is installed, which performs the function of power contact and allows you to move the overtook clutch with the gear along the rotor axis so that it goes into engaging with the flywheel's crown. The plug with which the gear moves is made of plastic or metal plates.

How does the starter work?

And now you need to talk about how the starter of the car leads the crankshaft. The device, the principle of operation of this mechanism is simple, but there are several nuances that affect normal functioning. When the key turns into the ignition lock, the voltage is supplied to the control contact of the retractor relay. At the same time, the pulling anchor moves, the gear of the Bendix is \u200b\u200bintroduced into engage with the flywheel.

Also, the retractor relay closes the power contacts and supplies the supply voltage to the winding of the electric motor. As soon as the key position changes, power will turn off from the control output traction relay. At the same time, the spring, which is inside the relay, will drop an anchor, and the power contacts will open. At the same time, the bendix will come out of the engagement with the flywheel.

Reliele retractor

To reduce consumption current, the relay is manufactured using a circuit in which two windings are applied. The first operates only in the initial moment of switching on, so that the core of the retractor relay completely squeezed the spring and closed the contacts.

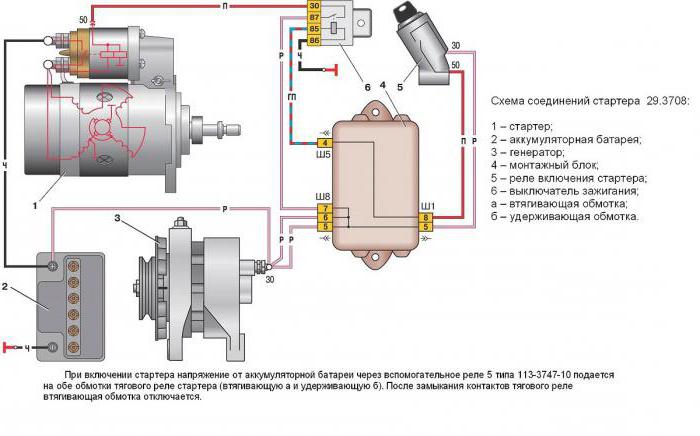

The second winding made from a thin wire is called retention. Its appointment is to keep the core in the squeezing position. Feature Schemes for connecting windings:

- Each coil has two outputs. One of them is connected to the control output of the retractor relay.

- On the holding coil, the second conclusion is connected with the mass.

Holding coil is connected to a mass and positive output. And the current through it passes, but only in the case when the key turns into the extreme position "start" in the ignition lock. On the retractor coil, the second contact is connected to the positive output of the car starter motor. The scheme and species are shown in the drawings.

When the voltage is applied to the retractor, passing through the coils of the stator and the rotor, connects to a minus power. At the same time, the current will cease to go through the pull-up coil. In this case, only the holding winding will work. With the help of these two windings, you can achieve very high effort For tightening the core, and also significantly reduce the current required for retention.

Bushes and brushes

These are two components that affect the normal functioning of the electric motor. Plus power is transmitted on the brushes, and in the bushings passes minus on the rotor winding. When disassembling the starter you need special attention to pay the state of these components.

If there is a loading of the sleeves, they must be replaced. With excessive wear of the brush node, the starter operation is undesirable. At the same time, you need to check the status of the lamellas on the rotor. If necessary, it should be cleaned of contamination. But before starting the work, carefully examine the car starter device to make repairs to the most effectively.

What is the starter and for what it is present in the car knows perhaps every boy. It is one of the main elements to launch an internal combustion engine, and any violations in its normal operation will make this process almost impossible. Despite the fact that the device of this node does not differ in difficulty and similar to most modern cars, few of the car owners will be able to independently dig a starter or carry out any repair work.

If within the city, all this can make a master from the nearest car service, then on a deserted track, and even in winter timeThe breakdown of this node can lead to sad consequences. Despite all this, few of the cadets of the driving school during their training pay due attention to the device of the car engine as a whole, and the starter in particular. If we talk about this vehicle node is quite simple, it is a powerful electric motor with a gear, by means of which the crankshaft is rotated at the time of rotation of the ignition key.

Starter device - just about complex

A small in size of the unit consists of a variety of details, among which are all a few main.

Most starters produced today are identical to each other. Of course, there are also small differences. For example, the principle of operation of this node installed on cars with automatic transmission may differ. Thus, there are necessarily holding windings, designed for the impossibility of a random motor start, when the gearbox selector occupies any running position. In addition, the mechanisms of automatic separation of the gear may differ.

Principle of the standard automotive starter

To understand how the starter works, the whole process can be divided into three main stages:

- the starter gear connection with the crankshaft flywheel;

- launch of the starter;

- separation of the flywheel of the crankshaft and the gear of the starter.

After a successful start of the car engine, the power supply to the electromotor stops, and in the future operation of the motor, it does not take part. If you submit it to work in more detail, it will look like this.

On this, the work of this node is stopped, and until the next launch of the motor in the car, it does not accept participation. Despite such a short-term work, the assignment of the starter for the car is difficult to overestimate, and any malfunctions will lead to the full inability to start the engine.

Other car starter designs

Despite the principal similarity of the main part of the starters, there is one significant difference in the design. On modern cars with diesel enginesas well as on motors high powerAs a rule, a rotary starter is mounted, or a device with a gearbox. It has a special planetary gearbox under the main building, which, due to its design, allows the voltage being passed through itself to be repeated and, accordingly, increase the torque. This is especially important for powerful motors. In addition, such a starter scheme has other advantages:

Justice for the sake of, it is worth noting that simple modifications have considerable advantages, which should include:

- an extremely simple design that allows you to repair any complexity with your own hands;

- the starter drive instantly clutches with the crankshaft drive, due to which the start of the motor is carried out almost instantly;

About how the starter works and how it works shown on the video:

Is it possible to extend the life starter

Regardless of its design, the car starter is a fairly expensive node, and his sudden failure inevitably entail unforeseen material expenses. Therefore, during the operation of the car's performance of this item, maximum attention should be paid to the maximum, except for the period of its trouble-free operation will also help compliance with the elementary rules:

To prevent a critical moment when the starter needs to be replaced either expensive and long-term repair in the service, you should pay attention to any changes in its usual work. A few signs can be attributed to the number of the most common precursors near the breakdown.

- The delay in the work that appears when the ignition key appears, which serves as a signal to be promptly checked by the retractor starter.

- In the warm season, at normal oil viscosity, the crankshaft rotation is noted - in this case Immediately checks the state of bearings or brushes of the device.

- Muffed out the starter gear out of engagement with the crown of the crankshaft, which is often the cause of such a phenomenon.

- When turning the ignition key, the sound is heard characteristic to start a motor, but the start itself does not occur.

- Upon confirmed intake of the power supply - its rotation is completely absent.

- After starting and started independent work The engine, the starter is not turned off, continuing the rotation and consumption of a huge amount of electricity.

Diagnostics - better to trust a professional

Any of the above faults itself is not critical, but if it does not fix it on time, it can lead to full exit Devices in order. Despite the fact that the place where the starter is located does not differ in difficult access, and its check is possible, with your own hands, it takes a certain experience. Moreover, if the starter is new or with a slight service life, it is much easier to give it to professional diagnostics.

It is held on a special bench, allowing to identify absolutely all violations in its normal work. With a lack of experience and knowledge, an independent damage of this node and its repair will end with the need to replace it, and when the device is reversed, the device's connection scheme can be broken. If excluded mechanical malfunctionswhich are associated with the wear of its main parts, the main faults and problems of the starter are the electrical part:

- break electrical chain;

- closure inside the device case;

- the combination of the mechanism itself in those places where the contact of the working elements and electric current Large tension.

Separately it is worth mentioning about wear brushes. When improper control and replacement of this consumable element, the device power drops sharply, and even with a fully charged battery, the motor start is quite difficult to implement.

Passage long way Of its formation and development, modern vehicles have a lot of improved systems and mechanisms, the details of which are presented are all large and greater requirements. Here, for example, a car starter ... Everyone knows his exceptional importance in terms of the full functioning of the car, therefore, it is often the subject of special concerns of the car owner, especially if he, the happy owner last model With the built-in automatic transmission (in case of failure of the starter, use the crowning handle to start the engine, as the owners of obsolete brands do no longer). Based on the special importance of the question, we counted we need to consider the types of starters, the device and the principles of their action, as well as possible malfunctions and ways to eliminate them.

Types and appointment of starter

The automotive starter is represented as a small quiet electric motor that ensures the initial rotation of the crankshaft. It is needed to maintain the necessary frequency of rotation, which the most directly affects the further launch of the engine. Often, start gasoline engine The average volume of cylinders requires the presence of a starter with approximately 3 kW of electricity. Starter can be called the motor direct currentwhich receives energy from battery battery.It took the tension with the help of four brushes (an integral part of any starter), significantly increases the power of the electric motor itself. All existing today electromagnetic engines This kind is divided into two main groups: having a gearbox and those that have no.

Many specialists advise to apply the starter with the gearbox, which is argued by its reduced current need. In other words, the devices of this species will be able to provide effective rotation of the crankshaft even with low charge rechargeable battery. Another advantage of using a starter with a gearbox is the presence of permanent magnets in its design, which significantly reduce the possibility of problems with the winding of the device. True, if you look at the other hand, the probability of breaking the rotating gear on the contrary increases. As a rule, this version of the development of events, most often, is found at factory marriage or in the case of low-quality production.

Many specialists advise to apply the starter with the gearbox, which is argued by its reduced current need. In other words, the devices of this species will be able to provide effective rotation of the crankshaft even with low charge rechargeable battery. Another advantage of using a starter with a gearbox is the presence of permanent magnets in its design, which significantly reduce the possibility of problems with the winding of the device. True, if you look at the other hand, the probability of breaking the rotating gear on the contrary increases. As a rule, this version of the development of events, most often, is found at factory marriage or in the case of low-quality production.

Starters without a gearbox, have a direct impact on the rotation of the gear. In this case, the owners vehicle With such a system, won due to the simplicity of the design of the device, thanks to which they are better amenable to repair actions. In addition, immediately after supplying the current to the electromagnetic switch, the gear is instantly connected to the flywheel, which ensures fairly fast ignition. Also, do not forget about the high endurance of such starters, especially since the probability of breakage due to the effect of electricity is practically reduced to zero. However, in the work of starters that do not have a gearbox, not everything is so flawless and there is a possibility of workers failures at low temperatures.

How is the starter?

In fact, the design of the starter is not particularly difficult, and the main components of the elements are the electric motor, anchor, a retracting relay, overtaking coupling (Bendix), brush holders.

Housing(The electric motor) is represented as a steel cylindrical detail. The excitation windings are attached to its inner wall (usually four) and cores (poles). The mount is carried out by means of a screw compound, in which the screw is screwed into the core, and the one, in turn, presses the winding to the wall. Also, in the case there are threaded technological holesWith the help of which the front part is carried out, where the overtaking coupling movement occurs.

Housing(The electric motor) is represented as a steel cylindrical detail. The excitation windings are attached to its inner wall (usually four) and cores (poles). The mount is carried out by means of a screw compound, in which the screw is screwed into the core, and the one, in turn, presses the winding to the wall. Also, in the case there are threaded technological holesWith the help of which the front part is carried out, where the overtaking coupling movement occurs.

Anchor - The part is made of doped steel and having a type of axis. The core and collector plates are pressed on it. In the design of the core there are special grooves intended for laying anchor windings, the ends of which are securely attached to the collector plates. Collective plates, in circular order, installed on a dielectric basis. The diameter of the core and the inner diameter of the case (along with the windings) is directly related to each other. The anchor attachment in the front and the back cover of the starter is performed using brass (less than copper) bushings that simultaneously perform the role of bearings.

Retractor (or traction) relay It is used to transfer power from the ignition lock to the starter electric motor, while performing another important task - pushing the overtaking coupling. In the rear of the housing of the retractor relay, power contacts are placed, referred to as "pyataks", as well as made of soft materials, movable jumper. "Pyataki" is ordinary bolts pressed in the ebonite lid of the traction relay. With the help of nuts, the power wires coming from the battery and the "plus" brushes of the starter are attached to them. The core of the traction relay and the overtaking coupling (better known as "Bendix") are connected to each other by means of a moving "rocker".

Retractor (or traction) relay It is used to transfer power from the ignition lock to the starter electric motor, while performing another important task - pushing the overtaking coupling. In the rear of the housing of the retractor relay, power contacts are placed, referred to as "pyataks", as well as made of soft materials, movable jumper. "Pyataki" is ordinary bolts pressed in the ebonite lid of the traction relay. With the help of nuts, the power wires coming from the battery and the "plus" brushes of the starter are attached to them. The core of the traction relay and the overtaking coupling (better known as "Bendix") are connected to each other by means of a moving "rocker".

Overtaking coupling(Bendix) is a moving roller mechanism fixed on the anchor shaft. One of its main tasks is the transfer of torque on the weden of the flywheel, using the special gear gear for these purposes. After the engine starts, it dismisses the weden of the flywheel and the drive gear, thereby providing stable operation and the safety of the starter. The entire design is assembled in such a way that when transmitting torque to Bendix in one direction, which are in the separator rollers, come out of the grooves and hard fix the gear to the outer clip. When is the rotation in opposite sideThe rollers are "hiding" into the separator and the gear can rotate regardless of the outer clip.

Brush holders and brushes Provide the operation of the operating voltage to the collector plates of the anchor. The brush holder is represented as a dielectric closure having metal inserts, with dotted welding, the contacts of the brushes are welded to pole plates, which, as a rule, are "tails" of excitation windings. By performing the main operating cycle of the starter, the belt holders increase the power of the electric motor.

Brush holders and brushes Provide the operation of the operating voltage to the collector plates of the anchor. The brush holder is represented as a dielectric closure having metal inserts, with dotted welding, the contacts of the brushes are welded to pole plates, which, as a rule, are "tails" of excitation windings. By performing the main operating cycle of the starter, the belt holders increase the power of the electric motor.

The designs of most starters are similar to each other and necessarily include all of the above components. If there are differences, they are insignificant and, most often, relate to the mechanism of automatic opening of the gear. Also, the starter of cars with automatic transmissionsIt has additional retention windings designed to prevent the motor startup in cases of selecting the selector to any of the running positions. Difference between various models Starters lies in their sizes, power and supplied voltage. So, for example, if for starter operation a passenger car enough nutrition from 12 in battery, then for a starter heavy trucks - This will not be enough and need to use 24 V.

Principle of operation of the starter

The entire working process of the automotive electric starter is conventionally divided into three stages: On the first - the drive gear is connected to the wedding of the flywheel; On the second - the starter is launched, and the third stage provides for the discharge of the drive gear and flywheel. The starter work is short-term, since after performing the main function (transmission of torque on the engine), it no longer participates in further motion car. Detailed principle The work of the starter looks like this: When the driver turns the key in the ignition lock to the start position, the current with the battery is transmitted to the ignition lock, and then on the traction relay.

The entire working process of the automotive electric starter is conventionally divided into three stages: On the first - the drive gear is connected to the wedding of the flywheel; On the second - the starter is launched, and the third stage provides for the discharge of the drive gear and flywheel. The starter work is short-term, since after performing the main function (transmission of torque on the engine), it no longer participates in further motion car. Detailed principle The work of the starter looks like this: When the driver turns the key in the ignition lock to the start position, the current with the battery is transmitted to the ignition lock, and then on the traction relay.

After that, the bendix drive gear (overtaking clutch) moves and is connected to the flywheel, which contributes to the circuit of the chain and the subsequent voltage supply to the electric motor. As a result of the described actions, it starts car Engine, And after its revolutions begin to exceed the speed of the starter itself, the overtaking clutch disconnects the drive gear from the electric motor shaft. All, before the next start of the power unit, the starter may not strain.

Possible starter faults

Like any other mechanism in the design of the car, the starter cannot work all the time. Of course, it turns out a much smaller load than, let's say, on the same internal combustion engine, however, it cannot be completely avoiding the breakdown. The reasons for each individual malfunction can be somewhat and what to understand in detail in the problem arising, without solid diagnostics can not do. We will talk about the repair of the starter a little later, but now let's consider all possible malfunctions of this important device.

Like any other mechanism in the design of the car, the starter cannot work all the time. Of course, it turns out a much smaller load than, let's say, on the same internal combustion engine, however, it cannot be completely avoiding the breakdown. The reasons for each individual malfunction can be somewhat and what to understand in detail in the problem arising, without solid diagnostics can not do. We will talk about the repair of the starter a little later, but now let's consider all possible malfunctions of this important device.

And so, for a start, the starter may simply do not turn on. The causes of this phenomenon can be:

- breakdown of the starter relay (opening, inclusion, contact disk offset);

Disturbance of the power supply chain (possibly due to the weak tightening of wires or internal corrosion); - short winding closure;

Lack of contact in the mechanism that is responsible for inclusion of ignition.

Also, the problem in the work is considered slow rotation The crankshaft, even if the starter started. The presence of this malfunction may be associated with increased viscosity oily oil that does not match the season; problems with the battery (its breakdown or discharge); The oxidation of the conclusions of the battery wires, weak tightening of the tips or violation of the brush contact.

Sometimes it happens that the anchor seems to be rotated, but for some reason it does not scroll through the crankshaft. In this case, the causes of the malfunction may be hidden in towing the coupling free travel Drive or in difficulty moving the drive by screw cutting shaft.

Another malfunction often found in the starter is a gear, which cannot be engaged. This happens as a result of the formation of treatment in the teeth of the wint of the flywheel, or, as a result of improper adjustment of the moment of closing the contacts of the switch and the drive gear. Also, one of the options possible causes There is a weakening of the buffer spring springs.

Another malfunction often found in the starter is a gear, which cannot be engaged. This happens as a result of the formation of treatment in the teeth of the wint of the flywheel, or, as a result of improper adjustment of the moment of closing the contacts of the switch and the drive gear. Also, one of the options possible causes There is a weakening of the buffer spring springs.

Of course, the lack of starter launch is a problem, but the malfunction is also considered to be too long work when the engine has already started, and the starter still continues to rotate. In this case, it can be assumed to have a problem in the ignition lock (instead of); Closing the winding of the relay or in the drive of the drive placed on the shaft of the anchor. In addition, there is some kind of malfunction and the impact contacts of the traction relay.

If during the starter process, you noticed elevated level Noise, it may be a consequence of the following faults:

- Drive gear with a receipt comes out of engagement with a gear crown;

Starter attachments are substantially weakened;

The density of the attachment of the pole of the starter decreased and the anchor began to cling it.

Starter repair

And so, imagine that you found one of the above signs of the starter fault. Naturally, the first step towards its elimination will be full diagnosisIn order to determine the exact location of the breakdown. To begin, it is worth checking the wiring, or rather the wires from the battery to the starter and the wire passing through the relay from the ignition lock. Perhaps it is in this detail and a malfunction lies. If everything is in order with the wires and with the relay, then you will have to dismantle the starter itself.

And so, imagine that you found one of the above signs of the starter fault. Naturally, the first step towards its elimination will be full diagnosisIn order to determine the exact location of the breakdown. To begin, it is worth checking the wiring, or rather the wires from the battery to the starter and the wire passing through the relay from the ignition lock. Perhaps it is in this detail and a malfunction lies. If everything is in order with the wires and with the relay, then you will have to dismantle the starter itself.

In each separate model The car described item may differ in size, the way of fastening or location, but despite this, the principle of operation they have almost the same.

Note! For a detailed inspection and subsequent repair work, the starter disassembly must be fulfilled. Step-by-step starter removal instruction has the following form:

1. Disconnect the battery (until this point, it is impossible to touch the starter, as it may cause a closure);

2. Unscrew the current electrical cables with the starter terminals and the stripping relays; Remove the engine protection;

3. Unscrew the starter attachment bolts;

4. Remove the starter raising up.

After the device turned out to be in your hands, it should be checked. To carry out this operation you will need a charged battery:mass need to be connected to the housing, and a positive wire - to the contact bolt If the relay is properly, the bendix (overtaking clutch) will be extended in front. In the case when the starter has not earned after connecting, you can safely talk about the fault of the brushes or burnt winding, but usually the case is still in brushes.

After the device turned out to be in your hands, it should be checked. To carry out this operation you will need a charged battery:mass need to be connected to the housing, and a positive wire - to the contact bolt If the relay is properly, the bendix (overtaking clutch) will be extended in front. In the case when the starter has not earned after connecting, you can safely talk about the fault of the brushes or burnt winding, but usually the case is still in brushes.

The next step on the way to eliminate the problem there is a disassembly of the device. To carry out the intended, it is necessary to unscrew the two bolts of the mount, after which the hull together with anchor and brushes is removed. At the same time you can also explore the gearbox: for this we remove protective cover And providim visual diagnosis. If everything is good - lubricate the gears with lubricant, close the lid and postpone all this aside.

Now take in your hands electrical part The starter, which, according to the results of the preliminary inspection, needs to be repaired, pull out the brush and anchor body from the body. To withdraw them, just press the axis with your finger and since it holds only through a magnetic field, should come out without problems. Then, with the help of a crosst screwdriver, unscrew the two screws and remove upper cover (under it placed washer and a stop ring).

After everything is already cleared, you need to remove the back cover, inspected there the sleeve there - it is also often vulnerable place In the starter. When the sleeve is worn out, the axis is pulled out and the starter is difficult to scroll through the motor, or it does not twist it at all. At each maintenance Or repair, experts recommend changing all bushings.

An important part of the starter design is brushes and if they are very erased - the device will definitely not work. Therefore, when disassembling the starter, be sure to pay them attention, and if the inspection confirms the preliminary diagnosis, it is better to replace the broken parts new. It is very difficult to restore such brushes (a very strong soldering iron is required), so it's easier to buy a new block. Note! Inside the block brushes there is a plastic sleeve, with which brushes to stay in a compressed state. It can not be drawn in any way, otherwise you complicate the subsequent procedure for dressing the block anchor.

An important part of the starter design is brushes and if they are very erased - the device will definitely not work. Therefore, when disassembling the starter, be sure to pay them attention, and if the inspection confirms the preliminary diagnosis, it is better to replace the broken parts new. It is very difficult to restore such brushes (a very strong soldering iron is required), so it's easier to buy a new block. Note! Inside the block brushes there is a plastic sleeve, with which brushes to stay in a compressed state. It can not be drawn in any way, otherwise you complicate the subsequent procedure for dressing the block anchor.

We now turn to the inspection of the Rotor (Anchor) of the starter. If in its grooves you noticed the dirt or any other garbage, they can be cleaned with the help of a saw for metal or a flat thin screwdriver. The surface adjacent to the brushes is better to clean and align small emery paper. After all the specified stages of work are already behind, collect a starter in the reverse order and check its performance: it works - it means to install back to the vehicle.

In the process of reverse assembly of the starter, do not forget to process lubricant material All its movable parts (gearbox, sleeve). Remember! So that the starter does not fail in the most inappropriate moment for you, you need to spend it at least once a year technical inspection followed by service. Maintenance consists of all of the above activities, after which the starter power increases and the number of current consumed is reduced. As a result, the engine launch is significantly facilitated in the cold season.

Subscribe to our ribbons in